Method for controlling deformation of ceramic blank in gel casting process

A gel injection molding, deformability technology, applied in manufacturing tools, ceramic molding workshops, ceramic molding machines, etc., can solve problems such as deformation, and achieve the effect of uniform distribution and small deformability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

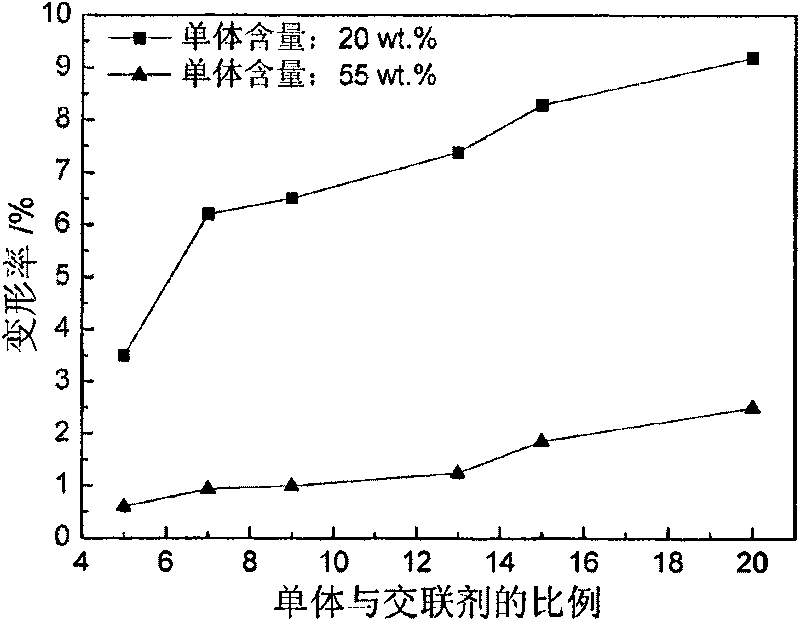

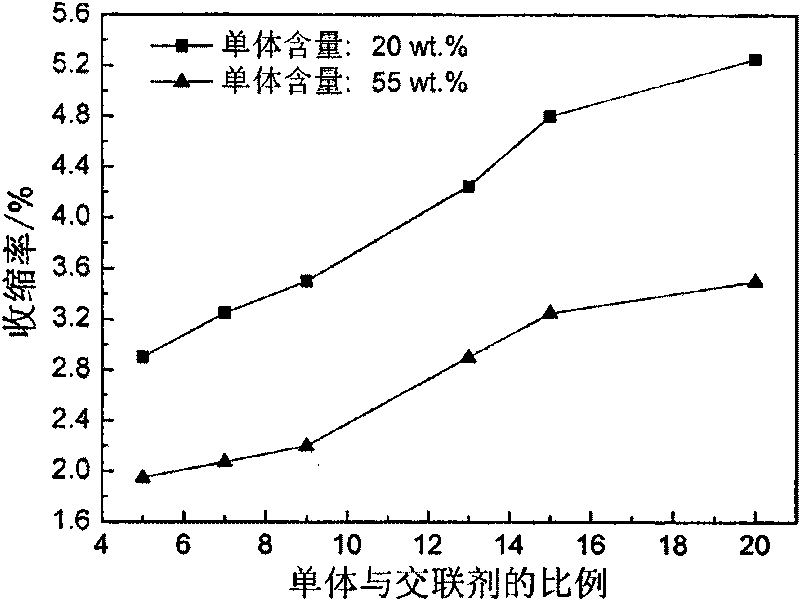

[0034] Mix 20% mixture (acrylamide and N, N'-methylenebisacrylamide), the ratio of monomer to crosslinking agent is 5, 2% dispersant and water to prepare a premix, add 40 % silicon nitride powder and 3% sintering aid (Al 2 o 3 ;Y 2 o 3 ), adjust the pH value to 9-11, and prepare the slurry after ball milling for 12 hours; after the slurry is degassed in vacuum, add an initiator, degass it again, and inject it into the mold, and react for 30-60 minutes at 40-65°C The slurry is gelled and solidified, demoulded, and dried under the conditions of 25° C. and 98% humidity to obtain a green body. The deformation rate, shrinkage rate and bending strength of the obtained silicon nitride ceramic body are 3.5%, 2.9% and 27.9 MPa respectively.

Embodiment 2

[0036] Mix 55% mixture (acrylamide and N,N'-methylenebisacrylamide), the ratio of monomer to crosslinking agent is 5, 2% dispersant and water to prepare a premix, add 40 % silicon nitride powder and 3% sintering aid (Al 2 o 3 ;Y 2 o 3), adjust the pH value to 9-11, and prepare the slurry after ball milling for 12 hours; after the slurry is degassed in vacuum, add an initiator, degass it again, and inject it into the mold, and react for 30-60 minutes at 40-65°C The slurry is gelled and solidified, demoulded, and dried under the conditions of 25° C. and 98% humidity to obtain a green body. The deformation rate, shrinkage rate and bending strength of the obtained silicon nitride ceramic body are 0.6%, 1.95% and 60.2MPa respectively.

Embodiment 3

[0038] Mix 20% mixture (acrylamide and N, N'-methylenebisacrylamide), the ratio of monomer to crosslinking agent is 7, 2% dispersant and water to prepare a premix, add 40 % silicon nitride powder and 3% sintering aid (Al 2 o 3 ;Y 2 o 3 ), adjust the pH value to 9-11, and prepare the slurry after ball milling for 12 hours; after the slurry is degassed in vacuum, add an initiator, degass it again, and inject it into the mold, and react for 30-60 minutes at 40-65°C The slurry is gelled and solidified, demoulded, and dried under the conditions of 25° C. and 98% humidity to obtain a green body. The deformation rate, shrinkage rate and bending strength of the obtained silicon nitride ceramic body are 6.2%, 3.25% and 28.9 MPa respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com