Patents

Literature

56results about How to "Overcome cohesion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Oil displacement composition used for low permeability oil reservoirs, and preparation method thereof

The invention relates to an oil displacement composition used for low permeability oil reservoirs, and a preparation method thereof, and mainly solves the problems of easy stratum obstruction and difficult injection in the low permeability oil reservoir oil displacement process of present composite flooding polymers. The oil displacement composition contains a long carbon chain betaine surfactant and an inorganic salt, wherein the long carbon chain betaine surfactant is anyone selected from long chain carboxylic acid betaine and sulfonic acid betaine, the carbon chain is a C14-C40 alkyl or alkenyl group, the inorganic salt is anyone of or a composition of CaCl2, MgCl2, NaCl and NaHCO3, and a mass ratio of the long carbon chain betaine surfactant to the inorganic salt is 1:(1-100). The oil displacement composition has the advantages of formation of oil-water ultralow interface tension, decompression and augmented injection, and simple system, well solves the problems, and can be used in the intensified oil production process of the low permeability oil reservoirs.

Owner:CHINA PETROLEUM & CHEM CORP +1

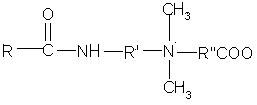

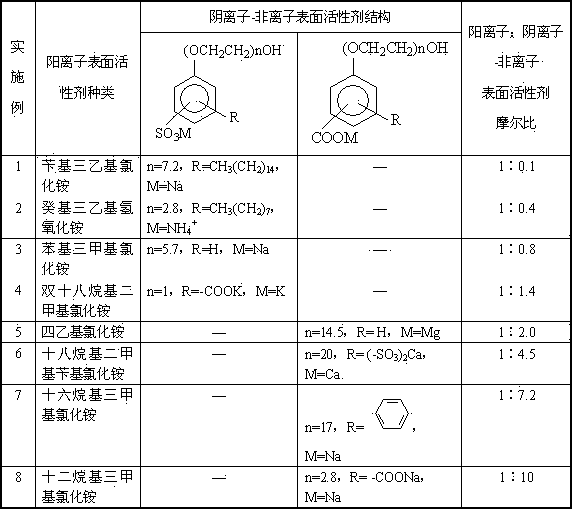

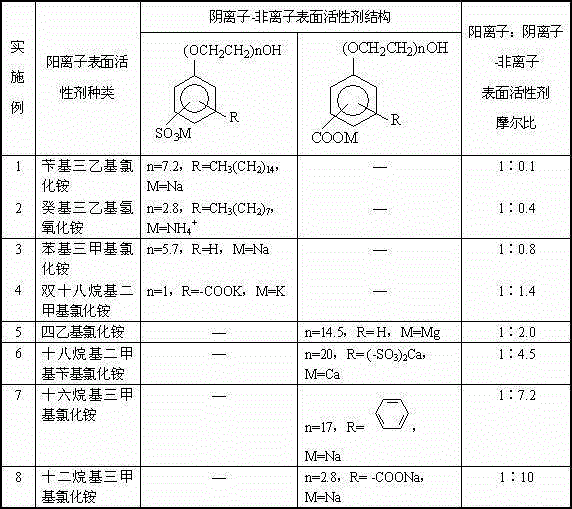

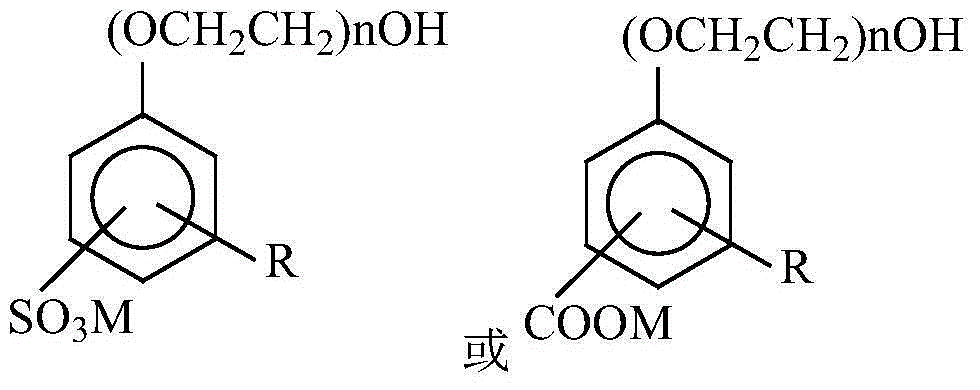

Surfactant combination for enhancing oil recovery and preparation method thereof

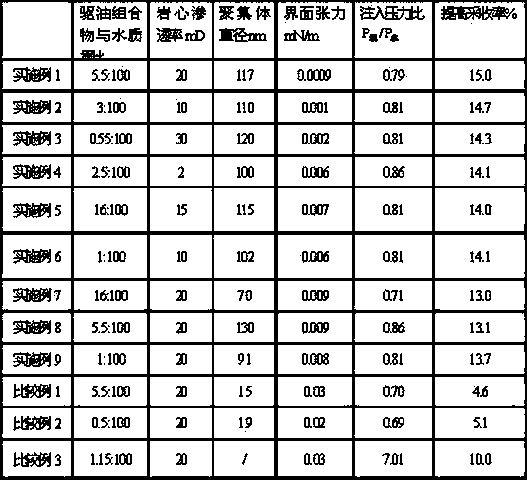

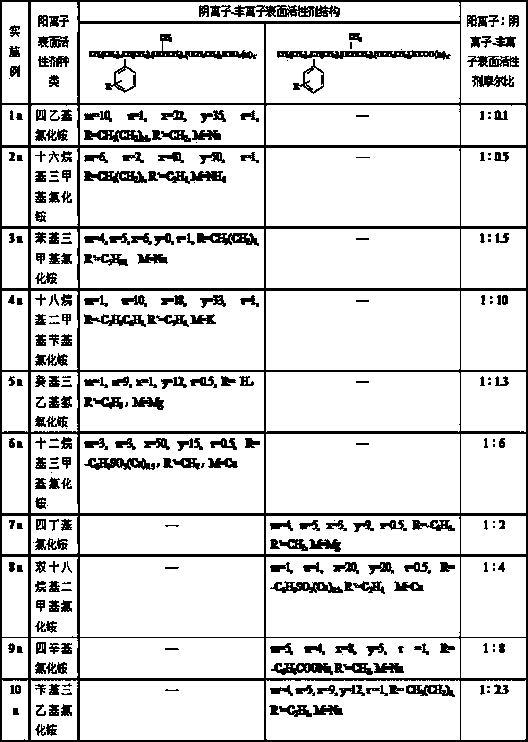

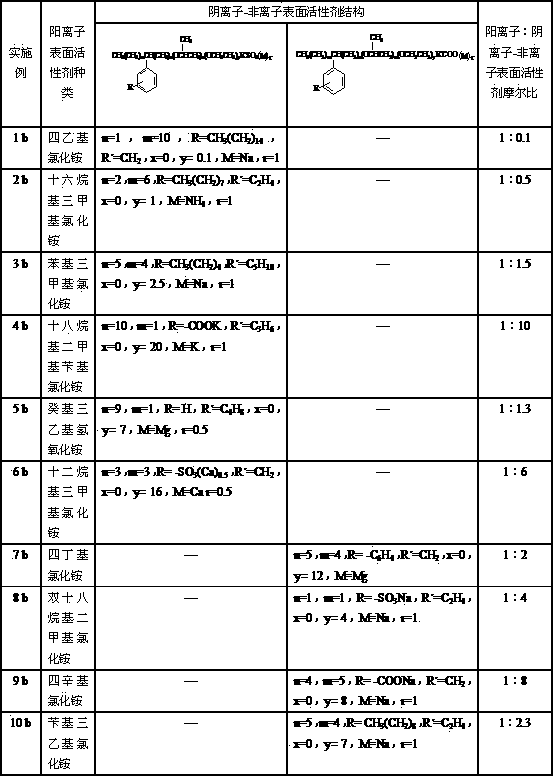

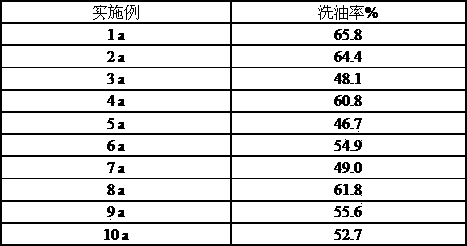

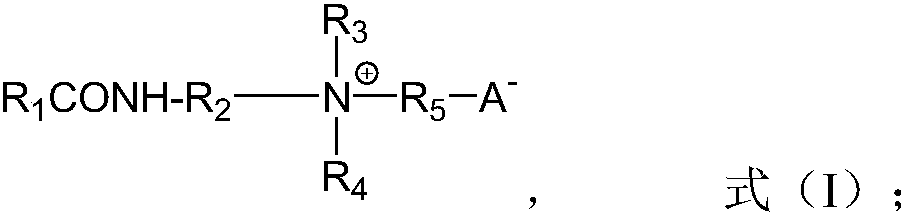

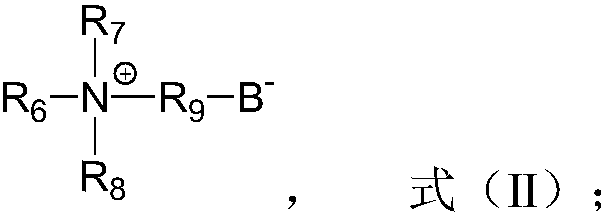

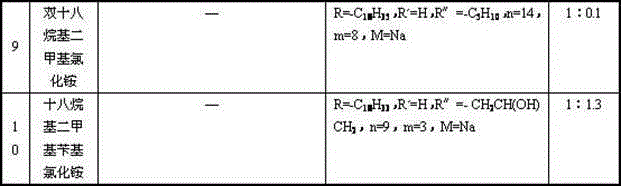

ActiveCN103773347AOvercome cohesionImprove oil displacement efficiencyDrilling compositionChemistryCorrosion

