Efficient surfactant composition for oil displacement and preparation method of composition

A surfactant and composition technology, applied in the field of high-efficiency oil displacement surfactant composition and its preparation, can solve problems such as corrosion of equipment and pipelines, difficulties in demulsification, damage to formations and oil wells, and low use concentration, and achieve The effect of high interface activity, avoiding damage, and strong oil washing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

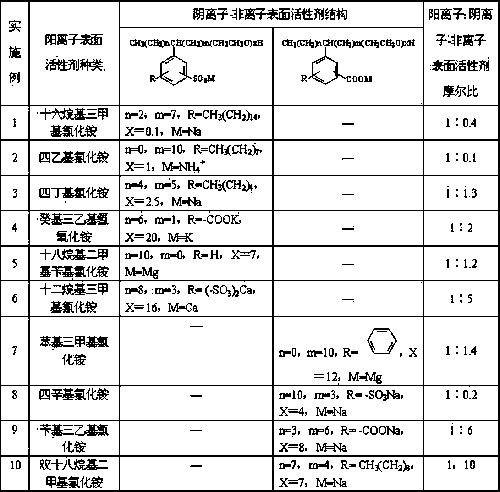

[0017] Add CH3(CH2)2CH=CH(CH2)6OH and NaOH to the reaction kettle according to the molar ratio of 1:1.5, stir for 30 minutes, add the required ethylene oxide, and react at 200oC for 1 hour; Add pentadecyl substituted benzenesulfonic acid at a molar ratio of 1:4, continue the reaction at 50oC for 20 hours, then add 5% KOH aqueous solution to neutralize to pH>10, let stand to separate, add 10% NaOH to the oil phase Hydrolyze at 100oC for 20 hours to obtain polyoxyethylene ether sulfonate anionic-nonionic surfactant; cetyltrimethylammonium chloride and the anionic-nonionic surfactant prepared by the present invention are dissolved in water respectively, Stir for 30 minutes, prepare 0.3% aqueous solution, then mix the above-mentioned surfactants according to cation: anion-nonionic surfactant molar ratio 1: 0.4, obtain surfactant composition 1, its composition and structure are shown in Table 1.

Embodiment 2

[0019]Add CH3CH=CH(CH2)9OH and NaOH to the reactor according to the molar ratio of 1:4, stir for 30 minutes, add the required ethylene oxide, and react at 100oC for 20 hours; Add octylbenzenesulfonic acid at a molar ratio of 1:6, continue the reaction at 200oC for 1 hour, then add 10% NaOH aqueous solution to neutralize to pH>10, let stand to separate, add 10% ammonia water to the oil phase and hydrolyze at 300oC for 5 hours, Obtain polyoxyethylene ether sulfonate anionic-nonionic surfactant; Tetraethylammonium chloride and the anionic-nonionic surfactant prepared by the present invention are dissolved in water respectively, stir 30 minutes, be mixed with 0.3% aqueous solution, Then the above-mentioned surfactants were uniformly mixed according to the cationic:anionic-nonionic surfactant molar ratio of 1:0.1 to obtain surfactant composition 2, whose composition and structure are shown in Table 1.

Embodiment 3

[0021] Add CH3(CH2)3CH=CH(CH2)4OH and KOH to the reactor according to the molar ratio of 1:1.5, stir for 30 minutes, add the required ethylene oxide, and react at 160oC for 6 hours; Add pentyl-substituted benzenesulfonic acid at a molar ratio of 1:3 to benzenesulfonic acid, continue the reaction at 100oC for 12 hours, then add 5% NaOH aqueous solution to neutralize to pH > 10, let stand to separate, add 30% NaOH to the oil phase 200oC hydrolysis for 15 hours to obtain polyoxyethylene ether sulfonate anionic-nonionic surfactant; tetrabutylammonium chloride and the anionic-nonionic surfactant prepared by the present invention were dissolved in water respectively, stirred for 30 minutes, and prepared into a 0.3% aqueous solution, and then the above-mentioned surfactants were mixed uniformly according to the cation:anion-nonionic surfactant molar ratio of 1:1.3 to obtain surfactant composition 3, whose composition and structure are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com