Corrosion-resistant concrete water-based release agent and preparation method thereof

A release agent and concrete technology, which can be used in manufacturing tools, lubricating compositions, ceramic molding machines, etc., can solve the problems of instability, poor effect, easy delamination of release agents, etc., to improve anti-corrosion performance and good lubrication performance. , Improve the effect of mold release performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A preparation method of anti-corrosion concrete water-based release agent, the preparation steps are as follows:

[0048] S1: After mixing tall oil lubricants, paraffin wax and emulsifier, add them into water, heat up to 40°C, and stir at constant temperature for 30min to obtain a solution;

[0049] S2: adding nonionic surfactant, anionic surfactant and imidazoline quaternary ammonium salt preservative to solution a and stirring continuously for 30min to obtain solution b;

[0050] S3: Add the thickener to the b solution and continue to stir for 1 hour to obtain the anti-corrosion concrete water-based release agent.

[0051] In this example, tall oil is used as the tall oil lubricant, polyethylene wax is used as the paraffin wax, OP-7 is used as the emulsifier, fatty alcohol polyoxyethylene ether is used as the nonionic surfactant, and α-alkenyl is used as the anionic surfactant. Sodium sulfonate, imidazoline quaternary ammonium salt preservatives use imidazoline quate...

Embodiment 2

[0056]A kind of preparation method of anticorrosion concrete water-based release agent, the difference with embodiment 1 is,

[0057] The preparation steps are as follows:

[0058] S1: After mixing tall oil lubricants, paraffin wax and emulsifier, add them into water, heat up to 50°C, and stir at constant temperature for 40min to obtain a solution;

[0059] S2: adding nonionic surfactant, anionic surfactant and imidazoline quaternary ammonium salt preservative to solution a and stirring continuously for 40min to obtain solution b;

[0060] S3: Add the thickener to the b solution and continue to stir for 1.5 hours to obtain the anti-corrosion concrete water-based release agent.

Embodiment 3

[0062] A preparation method of a water-based release agent for anti-corrosion concrete is different from Example 2 in that each component of its raw materials and their corresponding parts by weight are shown in Table 2.

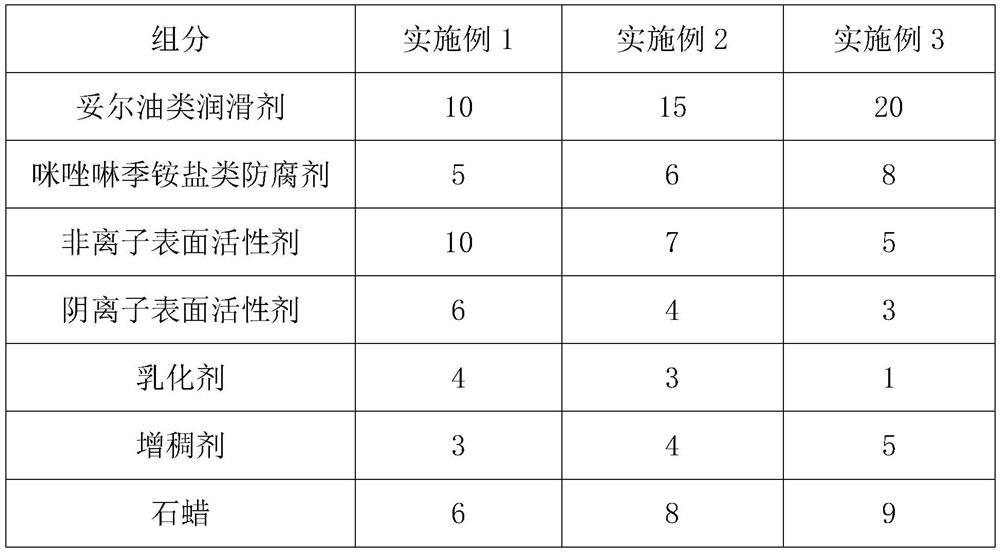

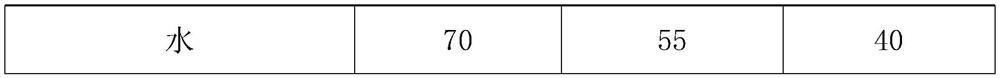

[0063] Each raw material and its weight (kg) in the embodiment 1-3 of table 2

[0064]

[0065]

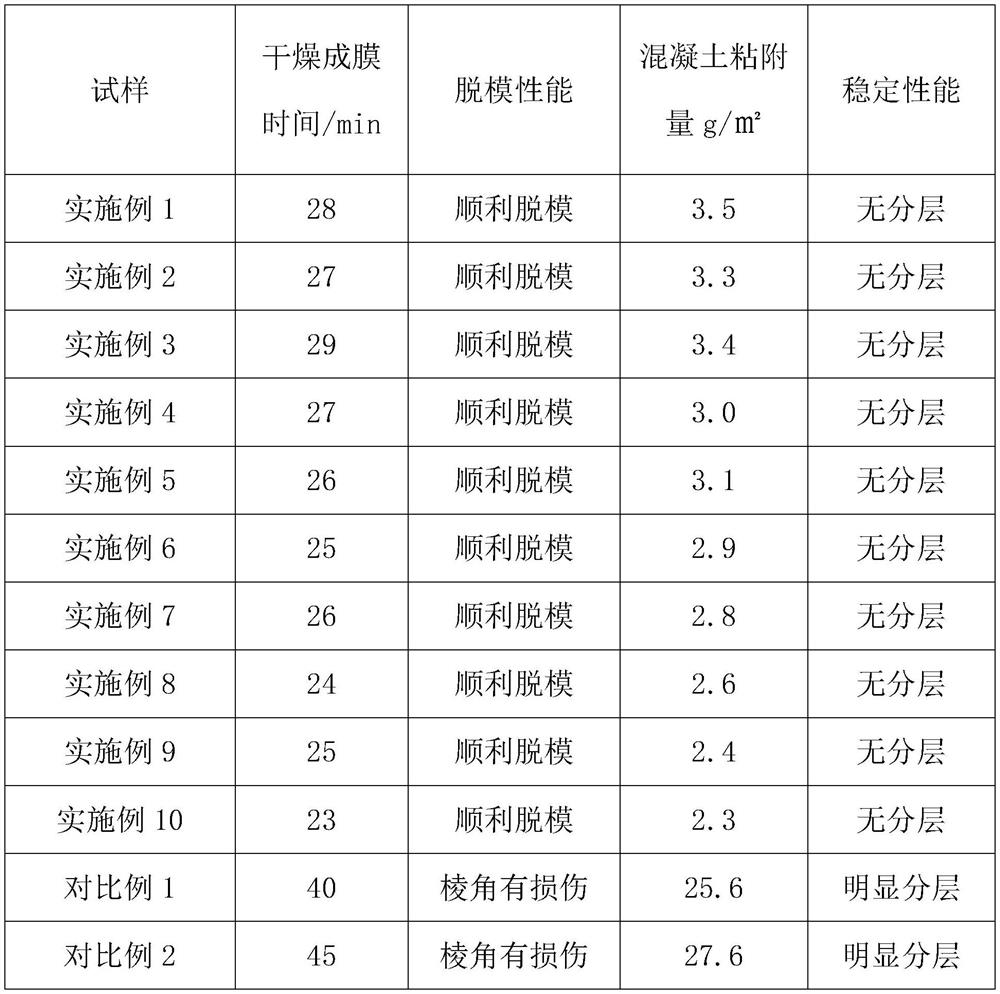

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com