Clean crushing liquid system

A clean fracturing fluid and system technology, applied in production fluids, wellbore/well components, chemical instruments and methods, etc., can solve the problems of high cost of guar gum fracturing fluid, high content of guar gum insolubles, complex preparation process, etc. problem, to achieve the effect of saving manpower, strong shear resistance, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The clean fracturing fluid consists of 0.35wt% thickener, 0.17wt% synergist, 1wt% anti-swelling agent, 0.15wt% gel breaker and the rest of water.

[0042]The thickener is thickener GRF-1L for clean fracturing fluid of Sichuan Guangya Polymer Chemical Co., Ltd.; the synergist is thickening synergist GRF-1L for clean fracturing fluid of Sichuan Guangya Polymer Chemical Co., Ltd. 2A; anti-swelling agent is potassium chloride; gel breaker is ammonium persulfate.

[0043] Pour 500ml of water into the waring agitator, and adjust the speed of the waring agitator until the center shaft of the agitator can be seen. Add 1.75g thickener GRF-1, stir for 10min, then add 5g potassium chloride, continue stirring for 2min, then add 0.85ml synergist GRF-2, continue stirring for 2min, finally add 0.75g ammonium persulfate, stir evenly, Get clean fracking fluid.

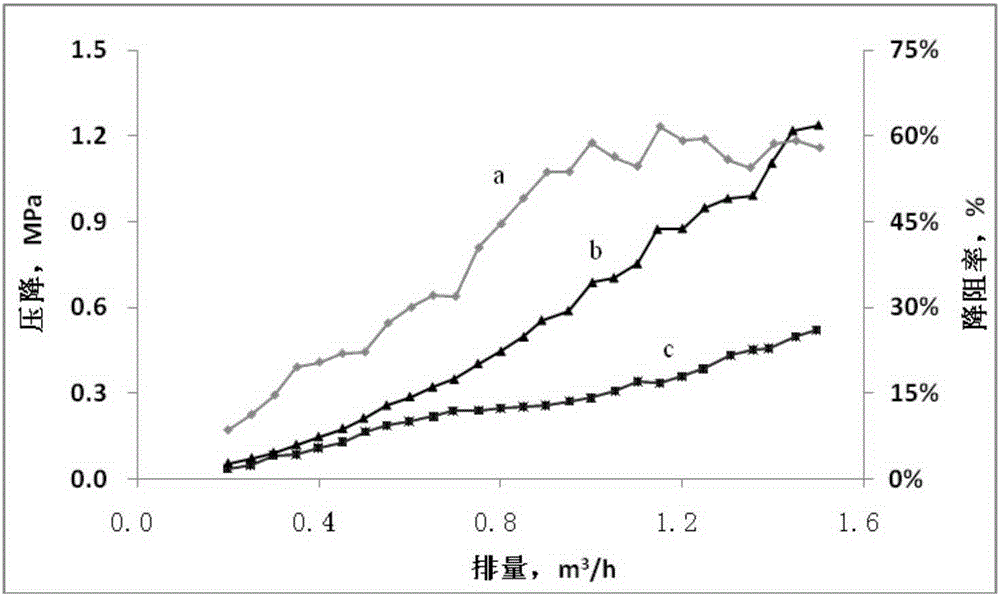

[0044] Test the performance of the clean fracturing fluid obtained in Example 1 according to the temperature and shear res...

Embodiment 2

[0046] The clean fracturing fluid consists of 0.38wt% thickener, 0.19wt% synergist, 1wt% anti-swelling agent, 0.15wt% gel breaker and the rest of water.

[0047] The thickener is thickener GRF-1L for clean fracturing fluid of Sichuan Guangya Polymer Chemical Co., Ltd.; the synergist is thickening synergist GRF-1L for clean fracturing fluid of Sichuan Guangya Polymer Chemical Co., Ltd. 2A; anti-swelling agent is potassium chloride; gel breaker is ammonium persulfate.

[0048] Pour 500ml of water into the waring agitator, and adjust the speed of the waring agitator until the center shaft of the agitator can be seen. Add 1.9g thickener GRF-1, stir for 10min, then add 5g potassium chloride, continue stirring for 2min, then add 0.95ml synergist GRF-2, continue stirring for 2min, finally add 0.75g ammonium persulfate, stir evenly, Get clean fracking fluid.

