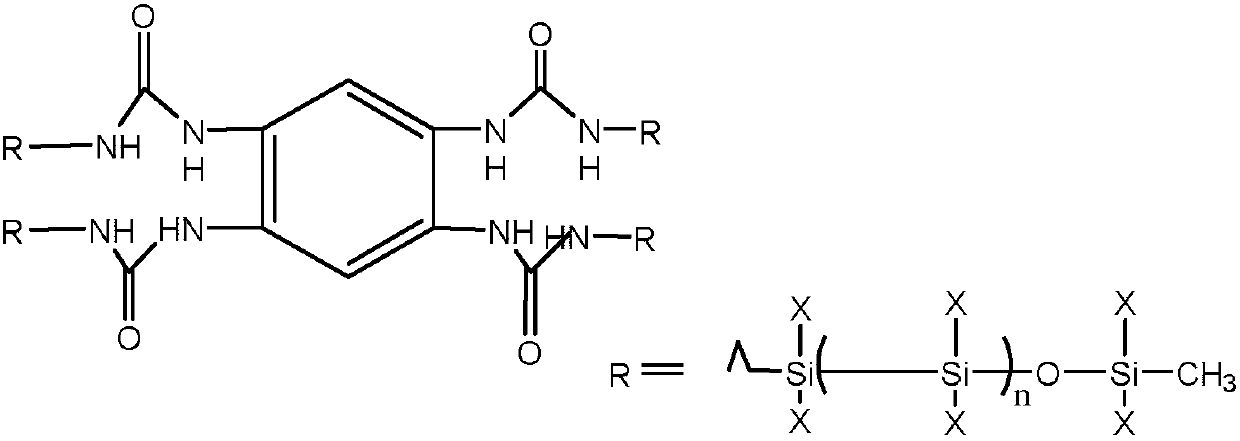

Preparation method of tetraphenylurea siloxane polymer supercritical carbon dioxide thickener

A technology of benzene tetraurea siloxane and carbon dioxide is applied in the field of preparation of supercritical carbon dioxide thickener of benzene tetraurea siloxane polymer, which can solve the problem of hindering the fracturing and stimulation of fluorine-containing substances and the high price of fluorine-containing substances. , groundwater resource pollution and other problems, to achieve the effect of excellent thickening effect, good compatibility and little formation damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Embodiment 1, a kind of preparation method of siloxane polymer supercritical carbon dioxide thickener comprises steps as follows:

[0056] (1) Preparation of pyromellitic azide

[0057] Under nitrogen protection, 1.4 g of sodium azide was dissolved in deionized water into a three-necked flask, and cooled to 0°C. In another single-necked flask, dissolve 3g of pyromellitic chloride in 30mL of tetrahydrofuran, stir evenly and cool to room temperature, slowly drop the dissolved 3g of pyromellitic chloride into the low-temperature solution of sodium azide, and after 1.5h, a white Precipitated sodium pyromellityl azide. The white precipitated solid was dissolved in 30 mL of toluene at 0°C and stirred for 4 h, the toluene layer was separated, washed with water and saturated brine, dried over magnesium sulfate and filtered to obtain 3 g of pyromellitic azide.

[0058] (2) Preparation of amino side chain modified siloxane polymer

[0059] Under the protection of nitrogen, add...

Embodiment 2

[0062] Example 2, as described in Example 1, the operation steps are the same, the difference is that the azide used in the step (1) is potassium azide, and the usage amount is 1.8g.

Embodiment 3

[0063] Embodiment 3, as described in embodiment 1, the difference is that toluene is 20mL in the step (1).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com