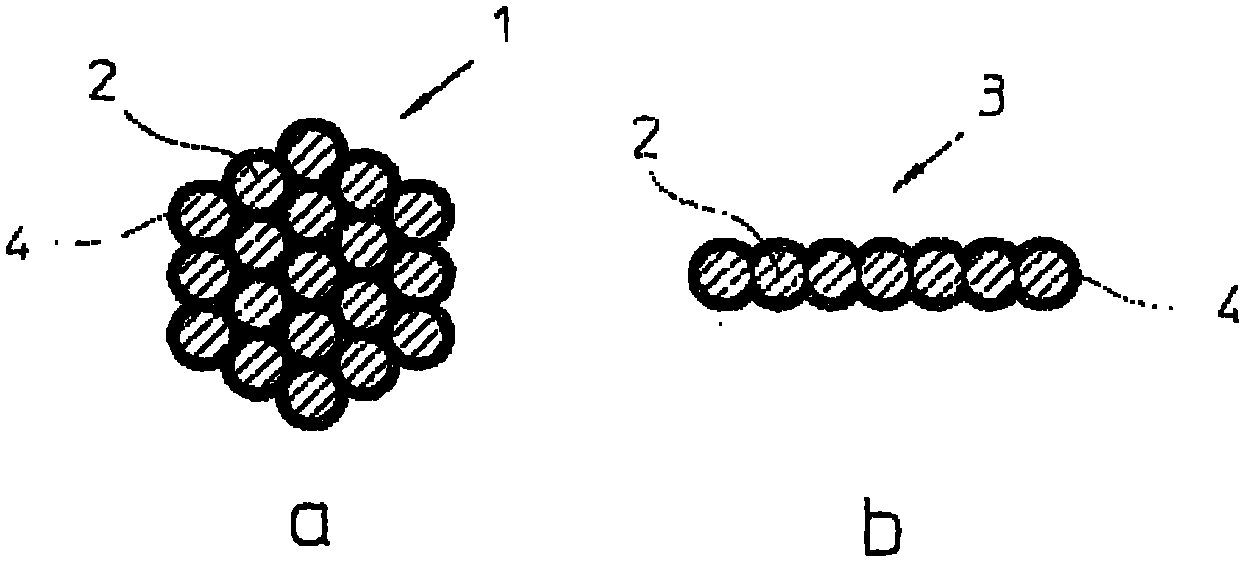

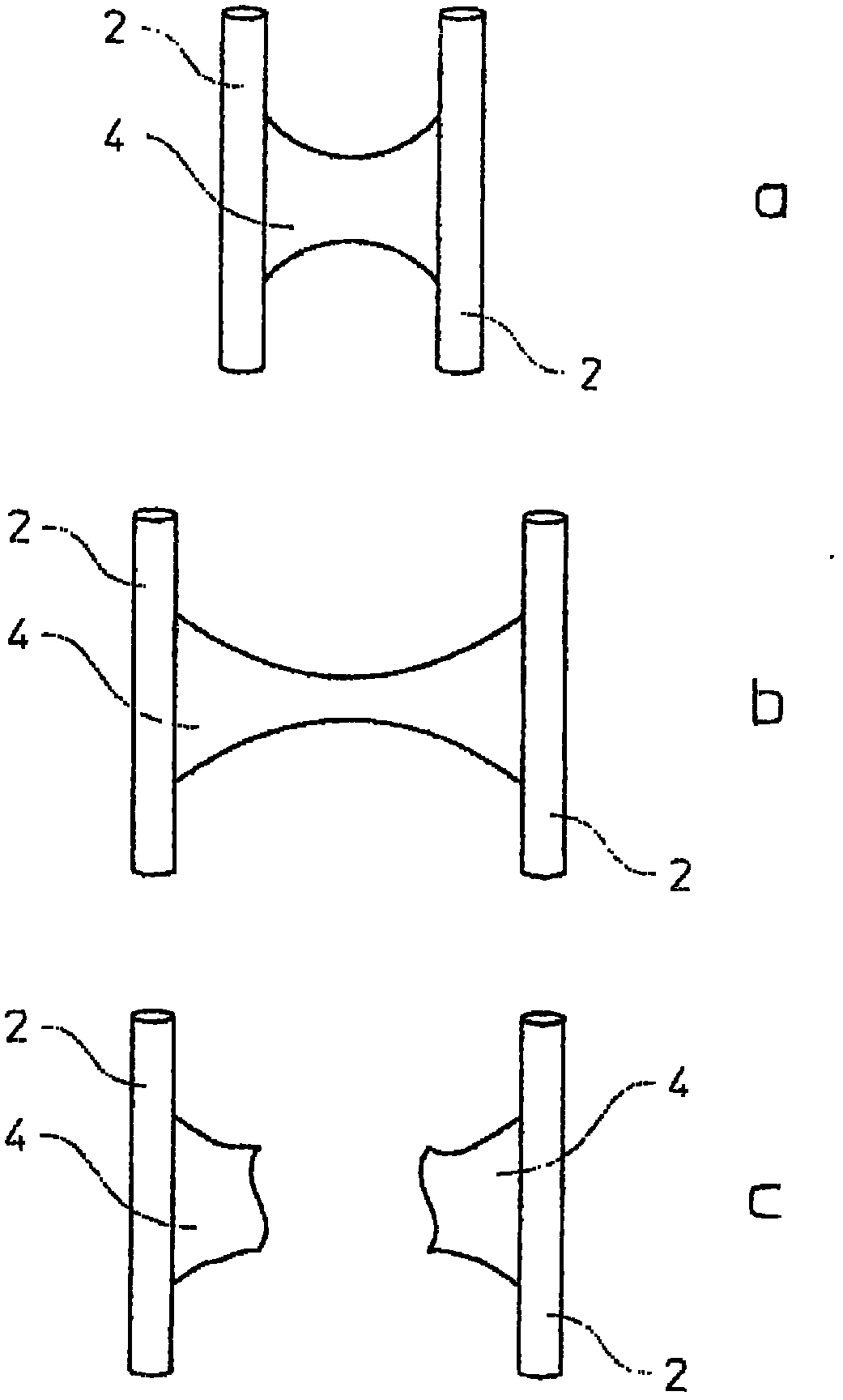

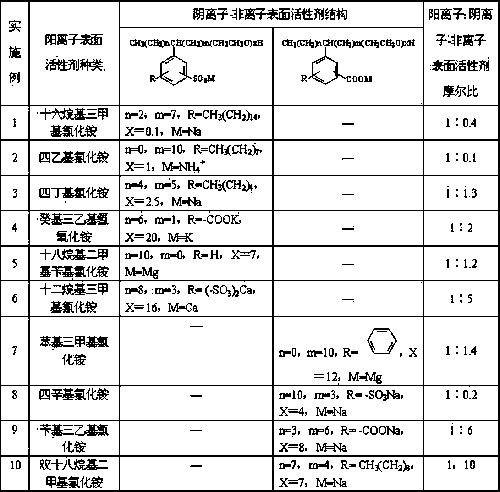

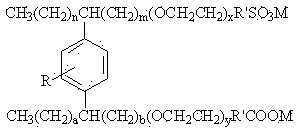

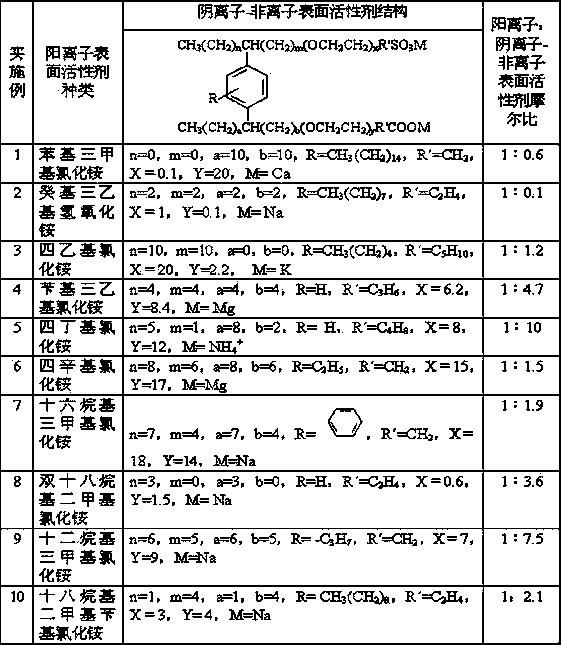

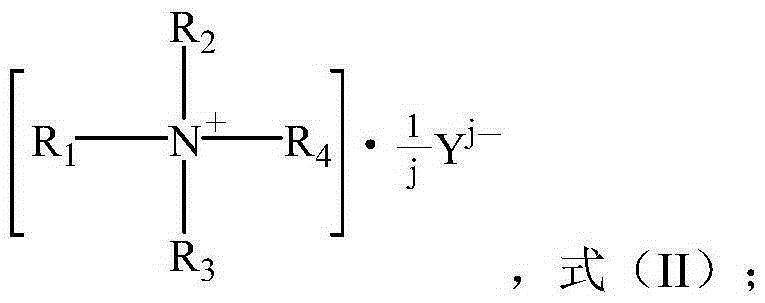

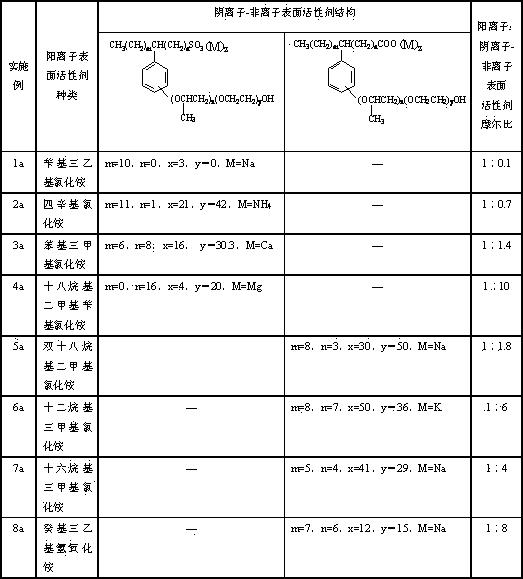

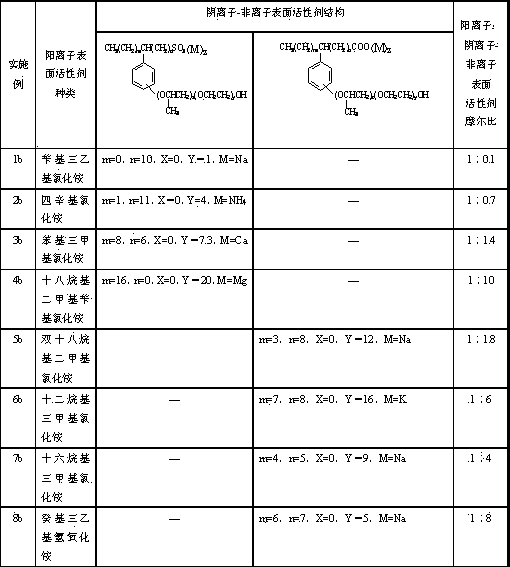

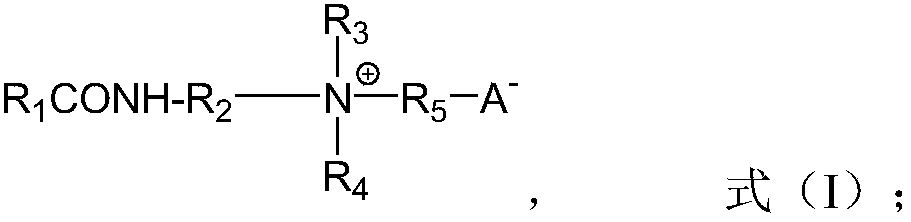

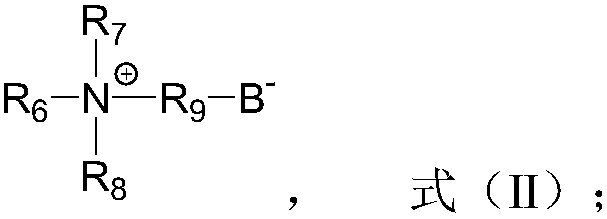

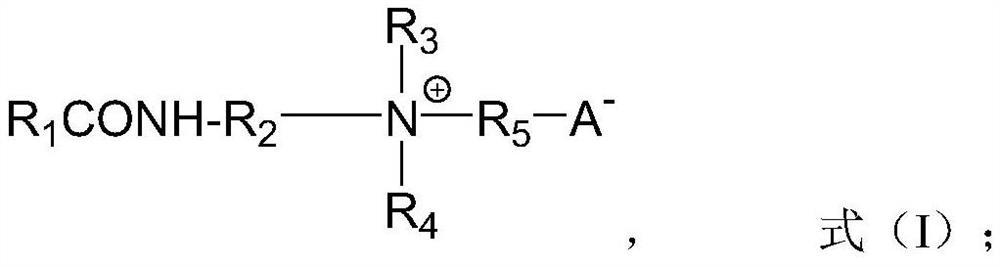

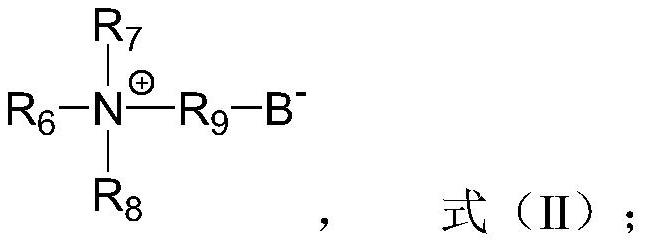

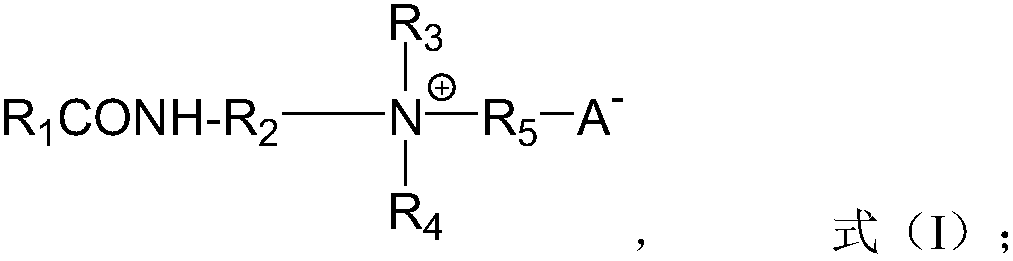

The invention relates to a surfactant combination for enhancing oil recovery and a preparation method thereof, and mainly solves the problem of low oil displacement efficiency in the tertiary recovery process in the existing surfactants and the problem of damage to stratums and oil wells, corrosion of equipment and pipes and difficulty in demulsification because inorganic base is contained in oil displacement systems. The surfactant combination comprises a cationic surfactant and an anionic-nonionic surfactant, wherein the cationic surfactant is selected from any one of quaternary ammonium salt and quaternary ammonium alkali; the anionic-nonionic surfactant is a surfactant containing ethoxy nonionic groups and carboxyl or sulfo anionic groups; the mol ratio of the cationic surfactant to the anionic-nonionic surfactant is (1:0.01) to (1:100). The surfactant combination and the preparation method thereof preferably solve the problems, and can be applied to the tertiary recovery process of oil fields.

Owner:CHINA PETROLEUM & CHEM CORP +1

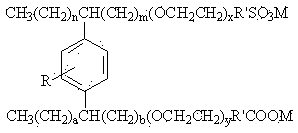

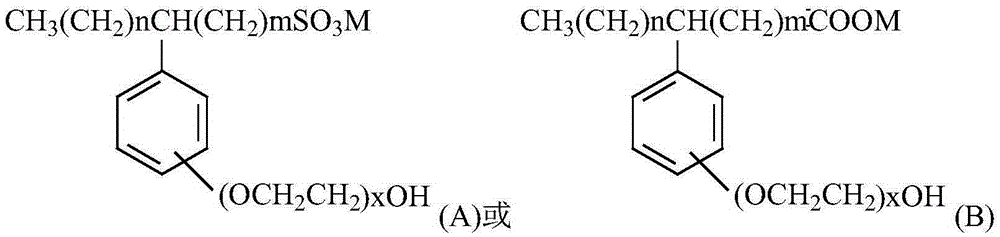

Oil-displacement surfactant composition, preparation method and application

ActiveCN104277814AImprove surface activityLarge adsorption capacitySulfonic acids salts preparationDrilling compositionAlkaline earth metalSURFACTANT BLEND

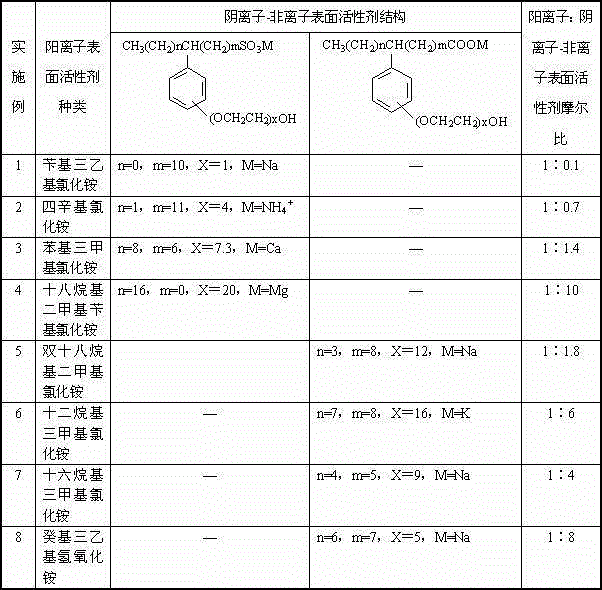

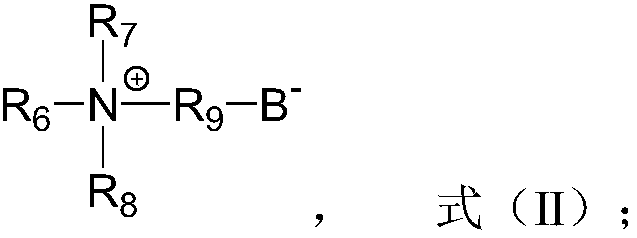

The invention relates to an oil-displacement surfactant composition, a preparation method and application, and mainly solves the problems that conventional surfactants are bad in oil displacement efficiency in the process of tertiary oil recovery, and an oil displacement system damages stratums and oil wells, corrodes equipment and pipelines and cause demulsification difficulty because of a contained inorganic base. The employed oil-displacement surfactant composition comprises a cationic surfactant and an anionic-nonionic surfactant with the molar ratio of 1:0.01-1:100, wherein the anionic surfactant is at least one selected from quaternary ammonium salts or quaternary amine bases, and the anionic-nonionic surfactant has the molecular general formula shown in the specification, and the in general formula, M is any one of alkali metals, alkali earth metals and ammonium radical. The technical scheme relatively well solves the above problems, and is applicable to an enhanced oil recovery process of oil fields.

