Hydrophobic association polymer-surfactant composition and composite flooding system

A composite surfactant and surfactant technology, which is applied in the direction of drilling composition, production fluid, wellbore/well components, etc., can solve the problems affecting the oil displacement efficiency of poly-surface binary composite flooding, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] Components and contents of binary compound flooding:

[0066] Hydrophobic association polymer: 0.05~0.15;

[0067] Composite surfactant: 0.1~0.5;

[0068] Water: 99.35 ~ 99.85.

[0069] Hydrophobic association polymer: the degree of hydrolysis is 22%, the hydrophobic group R 11 for -(CH 2 ) 2 -N(CH 3 ) 2 -C 14 h 29 Cl (content is 1.5mol%) polyacrylamide (that is x:y:z=76.5:22:1.5, M 2 =Na + ).

[0070] Each component and content of composite surfactant: (wt%)

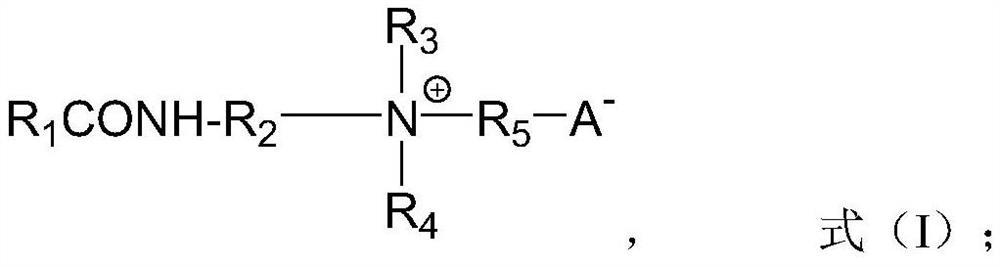

[0071] Palmimidopropyl Betaine (R 1 =C 15 , R 2 =C 3 , R 3 , R 4 =C 1 , R 5 =C 1 , A is COO - ): 40;

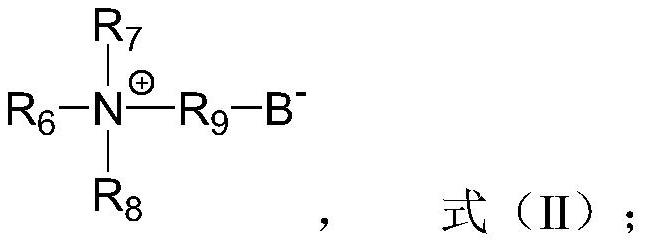

[0072] Cetyl dimethyl betaine (R 6 =C 16 , R 7 , R 8 , R 9 =C 1 , B is COO - ): 20;

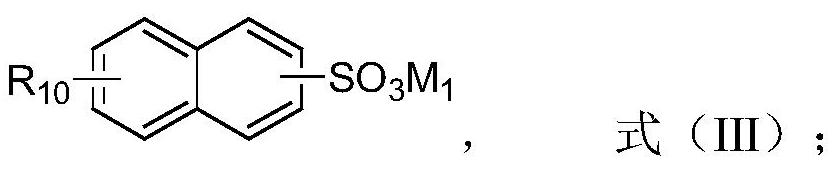

[0073] Sodium 6-methyl-2-naphthalenesulfonate: 40.

[0074] Binary compound flooding system preparation: under the conditions of 50°C and 600rpm rotation speed, the above hydrophobic association polymer was dissolved in simulated water or oil field water to prepare a polymer mother liquor with a con...

Embodiment 2

[0076] Components and contents of binary compound flooding:

[0077] Hydrophobic association polymer: 0.05~0.15;

[0078] Composite surfactant: 0.1~0.5;

[0079] Water: 99.35 ~ 99.85.

[0080] Hydrophobic association polymer: the degree of hydrolysis is 25%, the hydrophobic group is -CH 2 -N(CH 3 ) 2 -C 18 h 37 Br (content is 1.0mol%) polyacrylamide (ie x:y:z=74:25:1, M 2 =Na + ).

[0081] Each component and content of composite surfactant: (wt%)

[0082] Erucamidopropyl Betaine (R 1 =C 21 , R 2 =C 3 , R 3 , R 4 , R 5 =C 1 , A is COO - ): 42;

[0083] Octadecyldimethylbetaine (R 6 =C 18 , R 7 , R 8 , R 9 =C 1 , B is COO - ): 28;

[0084] Sodium 1-naphthalenesulfonate: 30.

[0085] Binary compound flooding system preparation: under the conditions of 50°C and 600rpm rotation speed, the above hydrophobic association polymer was dissolved in simulated water or oil field water to prepare a polymer mother liquor with a concentration of 0.5%. At room temp...

Embodiment 3

[0087] Components and contents of binary compound flooding:

[0088] Hydrophobic association polymer: 0.05~0.15;

[0089] Composite surfactant: 0.1~0.5;

[0090] Water: 99.35 ~ 99.85.

[0091] Hydrophobic association polymer: the degree of hydrolysis is 25%, the hydrophobic group is -CH 2 -N(CH 3 ) 2 -C 16 h 33 Br (content is 1.2mol%) polyacrylamide (namely x:y:z=73.8:25:1.2, M 2 = K + ).

[0092] Each component and content of composite surfactant: (wt%)

[0093] Cocamidopropyl Betaine (R 1 =C 7 ~C 17 , R 2 =C 3 , R 3 , R 4 =C 1 , R 5 =C 2 , A is SO 3 - ): 36;

[0094] tetradecyl dimethyl betaine (R 6 =C 14 , R 7 , R 8 =C 1 , R 9 =C 2 , B is SO 3 - ):twenty four;

[0095] Sodium 7-ethyl-1-naphthalenesulfonate: 40.

[0096] Binary compound flooding system preparation: under the conditions of 50°C and 600rpm rotation speed, the above hydrophobic association polymer was dissolved in simulated water or oil field water to prepare a polymer mother li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com