High temperature resistant cleansing emulsion or microemulsion fracturing fluid and preparation method thereof

A high-temperature, hydraulic technology, applied in chemical instruments and methods, drilling compositions, reagents, etc., can solve the problems of difficult sand mixing tanks, slow dissolution, and inconvenient on-site use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

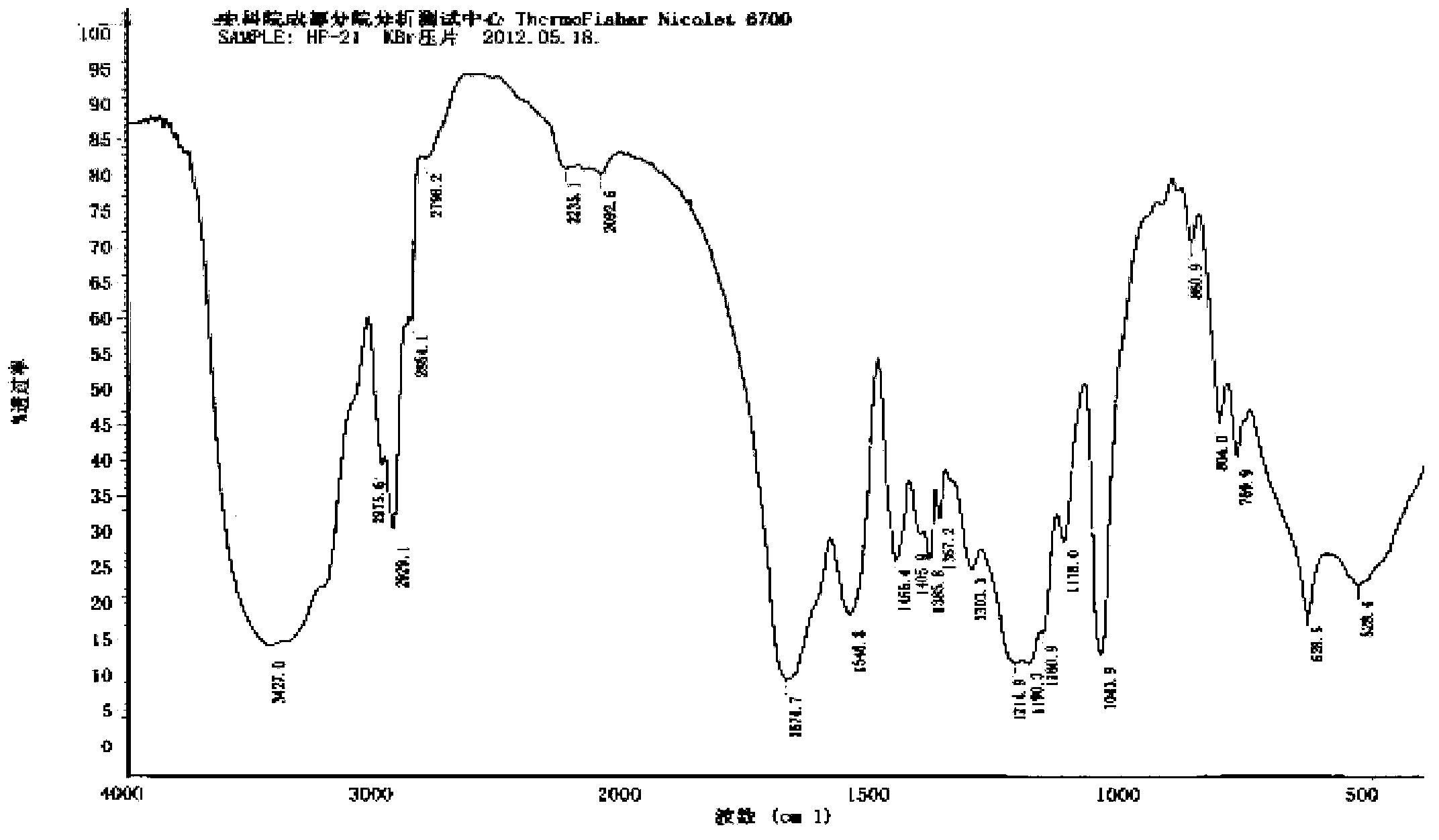

Image

Examples

Embodiment 1

[0223] Example 1: Preparation of high temperature resistant clean emulsion fracturing fluid

[0224] The implementation steps of this embodiment are as follows:

[0225] Step A: Prepare oil phase and emulsifier mixture

[0226] Add the mixed emulsifier composed of 30 parts by weight of white oil phase and 3 parts by weight of Pingping plus O-10 and span80 to the reactor equipped with mechanical stirring device, nitrogen inlet, constant pressure funnel and thermometer. Stir at constant temperature under certain conditions to obtain a homogeneous mixture;

[0227] Step B: Preparation of the aqueous phase

[0228] Acrylamide monomer A, (meth)acrylic acid monomer B, acryloxyethyl dimethyl octadecyl ammonium chloride monomer C and acrylamido sodium p-benzoate monomer D according to their weight ratio 10:10:0.5:0.25 is dissolved in water, the ratio of monomer weight to water weight is 1:1, the total weight of the water phase is 70, and 0.1% EDTA disodium salt is added based on th...

