Annular metal-ceramic gradient material and preparation method thereof

A gradient material, annular technology, applied in metal processing equipment, transportation and packaging, etc., can solve the problems of mismatch of thermodynamic properties of interlayer bonding parts, increase the use cost of liquid metal batteries, and difficulty in controlling the size of gradient material stacks. The effect of uniform distribution of gradient components, small deformation and high molding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

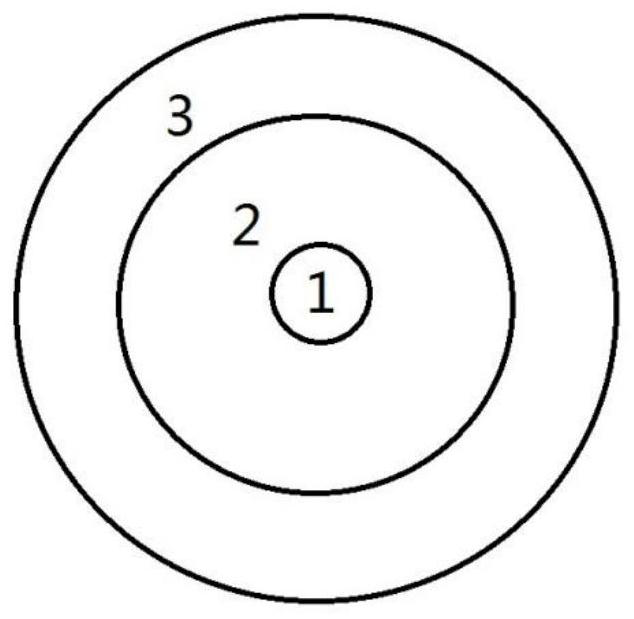

[0132] The preferred embodiment of the annular metal-ceramic gradient material of the present invention is as follows:

[0133] The number of layers of the gradient layer is 6 layers, and the pure ceramic powder is selected from AlN powder (aluminum nitride ceramic powder), and the pure metal powder is selected from Mo powder (molybdenum metal powder).

[0134] The innermost layer is the first layer,

[0135] The raw material powder is AlN powder, and the ratio accounts for 90%;

[0136] The dispersant is dibutyl phthalate, with a ratio of 2.25%;

[0137] The binder is a mixture of high and low density polyethylene, with a ratio of 2.8%;

[0138] Lubricants are paraffin wax and stearic acid wax, proportioning 4.32%;

[0139] The sintering aid is diyttrium trioxide, proportioning 0.63%;

[0140] Second floor,

[0141] The raw material powder is 72% AlN powder + 18% Mo powder, and the ratio accounts for 90%;

[0142] The dispersant is dibutyl phthalate, with a ratio of 2.2...

Embodiment example 1

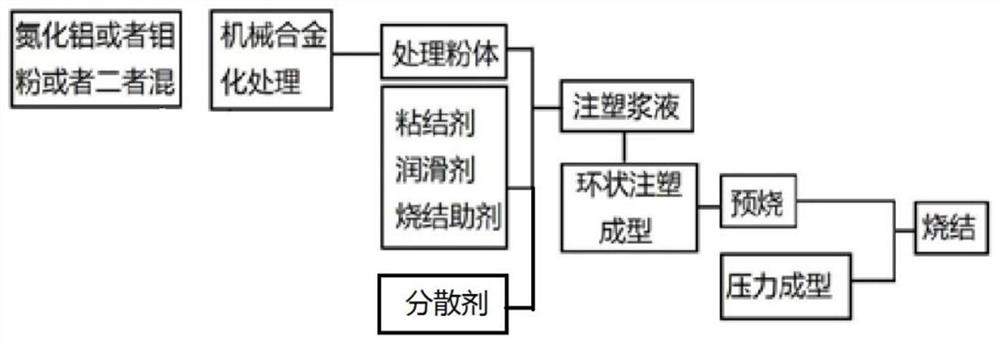

[0205] This implementation case provides a method for preparing a 6-layer AlN / Mo gradient material. Wherein, the preparation process includes the following specific steps:

[0206] (1) The number of gradient layers of the designed AlN / Mo gradient material is 6 layers, and the thickness of each layer can be determined according to specific requirements. The composition and ratio of each layer of powder from the inside to the outside are as follows: the innermost layer (AlN) 100wt.%, the second inner layer (AlN) 80wt.% + (Mo) 20wt.%, and the inner middle layer (AlN) 60wt. .% + (Mo) 40wt.%, biased towards the outer middle layer (AlN) 40wt.% + (Mo) 60wt.%, the second outer layer (AlN) 20wt.% + (Mo) 80wt.%, the outermost layer ( Mo) 100wt.%.

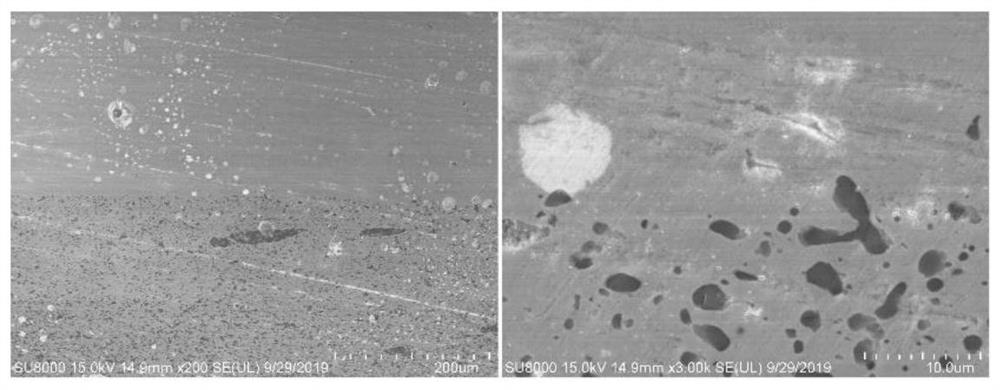

[0207] (2) Select AlN powder and Mo powder as raw powder materials, the raw particle size of AlN powder is 50nm, and the raw particle size of Mo powder is less than 1 μm. AlN powder and Mo powder are used to configure the original mixed ra...

Embodiment example 2

[0213] This implementation case provides a method for preparing an alumina-tungsten (W / Al2O3) cermet gradient material, wherein the preparation process includes the following specific steps:

[0214](1) The number of gradient layers of the designed W / Al2O3 gradient material is 4 layers, and the thickness of each layer can be determined according to specific requirements. The composition and ratio of each layer of powder from the inside to the outside are as follows: the innermost layer (Al2O3) 100wt.%, the second inner layer (Al2O3) 80wt.% + (W) 20wt.%, the second outer layer (Al2O3) 20wt.% + (W) 80wt.%, the outermost layer (W) 100wt.%.

[0215] (2) Select Al2O3 powder and W powder as the original powder materials, the original powder particle size of Al2O3 powder is 20-30nm, and the original particle size of W powder is less than 1μm. Al2O3 powder and W powder are used to configure the original mixed raw materials of each layer according to the ratio set in step 1, and then ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com