releasable anchor packer

A technology of packer and well sealing, which is applied in sealing/isolation, wellbore/well parts, earthwork drilling and production, etc., and can solve the problem of increased difficulty in unblocking the packer, increasing the difficulty of re-unblocking, and unblocking Plugging operations are complicated and other problems, to achieve the effect of easily destroying cement bridge plugs, reducing the difficulty of anchor release, and saving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

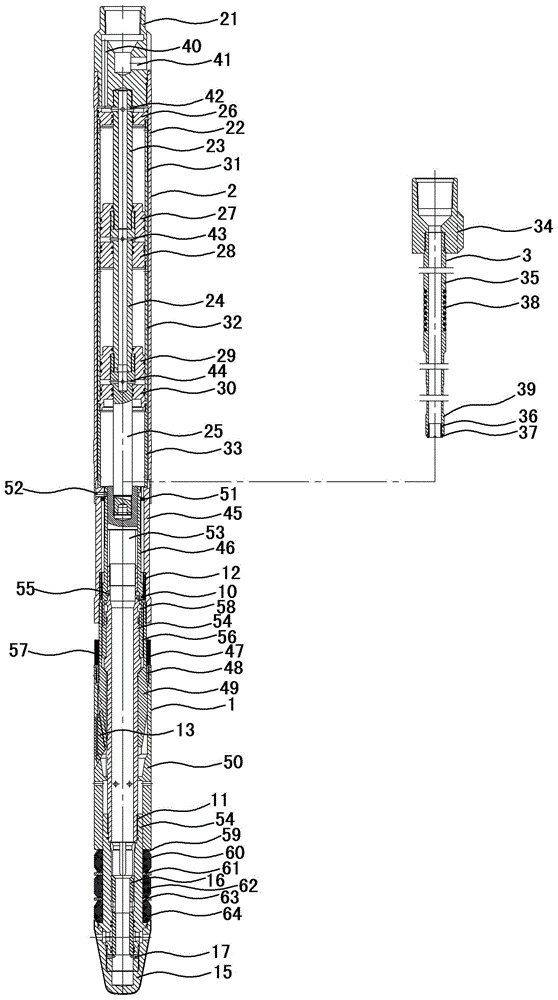

[0007] like figure 1 As shown, it includes a well sealing device 1 including a central pipe 11, a circlip sleeve 12, several slips 13, a rubber cartridge assembly 14 and a guide head 15, and it also includes a hydraulic device 2 and a pressure guiding core device 3, Hydraulic device 2 is made up of upper joint 21, overcoat 22, upper central pipe 23, central central pipe 24, lower central pipe 25, upper piston one 26, upper piston two 27, upper piston three 28, upper piston four 29, lower piston 30, The upper middle sleeve 31, the middle middle sleeve 32 and the lower middle sleeve 33 are formed. The lower end of the upper joint 21 is axially connected with the upper end of the outer sleeve 22 through external threads, and the upper central pipe 23 is located at the inner upper end of the outer sleeve 22 and connected with the upper end of the upper joint 21 through external threads. The lower end is connected, the upper piston one 26 is located below the upper joint 21 and is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com