Owner:CHINA PETROLEUM & CHEM CORP +1

Surfactant composition for chemical displacement of reservoir oil and preparation method thereof

ActiveCN103540305AImprove surface activityLarge adsorption capacityDrilling compositionQuaternary ammonium cationSURFACTANT BLEND

The invention relates to a surfactant composition for chemical displacement of reservoir oil and a preparation method thereof, mainly for solving the problems that the conventional surfactant is poor in oil displacement efficiency in the tertiary oil recovery process and an oil displacement system containing inorganic base damages stratums and oil wells, corrodes equipment and pipelines and results in difficult demulsification. The surfactant composition provided by the invention comprises a cationic surfactant and an anionic-nonionic surfactant, wherein the cationic surfactant is at least one of quaternary ammonium salt and quaternary ammonium alkali; the anionic-nonionic surfactant is a surfactant containing an ethyoxyl nonionic group and a carboxyl or sulfonic acid group anionic group; and the molar ratio of the cationic surfactant to the anionic-nonionic surfactant is (1:0.01)-(1:100); and by the adoption of the surfactant composition and the preparation method of the surfactant composition, the above problems can be well solved. The surfactant composition can be applied to tertiary oil recovery process of an oil field.

Owner:CHINA PETROLEUM & CHEM CORP +1

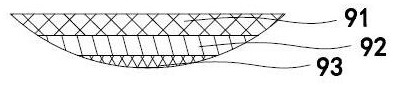

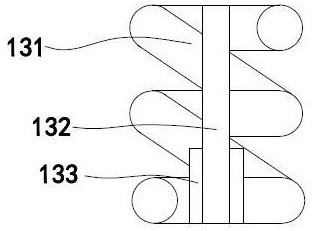

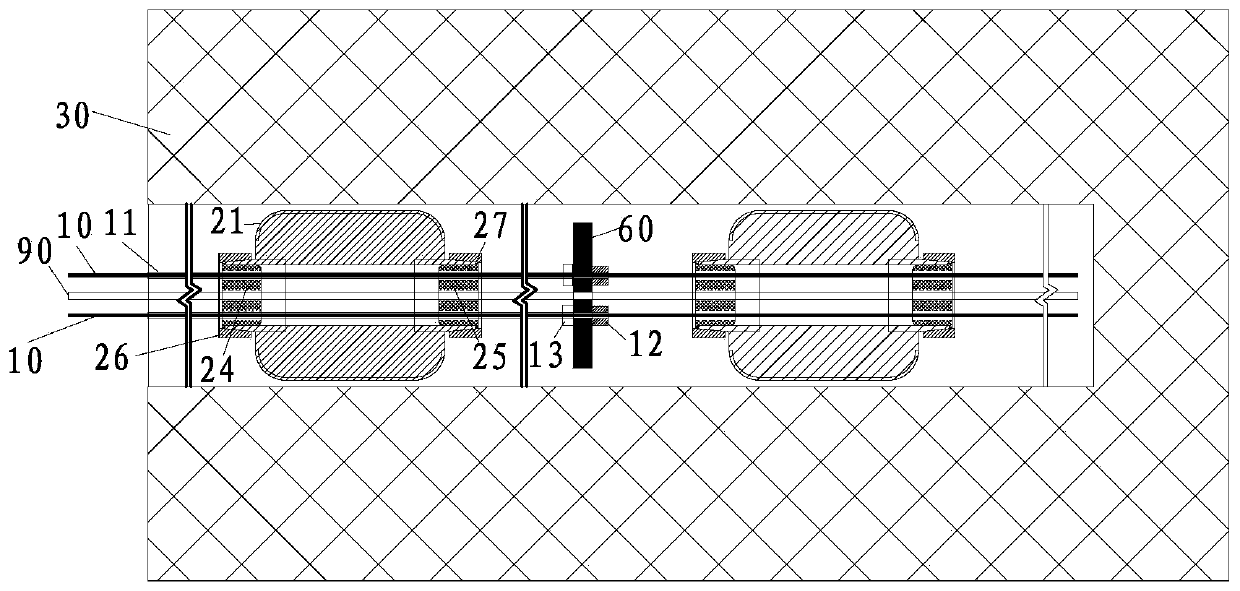

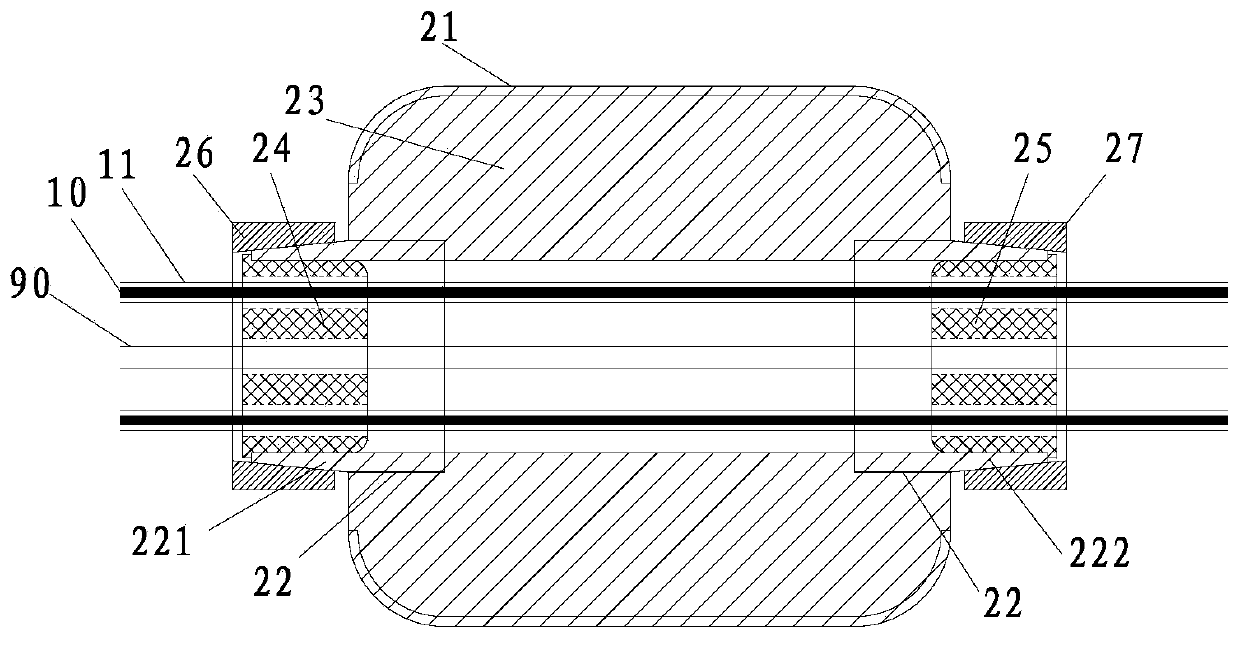

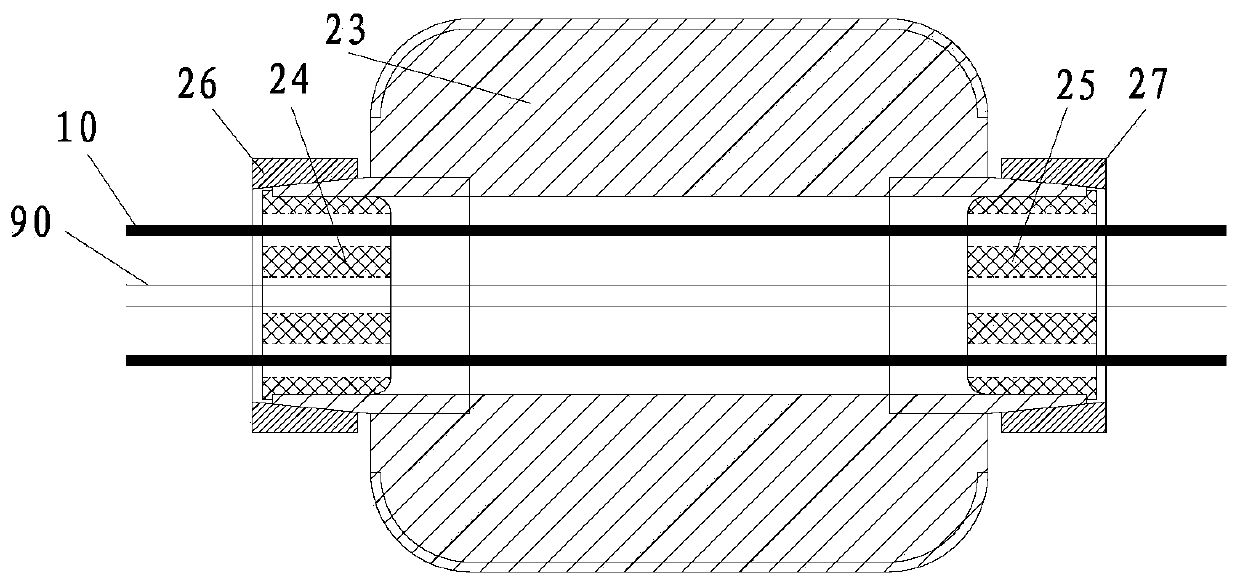

Method for production of a multi-axial wire structure, unidirectional fiber layers and method for production thereof, multi-axial wire structure and composite part with a matrix

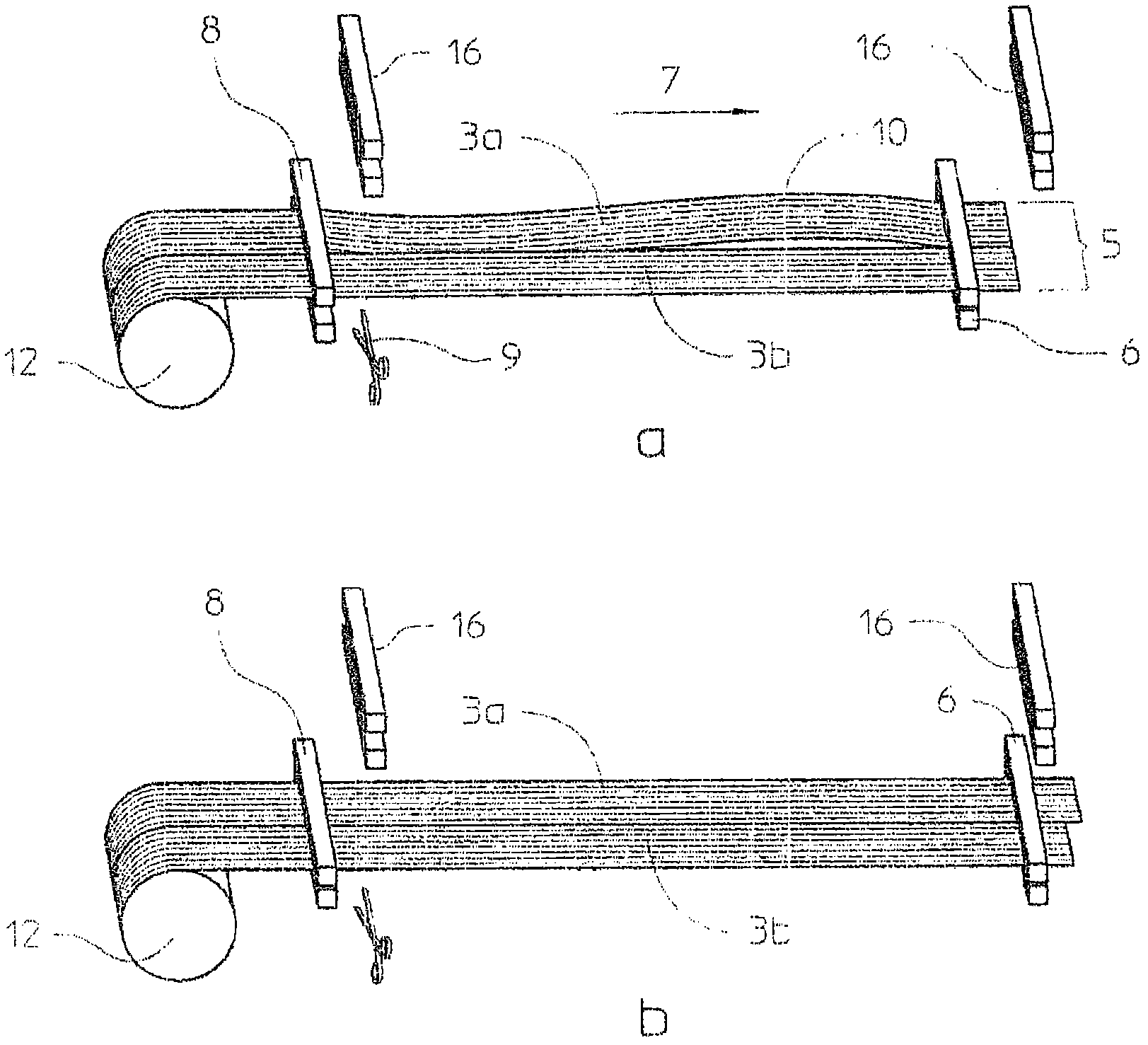

ActiveCN102066638AMechanical longitudinal stress balanceOvercome cohesionFilament handlingCoatingsYarnEngineering

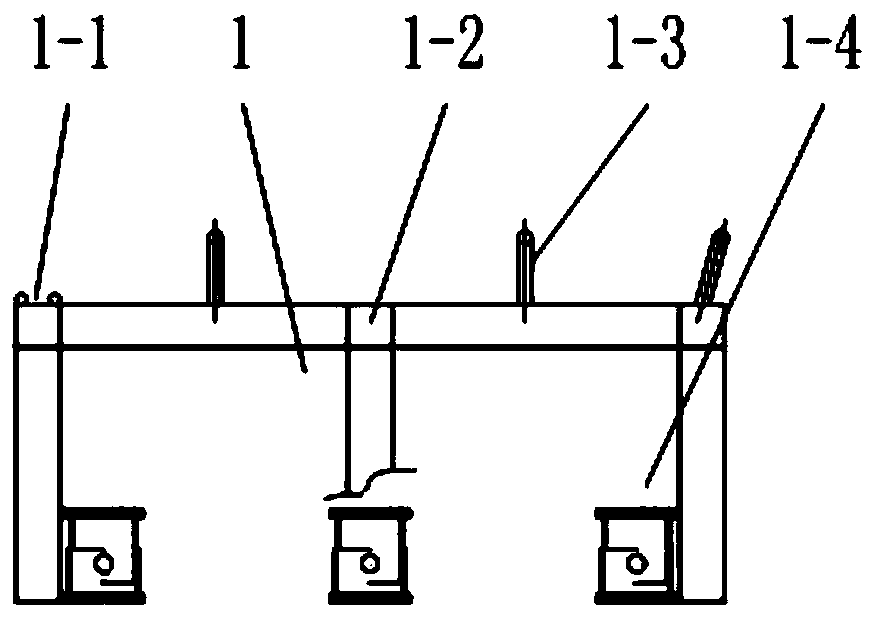

A known method from fiber engineering is improved in which fibers consisting of a large number of filaments are broadened out into bands (3a, 3b), placed side by side and pulled by a grasper (6) over a transport device in the form of segments (5) cut to size, and are secured thereon by means of an extending-clamping device (16). The direction of movement of the grasper (6) is denoted by reference number (7) and the required separating device by reference number (9). The novelty consists in that the bands (3a, 3b) of the segment (5) are combined and set to the side of the segment in an essentially non-bonded manner. A method is provided herein such that the measures for obtaining a transverse cohesion extending laterally across several bands (3a, 3b) are omitted. However, a transverse cohesion imprinted from the outside can extend across the filaments of a single band (3a, 3b). In this manner, the bands (3a, 3b) are set aside in a particularly uniform and smooth manner. When laid by means of the grasper (6), differences in length and tension between the single bands (3a, 3b) are compensated, which would be expressed, for example, as bulges (10). An additional, short tug on the already almost completely transported segment (5) is possible. The retention force for tightening can be applied by a braked supply coil of the starting material. The illustration 'a' denotes the state of the segment before the compensation movement, illustration 'b' denotes the state thereafter.

