A method for preparing an optical fiber preform

An optical fiber preform and vapor deposition technology, which is applied in glass manufacturing equipment, manufacturing tools, etc., can solve the problems of uneven distribution and complex doping process, achieve simple means, simple doping process, and overcome the uneven distribution of alkali metals. uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

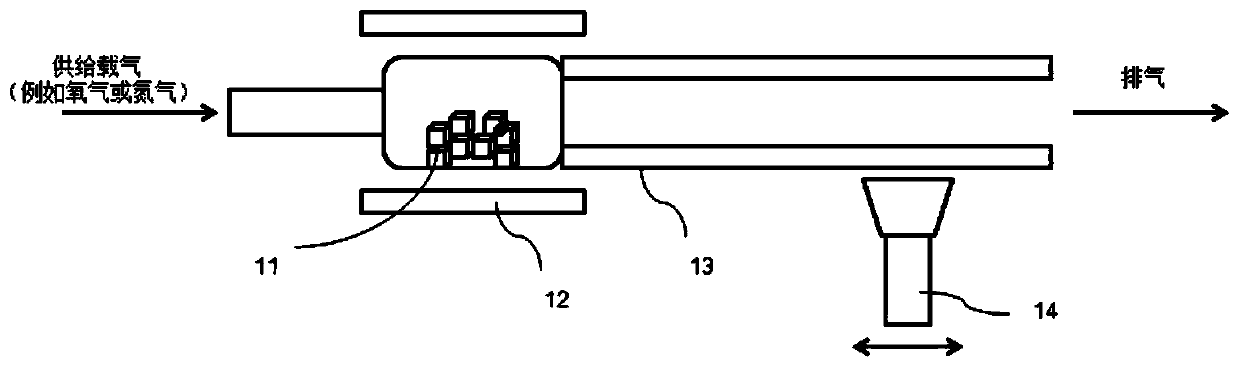

Image

Examples

Embodiment 1

[0036] A method for preparing an optical fiber preform, wherein, every 30kg of liquid SiCl 4 5-200g of alkali metal raw material is added to the mixture, and the alkali metal raw material is powdered alkali metal halide KBr.

