Surfactant composition for chemical flooding and preparation method thereof

A surfactant and chemical flooding technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of poor oil displacement efficiency, corrosion equipment and pipeline demulsification difficulties, damage, etc., and achieve high interfacial activity. , Conducive to stripping and improve oil displacement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

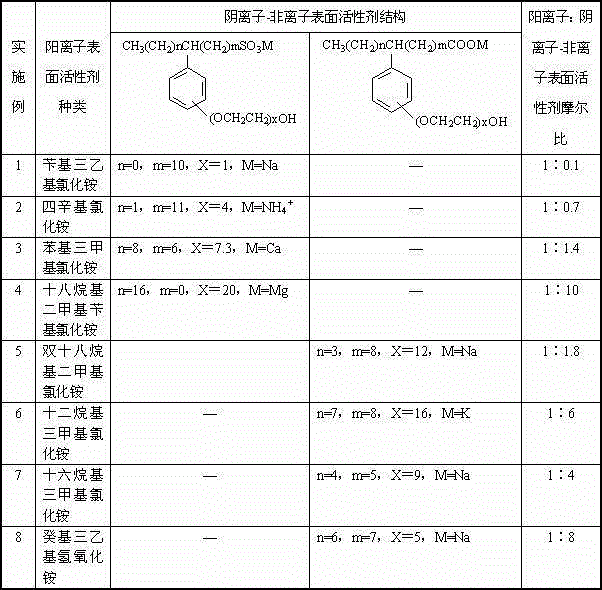

Embodiment 1

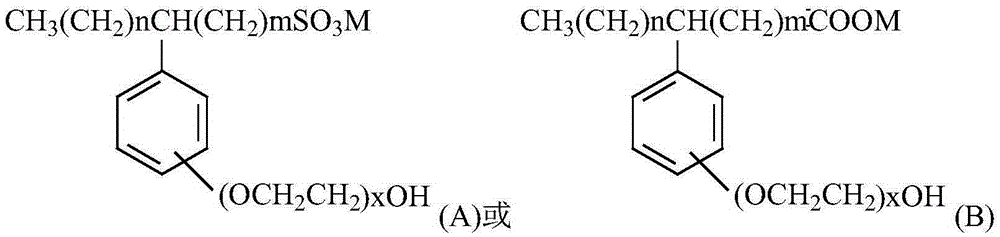

[0023] Alkylphenol polyoxyethylene ether (1), CH 3 CH=CH(CH 2 ) 9 SO 3 Na and 5wt%HF add reactor, at 50 oC reacted for 20 hours, wherein alkylphenol polyoxyethylene ether (1): CH 3 CH=CH(CH 2 ) 9 SO 3 The molar ratio of Na is 1:0.1, and then 30% NaOH is added to neutralize, and the oil and water are separated, and the water phase is obtained as an anionic-nonionic surfactant.

[0024] Benzyltriethylammonium chloride and the alkylaryl polyoxyethylene ether sodium sulfonate surfactant prepared by the present invention were respectively dissolved in water, stirred for 30 minutes, and mixed with 0.3% aqueous solution, and then the above surfactant was prepared according to Cationic:anionic-nonionic surfactant molar ratio 1:0.1 was mixed evenly to obtain surfactant composition 1, whose composition and structure are shown in Table 1.

Embodiment 2

[0026] Alkylphenol polyoxyethylene ether (4), CH 3 CH 2 CH=CH(CH 2 ) 10 SO 3 Na and 2wt%ClSO 3 H was added to the reactor, at 150 o C reacted for 1 hour, wherein alkylphenol polyoxyethylene ether (4): CH 3 CH=CH(CH 2 ) 10 SO 3 The molar ratio of Na is 1:0.2, and then ammonia water is added to neutralize, and oil and water are separated, and anionic-nonionic surfactants are obtained from the aqueous phase.

[0027] Tetraoctyl ammonium chloride and the alkylaryl polyoxyethylene ether sodium sulfonate surfactant prepared by the present invention were respectively dissolved in water, stirred for 30 minutes, and formulated into a 0.3% aqueous solution, and then the above-mentioned surfactant was used according to the cationic: Anionic-nonionic surfactant molar ratio 1:0.7 was mixed evenly to obtain surfactant composition 2, whose composition and structure are shown in Table 1.

Embodiment 3

[0029] Alkylphenol polyoxyethylene ether (7.3), CH 3 (CH 2 ) 8 CH=CH(CH 2 ) 5 SO 3 Na and 4wt% p-toluenesulfonic acid add reactor, at 80 o C reacted for 12 hours, wherein alkylphenol polyoxyethylene ether (7.3): CH 3 (CH 2 ) 8 CH=CH(CH 2 ) 5 SO 3 Na molar ratio is 1:0.4, then add 10% Ca(HCO 3 ) 2 Neutralize, and carry out oil-water separation, the water phase obtains anionic-nonionic surfactant.

[0030] Phenyltrimethylammonium chloride and the alkyl aryl polyoxyethylene ether sodium sulfonate surfactant prepared by the present invention were dissolved in water respectively, stirred for 30 minutes, and were mixed with 0.3% aqueous solution, and then the above surfactant was prepared according to Cationic:anionic-nonionic surfactant molar ratio 1:1.4 was evenly mixed to obtain surfactant composition 3, whose composition and structure are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com