Parameter analysis method and device for wetting clay sand quality for casting

A technology for wet clay sand and quality parameters, which is used in measuring devices, analyzing materials, and material analysis by electromagnetic means, which can solve the problems of complex test procedures and long test cycles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

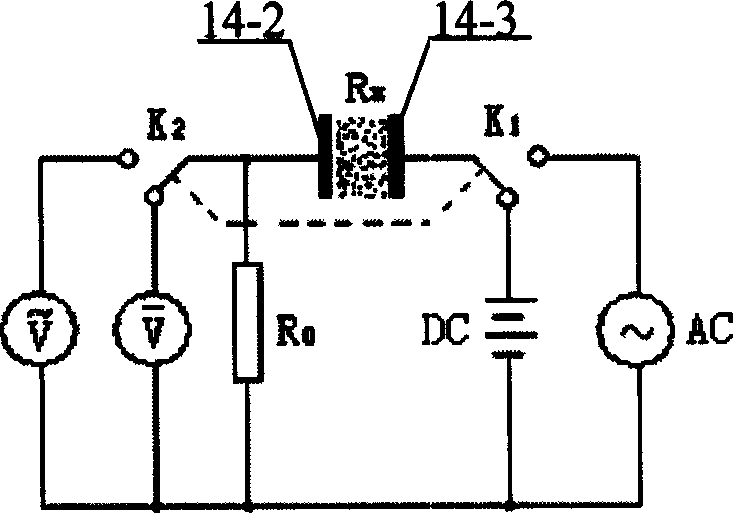

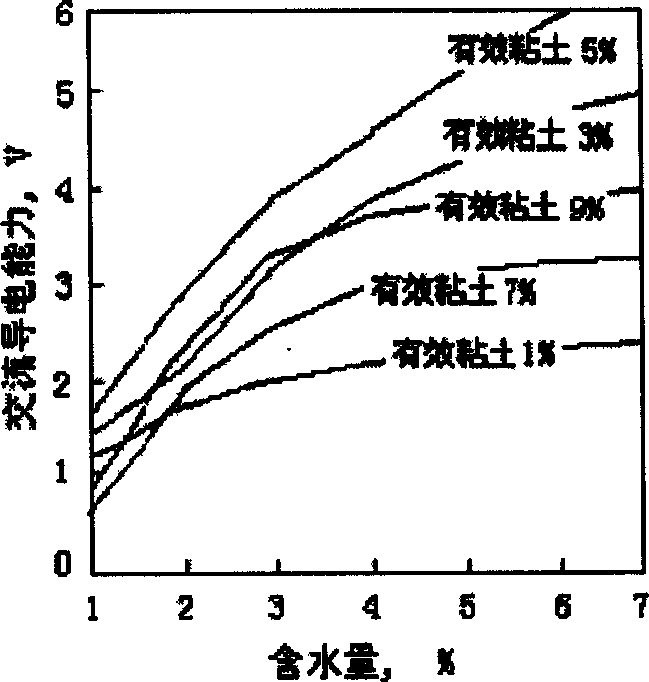

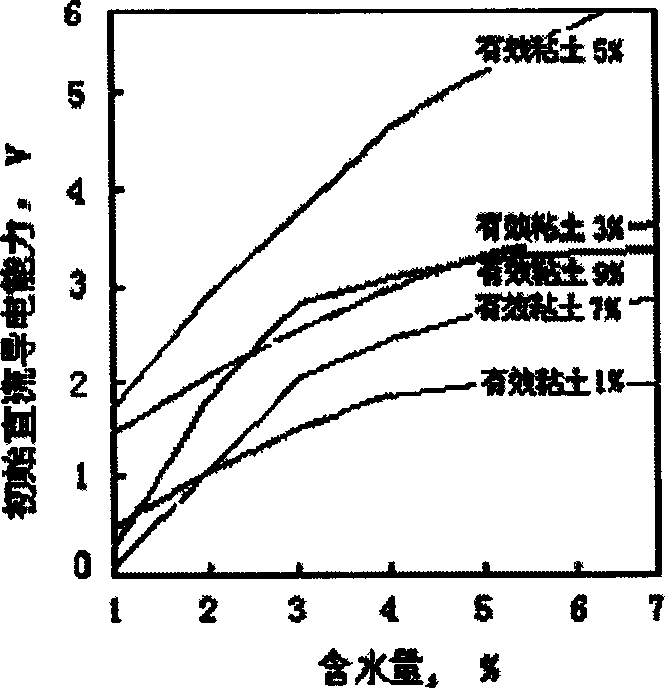

[0006] Specific implementation mode one: the following combination Figure 1 to Figure 5 and Figure 18 This embodiment will be specifically described. The present invention is realized by the following scheme: a method for quickly analyzing the quality parameters of green mold clay sand for casting, which is completed by the following steps: one, making a sample block of the clay sand to be tested; two, passing through the sample block with alternating current And measure the AC conductivity of the sample block; 3. Pass a direct current in the sample block and measure the initial DC conductivity and the rate of change of the DC conductivity of the sample block; 4. Measure the temperature of the sample block and the tightness of the sample block 5. Input the measured AC conductivity, initial DC conductivity, DC conductivity change rate, temperature and compaction rate of the sample block into the computer database. The database is based on the sample block AC conductivity, in...

specific Embodiment approach 2

[0025] Specific implementation mode two: the following combination Figure 6 to Figure 1 6 and FIG. 19 specifically describe this embodiment.

[0026] This embodiment consists of a mechanism frame 1, a sand screening motor 2, a sand screening cylinder 3, a screen 12, a funnel 4, two funnel connecting rods 5, an auxiliary cylinder 6, a longitudinal bottom guide rail 7, a sample cylinder bottom plate 8, a trolley 9, Small wheel 9-1, sample cylinder support 11, sample cylinder 13, sample cylinder 14, lateral sliding guide rail 15, rolling element 17, bottom plate cylinder 18, cylinder cylinder 19, trolley moving cylinder 20, compaction cylinder 21, Displacement sensor 22, air permeability detection cylinder 23, air permeability detection device 29, No. 1 pressure sensor 24, No. 2 pressure sensor 16, load cell 26, strength detection cylinder 27 form. A left sand level electrode 6-1 and a right sand level electrode 6-2 are fixed on the inner wall of the auxiliary cylinder 6, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com