Oil displacement composition for low permeability reservoir and preparation method thereof

A low-permeability and composition technology, which is applied to drilling compositions, chemical instruments and methods, etc., can solve problems such as formation blockage and injection difficulties, and achieve the effects of improving oil displacement efficiency and overcoming cohesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

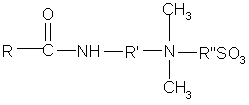

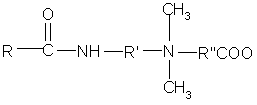

Method used

Image

Examples

Embodiment 1

[0030] Put 9-octadecenoic acid and N,N-dimethyl-1,4-butanediamine into the reaction kettle at a molar ratio of 1:1.5, stir at 165°C for 8 hours, and then vacuumize the oil pump at 165°C to remove untreated The reacted N,N-dimethyl-1,4-butanediamine has a content of 99.0wt% octadecenamide butanediamine as determined by liquid chromatography. Add sodium 4-chlorobutyrate to the above system according to the molar ratio of 9-octadecenoic acid to sodium 4-chlorobutyrate at 1:1.5, and react at 85°C for 6 hours. After the reaction, wash with absolute ethanol to remove After the unreacted sodium 4-chlorobutyrate was evaporated to remove the solvent, octadecylenamide butyl betaine was obtained with a content of 97.0wt%.

[0031] Octadecenamide butyl betaine and NaCl are mixed according to the mass ratio of 1:10 to form the oil displacement composition, and the oil displacement composition and water are mixed uniformly according to the mass ratio of 5.5:100, and the Malvern dynamic ligh...

Embodiment 2

[0035] Put 12-tetradecenoic acid and N,N-dimethyl-1,2-ethylenediamine into the reaction kettle according to the molar ratio of 1:3, stir at 160°C for 10h, and then remove it by vacuuming with an oil pump at 165°C The content of unreacted N,N-dimethyl-1,2-ethylenediamine was determined by liquid chromatography to be 98.9wt%. Then add sodium 2-chloroethylsulfonate to the above system according to the molar ratio of 12-tetradecenoic acid to sodium 2-chloroethylsulfonate as 1:3, and react with 80°C for 10h. After the reaction, use Wash with absolute ethanol to remove unreacted sodium 2-chloroethylsulfonate, and evaporate the solvent to obtain tetraceramide ethyl betaine with a content of 97.1 wt%.

[0036] Tetraceramide ethyl betaine and CaCl 2 The oil displacement composition is mixed according to the mass ratio of 1:5, and the oil displacement composition and water are mixed uniformly according to the mass ratio of 3:100, and the size of the micelles formed at 25°C is measured ...

Embodiment 3

[0040] Put 7,15-eicosenoic acid and N,N-dimethyl-1,2-ethylenediamine into the reaction kettle at a molar ratio of 1:2, stir at 170°C for 20 hours, and then vacuumize with an oil pump at 165°C The unreacted N,N-dimethyl-1,2-ethylenediamine was removed, and the content of triacylenamide ethylenediamine was determined to be 99.0wt% by liquid chromatography. Add sodium chloromethanesulfonate to the above system according to the molar ratio of 7,15-eicosenoic acid to sodium chloromethanesulfonate at 1:1.5, and react with 95°C for 3 hours. After the reaction, wash with absolute ethanol to remove The unreacted sodium chloromethanesulfonate was evaporated to remove the solvent to obtain triacylamidoethyl betaine with a content of 97.3wt%.

[0041] triacylamide ethyl betaine and NaHCO 3 The oil displacement composition is mixed according to the mass ratio of 1:2, and the oil displacement composition and water are mixed uniformly according to the mass ratio of 0.55:100, and the size of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com