Hydrophobic associative polymer-surfactant binary composition and composite flooding system thereof

A composite surfactant and surfactant technology, which can be used in drilling compositions, production fluids, wellbore/well components, etc., can solve problems such as affecting the poly-surface binary composite flooding and increasing the viscosity of the system.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] The components and content (wt%) of binary compound flooding:

[0065] Hydrophobic association polymer: 0.05~0.15;

[0066] Composite surfactant: 0.1~0.5;

[0067] Water: 99.35 ~ 99.85.

[0068] Hydrophobic association polymer: the degree of hydrolysis is 23%, the polyacrylamide (namely x:y:z=76:23:1, M 2 =Na + ).

[0069] Each component and content (wt%) of composite surfactant:

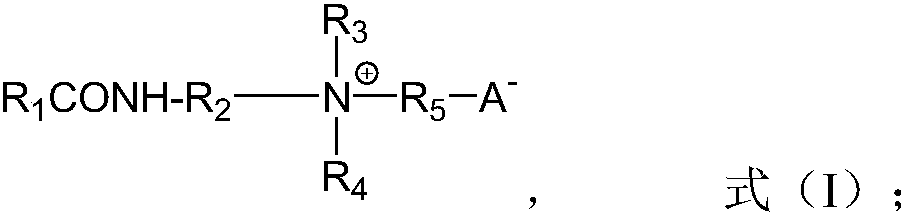

[0070] Oleamidopropyl Betaine (R1 =C 17 , R 2 =C 3 , R 3 , R 4 =C 1 , R 5 =C 1 , A is COO - ): 40;

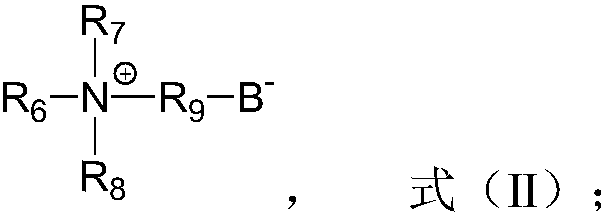

[0071] Cetyl dimethyl betaine (R 6 =C 16 , R 7 , R 8 =C 1 , R 9 =C 1 , B is COO - ): 30;

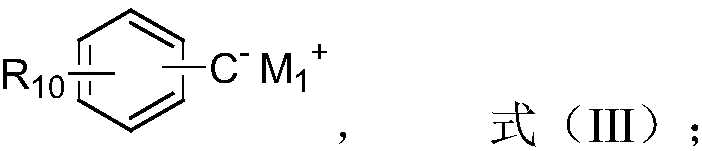

[0072] Sodium Salicylate: 30.

[0073] Binary compound flooding system preparation: under the conditions of 50°C and 600rpm rotation speed, the above hydrophobic association polymer was dissolved in simulated water or oil field water to prepare a polymer mother liquor with a concentration of 0.5%. At room temperature, mix oleic acid amidopropyl betaine, cetyl dimethyl betaine and...

Embodiment 2

[0075] The components and content (wt%) of binary compound flooding:

[0076] Hydrophobic association polymer: 0.05~0.15;

[0077] Composite surfactant: 0.1~0.5;

[0078] Water: 99.35 ~ 99.85.

[0079] Hydrophobic association polymer: the degree of hydrolysis is 20%, the polyacrylamide (that is x:y:z=79.2:20:0.8, M 2 =Na + ).

[0080] Each component and content (wt%) of composite surfactant:

[0081] Erucamidopropyl Betaine (R 1 =C 21 , R 2 =C 3 , R 3 , R 4 , R 5 =C 1 , A is COO - ): 42;

[0082] Octadecyldimethylbetaine (R 6 =C 18 , R 7 , R 8 , R 9 =C 1 , B is COO - ): 28;

[0083] Sodium p-toluenesulfonate: 30.

[0084] Binary compound flooding system preparation: under the conditions of 50°C and 600rpm rotation speed, the above hydrophobic association polymer was dissolved in simulated water or oil field water to prepare a polymer mother liquor with a concentration of 0.5%. At room temperature, mix erucamidopropyl betaine, octadecyldimethyl betaine a...

Embodiment 3

[0086] The components and content (wt%) of binary compound flooding:

[0087] Hydrophobic association polymer: 0.05~0.15;

[0088] Composite surfactant: 0.1~0.5;

[0089] Water: 99.35 ~ 99.85.

[0090] Hydrophobic association polymer: degree of hydrolysis is 22%, polyacrylamide (ie x:y:z=76.6:22:1.4, M 2 = K + ).

[0091] Each component and content (wt%) of composite surfactant:

[0092] Cocamidopropyl Betaine (R 1 =C 7 ~C 17 , R 2 =C 3 , R 3 , R 4 =C 1 , R 5 =C 2 , A is SO 3 - ): 36;

[0093] tetradecyl dimethyl betaine (R 6 =C 14 , R 7 , R 8 =C 1 , R 9 =C 2 , B is SO 3 - ): 34;

[0094] Sodium Benzoate: 30.

[0095] Binary compound flooding system preparation: under the conditions of 50°C and 600rpm rotation speed, the above hydrophobic association polymer was dissolved in simulated water or oil field water to prepare a polymer mother liquor with a concentration of 0.5%. At room temperature, mix cocamidopropyl betaine, myristyl dimethyl betaine a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com