Preparation method of nanoscale ultramicro wall-broken freeze-dried fruit powder

A technology of ultra-fine broken walls and dried fruit powder, which is applied in food drying, food science, etc., can solve the problems of aromatic substances escaping bioactive components, freeze-dried fruit powder nutrient loss, etc., to achieve easy nutrition, fast speed and better effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

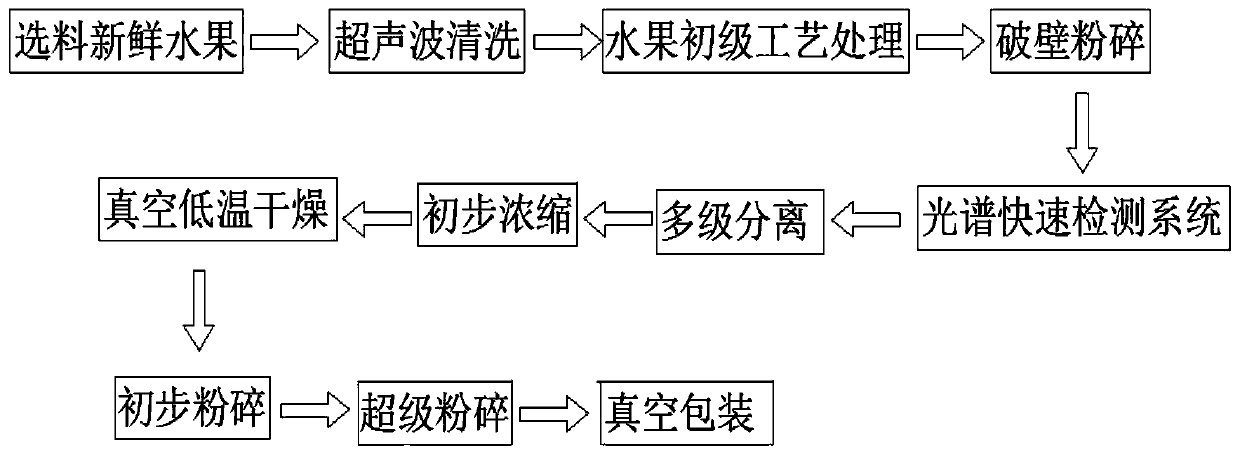

Image

Examples

Embodiment 1

[0027] A method for preparing nanoscale ultramicro-broken freeze-dried fruit powder, characterized in that the steps of the preparation process are as follows:

[0028] (1) Selection of fresh fruits: selection of better quality (according to color and maturity), fresher fruits are used as raw materials for the preparation of freeze-dried fruit powder;

[0029] (2) Ultrasonic cleaning: it can remove the dust, sediment, some microorganisms and possible residual chemicals on the surface of the fruit and other processed fruits;

[0030] (3) Primary process of fruit processing: according to the characteristics of the fruit, the primary process of fruit such as shelling and pitting is carried out;

[0031] (4) Wall-breaking and crushing: not only avoids the disadvantages of easy oxidation and decomposition of nutrients when the fruit is beaten at high speed, but also the fruit juice produced is silky and delicate, the effect is better, and the nutrients are easier to absorb;

[003...

Embodiment 2

[0047] A method for preparing nanoscale ultramicro-broken freeze-dried fruit powder, characterized in that the steps of the preparation process are as follows:

[0048] (1) Selection of fresh fruits: selection of better quality (according to color and maturity), fresher fruits are used as raw materials for the preparation of freeze-dried fruit powder;

[0049] (2) Ultrasonic cleaning: it can remove the dust, sediment, some microorganisms and possible residual chemicals on the surface of the fruit and other processed fruits;

[0050] (3) Primary process of fruit processing: according to the characteristics of the fruit, the primary process of fruit such as shelling and pitting is carried out;

[0051] (4) Wall-breaking and crushing: not only avoids the disadvantages of easy oxidation and decomposition of nutrients when the fruit is beaten at high speed, but also the fruit juice produced is silky and delicate, the effect is better, and the nutrients are easier to absorb;

[005...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com