Owner:KARL MAYER TECH TEXTILIEN GMBH

Efficient surfactant composition for oil displacement and preparation method of composition

InactiveCN107828398AImprove surface activityLarge adsorption capacityDrilling compositionQuaternary ammonium cationSURFACTANT BLEND

The invention relates to efficient surfactant composition for oil displacement and a preparation method of the composition and mainly solves the problems that existing surfactants have poor oil displacement efficiency in the tertiary oil recovery process, an oil displacement system damages strata and oil wells, corrodes equipment and pipelines and demulsification is difficult because of inorganicbase contained in the oil displacement system. The efficient surfactant composition for oil displacement comprises a cationic surfactant and an anion-non-ionic surfactant, wherein the cationic surfactant is selected from any one of quaternary ammonium salt and quaternary amine alkali, the anion-non-ionic surfactant is a surfactant containing ethyoxyl nonionic groups and carboxyl or sulfonyl anionic groups, and the mole ratio of the cationic surfactant to the anion-non-ionic surfactant is (1:0.01)-(1:100). By means of the technical scheme of the preparation method, the problem is better solved,and the efficient surfactant composition can be used for the tertiary oil recovery process of the oil field.

Owner:展红明

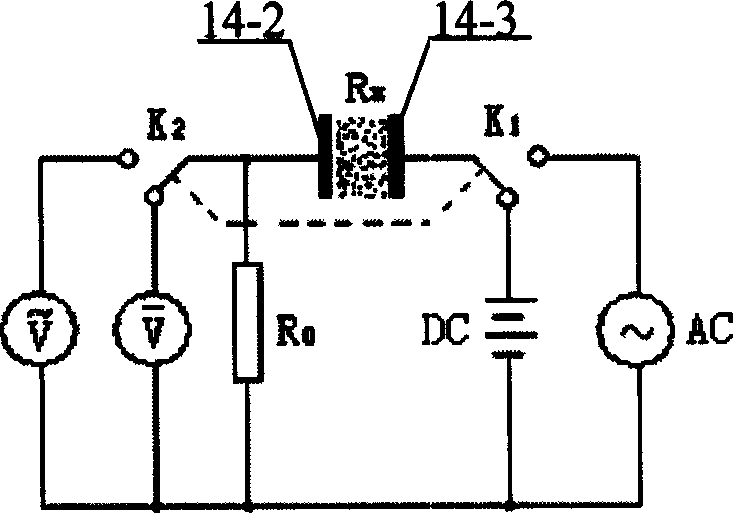

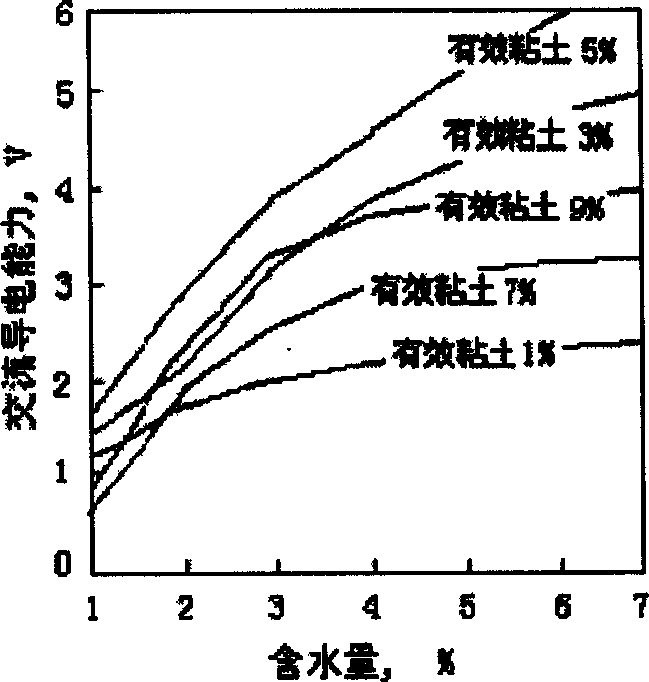

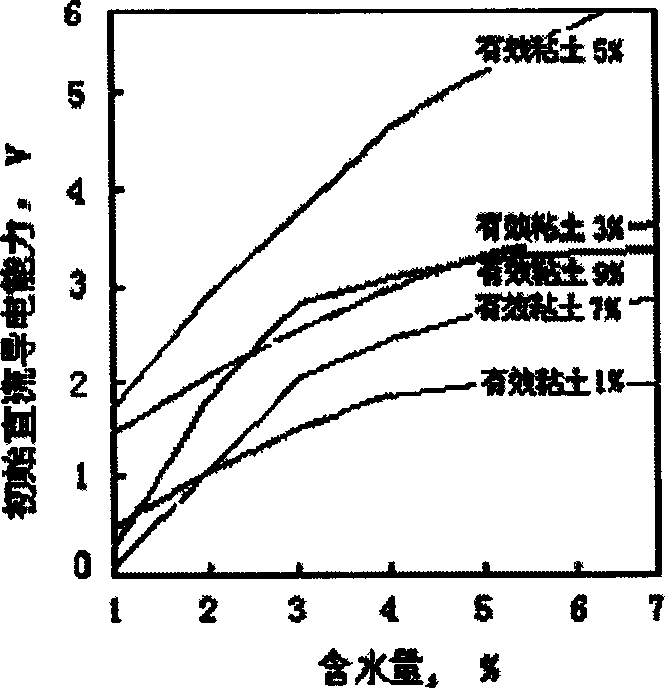

Parameter analysis method and device for wetting clay sand quality for casting

InactiveCN1601278AOvercome cohesionFast testMaterial thermal conductivityMaterial testing goodsIt equipmentSand sample

The invention belongs to a quick analysis method of wet-type clay sand quality parameters for casting and its equipment. In particular it relates to a method for detecting effective clay content, water content, air permeability and comprehensive strength of wet-type clay sand and its equipment. Said method is characterized by that applying AC power supply and DC power supply to standard sand sample at twice successively to make excitation, and utilizing measured sand sample AC conductive capability, initial AC conductive capability, AC condutive capability change rate and other information parameters obtained in the sample-making process to solve the effective clay content and water content, and can obtain tested result within few seconds. Said equipment includes sand sample barrel, strength detection cylinder, piston rod and weighing sensor, etc.

Owner:HARBIN UNIV OF SCI & TECH

Surfactant composition for tertiary oil recovery and preparation method thereof

ActiveCN103540306AImprove surface activityLarge adsorption capacityDrilling compositionEmulsionQuaternary ammonium cation

The invention relates to a surfactant composition for tertiary oil recovery and a preparation method thereof, mainly for solving the problems that the existing surfactant has poor oil displacement efficiency in tertiary oil recovery, inorganic base contained in a displacement of reservoir oil system damages the stratum and oil wells, corrodes equipment and pipelines, and results in difficult emulsion breaking. The surfactant composition comprises a cationic surfactant and an anion-nonionic surfactant, wherein the cationic surfactant is any one of quaternary ammonium salt and quaternary amine alkali, the anion-nonionic surfactant contains ethyoxyl nonionic group and carboxyl or sulfonic acid group anionic group, and the molar ratio of the cationic surfactant to the anion-nonionic surfactant is 1:0.01-1:100. Due to adoption of the surfactant composition and the preparation method, the above problems can be well solved. The technical scheme can be used in the oil field tertiary oil production process.

Owner:CHINA PETROLEUM & CHEM CORP +1

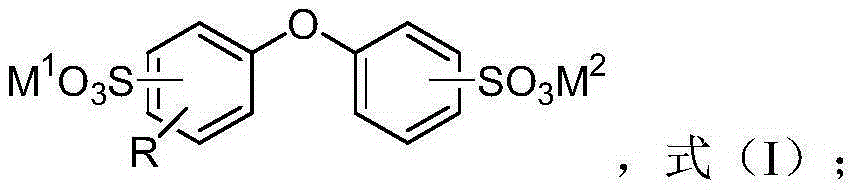

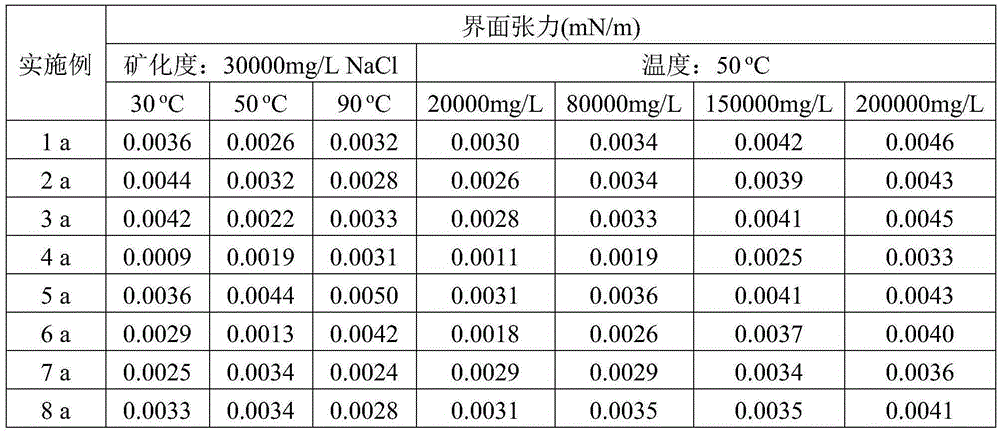

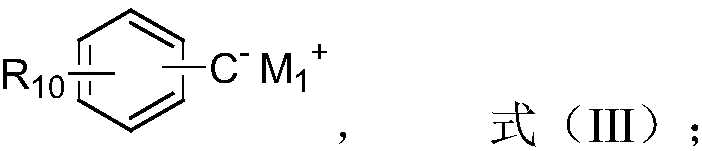

Compound surfactant composition for displacement of reservoir oil with hypersalinity

ActiveCN106590572AOvercome cohesionImprove oil displacement efficiencyDrilling compositionAmmonium compoundsIon

The invention relates to a compound surfactant composition and an application. The composition mainly solves the problem of low efficiency of reservoir oil displacement in tertiary oil recovery process of oil reservoir with hypersalinity due to surfactants. The compound surfactant composition comprises an anionic surfactant and a cationic surfactant, the mol ratio of the anionic surfactant and the cationic surfactant is 1:(0.01-100), wherein the cationic surfactant is selected from at least one of quarternary ammonium compounds, and the anionic surfactant is expressed by a molecular general formula shown in a formula (I); M1 and M2 are independently selected from any one of ammonium ion or alkali metal ion, and R is anyone of H, C1-C10 fatty group or aromatic base. The technical scheme better solves the problem and can be applied to tertiary oil recovery process of oil reservoir with hypersalinity.

