Water suspensible propping agent for oil and gas well fracturing and preparation method thereof

A technology of proppant and coupling agent, which is applied in the field of suspendable proppant in fracturing water and its preparation, can solve the problems affecting the performance of water-swellable polymers, increase the volume of proppant, and have no expansibility, etc., to achieve increased Large volume, improved flow conductivity, complete gel breaking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

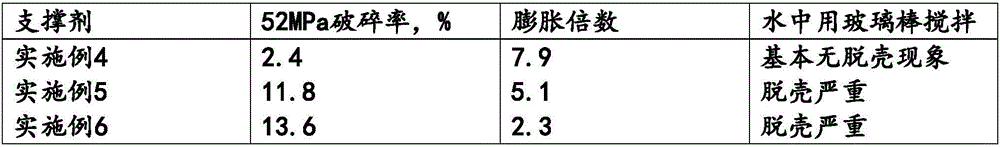

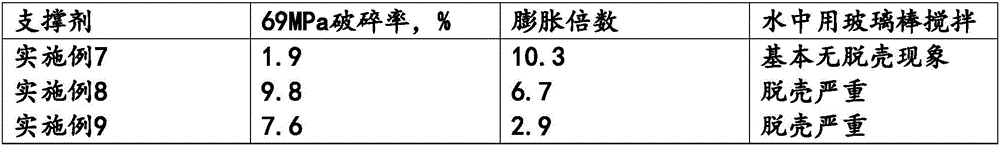

Examples

Embodiment 1

[0043] Sulfonate polyester polyol synthesis example 1: 11.1 kilograms of sodium dimethyl sulfonate isophthalate, 18.7 kilograms of isophthalic acid, 15.9 kilograms of diethylene glycol, and 27.0 kilograms of triethylene glycol Add 50 grams of zinc acetate and zinc acetate into the reaction kettle, protect it with nitrogen, heat up to 120°C and start stirring, heat to 140-160°C and keep it for one hour, gradually raise the temperature to 170°C, keep it at 170-175°C, when the acid value is less than 90mgKOH / g and when the reactant is completely clear and transparent, cool down to 140°C, add 22.2 kg of phthalic anhydride and 0.67 kg of trimethylolpropane, heat up to 140-160°C for one hour, then gradually raise the temperature to 190°C, and control the internal temperature during the heating process Not exceeding 103°C, keep warm at 190-200°C, when the acid value is less than 60mgKOH / g, vacuum until the acid value drops below 1mgKOH / g to obtain sulfonate polyester polyol with a hy...

Embodiment 2

[0045]Sulfonate polyester polyol synthesis example 2: 13.4 kilograms of sodium sulfonate isophthalate, 14.8 kilograms of phthalic anhydride, 16.9 kilograms of diethylene glycol, 32.0 kilograms of tetraethylene glycol and dibutyltin oxide Put 28 grams into the reaction kettle, protect it with nitrogen, heat up to 120°C and start stirring, heat to 140-160°C and keep it for one hour, gradually raise the temperature to 170°C, keep it at 170-175°C, and cool down when the acid value is less than 90mgKOH / g To 160°C, add 22.2 kg of phthalic anhydride and 2.6 kg of trimethylolpropane, raise the temperature to 140-160°C for one hour, then gradually raise the temperature to 190°C, and control the internal temperature during the heating process to not exceed 103°C. Insulation, when the acid value is less than 60mgKOH / g, vacuum until the acid value drops below 1mgKOH / g to obtain a sulfonate polyester polyol with a hydroxyl value of 57.6mgKOH / g.

Embodiment 3

[0047] Sulfonate polyester polyol synthesis example 3: 22.2 kilograms of sodium dimethyl sulfonate isophthalate, 11.1 kilograms of phthalic anhydride, 33.75 kilograms of triethylene glycol, 45.0 kilograms of polyethylene glycol and 56 grams of zinc acetate Put it into the reaction kettle, protect it with nitrogen, raise the temperature to 120°C and start stirring, heat to 140-160°C and keep it for one hour, gradually raise the temperature to 170°C, keep it at 170-175°C, and cool down to 160 when the acid value is less than 90mgKOH / g ℃, add 22.2 kg of phthalic anhydride and 5.4 kg of trimethylolpropane, raise the temperature to 140-160 ℃ for one hour, gradually raise the temperature to 190 ℃, control the internal temperature not to exceed 103 ℃ during the heating process, keep the temperature at 190-200 ℃, When the acid value is less than 60mgKOH / g, vacuumize until the acid value drops to 1mgKOH / g to obtain a sulfonate polyester polyol with a hydroxyl value of 52.1mgKOH / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com