Heat resistance and salt tolerance polymer for oil displacement and preparation method thereof

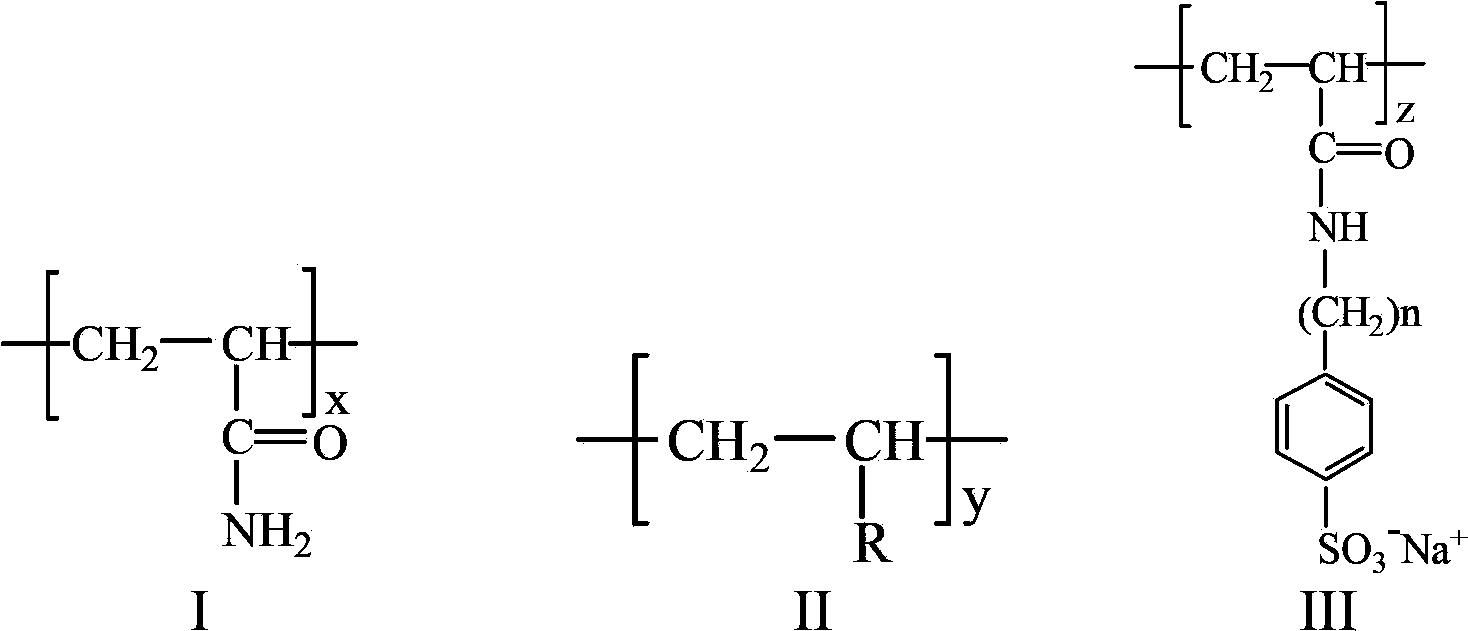

A temperature-resistant, salt-resistant, polymer technology, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems that HPAM is not suitable for high-temperature and high-salt reservoirs, so as to improve oil displacement efficiency, stability, The effect of improving viscoelasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

