Temperature-resistant and salt-tolerant foaming agent system for thermal recovery of heavy oil reservoir and preparation method

A temperature-resistant, salt-resistant, foaming agent technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of wasting resources, increasing sweep efficiency, reducing the flow rate of displacement fluid and crude oil, and saving costs Cost, good thermal stability, effect of increased apparent viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

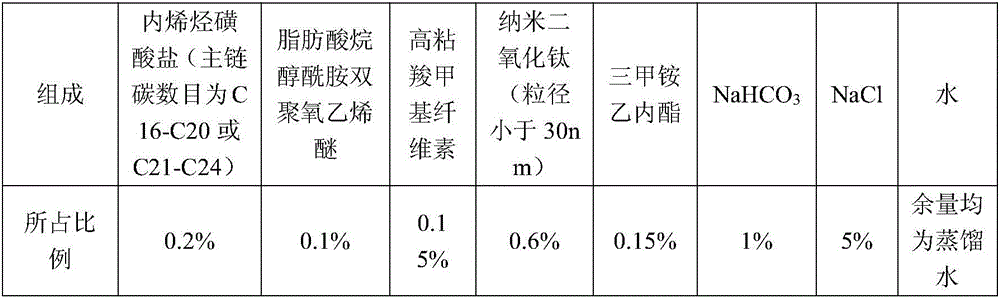

[0023] Heat-resistant and salt-resistant foaming agent system for heavy oil thermal recovery reservoirs, the solvent used is distilled water, and then a certain amount of foaming agent main agent, foam stabilizer, foam fixing agent, foam accelerator, alkaline substances and inorganic salts are added , and then use a magnetic stirrer to continuously stir the mixed liquid for 1.5h, and then vibrate with an ultrasonic oscillator, so that the main foaming agent, foam stabilizer, and foam accelerator can be evenly attached to the surrounding solid particles. The composition of the blowing agent system is shown in Table 1.

[0024] Table 1 Composition of temperature-resistant and salt-resistant foaming agent system in heavy oil thermal recovery reservoirs

[0025]

[0026] Put the prepared temperature-resistant and salt-resistant foaming agent system solution into a high-temperature and high-pressure reaction kettle, and age it at 300°C for 48 hours, and evaluate the foaming perf...

Embodiment 2

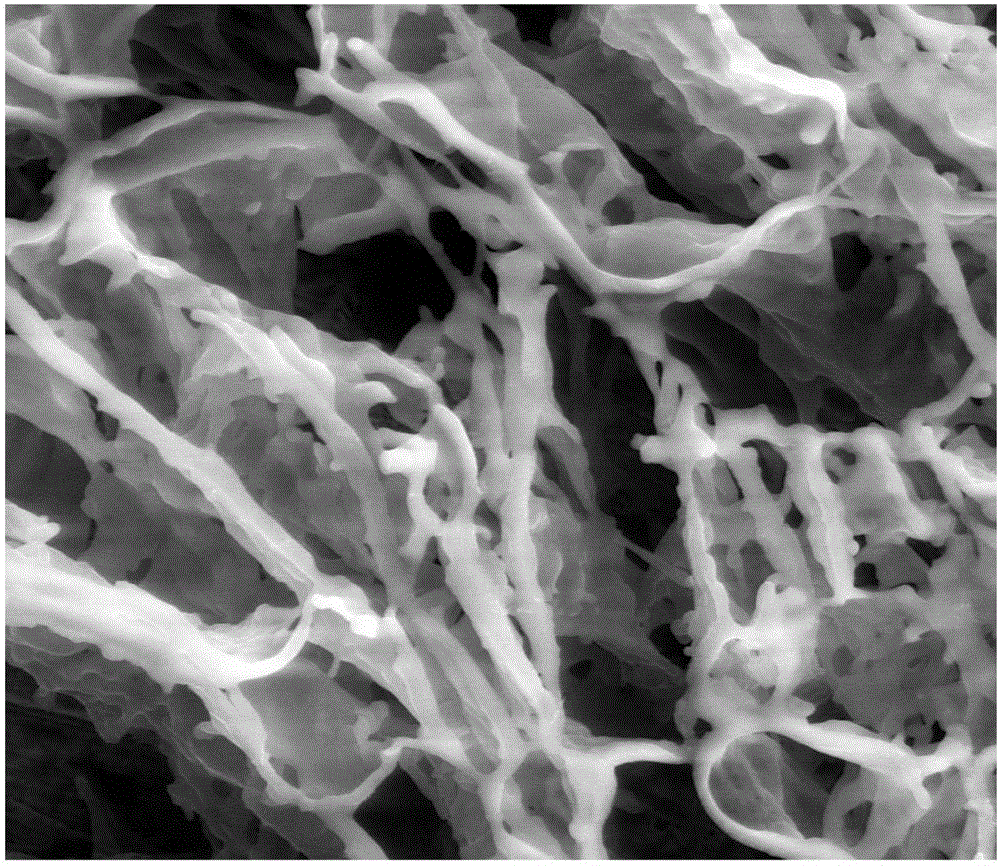

[0029]According to the steps in the above example 1, the composition of the foaming agent system was prepared, and its microscopic morphology was observed by scanning electron microscopy. attached by figure 1 The local structure diagram of the foam can be seen, and the foam produced is moderate in size and uniform in structure.

Embodiment 3

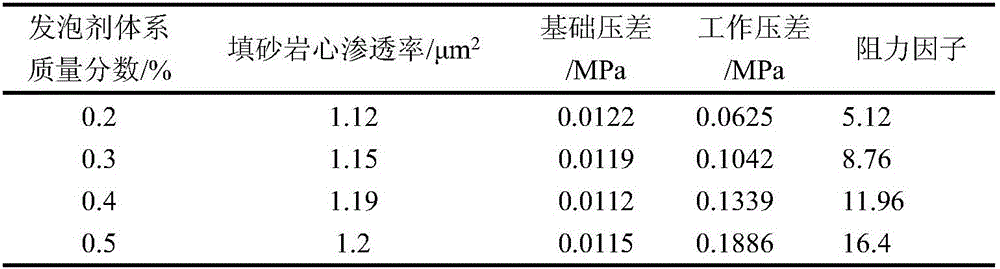

[0031] Following the procedure in Example 1 above, a blowing agent system was prepared. A one-dimensional single-tube model was used to evaluate the performance of the temperature-resistant and salt-resistant blowing agent system. The experimental device is a one-dimensional single-pipe model, and the sand-filled model is 50.0 cm long and 2.54 cm in diameter. Fill the core with quartz sand, place a single tube horizontally in a constant temperature oven, first saturate the core with water, measure the water phase permeability of the core, and then inject water and gas into the core at the same time according to a certain gas-liquid ratio. When the pressure difference at both ends of the core reaches a stable level, record the pressure difference at both ends of the core as the base pressure difference. The experimental temperature is 300°C, the injection rate is 3.0mL / min, the injected gas-liquid ratio is set at 1:1, and the back pressure is 8.2MPa. , the experimental results...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com