Owner:CHINA PETROLEUM & CHEM CORP +1

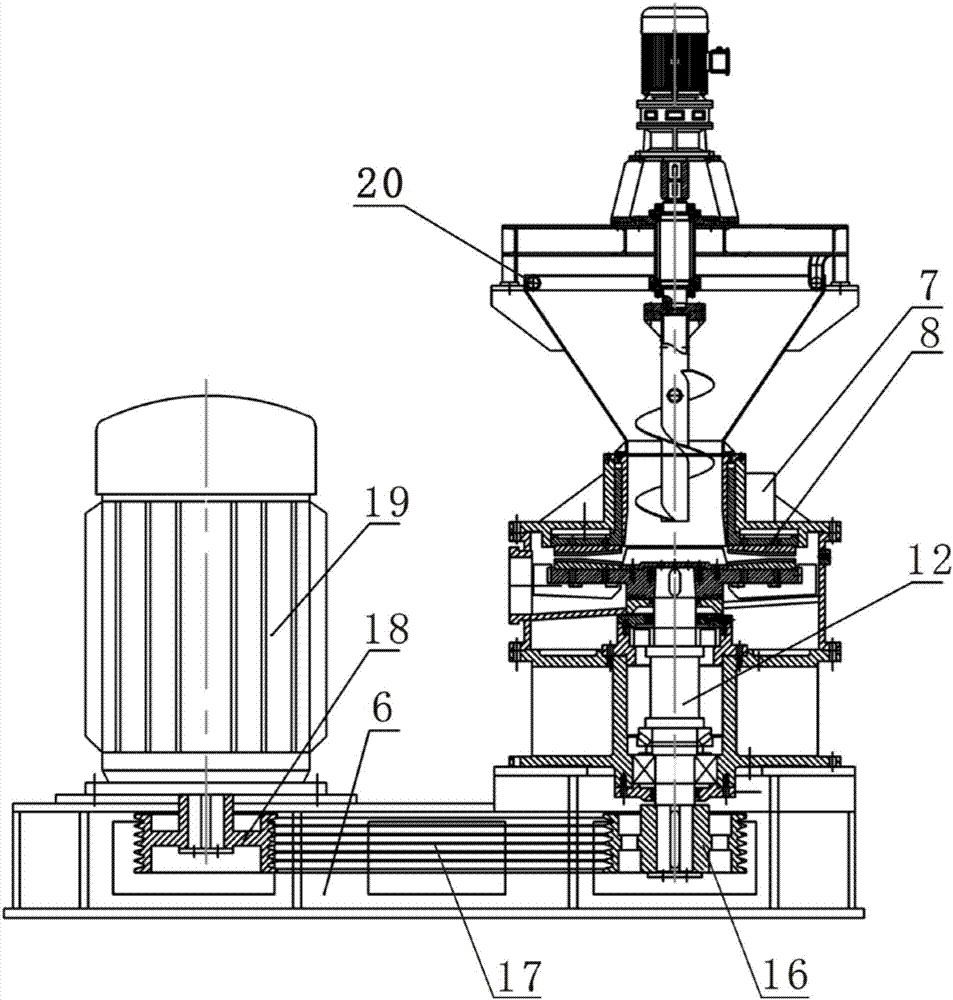

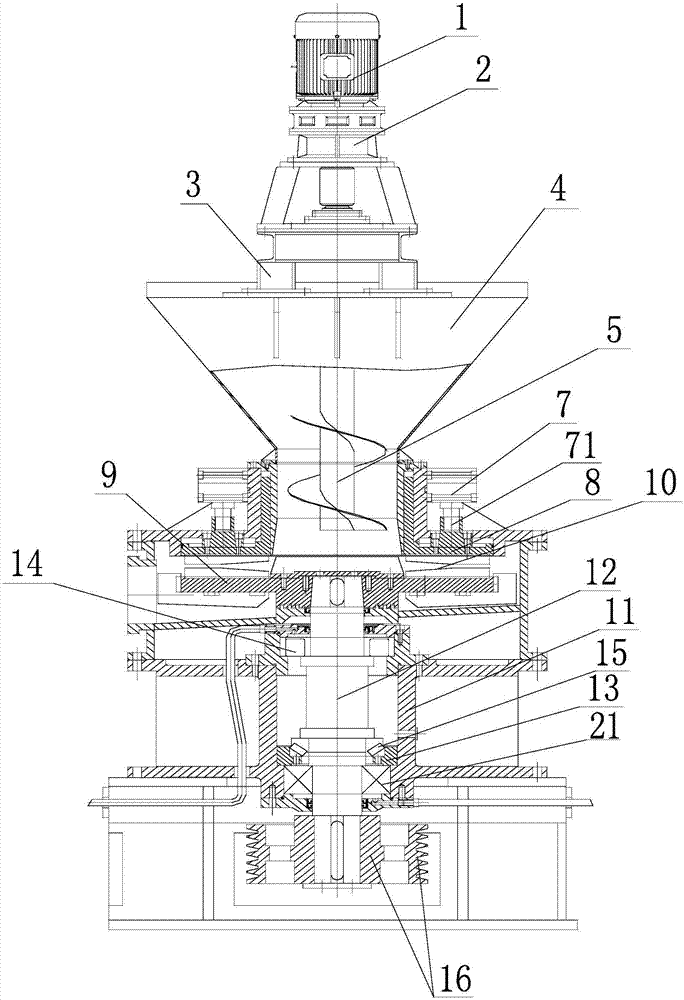

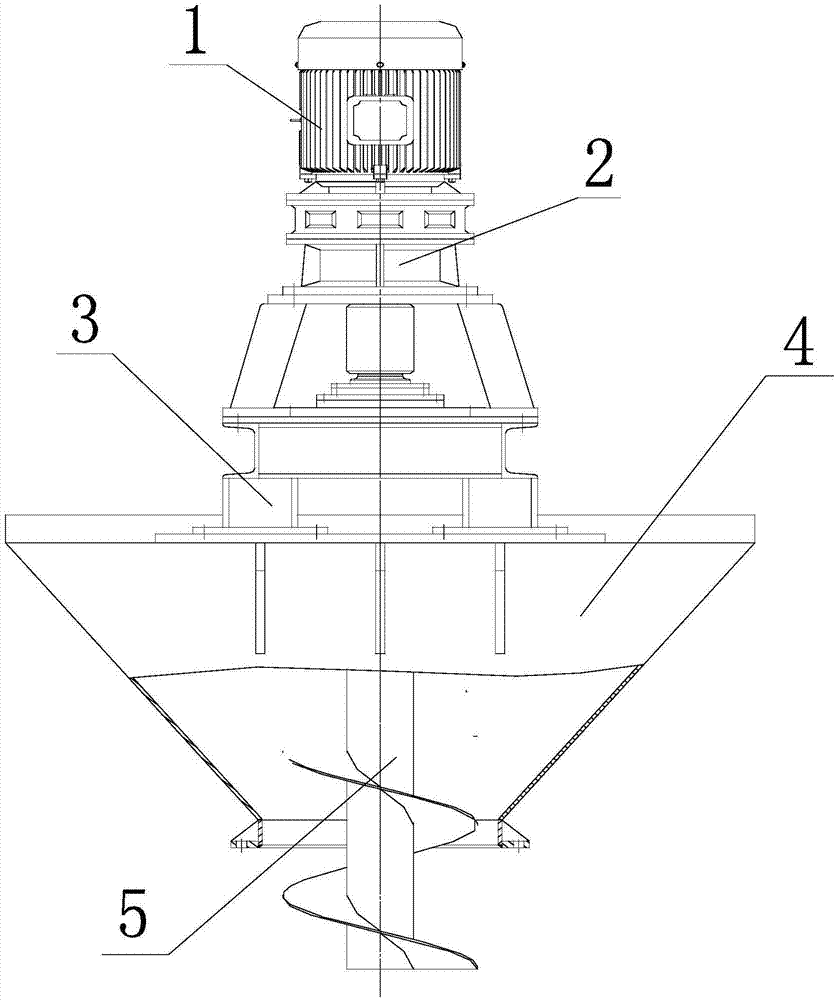

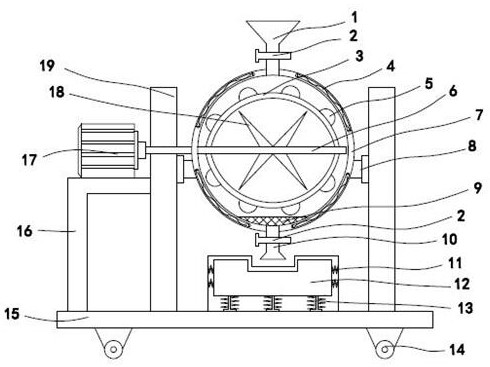

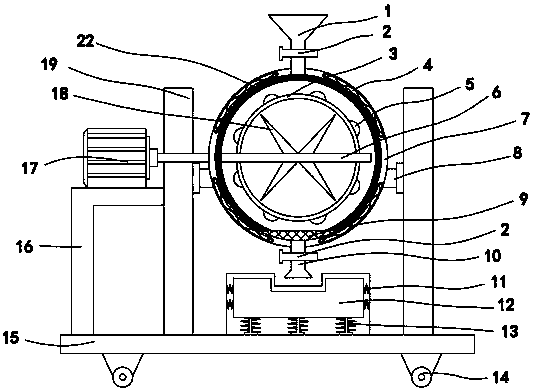

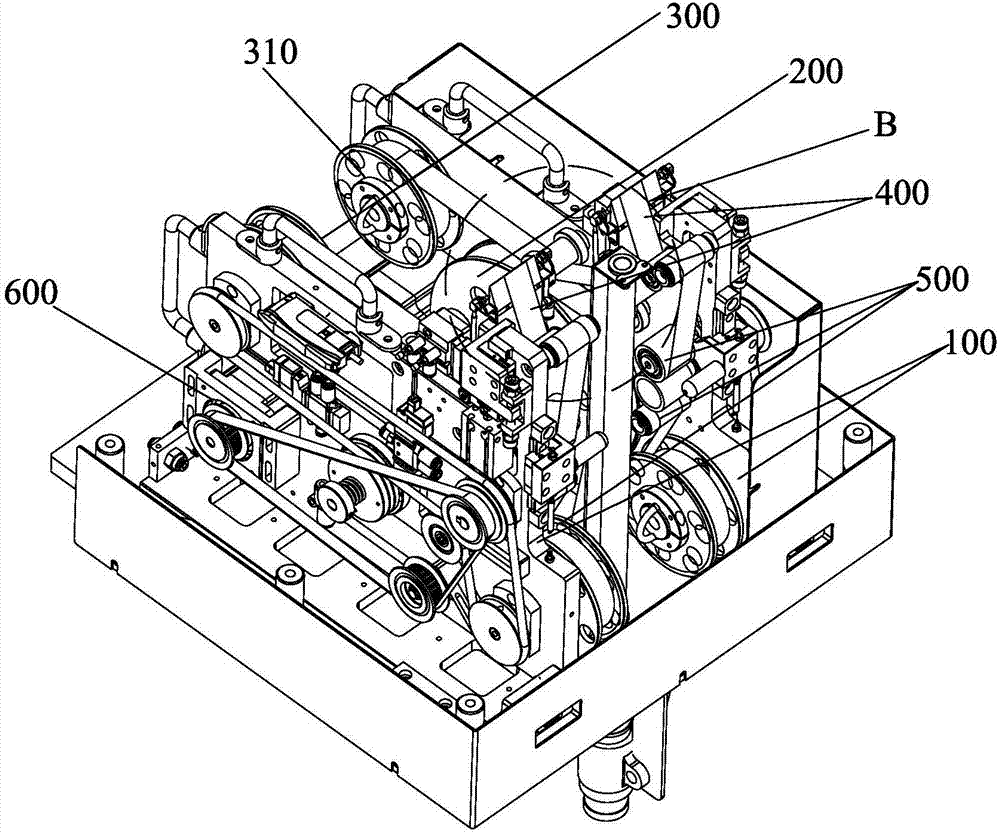

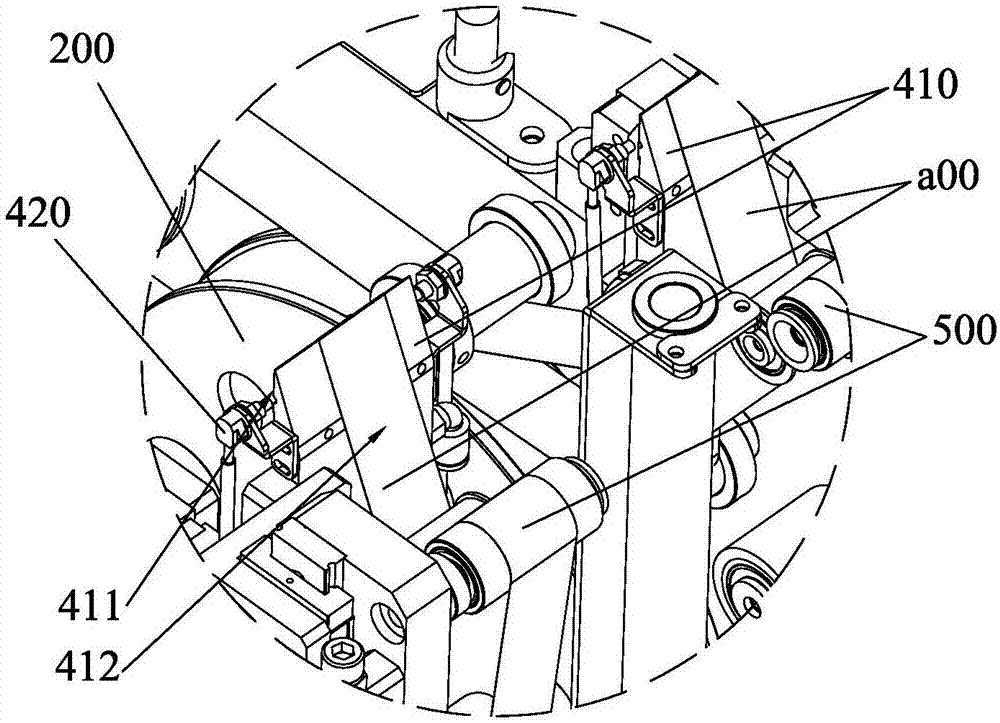

Straw fine screening machine

PendingCN107952523AOvercome cohesionIncrease surface areaCuttersCocoaElectric machineControl engineering

The invention discloses a straw fine screening machine. The straw fine screening machine comprises a feeding device, a grinding device, a rotating mechanism and a rotating motor. The feeding device comprises a support, a feeding motor, a feeding hopper and a spiral shaft; the feeding motor is installed on the support; a power output shaft of the feeding motor is fixedly connected with a spiral shaft; the grinding device comprises a grinding shell, an upper grinding disc and a lower grinding disc; a grinding chamber is formed inside the grinding shell; a discharging outlet of the feeding hoppercommunicates with the grinding chamber; a grinding gap space is formed between the upper grinding disc and the lower grinding disc; the rotating mechanism is arranged at the bottom of the lower grinding disc and comprises a bearing base and a rotating spindle; the rotating spindle is rotatably installed in a rotating cavity of the bearing base; a transmission wheel A is installed at the bottom ofthe rotating spindle; and a transmission wheel B is installed on a power output shaft of the rotating motor, and the transmission wheel B and the transmission wheel A are in power transmission connection through the transmission mechanism. Filament-shaped straw materials can be produced and machined on an assembly line, and the production efficiency is improved.

Owner:中科国兴(绵阳)科技有限公司

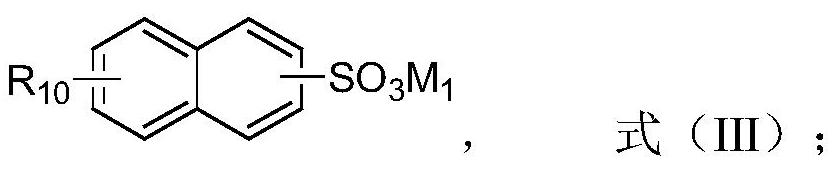

Hydrophobic associative polymer-surfactant binary composition and composite flooding system thereof

ActiveCN108314998AImprove surface activityReduce dosageFluid removalDrilling compositionBetaineCompound system

The invention relates to a hydrophobic associative polymer-surfactant binary composition for chemical oil flooding and a composite flooding system thereof, and mainly solves the problem that when a hydrophobic associative polymer existing in the prior art is compounded with a surfactant existing in the prior art, and the concentration of the surfactant is large, the viscosity of the compound system is reduced to affect the oil flooding efficiency of the polymer-surfactant binary composite flooding system, the problem can be well solved by the hydrophobic associative polymer-surfactant binary composition, and the hydrophobic associative polymer-surfactant binary composition can be used in oil recovery in an oil fields. The hydrophobic associative polymer-surfactant binary composition includes the following components: 1) a hydrophobic associative polymer comprising an acrylamide unit and a hydrophobic monomer unit; and 2) a composite surfactant comprising alkyl amido betaine, alkylbetaine and an aromatic acid salt in a mass ratio of (1 to 60): (1 to 60) :(20 to 60); wherein the mass ratio of the hydrophobic associative polymer to the composite surfactant is (0.5 to 3): (0.1 to 5).