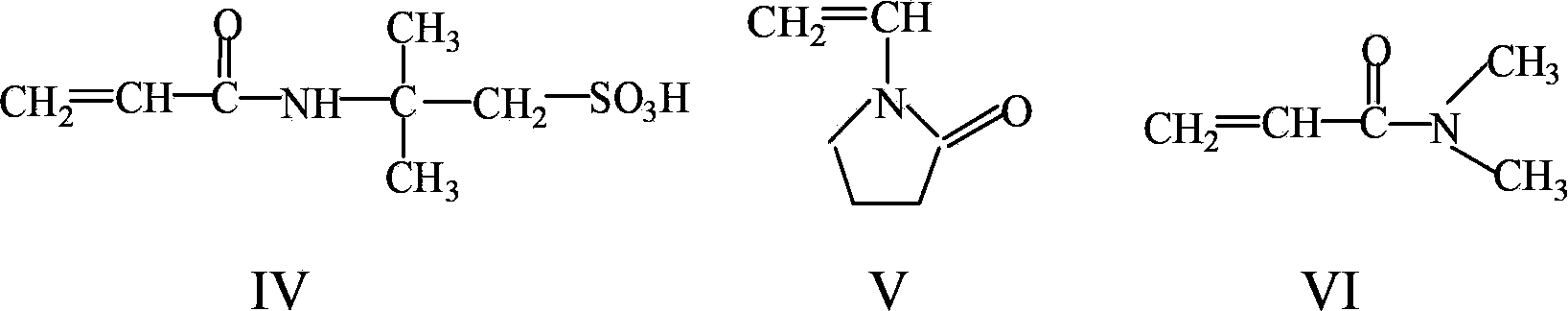

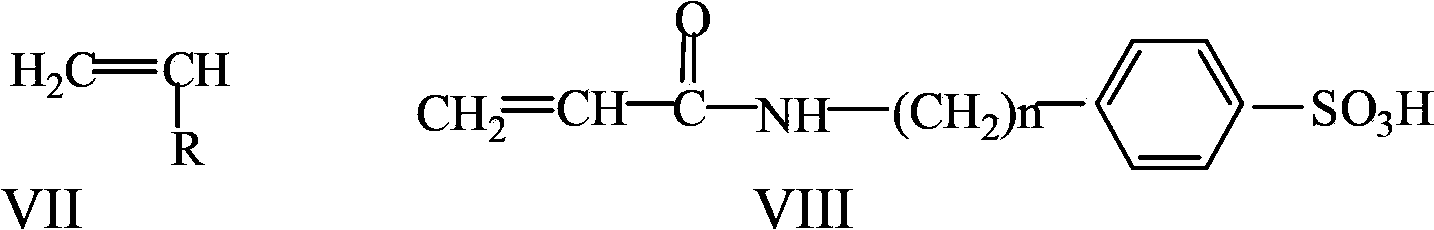

Method used

Image

Examples

Embodiment 1

[0033] Add 12.0g of acrylamide, 7.0g of 2-acrylamido-2-methylpropanesulfonic acid and 1.0g of the functional monomer represented by general formula VIII (n=0) into the polymerization reaction bottle, add deionized water 50.0 g was dissolved, then sodium hydroxide was added to adjust the pH to 7.1, and then 1.0 g of 1% EDTA-2Na aqueous solution and 0.5 g of 1% urea aqueous solution were sequentially added.

[0034] Put the polymerization reaction bottle in a constant temperature water bath, blow nitrogen to drive oxygen for 30 minutes, then add 4.0g of 0.1% potassium persulfate aqueous solution and 2.0g of 0.1% potassium bisulfite aqueous solution, initiate the reaction at 0°C, and continue to pass nitrogen Stopped after five minutes, and after 4 hours of polymerization reaction, the temperature was raised to 50° C. to continue the reaction for 6 hours to obtain rubber blocks. The rubber block is taken out, cut, granulated, pulverized, and sieved to obtain a white temperature-r...

Embodiment 2

[0037] Add 9.5g of acrylamide, 10.0g of 2-acrylamido-2-methylpropanesulfonic acid and 0.5g of the functional monomer represented by general formula VIII (n=1) into the polymerization reaction bottle, add deionized water 50.0 g was dissolved, then sodium hydroxide was added to adjust the pH to 8.1, and then 1.0 g of 1% EDTA-2Na aqueous solution and 1.0 g of 1% urea aqueous solution were sequentially added.

[0038] Put the polymerization reaction bottle in a constant temperature water bath, blow nitrogen to drive oxygen for 30 minutes, add 5.0g of 0.1% ammonium persulfate aqueous solution and 2.0g of 0.1% potassium bisulfite aqueous solution, initiate the reaction at 0°C, and continue to pass nitrogen for five Stop after 10 minutes. After 6 hours of polymerization reaction, the temperature was raised to 50° C. and the reaction was continued for 6 hours to obtain rubber blocks. The rubber block is taken out, cut, granulated, pulverized, and sieved to obtain a white temperature-r...

Embodiment 3

[0041] Add 13.9g of acrylamide, 6.0g of 2-acrylamido-2-methylpropanesulfonic acid and 0.1g of the functional monomer represented by the general formula VIII (n=2) into the polymerization reaction bottle, add deionized water 50.0 g was dissolved, then sodium hydroxide was added to adjust the pH to 9.5, and then 2.0 g of 1% EDTA-2Na aqueous solution and 0.5 g of 1% urea aqueous solution were sequentially added.

[0042]Put the polymerization reaction bottle in a constant temperature water bath, blow nitrogen to drive oxygen for 30 minutes, add 10 g of 0.1% ammonium persulfate aqueous solution and 5.0 g of 0.1% sodium bisulfite aqueous solution, initiate the reaction at 0°C, and continue to pass nitrogen for five minutes After 8 hours of polymerization, the temperature was raised to 50° C. and the reaction was continued for 5 hours to obtain rubber blocks. The rubber block is taken out, cut, granulated, pulverized, and sieved to obtain a white temperature-resistant and salt-resis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com