Nozzle for pulverized coal

A pulverized coal and nozzle technology is applied to a pulverized coal nozzle for blast furnace pulverized coal injection. effect of quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

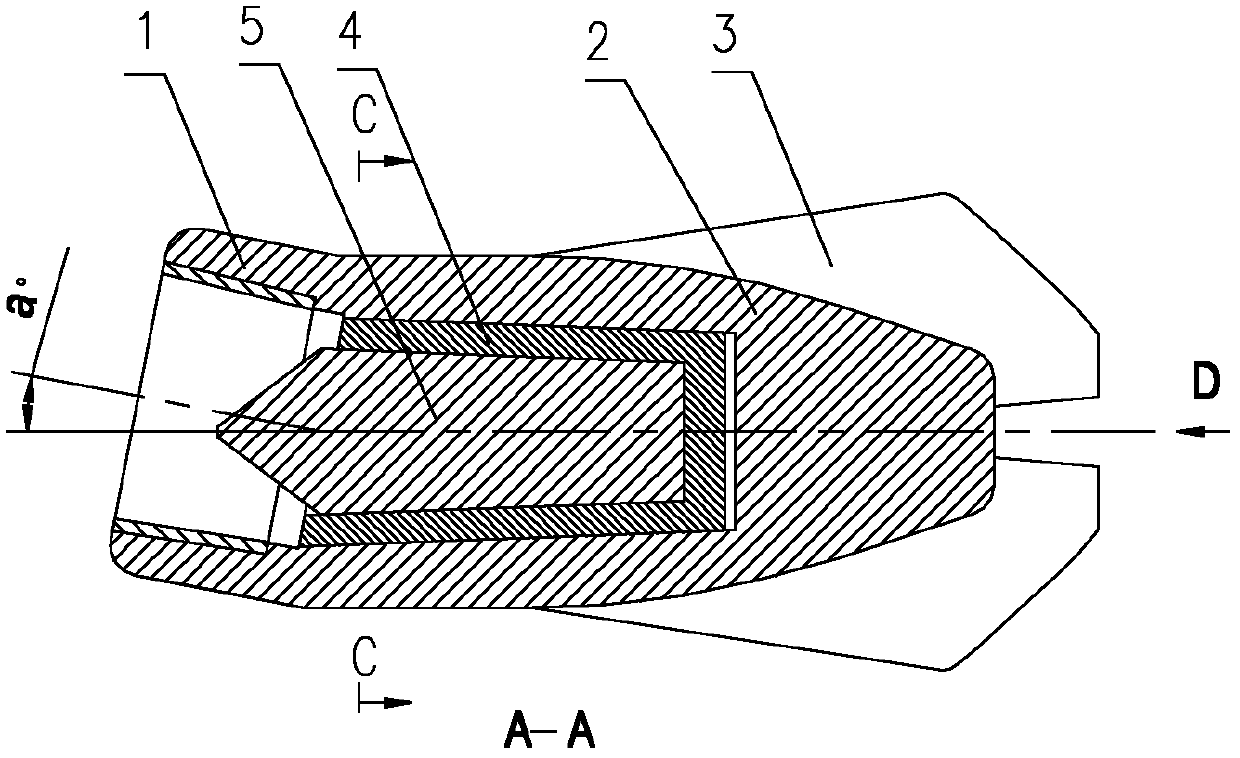

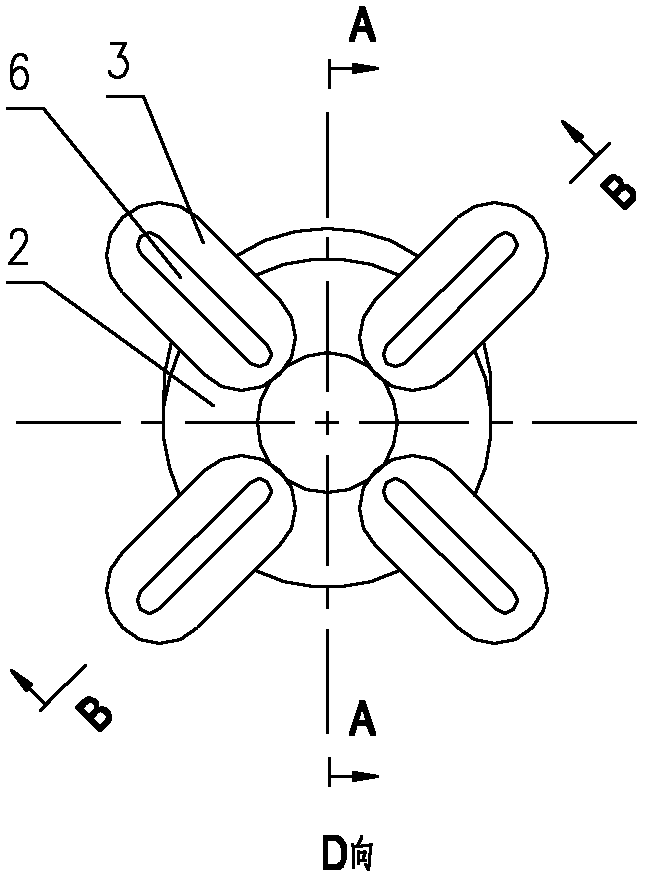

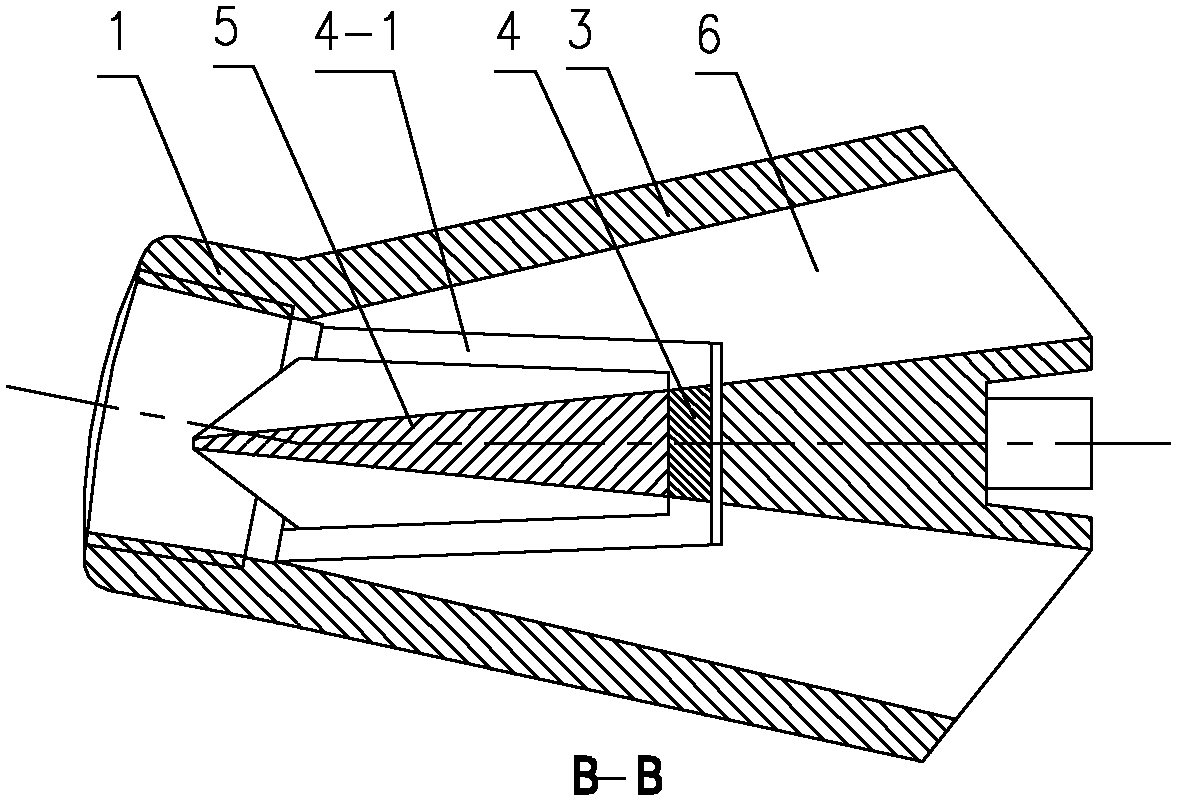

[0023] Such as figure 1 , 2 , 3,4 are embodiment 1. Such as Figure 5 , 6 For example 2.

[0024] Such as figure 1 As shown, the pulverized coal nozzle is composed of an interface section 1, a cone section 2, a nozzle pipe 3, a wear-resistant sleeve 4, and a distribution cone 5. The included angle between the centerline of the interface section 1 and the cone section 2 is 0-15°. Such as figure 2 As shown, on the outer circumference of the cone section 2, several nozzles 3 are distributed, and there are pulverized coal passages 6 in the nozzles 3 which communicate with the interface section 1. Such as image 3 As shown, in the cone section 2, a wear-resistant sleeve 4 is inlaid, and the wear-resistant sleeve 4 is provided with an opening 4-1 that matches the pulverized coal channel 6 opened by the nozzle 3, and the pulverized coal passes through the opening 4-1 Enter again in the pulverized coal channel 6 of nozzle pipe 3. Such as image 3 , 4 As shown, in the wear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com