Owner:CHINA PETROLEUM & CHEM CORP +1

A liquid medicine stirring device

ActiveCN109589817BEasy to rinseEasy maintenanceAntifouling/underwater paintsRotary stirring mixersMedicinal herbsEngineering

The invention provides a liquid medicine stirring device, which belongs to the technical field of stirring equipment, and includes a spherical stirring box. The middle parts of both sides of the spherical stirring box are connected to connecting rods through support seats. The vibration wheel, the upper end of the spherical mixing box is connected to the feeding hopper, the lower end of the spherical mixing box is connected to the discharging hopper, and the inside of the spherical mixing box is equipped with a cutting knife group and an arc-shaped stirring rod. The device can fully stir the medicinal liquid with fast stirring speed and high stability. The stirred medicinal liquid is relatively uniform and the mixing degree is high, and the release rate of active ingredients of medicinal materials can also be improved.

Owner:YUNNAN DAI PHARMA

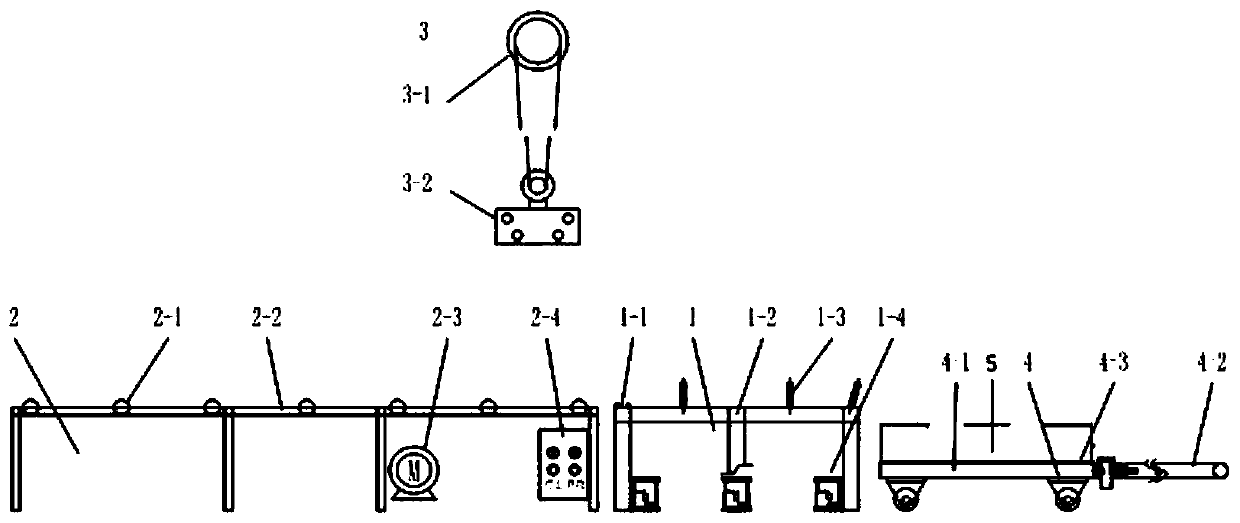

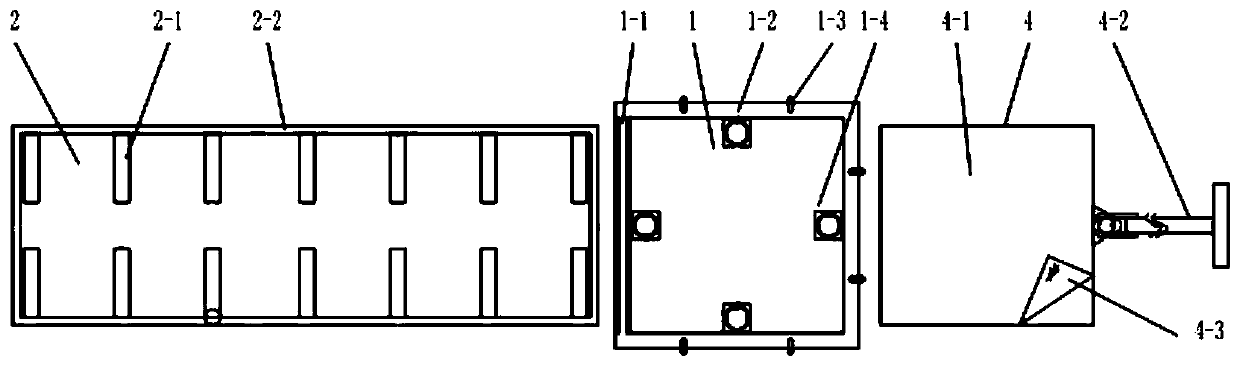

Prefabricated part quick demolding frame and assembly line operation method thereof

ActiveCN109866316AReduce turnoverReduce the number of sparesDischarging arrangementCeramic shaping plantsBraced frameEngineering

The invention discloses a prefabricated part quick demolding frame and an assembly line operation method thereof. The prefabricated part quick demolding frame comprises a quick demolding frame body, aprefabricated part-mold conveyor, an overturning lifter and a prefabricated part transport flat car; the quick demolding frame body is composed of a mold clamping groove, a support frame, a guide pinand a plug type telescopic sleeve; the prefabricated part-mold conveyor is used for conveying a to-be-demolded prefabricated part to one side of the quick demolding frame body and comprises a rollerset, a bracket, a driving motor and a controller; the overturning lifter is mounted directly above the end, close to the quick demolding frame body, of the prefabricated part-mold conveyor and comprises an electric hoist or a manual hoist and a grabbing lifter; when the prefabricated part is demolded, the prefabricated part transport flat car is located directly below the quick demolding frame body and receives the dropped demolded prefabricated part; and the prefabricated part transport flat car comprises a wheeled flat car assembly, a pulling rod and a cushion pad. The prefabricated part quick demolding frame and the assembly line operation method thereof are reasonable in design, low in labor intensity, good in usage effect, high in production efficiency, economical and practical.

Owner:CHINA RAILWAY FIRST GRP CO LTD +1

Preparation of nanometer microemulsion and application of nanometer microemulsion in improvement of gas production rate of gas field

InactiveCN111087506ALow surface activity lossReduce mining costsDrilling compositionActive agentOil phase

The invention relates to the technical field of oil and gas exploitation, in particular to preparation of a nanometer microemulsion and application of the nanometer microemulsion in improving the gasproduction rate of a gas field. The nanometer microemulsion comprises the following components: 35 to 55 parts of an oil-based solvent, 20 to 40 parts of a water-soluble monomer, 5 to 10 parts of a cationic surfactant, 3 to 6 parts of an anionic-nonionic surfactant, 1 to 4 parts of a lipophilic emulsifier, 0.5 to 1.5 parts of a hydrophilic emulsifier and 0.3 to 0.8 part of a surface active synergist. The preparation method comprises the steps of oil phase preparation, water phase preparation, an oil phase-water phase mixed reaction and the like. The nanometer microemulsion can form ultralow interfacial tension with oil gas, so cohesion between the oil gas is effectively overcome, outflow of the oil gas is facilitated, and the gas production rate of a gas field is greatly increased; in addition, the microemulsion is not prone to adsorption and elution in the exploitation process of the gas field, surface activity loss is low, and therefore, oil gas production cost is reduced.

Owner:郑州洁灵科技有限公司

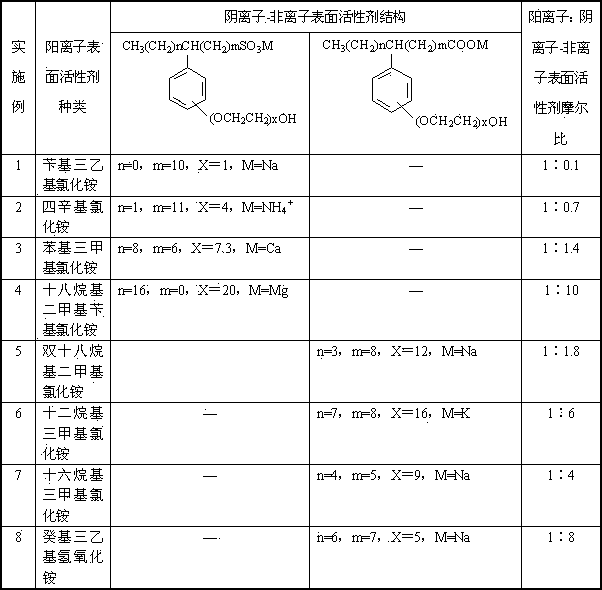

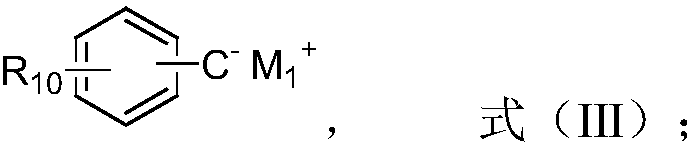

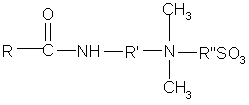

Surface active agent composition for chemical displacement of reservoir oil and preparation method and application thereof

ActiveCN104232046AImprove surface activityLarge adsorption capacityDrilling compositionQuaternary ammonium cationAlkaline earth metal

The invention relates to a surface active agent composition for chemical displacement of reservoir oil, and a preparation method and application thereof, and mainly solves the problems of poor displacement efficiency in a tertiary oil recovery process, and harm to the stratum and the oil field, corrosion of equipment and pipeline and difficult demulsification due to oil inorganic alkali contained in displacement system. The invention adopts the surface active agent composition comprising a cationic surface active agent and an anionic-non-ionic surface active agent. The cationic surface active agent is at least one selected from the group consisting of quaternary ammonium salt or quaternary ammonium alkali; and the anionic-non-ionic surface active agent is represented by a molecular general formula shown as (A) or (B), wherein M represents one of an alkali metal, an alkaline earth metal and ammonium, m and n are selected from 0-14, and x and y are selected from 0-100. The technical scheme well solves the above problems, and can be used in tertiary oil recovery process.

Owner:CHINA PETROLEUM & CHEM CORP +1

Surfactant composition for chemical flooding and preparation method thereof

ActiveCN103540305BImprove surface activityLarge adsorption capacityDrilling compositionCompound (substance)SURFACTANT BLEND

The invention relates to a surfactant composition for chemical displacement of reservoir oil and a preparation method thereof, mainly for solving the problems that the conventional surfactant is poor in oil displacement efficiency in the tertiary oil recovery process and an oil displacement system containing inorganic base damages stratums and oil wells, corrodes equipment and pipelines and results in difficult demulsification. The surfactant composition provided by the invention comprises a cationic surfactant and an anionic-nonionic surfactant, wherein the cationic surfactant is at least one of quaternary ammonium salt and quaternary ammonium alkali; the anionic-nonionic surfactant is a surfactant containing an ethyoxyl nonionic group and a carboxyl or sulfonic acid group anionic group; and the molar ratio of the cationic surfactant to the anionic-nonionic surfactant is (1:0.01)-(1:100); and by the adoption of the surfactant composition and the preparation method of the surfactant composition, the above problems can be well solved. The surfactant composition can be applied to tertiary oil recovery process of an oil field.

