Plugging agent used for foundation pit row pile retaining wall and using method of plugging agent

A plugging agent and a technology for retaining walls, which are applied in chemical instruments and methods, drilling compositions, infrastructure engineering, etc., can solve the problems of poor base surface conformity, low strength of the plugging agent, and high price. To achieve the effect of compact structure, improve leakage plugging effect, and improve bending resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] As a preferred embodiment of the present invention, this embodiment discloses:

[0041] A leak-stopping agent for foundation pit row pile enclosure walls, comprising the following raw materials by mass percentage: 50% of aluminate cement clinker, 6% of anhydrite, 16% of rice fiber, 16% of sodium bentonite, Walnut shell chips 12%.

[0042] After mixing the above four materials evenly, refer to the test of GB23440-2009 "Inorganic Waterproof Plugging Material" to obtain the performance index of the plugging agent of this embodiment: initial setting time 8min, final setting time 21min, 1h compressive strength 6MPa, 2h The compressive strength is 16.5MPa, and the 28d compressive strength is 48MPa.

[0043] In this example, the alkalinity coefficient of aluminate cement clinker is 0.9, the ratio coefficient of calcium aluminate is 3.0, the C2AS content is 7%, and the specific surface area of clinker grinding is 600m 2 / kg.

[0044] The specific surface area of anhydrit...

Embodiment 2

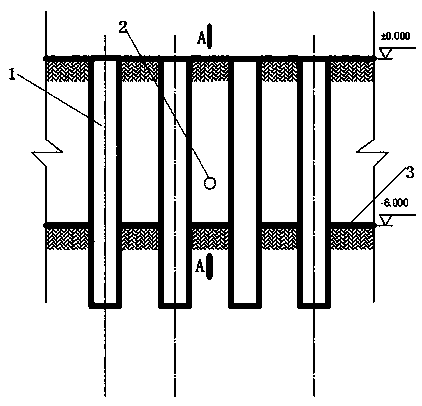

[0049] As another preferred embodiment of the present invention, with reference to the attached Figure 1-4 , this example discloses:

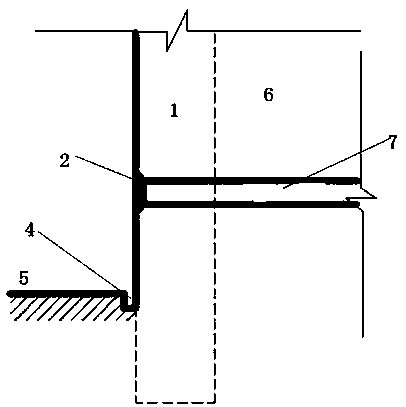

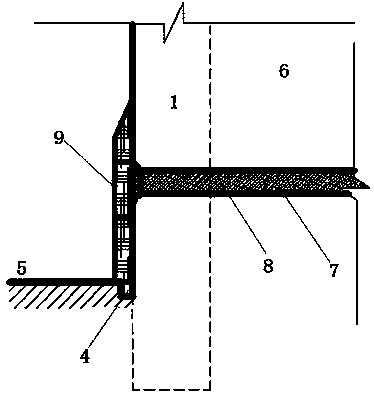

[0050] Utilize the leak-stopping agent in embodiment 1, block the water leakage 2 of 300mm on the retaining wall of row pile 1, as figure 1 As shown, in the foundation pit 5 of the foundation 3, a row of piles 1 and an enclosure wall are arranged, and a water leak 2 is arranged on the enclosure wall. The specific usage method is:

[0051] Step A, clean up the mud and stones on the surface of the leaking port 2, chisel the leaking port 2 into a funnel shape, and reduce the water pressure at the outlet of the leaking place; at the same time, put stones in the sack 9 for standby;

[0052] Step B. After fluffing the hemp rope fiber and cotton fiber, use pliers to stuff it into the water leak 2; the machine passes through the water leak 2 on the enclosure wall, and inserts the filling fiber 8 into the soil layer 6 behind the enclosure wall In the...

Embodiment 3

[0057] As another preferred embodiment of the present invention, this embodiment discloses:

[0058] A leak-stopping agent for pile-row retaining walls of foundation pits, comprising the following raw materials by mass percentage: 64% of aluminate cement clinker, 10% of anhydrite, 2% of straw fiber, 4% of sodium-based bentonite, Walnut shell chips 20%.

[0059] After mixing the above four materials evenly, refer to the test of GB23440-2009 "Inorganic Waterproof Plugging Material" to obtain the performance indicators of the plugging agent of this embodiment: initial setting time 7min, final setting time 18min, 1h compressive strength 7.3MPa, 2h compressive strength 17.6MPa, 28d compressive strength 54MPa.

[0060] In the present embodiment, the alkalinity coefficient of aluminate cement clinker is 0.85, the ratio coefficient of calcium aluminate is 2.5, and C 2 The content of AS is 15%, and the specific surface area of clinker grinding is 600m 2 / kg.

[0061] The specific...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com