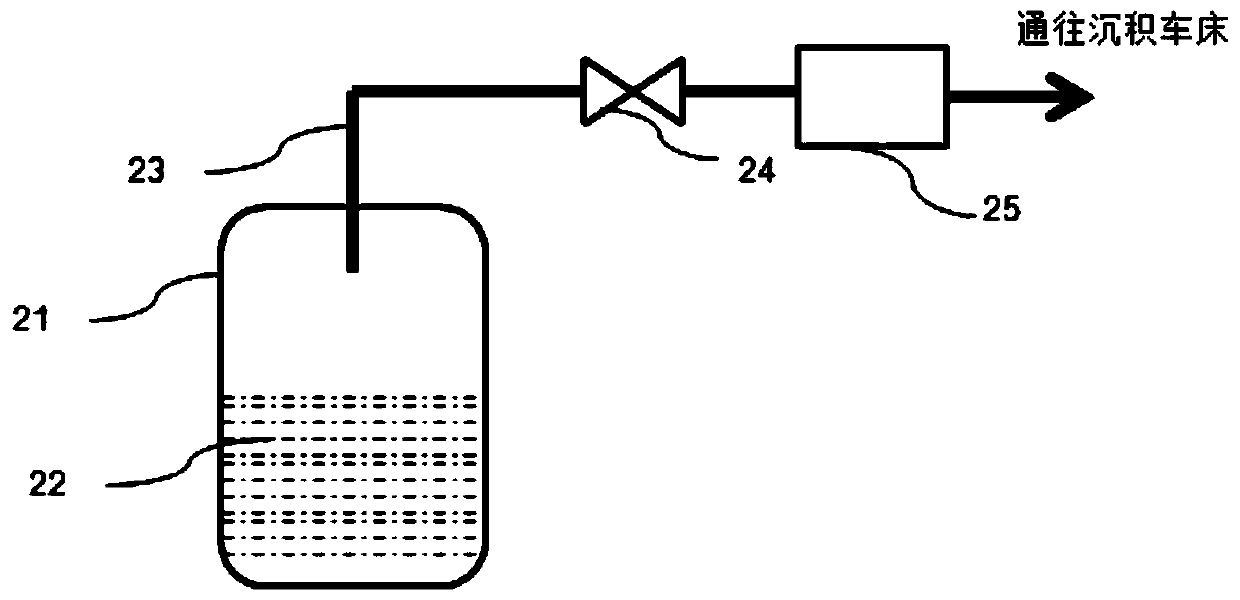

[0037] Such as figure 2 As shown, the SiCl in the source of the core layer deposition raw material for preparing the optical fiber preform 4 The feeding system of comprising evaporating bottle 21, the SiCl in the core layer deposition raw material supply source 4 22. Gas pipeline 23, valve 24, flow meter (MFC) 25, SiCl of core layer deposition raw material supply source 4 22 is contained in an evaporating bottle 21, and the evaporating bottle 21 communicates with the deposition reaction area through a gas pipeline 23; wherein, the gas pipeline 23 is provided with a valve 24 and a flow meter 25. Its specific working process is as follows:

[0038] 1) SiCl in the core layer deposition raw material supply source 4 22 contains 5g-200g of alkali meta...

Embodiment 2

[0042] A method for preparing an optical fiber preform, wherein, every 30kg of liquid SiCl 4 10-300g of alkali metal raw material is added to the mixture, and the alkali metal raw material is powdered alkali metal halide NaBr.

[0043] SiCl in the supply source of the core layer deposition raw material for preparing the optical fiber preform in this embodiment 4 The feeding system is the same as in Example 1. In this embodiment, alkali metals are simultaneously doped during the deposition process of the core layer, and the content of the alkali metals in the core region of the obtained optical fiber is evenly distributed, and the content of the alkali metals is 20-500 ppm.

Embodiment 3

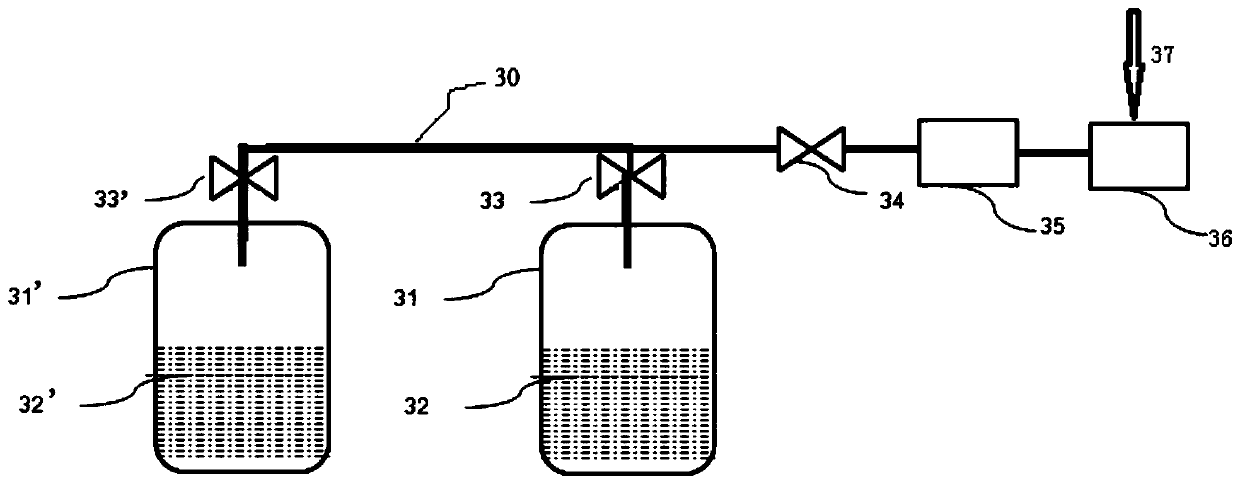

[0045] A method for preparing an optical fiber preform, which adopts plasma chemical vapor deposition (PCVD) to prepare an optical fiber preform, wherein the SiCl of the core layer deposition raw material supply source 4 Added alkali metal raw materials, every 30kg liquid SiCl 4 Add 50-500g alkali metal raw material KBr,; cladding deposition raw material supply source SiCl 4 SiCl with core deposition raw material supply source 4 Switch between valves.

[0046] Such as image 3 As shown, the feeding system for preparing an optical fiber preform includes a first evaporating bottle 31, a second evaporating bottle 31', a first valve 33, a second valve 33', a gas pipeline 30, a total valve 34, a flow meter 35 and a reaction Gas channel 37; SiCl of core layer deposition raw material supply source 4 32. SiCl of raw material supply source for cladding deposition 4 32' are respectively placed in the first evaporating bottle 31 and the second evaporating bottle 31', the first eva...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com