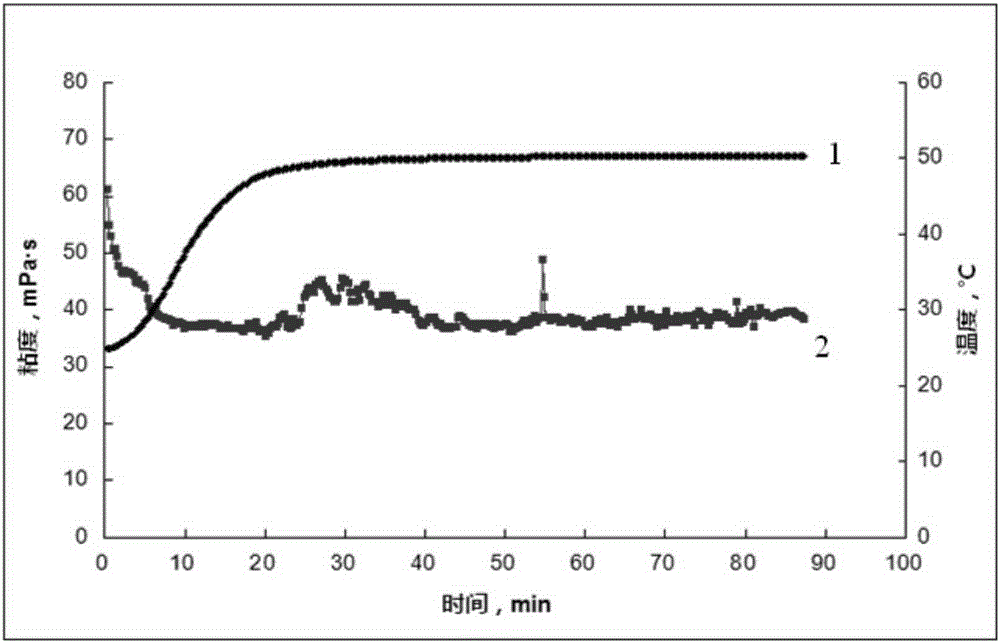

[0049] Test the performance of the clean fracturing fluid obtained in Example 2 according to the temperature and shear resis...

Embodiment 3

[0051] The clean fracturing fluid consists of 0.4wt% thickener, 0.2wt% synergist, 1wt% anti-swelling agent, 0.15wt% gel breaker and the rest of water.

[0052] The thickener is thickener GRF-1L for clean fracturing fluid of Sichuan Guangya Polymer Chemical Co., Ltd.; the synergist is thickening synergist GRF-1L for clean fracturing fluid of Sichuan Guangya Polymer Chemical Co., Ltd. 2A; anti-swelling agent is potassium chloride; gel breaker is ammonium persulfate.

[0053] Pour 500ml of water into the waring agitator, and adjust the speed of the waring agitator until the center shaft of the agitator can be seen. Add 2g of thickener GRF-1, stir for 10min, then add 5g of potassium chloride, continue to stir for 2min, then add 1ml of synergist GRF-2, continue to stir for 2min, finally add 0.75g of ammonium persulfate, stir evenly, and get clean Fracturing fluid.

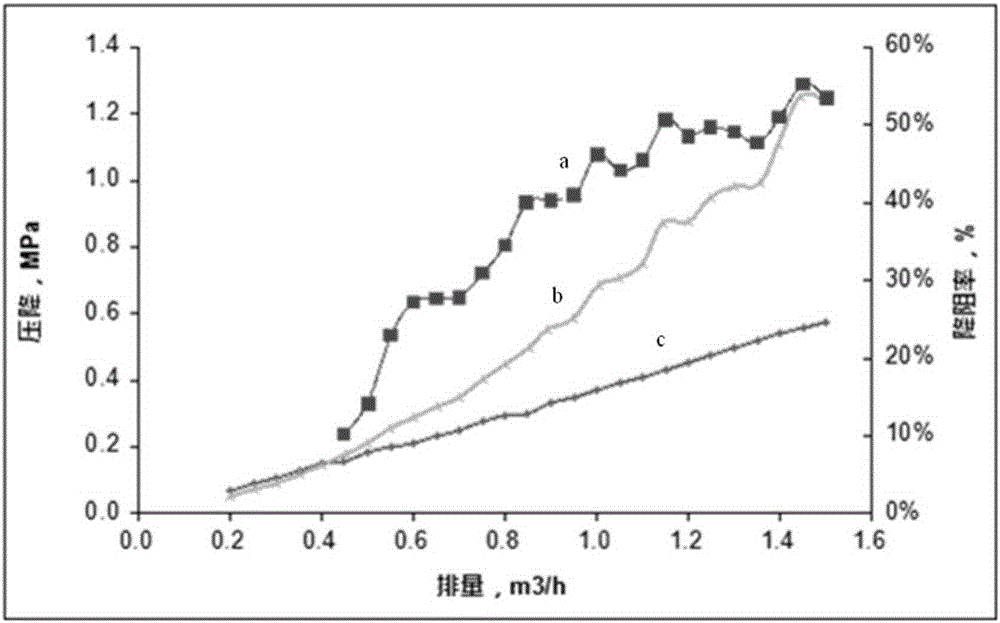

[0054] According to the performance evaluation method of SY / T5107-2005 water-based fracturing fluid, the performanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com