Organic base composite oil displacement system suitable for high-calcium oil reservoirs, and preparation method thereof

A compound oil displacement and organic alkali technology, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of fouling in the injection-production system and difficulties in the emulsification of the produced fluid, and achieve high oil displacement efficiency and improved The oil recovery rate and formation damage effect are small

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] The preparation method of the organic-alkali composite flooding system suitable for high-calcium reservoirs of the present invention is carried out according to the following steps:

[0054] (1) Take 0.1 kg of partially hydrolyzed polyacrylamide with a viscosity average molecular weight of 30 million and a degree of hydrolysis of 20% and add it to the first mixing container, add water according to the weight concentration of partially hydrolyzed polyacrylamide as 4500 mg / L, and control the temperature of the material at 80 ℃, stirred for 1.5 hours, and matured for 24 hours to obtain a polymer mother liquor;

[0055] (2) Add 0.3 kg of ethanolamine, 0.05 kg of petroleum sulfonate and the remaining amount of water into the second mixing container, then stir at 80°C for 10 minutes to obtain a mixed solution;

[0056] (3) Add the polymer mother liquor in step (1) to the mixed solution in step (2), and stir for 40 minutes to obtain the product.

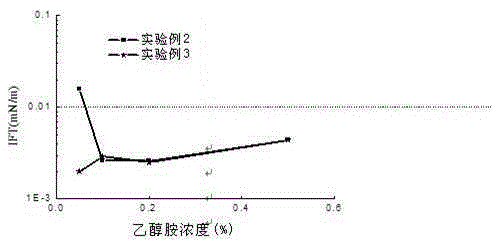

Embodiment 2

[0058] The preparation method of the organic-alkali composite flooding system suitable for high-calcium reservoirs of the present invention is carried out according to the following steps:

[0059] (1) Take 0.3 kg of partially hydrolyzed polyacrylamide with a viscosity average molecular weight of 15 million and a degree of hydrolysis of 25% and add it to the first mixing container, add water according to the weight concentration of partially hydrolyzed polyacrylamide as 5500 mg / L, and control the temperature of the material at 25 ℃, stirred for 2.5 hours, and matured for 48 hours to obtain a polymer mother liquor;

[0060] (2) Add 0.05 kg of ethanolamine, 0.4 kg of petroleum sulfonate and the remaining amount of water into the second mixing container, then stir at 25°C for 30 minutes to obtain a mixed solution;

[0061] (3) Add the polymer mother liquor in step (1) to the mixed solution in step (2), and stir for 20 minutes to obtain the product.

Embodiment 3

[0063] The preparation method of the organic-alkali composite flooding system suitable for high-calcium reservoirs of the present invention is carried out according to the following steps:

[0064] (1) Take 0.2 kg of partially hydrolyzed polyacrylamide with a viscosity average molecular weight of 22 million and a degree of hydrolysis of 20% and add it to the first mixing container, add water according to the weight concentration of partially hydrolyzed polyacrylamide at 5000 mg / L, and control the temperature of the material at 50 ℃, stirred for 2 hours, and matured for 36 hours to obtain a polymer mother liquor;

[0065] (2) Add 0.2 kg of ethanolamine, 0.2 kg of petroleum sulfonate and the remaining amount of water into the second mixing container, then stir at 50°C for 20 minutes to obtain a mixed solution;

[0066] (3) Add the polymer mother liquor in step (1) to the mixed solution in step (2), and stir for 30 minutes to obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com