Method for production of a multi-axial wire structure, unidirectional fiber layers and method for production thereof, multi-axial wire structure and composite part with a matrix

A unidirectional fiber, multiaxial technology, used in textiles and papermaking, conveying filamentous materials, coatings, etc., to solve problems such as violations, length differences and stress differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

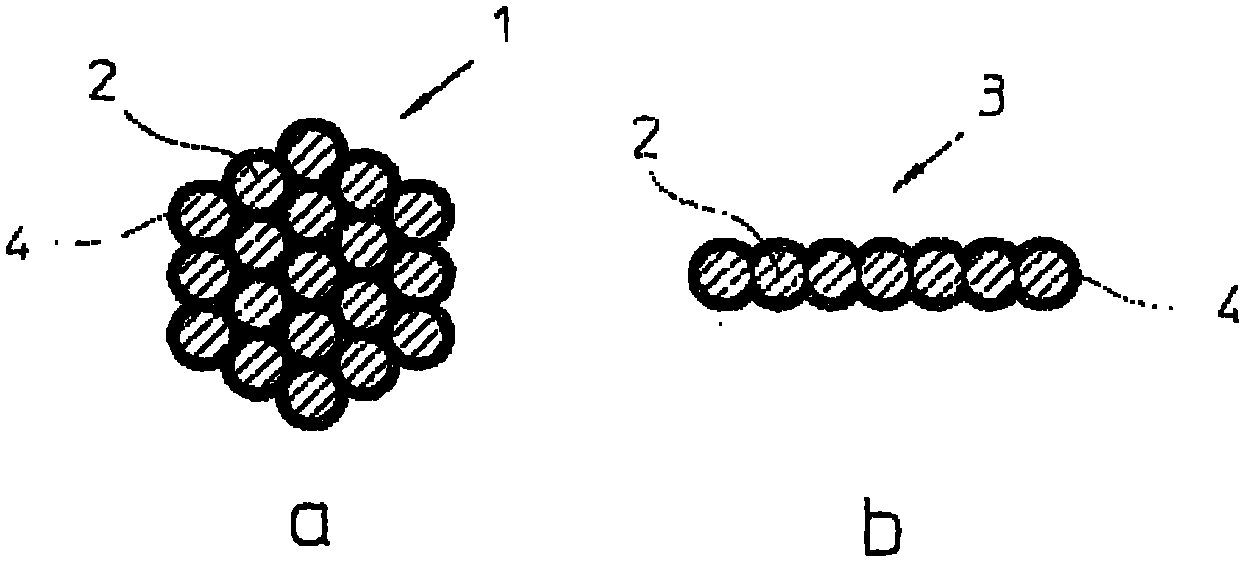

[0041] exist figure 1 A very schematic cross-sectional representation of an individual fiber 1 , which may be a carbon fiber, is shown in sub-figure a of . Fibers (often also called yarns, cables or monofilament cables) consist of a large number of monofilaments 2 . In the context of interest here, carbon fibers 1 with a K value of from 12 to 50 and greater, ie carbon fibers consisting of 12,000 to 50,000 individual filaments 2 and more, are possible. For economical reasons thinner fabrics of unidirectional yarns are produced, wherein fibers 1 are extracted as raw material according to the partial diagram a and widened in a spreading device. The fibers of the raw material do not necessarily have a polygonal or approximately circular cross-section as shown here. Common commercial forms also use fiber strips which already have an approximately rectangular flattened cross-section, but are still too thick for practical use and therefore likewise have to be widened.

[0042] De...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com