A kind of preparation method of acrylate/siloxane polymer supercritical carbon dioxide thickener

A technology based on acrylate and carbon dioxide, which is applied in chemical instruments and methods, drilling compositions, bulk chemical production, etc., can solve problems such as many follow-up problems, serious formation damage, and expensive fluorine-containing substances, and achieve reduction The effect of dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

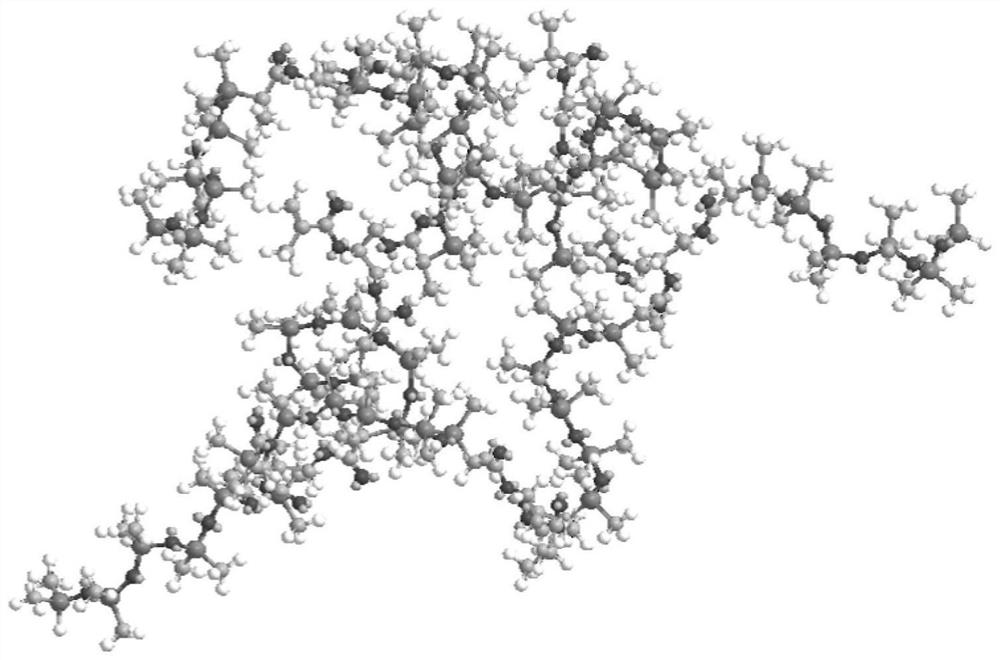

[0048] Embodiment 1, a kind of preparation method of acrylate / siloxane supercritical carbon dioxide thickener comprises steps as follows:

[0049] (1) Add 9.21 g of glycerin to a 500 mL three-necked flask equipped with a reflux device, catalyst Mg-Al-HT accounting for 1.5% of the total system, and hydroquinone accounting for 2% of the total system. Then start to stir and heat up. When the temperature rises to 105°C, 30.036 g of methyl methacrylate is gradually added dropwise to carry out transesterification reaction. After 6 hours of reaction, the liquid in the flask is filtered, and the filtrate obtained by separating the catalyst and polymerization inhibitor is decompressed. Distillation gives a colorless and transparent product glycerol trimethacrylate.

