Straw fine screening machine

An extension and straw technology, applied in agricultural machinery and tools, cocoa, cutting equipment, etc., can solve the problems of low work efficiency, inability to form filamentous materials, and inability to realize mechanized operations, etc., and achieve the effect of faster response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

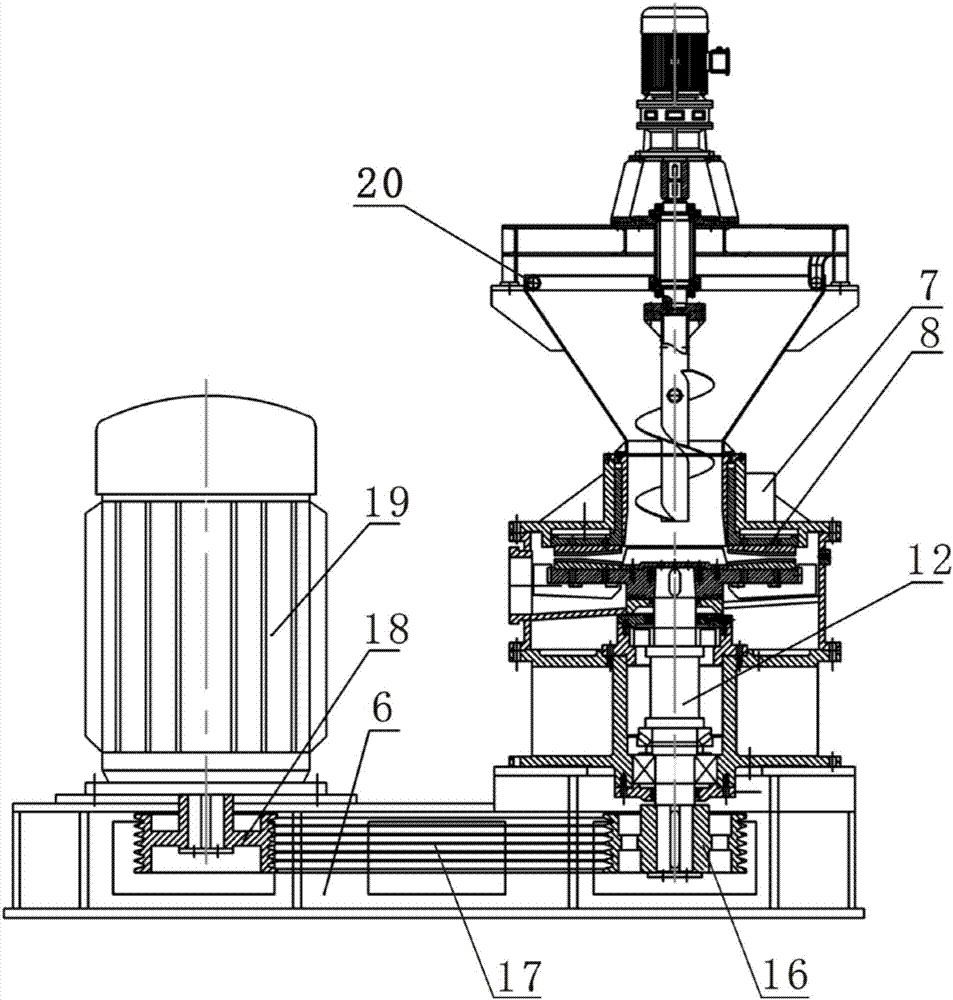

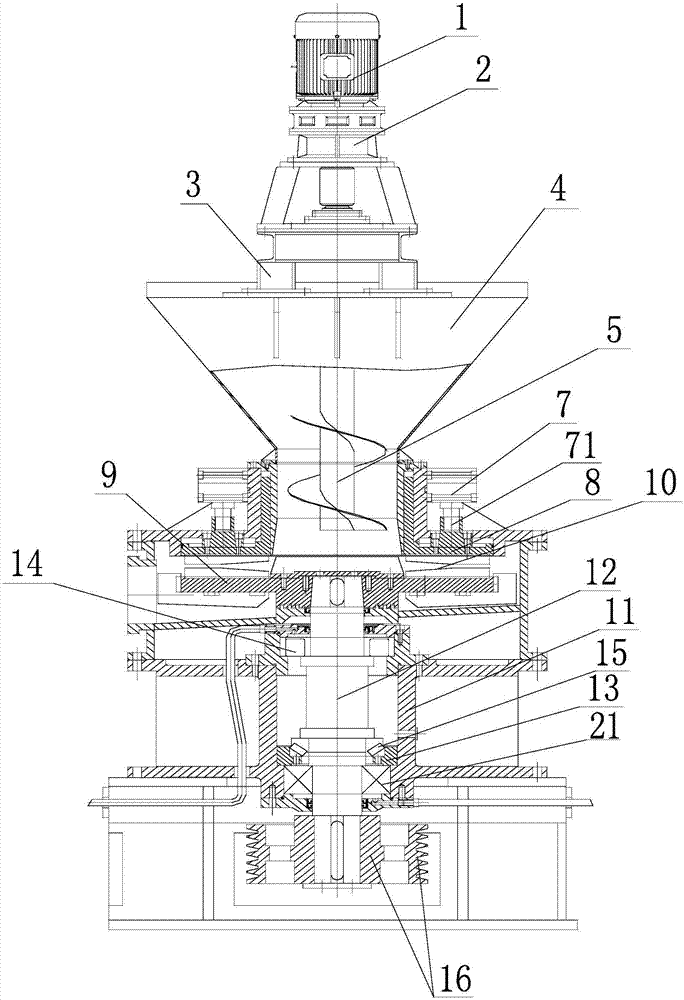

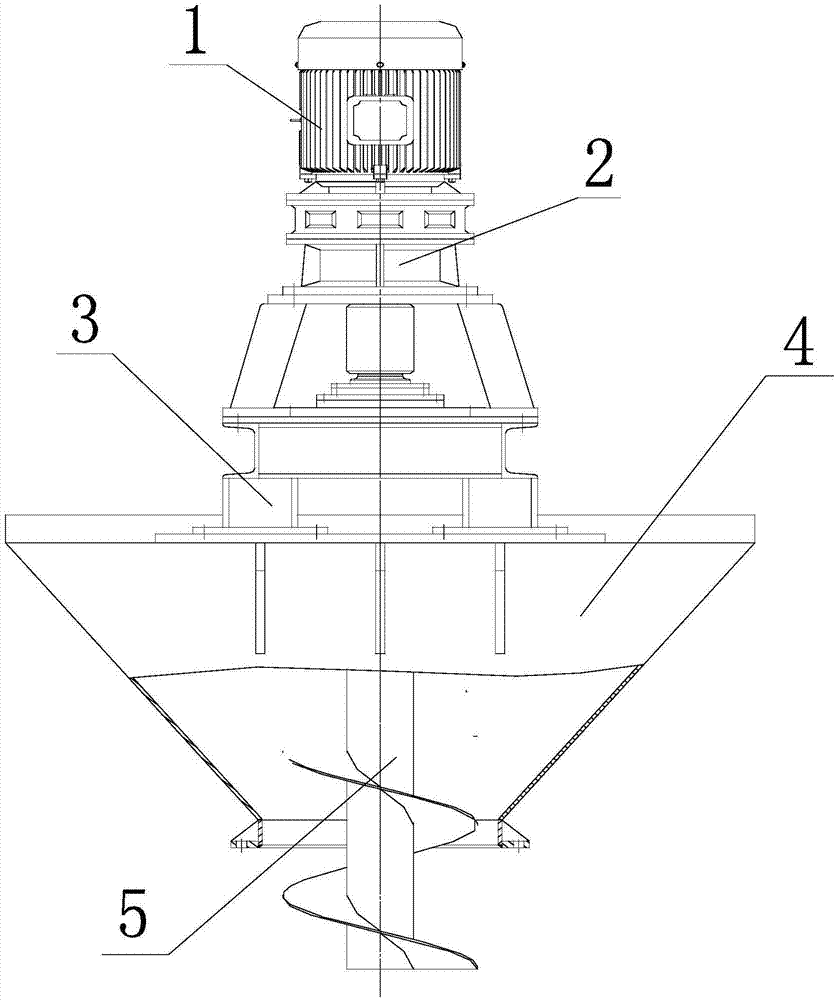

[0024] Such as Figure 1 ~ Figure 3 As shown, a straw fine separator includes a feeding device, an abrasive device, a rotary mechanism and a rotary motor 19. The feeding device includes a bracket 3, a feeding motor 1, a reducer 2, a lower hopper 4, a screw shaft 5, and a lower hopper 4 The top has a feed port, the bottom of the lower hopper 4 has a discharge port, the top of the lower hopper 4 is installed with a bracket 3, and the feed motor 1 is installed on the bracket 3, the power output shaft of the feed motor 1 and the input shaft of the reducer 2 Through the coupling power connection, the output shaft of the reducer 2 is fixedly connected with the top of the screw shaft 5, and the screw shaft 5 is placed inside the lower hopper 4.

[0025] Such as figure 2 As shown, the abrasive device comprises an abrasive housing, an upper grinding disc 8, and a lower grinding disc 9. The inside of the abrasive housing has an abrasive chamber 10. The upper grinding disc 8 and the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com