Owner:CHINA PETROLEUM & CHEM CORP +1

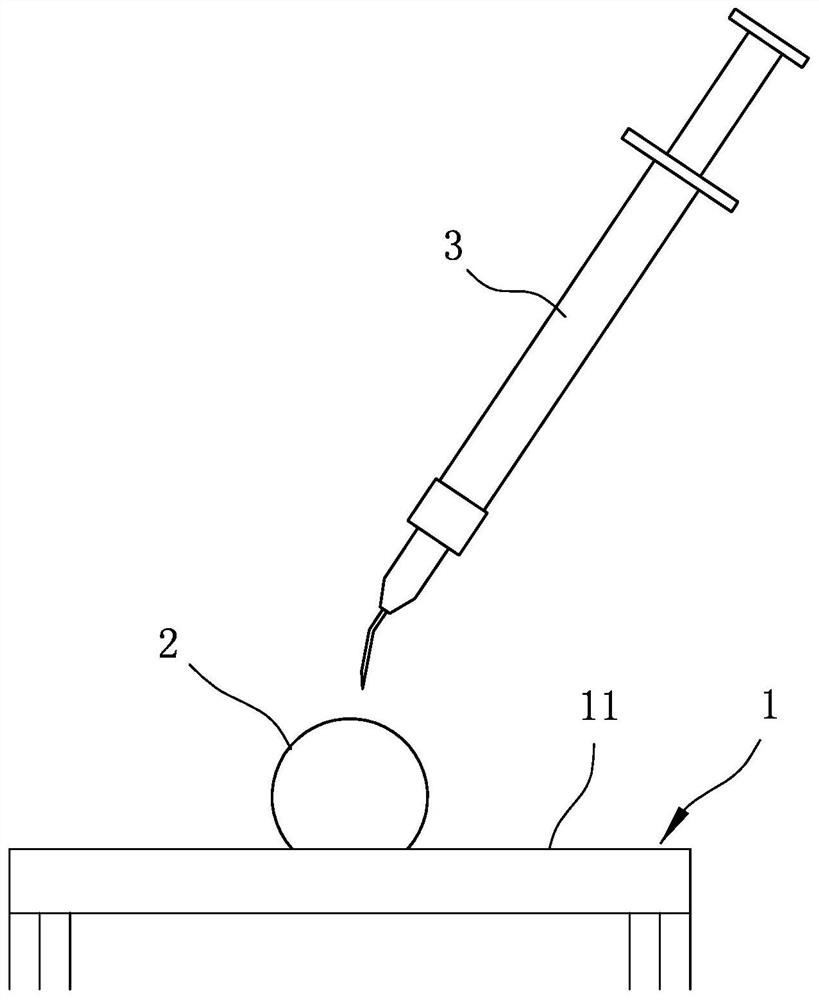

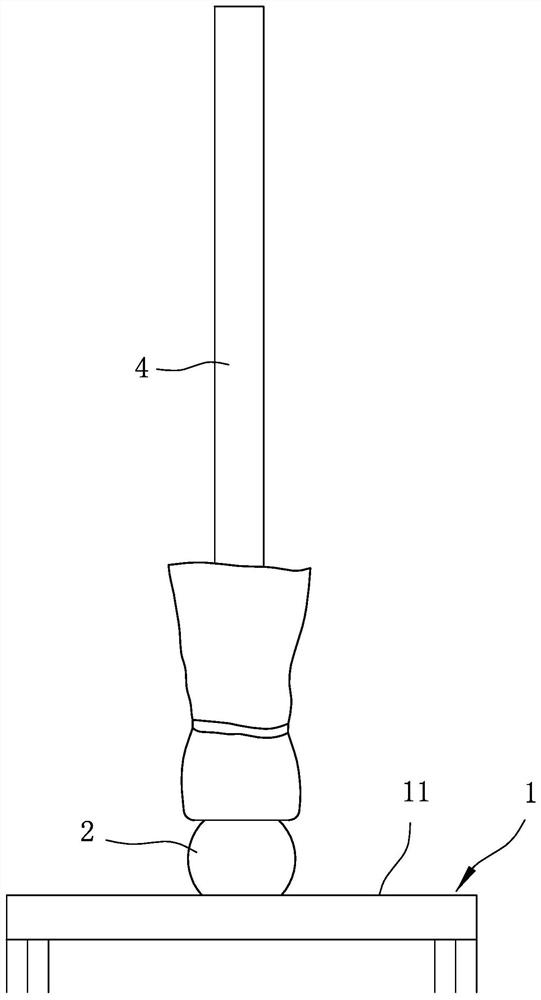

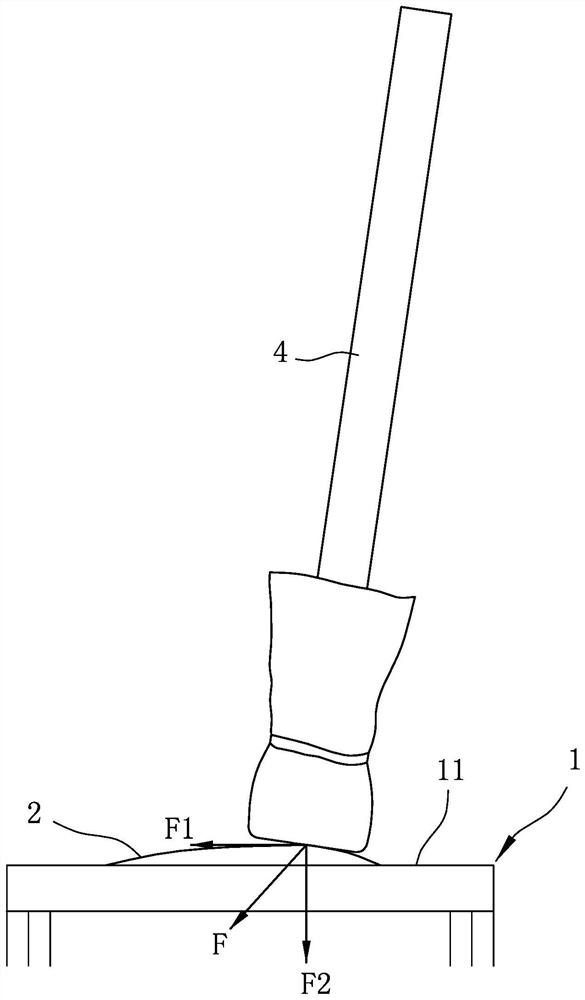

Method for smearing liquid metal on heat generating surface or heat conducting surface

PendingCN111945159AOvercome cohesionOvercoming Uniform CoatingMetallic material coating processesPhysicsInjector

A method for smearing liquid metal on a heat generating surface or a heat conducting surface is suitable for coating the heat generating surface or the heat conducting surface of a target object, andthe method for smearing comprises an squeezing injecting step and a uniform coating step. In the squeezing injecting step, the liquid metal is squeezed out of an injector into the heat generating surface, the heat conducting surface or other containers. In the uniform coating step, a tool is in contact with the liquid metal, force is applied to the liquid metal to destroy the cohesion of the liquid metal, and then the tool is operated to perform smearing back and forth so that the heat generating surface or the heat conducting surface is uniformly coated with the liquid metal. The cohesion ofthe liquid metal is destroyed by applying the external force, so that the liquid metal is not spherical any more, and finally, the heat generating surface or the heat conducting surface of the targetobject is uniformly coated with the liquid metal by driving the tool back and forth, so that the effects of overcoming the cohesion of the liquid metal and achieving uniform coating are achieved.

Owner:MORNINGRICH TECH CO LTD

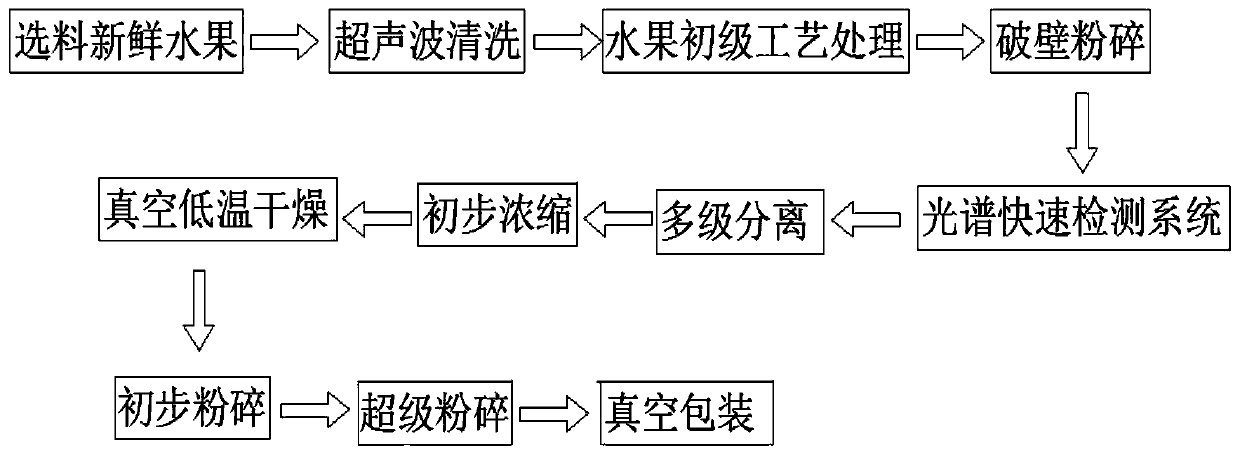

Preparation method of nanoscale ultramicro wall-broken freeze-dried fruit powder

The invention provides a preparation method of nanoscale ultramicro wall-broken freeze-dried fruit powder. The ultramicro wall-broken freeze-dried fruit powder is made through the process steps of fresh fruit selecting, ultrasonic cleaning, fruit primary process treatment, wall-breaking crushing, spectrum quick detection system, multistage separation, preliminary concentration, vacuum low-temperature drying, preliminary crushing, ultramicro crushing, vacuum packaging and the like. Beneficial components of fruit pulp and harmful components of pesticide residue heavy metal are analyzed through aspectrum quick detection system, characteristics of the beneficial components of the fruit pulp and the harmful components of the pesticide residue heavy metal are obtained through atlas comparison,fruits can be made into the nanoscale ultramicro wall-broken freeze-dried fruit powder, crushing can be conducted in a low-temperature state, the speed is high, crushing can be completed instantaneously, and thus bioactive components of the powder are retained to the utmost extent, so that a needed high-quality product is made advantageously.

Owner:安阳鲜宝食品科技有限公司

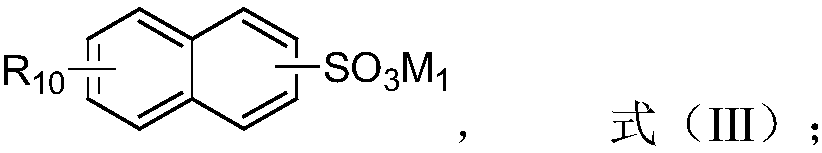

Hydrophobic association polymer-surfactant composition and binary combination flooding system

The invention relates to a hydrophobic association polymer-surfactant composition and a binary combination flooding system, and mainly solves the problem that the oil displacement efficiency of polymer-surfactant binary combination flooding is affected by reduction of the viscosity of a compounded system under the condition of a relatively large concentration of a surfactant during compounding ofa hydrophobic association polymer and a conventional surfactant in the prior art. By adoption of a technical scheme that the hydrophobic association polymer-surfactant binary combination flooding composition is prepared from the following components: the hydrophobic association polymer and a compound surfactant according to a mass ratio of (0.5 to 3):(0.1 to 5), and the compound surfactant is prepared from alkyl amido betaine, lauryl betaine and aromatic acid salt according to a mass ratio of (1 to 60):(1 to 60):(20 to 60), the problem is well solved, and the hydrophobic association polymer-surfactant composition can be applied to oil extraction in an oil field.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrophobic association polymer-surfactant composition and composite flooding system

ActiveCN108315002BImprove surface activityReduce dosageFluid removalDrilling compositionPolymeric surfacePolymer science

The invention relates to an efficient tackifying hydrophobic associative polymer-surfactant composition and a composite flooding system, and mainly solves the problem that when a hydrophobic associative polymer existing in the prior art is compounded with a surfactant existing in the prior art, and the concentration of the surfactant is large, the viscosity of the compound system is reduced to affect the oil flooding efficiency of the polymer-surfactant binary composite flooding system, the problem can be well solved by the hydrophobic associative polymer-surfactant binary composition, and thehydrophobic associative polymer-surfactant binary composition can be used in oil recovery in an oil fields. The hydrophobic associative polymer-surfactant binary composition includes the following components: a hydrophobic associative polymer and a composite surfactant in a mass ratio of (0.5 to 3): (0.1 to 5), wherein the composite surfactant comprises alkyl amido betaine, alkylbetaine and naphthalenesulfonate in a mass ratio of (1 to 60): (1 to 60) :(20 to 60).

Owner:CHINA PETROLEUM & CHEM CORP +1

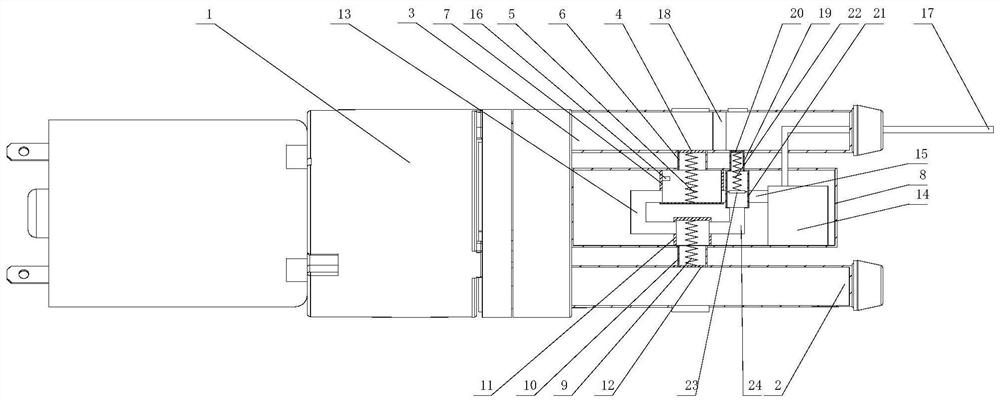

Miniature diaphragm water pump with overload protection function

ActiveCN113107819AOvercome cohesionAvoid damagePositive displacement pump componentsFlexible member pumpsAdhesive glueEngineering

The invention discloses a miniature diaphragm water pump with an overload protection function, which comprises a pump body, a water inlet end of the pump body is connected with a water inlet pipe, a water outlet end of the pump body is connected with a water outlet pipe, a first through hole is arranged on the water outlet pipe, a first sealing plate is connected to the first through hole, the first sealing plate makes contact with the side wall of the first through hole, and the first sealing plate is hermetically connected with the side wall of the first through hole through waterproof glue. The device can prevent a diaphragm and a transmission part in the pump body from being greatly damaged when a pipeline in a terminal product is blocked.

Owner:SHENZHEN CNHT LTD

Hydrophobic associative polymer-surfactant composition and composite flooding system

ActiveCN108315002AImprove surface activityReduce dosageFluid removalDrilling compositionPolymer scienceBetaine

The invention relates to an efficient tackifying hydrophobic associative polymer-surfactant composition and a composite flooding system, and mainly solves the problem that when a hydrophobic associative polymer existing in the prior art is compounded with a surfactant existing in the prior art, and the concentration of the surfactant is large, the viscosity of the compound system is reduced to affect the oil flooding efficiency of the polymer-surfactant binary composite flooding system, the problem can be well solved by the hydrophobic associative polymer-surfactant binary composition, and thehydrophobic associative polymer-surfactant binary composition can be used in oil recovery in an oil fields. The hydrophobic associative polymer-surfactant binary composition includes the following components: a hydrophobic associative polymer and a composite surfactant in a mass ratio of (0.5 to 3): (0.1 to 5), wherein the composite surfactant comprises alkyl amido betaine, alkylbetaine and naphthalenesulfonate in a mass ratio of (1 to 60): (1 to 60) :(20 to 60).

Owner:CHINA PETROLEUM & CHEM CORP +1

Constant-temperature intelligent controlled traditional Chinese medicinal herbal liquid stirrer

ActiveCN109589849ALarge specific surface areaIncreased release rateRotary stirring mixersTransportation and packagingSmart controlEngineering

The invention provides a constant-temperature intelligent controlled traditional Chinese medicinal herbal liquid stirrer, and belongs to the technical field of stirring equipment. The stirrer comprises a spherical stirring tank for stirring a medicinal liquid, wherein connecting rods are connected with middle parts on two sides of the spherical stirring tank through a supporting seat, and are positioned above a bearing bottom plate; at least four groups of damping wheels are arranged under the bearing bottom plate; a charge hopper is connected with the upper end of the spherical stirring tank,and a discharge hopper is connected with the lower end of the spherical stirring tank; a cutter set and an arc stirring rod are arranged inside the spherical stirring tank; a battery valve is arranged in the center of the charge hopper; baffles are connected with the inner wall of the charge hopper in an alternate manner; and rollers are arranged under the baffles. The device is good in insulation effect and high in stirring speed, the stirred medicinal liquid is relatively uniform and high in mixing degree, and the release speed of effective ingredients of medicinal materials can be promoted.