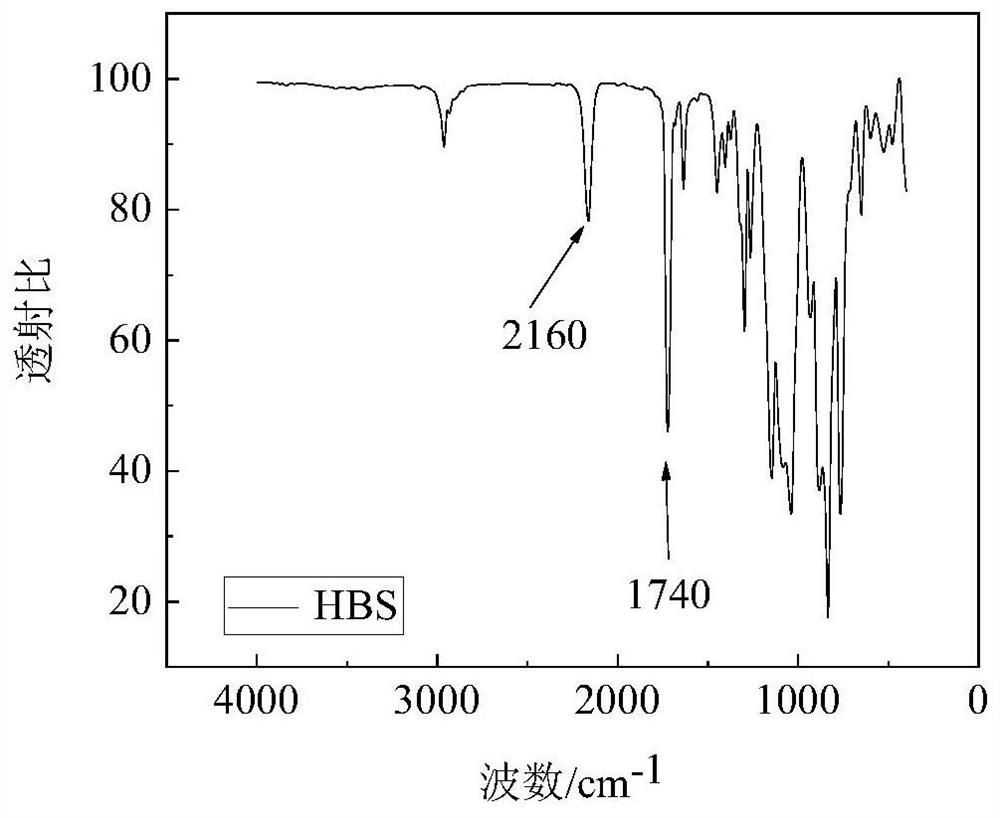

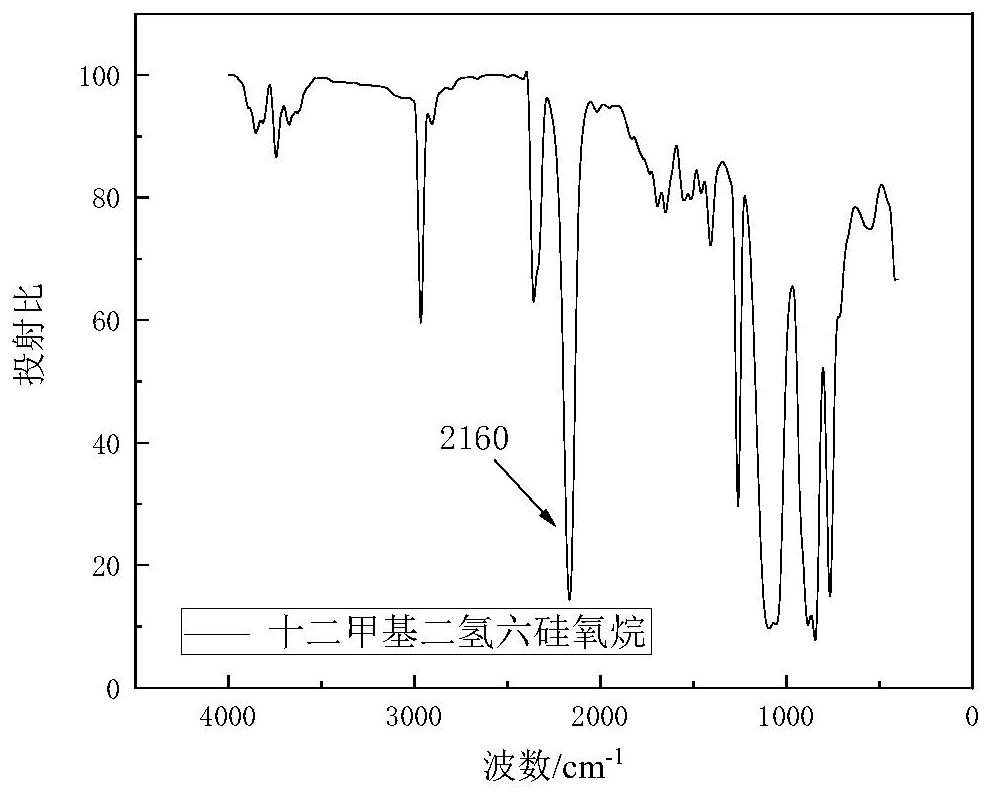

[0050] (2) Add 0.1525g glycerol trimethacrylate into a 50mL three-necked flask equipped with a reflux device, stir and raise the temperature to 90°C, add 30ppm chloroplatinic acid for activation for 2 hours; keep the tempe...

Embodiment 2

[0052] Embodiment 2, as described in embodiment 1, operation steps are consistent, difference is that the hydroquinone consumption used in step (1) is 2.5%.

Embodiment 3

[0053] Embodiment 3, as described in Embodiment 1, the difference is that the glycerol is 4.605g in the step (1), and the reaction temperature is 110°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com