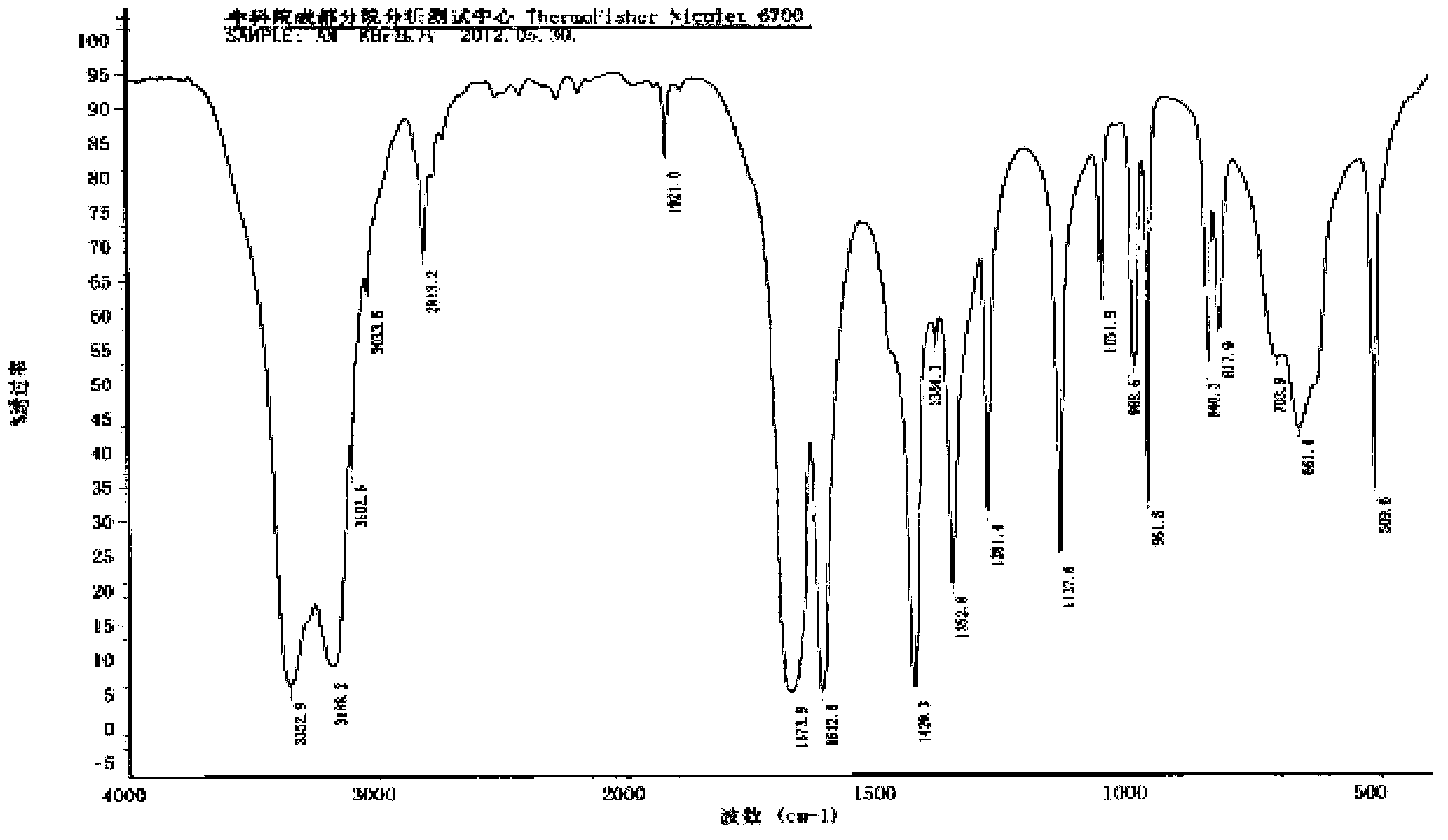

Embodiment 2

[0233] Example 2: Preparation of high temperature resistant clean emulsion fracturing fluid

[0234] The implementation steps of this embodiment are as follows:

[0235] Step A: Prepare oil phase and emulsifier mixture

[0236] Add the mixed emulsifier composed of 38 parts by weight of kerosene oil phase and 4 parts by weight of OP-1.5 and OP-7 to the reactor equipped with mechanical stirring device, nitrogen inlet, constant pressure funnel and thermometer. Constant temperature stirring under the condition to obtain a homogeneous mixture;

[0237] Step B: Preparation of the aqueous phase

[0238] (Meth) acrylamide monomer A, maleic anhydride monomer B, acryloyloxyethyl dimethyl octadecyl ammonium chloride monomer C and acrylamido sodium terebenzoate monomer D according to Their weight ratio is 65:65:1.0:0.80 soluble in water, the ratio of monomer weight to water weight is 1:1, the total weight of the water phase is 70, and 0.1% EDTA based on the total weight of the above mo...

Embodiment 3

[0242] Example 3: Preparation of high temperature resistant clean emulsion fracturing fluid

[0243] The implementation steps of this embodiment are as follows:

[0244] Step A: Prepare oil phase and emulsifier mixture

[0245] Add the mixed emulsifier composed of 60 parts by weight of diesel oil phase and 6 parts by weight of TX-10 and span80 to the reactor equipped with mechanical stirring device, nitrogen inlet, constant pressure funnel and thermometer, under the conditions of temperature 35°C and 280rpm Stir at a constant temperature to obtain a homogeneous mixture;

[0246] Step B: Preparation of the aqueous phase

[0247] N-hydroxypropyl (meth)acrylamide monomer A, fumaric acid monomer B, acryloyloxyethyl dimethyl octadecyl ammonium chloride monomer C and acrylamido sodium terebenzoate Body D is dissolved in water according to their weight ratio of 90:75:1.6:0.40, the ratio of monomer weight to water weight is 1:1, the total weight of the water phase is 70, and the to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com