A method for sealing the leakage point between the branch port of the natural gas trunk pipeline and the root valve of the branch pipeline from the inside

A leak point, natural gas technology, applied in the direction of pipes/pipe joints/pipe fittings, pipe components, mechanical equipment, etc., can solve the problems of inapplicable trunk pipelines and branch pipelines, affecting the normal transportation of natural gas, waste of resources and the environment, etc. The effect of convenience, less environmental damage and high safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The principles and features of the present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments. The examples cited are only used to explain the present invention, not to limit the scope of the present invention.

[0020] The equipment used in the method provided by the present invention (such as grease injection and drainage devices) are all conventional equipment, and the materials and drugs used (such as leak-stopping cement, fiber impregnated glue or fiber cloth) are all commercially available products.

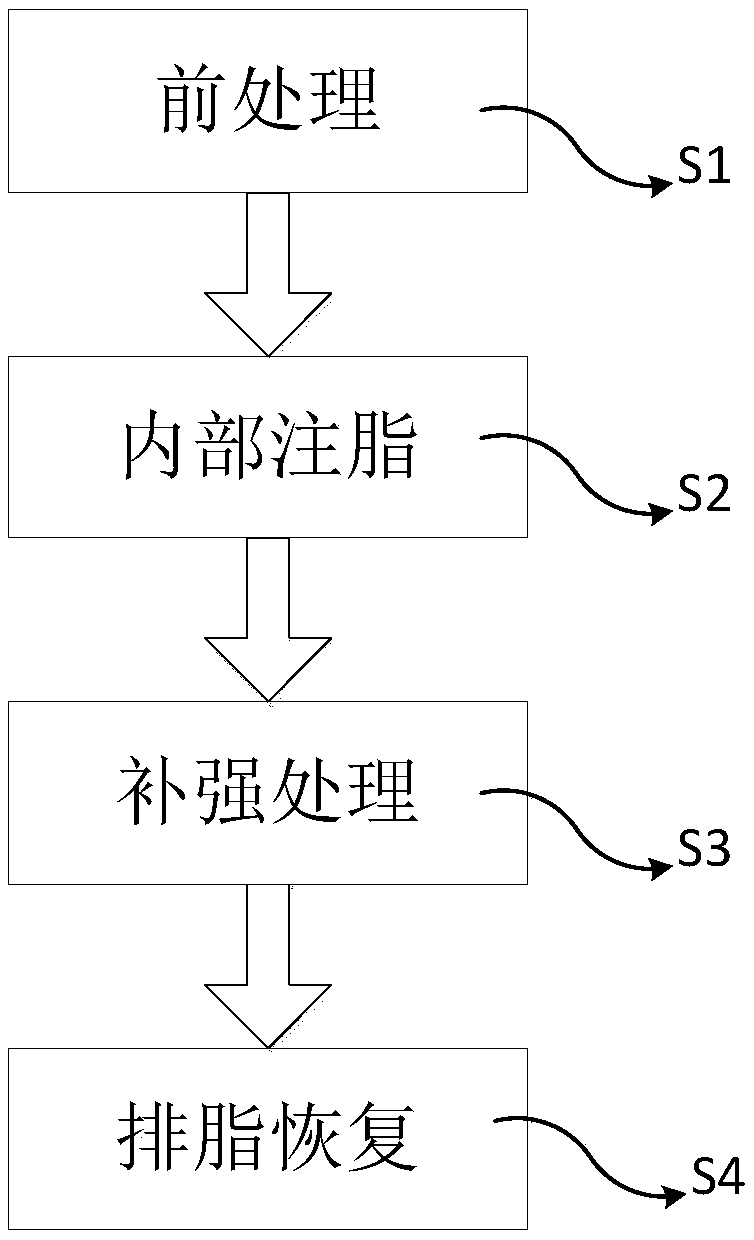

[0021] Such as figure 1 As shown, the present invention provides a method for blocking the leakage point between the branch of a natural gas trunk pipeline and the root valve of the branch pipeline from the inside, which includes the following steps:

[0022] S1. Pre-treatment: Close the root valve on the branch pipeline and the nearest shut-off valve downstream, and vent the pipe between the root valve a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com