Plugging slurry for enhancing pressure-bearing capacity of leakage formation and preparation method thereof

A technology of pressure-bearing capacity and loss-stopping slurry, applied in the field of oil drilling, can solve the problems of small increase in the pressure-bearing capacity of the leakage layer, low success rate of one-time loss-stopping, and high price of loss-stopping agents, so as to reduce the probability of lost circulation recurrence, The slurry mixing method of the plugging process is simple and convenient, and the effect of plugging time is high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

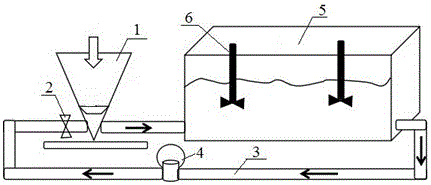

Method used

Image

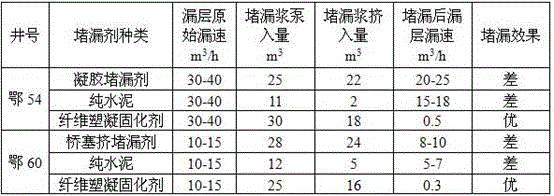

Examples

Embodiment 1

[0025] This embodiment provides a plugging slurry for improving the pressure bearing capacity of the lost formation, which is composed of the following substances in mass percentage: fiber plastic solidification agent 55%; asphalt powder for drilling 2%, oil well cement defoamer 0.1%, water 42.9%.

[0026] The preparation process is as follows: adding formula quantity of water into a container, sequentially adding formula quantity of asphalt powder for drilling, fiber plastic coagulation curing agent, oil well cement defoamer, and stirring evenly to obtain.

[0027] In this embodiment, the fiber plasticizing agent is composed of the following substances in mass percentage: 4% mineral fiber, 3% wood fiber, 5% mica powder, 3% gypsum, and 85% oil well G grade cement. Among them, the mineral fiber is brucite fiber, the fiber type is longitudinal fiber, and the pile length is 3-5mm; the wood fiber is a compound of pine fiber, poplar fiber and banyan fiber (mass ratio is 1:1:1) , t...

Embodiment 2

[0030] This embodiment provides a plugging slurry for improving the pressure bearing capacity of the lost formation, which is composed of the following substances in mass percentage: 60% fiber plastic solidification agent; 1% asphalt powder for drilling, 0.05% oil well cement defoamer, water 38.95%.

[0031] The preparation process is as follows: adding formula quantity of water into a container, sequentially adding formula quantity of asphalt powder for drilling, fiber plastic coagulation curing agent, oil well cement defoamer, and stirring evenly to obtain.

[0032] In this embodiment, the fiber plasticizing agent is composed of the following substances in mass percentage: 3% mineral fiber, 2% wood fiber, 4% mica powder, 3% gypsum, and 88% oil well G grade cement. Among them, the mineral fiber is brucite fiber and asbestos fiber (mass ratio is 2:1), the fiber type is longitudinal fiber, and the pile length is 3-5mm; the wood fiber is pine fiber, and the fiber length is 2-6mm...

Embodiment 3

[0035] This embodiment provides a plugging slurry for improving the pressure bearing capacity of the lost formation, which is composed of the following substances in mass percentage: 58% fiber plastic solidification agent; 1.5% asphalt powder for drilling, 0.1% oil well cement defoamer, water 40.4%.

[0036] The preparation process is as follows: adding formula quantity of water into a container, sequentially adding formula quantity of asphalt powder for drilling, fiber plastic coagulation curing agent, oil well cement defoamer, and stirring evenly to obtain.

[0037] In this embodiment, the fiber plasticizing agent is composed of the following substances in mass percentage: 2% mineral fiber, 1% wood fiber, 4% mica powder, 2% gypsum, and 92% oil well G grade cement. Among them, the mineral fiber is a compound of asbestos fiber, brucite fiber and sepiolite fiber (mass ratio is 2:1:1), the fiber type is longitudinal fiber, and the pile length is 3-5mm; the wood fiber is pine fib...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com