Owner:刘辉

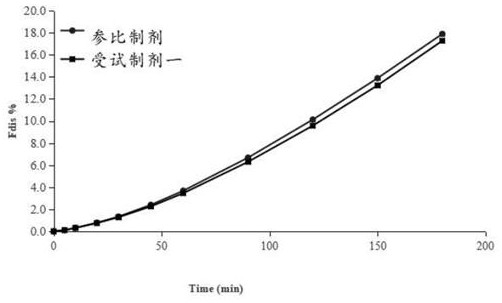

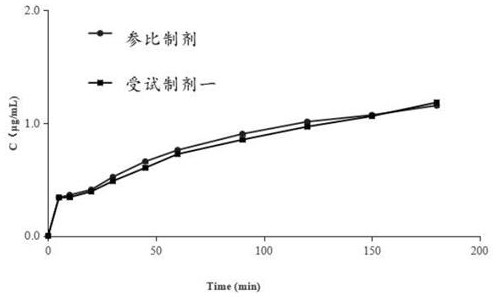

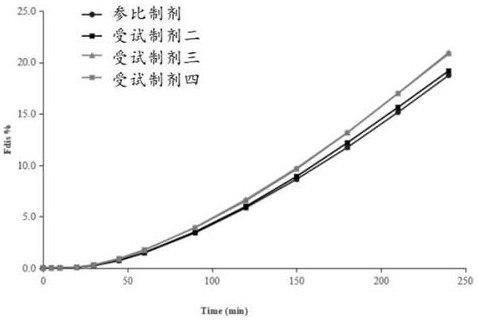

Method for determining the in vitro dissolution of felodipine sustained-release tablets

ActiveCN112526055BOvercome cohesionEnsure physiological temperatureComponent separationProlonged-release tabletDissolution

Owner:HUNAN HUIZE BIO PHARMA CO LTD

Oil displacement composition for low permeability reservoir and preparation method thereof

The invention relates to an oil displacement composition used for low permeability oil reservoirs, and a preparation method thereof, and mainly solves the problems of easy stratum obstruction and difficult injection in the low permeability oil reservoir oil displacement process of present composite flooding polymers. The oil displacement composition contains a long carbon chain betaine surfactant and an inorganic salt, wherein the long carbon chain betaine surfactant is anyone selected from long chain carboxylic acid betaine and sulfonic acid betaine, the carbon chain is a C14-C40 alkyl or alkenyl group, the inorganic salt is anyone of or a composition of CaCl2, MgCl2, NaCl and NaHCO3, and a mass ratio of the long carbon chain betaine surfactant to the inorganic salt is 1:(1-100). The oil displacement composition has the advantages of formation of oil-water ultralow interface tension, decompression and augmented injection, and simple system, well solves the problems, and can be used in the intensified oil production process of the low permeability oil reservoirs.

Owner:CHINA PETROLEUM & CHEM CORP +1

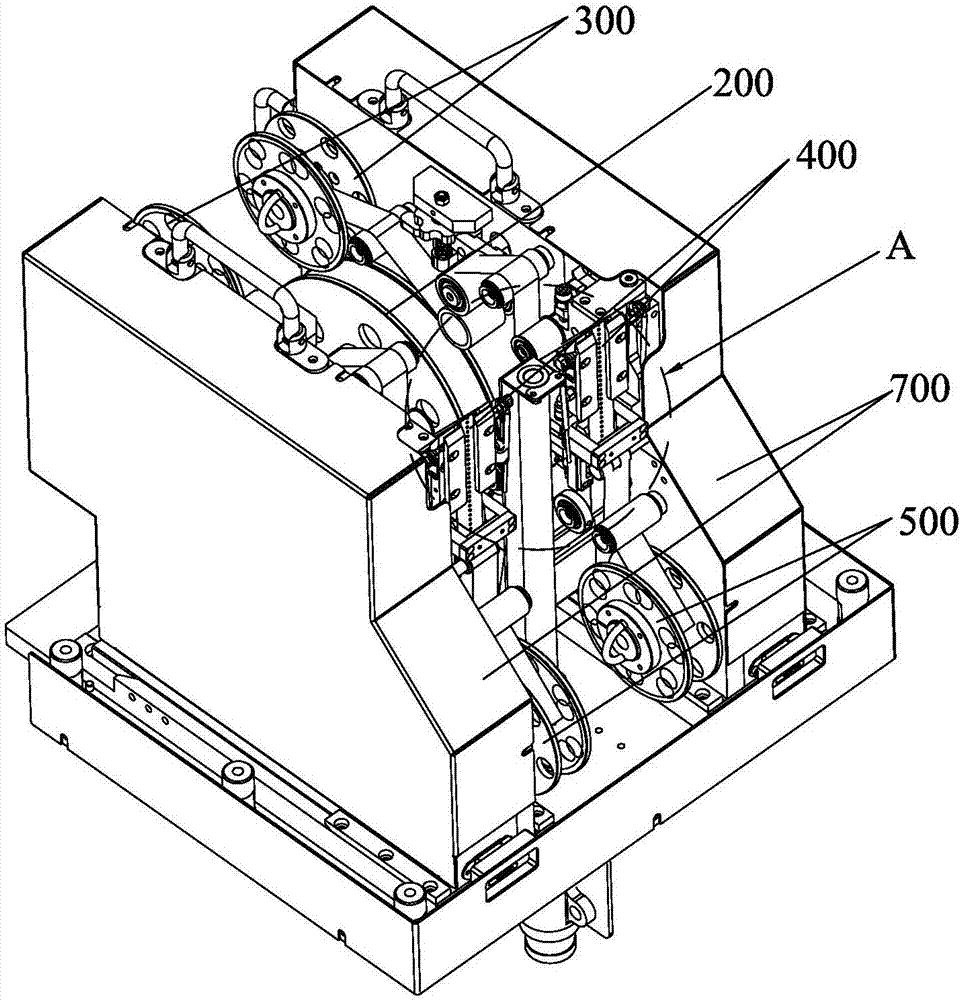

Automatic feeding device for buffer blocks

PendingCN106864808ARealize automatic feeding processOvercome cohesionPackagingReciprocating motionAcute angle

The invention provides an automatic feeding device for buffer blocks. The automatic feeding device is suitable for stripping a plurality of buffer blocks arranged on a release paper material strip and realizing automatic feeding of the buffer blocks. The automatic feeding device comprises a rack, a buffer block feeding mechanism, a material strip recycling mechanism and a separation mechanism, wherein the buffer block feeding mechanism, the material strip recycling mechanism and the separation mechanism are respectively arranged on the rack; the release paper material strip extending from the buffer block feeding mechanism is recycled by the material strip recycling mechanism after passing through the separation mechanism; the separation mechanism comprises a separation block, and a material strip feeding guide surface and a material strip recycling guide surface are respectively arranged on the front side and the rear side; the front ends of the material strip feeding guide surface and the material strip recycling guide surface are intersecting to form an acute angle; the separation block can do reciprocating motion relatively to the rack along the arrangement direction of the material strip feeding guide surface. As the separation block can do reciprocating motion, in the process of separating from release paper, the buffer blocks can be subjected to the absorption of an external buffer block absorbing head and the stripping effect of acute angle end faces at the same time; the adhesive property of the buffer blocks and the release paper is overcome by depending on combination of the two effects, and therefore the buffer block with small size can also be separated from the release paper successfully.

Owner:DONGGUAN WORLD PRECISION MACHINERY

Surfactant composition for enhanced oil recovery and preparation method thereof

ActiveCN103773347BImprove surface activityLarge adsorption capacityDrilling compositionQuaternary ammonium cationSURFACTANT BLEND

The invention relates to a surfactant combination for enhancing oil recovery and a preparation method thereof, and mainly solves the problem of low oil displacement efficiency in the tertiary recovery process in the existing surfactants and the problem of damage to stratums and oil wells, corrosion of equipment and pipes and difficulty in demulsification because inorganic base is contained in oil displacement systems. The surfactant combination comprises a cationic surfactant and an anionic-nonionic surfactant, wherein the cationic surfactant is selected from any one of quaternary ammonium salt and quaternary ammonium alkali; the anionic-nonionic surfactant is a surfactant containing ethoxy nonionic groups and carboxyl or sulfo anionic groups; the mol ratio of the cationic surfactant to the anionic-nonionic surfactant is (1:0.01) to (1:100). The surfactant combination and the preparation method thereof preferably solve the problems, and can be applied to the tertiary recovery process of oil fields.

Owner:CHINA PETROLEUM & CHEM CORP +1

Surfactant composition and its preparation method

ActiveCN103666431BImprove surface activityLarge adsorption capacityDrilling compositionEtherSURFACTANT BLEND

The invention relates to a surfactant composition and a preparation method thereof, which mainly solve the problems that the oil displacement efficiency of the existing surfactant is low in the tertiary oil recovery process and damage to strata and oil wells, corrosion to equipment and pipelines and difficulty in demulsification occur because an oil displacement system contains inorganic alkali. According to the technical scheme of the invention, the surfactant composition comprises cationic surfactant and anionic-nonionic surfactant, wherein the cationic surfactant is at least one selected from quaternary ammonium salt or quaternary amine alkali, the anionic-nonionic surfactant is at least one selected from alkanolamide polyoxy ethylene / propylene ether carboxylate or alkanolamide polyoxy ethylene / propylene ether sulfonate, and the mol ratio of the cationic surfactant to the anionic-nonionic surfactant is (1:0.01)-(1:100). The invention also provides a preparation method of the surfactant composition. Thus, the problems are well solved; and the invention can be used for the forced oil recovery process of oil fields.

Owner:CHINA PETROLEUM & CHEM CORP +1

Expansion shell bearing plate and anchor rod adopting same

PendingCN109853553AImprove the pull-out capacityIncrease stressBulkheads/pilesUltimate tensile strengthBonding strength

The invention relates to an expansion shell bearing plate. The expansion shell bearing plate comprises a tapered bearing plate, a through hole allowing a rod body of an anchor rod is formed in the center of the tapered bearing plate in the axial direction, the tapered bearing plate is provided with a flat plate part and a tapered part, a connecting end and a free end are arranged at the two ends of the tapered part in the axial direction, the outer diameter of the connecting end is larger than that of the free end, an annular extrusion table is formed at the joint of the connecting end and theflat plate part, and the annular extrusion table is provided with a first annular yielding pad. According to the anchor rod, when prestress is applied, due to the fact that the first annular yieldingpad is arranged on the annular extrusion table, a second annular yielding pad is fixed to the end face of the free end, and the tapered bearing plate can release certain deformation when extruding agrouting material, that is, certain 'yielding' deformation is produced. In the process of 'yielding', the tapered surface of the tapered part can extrude the surrounding grouting material in the radial direction, thus the grouting material produces radial expansion, then extrudes surrounding rock and earth mass, consequently normal stress of the interface between the grouting material and the rockand earth mass is greatly increased, the bonding strength of the interface between the grouting material and the rock and earth mass can be significantly enhanced, and thus the uplift bearing capacity of the anchor rod is greatly improved.

Owner:HUAQIAO UNIVERSITY

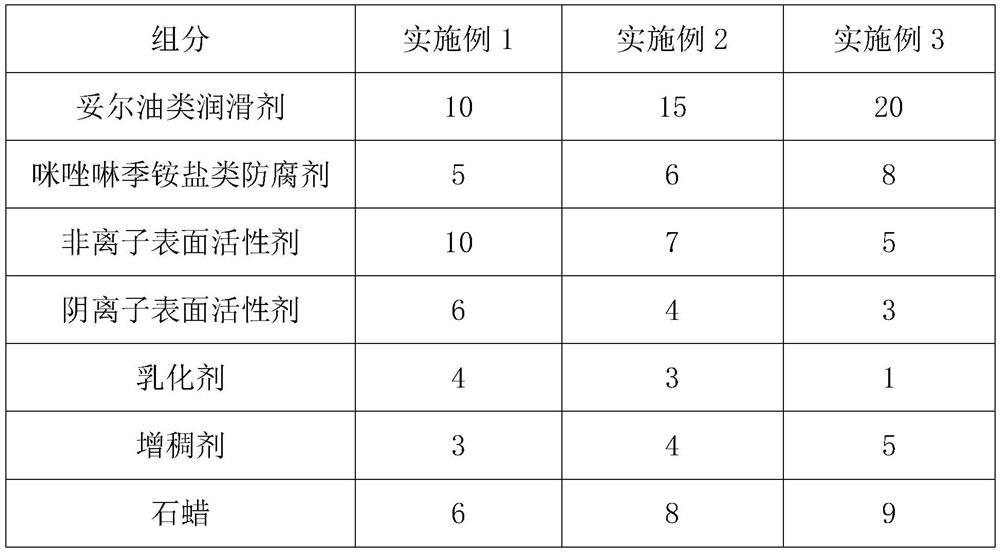

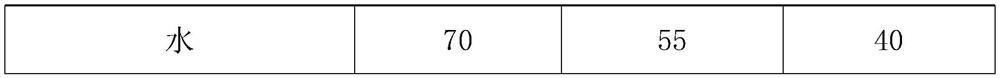

Corrosion-resistant concrete water-based release agent and preparation method thereof

PendingCN114591782AAct as mechanical lubricationGood release effectCeramic shaping apparatusLubricant compositionActive agentTall oil

The invention relates to the field of release agents, and particularly discloses an anticorrosive concrete water-based release agent and a preparation method thereof. The release agent is prepared from the following raw materials: 10 to 20 parts of tall oil lubricant; 5-8 parts of an imidazoline quaternary ammonium salt preservative; 5 to 10 parts of a nonionic surfactant; 3-6 parts of an anionic surfactant; 1-4 parts of an emulsifier; 3-5 parts of a thickening agent; 6-9 parts of paraffin; 40 to 70 parts of water; the preparation method comprises the following steps: mixing the tall oil lubricant, the paraffin and the emulsifier, adding the mixture into water, heating to 40-50 DEG C, and stirring at a constant temperature for 30-40 minutes to obtain a solution a; adding a nonionic surfactant, an anionic surfactant and an imidazoline quaternary ammonium salt preservative into the solution a, and continuously stirring for 30-40 minutes to obtain a solution b; and finally, adding the thickening agent into the solution b, and continuously stirring for 1-1.5 hours to obtain the anticorrosive concrete water-based release agent. The mold has the advantage of good demolding effect.

Owner:中建西部建设北方有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com