Anti-deformation titanium target material

A titanium target, anti-deformation technology, applied in metal material coating process, ion implantation plating, coating and other directions, can solve problems such as increasing the difficulty of target production, adverse effects of sputtering effect, etc., to avoid sparking phenomenon , the effect of increasing the roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

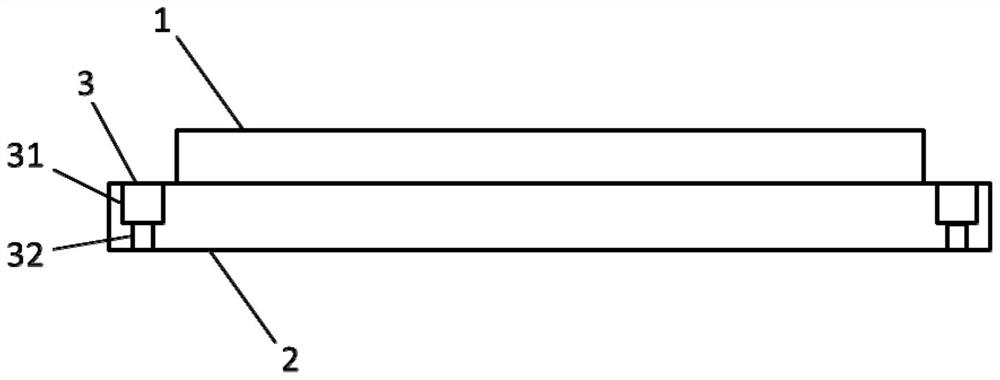

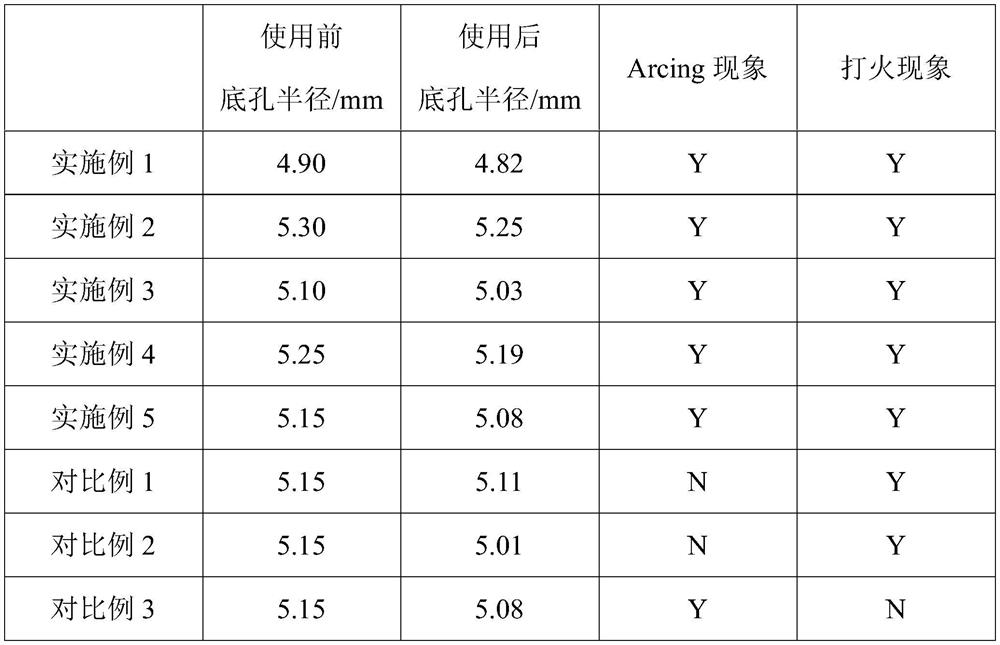

[0034] This embodiment provides an anti-deformation titanium target, the structure of which is as follows figure 1 As shown, the target is circular, and the target includes a back plate and a sputtering part connected to the back plate, the size of the sputtering part is smaller than the size of the back plate, and the edge of the back plate is provided with There are at least two installation stepped holes, the installation stepped holes include a counterbore and a bottom hole, and the ratio of the depth of the counterbore to the depth of the bottom hole is 1.25.

[0035]The size of the back plate is 390mm, the size of the sputtering part is 320mm, the depth of the installation step hole is 9.20mm, the depth of the counterbore is 5.35mm, and the radius of the bottom hole is 4.90mm.

[0036] A sandblasting area is provided on the bottom edge of the back plate, and the roughness of the sandblasting area is 8-9 μm.

[0037] The sandblasting raw material in the sandblasting area...

Embodiment 2

[0039] This embodiment provides an anti-deformation titanium target, the structure of which is as follows figure 1 As shown, the target is circular, and the target includes a back plate and a sputtering part connected to the back plate, the size of the sputtering part is smaller than the size of the back plate, and the edge of the back plate is provided with There are at least two installation stepped holes, the installation stepped holes include a counterbore and a bottom hole, and the ratio of the depth of the counterbore to the depth of the bottom hole is 1.55.

[0040] The size of the back plate is 400mm, the size of the sputtering part is 330mm, the depth of the installation step hole is 9.50mm, the depth of the counterbore is 5.60mm, and the radius of the bottom hole is 5.30mm.

[0041] A sandblasting area is provided on the bottom edge of the back plate, and the roughness of the sandblasting area is 10-11 μm.

[0042] The sandblasting raw material in the sandblasting a...

Embodiment 3

[0044] This embodiment provides an anti-deformation titanium target, the structure of which is as follows figure 1 As shown, the target is circular, and the target includes a back plate and a sputtering part connected to the back plate, the size of the sputtering part is smaller than the size of the back plate, and the edge of the back plate is provided with There are at least two installation stepped holes, the installation stepped holes include a counterbore and a bottom hole, the ratio of the depth of the counterbore to the depth of the bottom hole is 1.35.

[0045] The size of the back plate is 392 mm, the size of the sputtering part is 323 mm, the depth of the installation step hole is 9.30 mm, the depth of the counterbore is 5.45 mm, and the radius of the bottom hole is 5.10 mm.

[0046] A sandblasting area is provided on the bottom edge of the back plate, and the roughness of the sandblasting area is 8-9 μm.

[0047] The sandblasting raw material in the sandblasting ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com