Method for controlling precision of extrusion type 3D printing polymer line width

A 3D printing, polymer wire technology, applied in the field of 3D printing, can solve the problems of limited printing accuracy, harsh printing conditions, and rough printing boundaries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

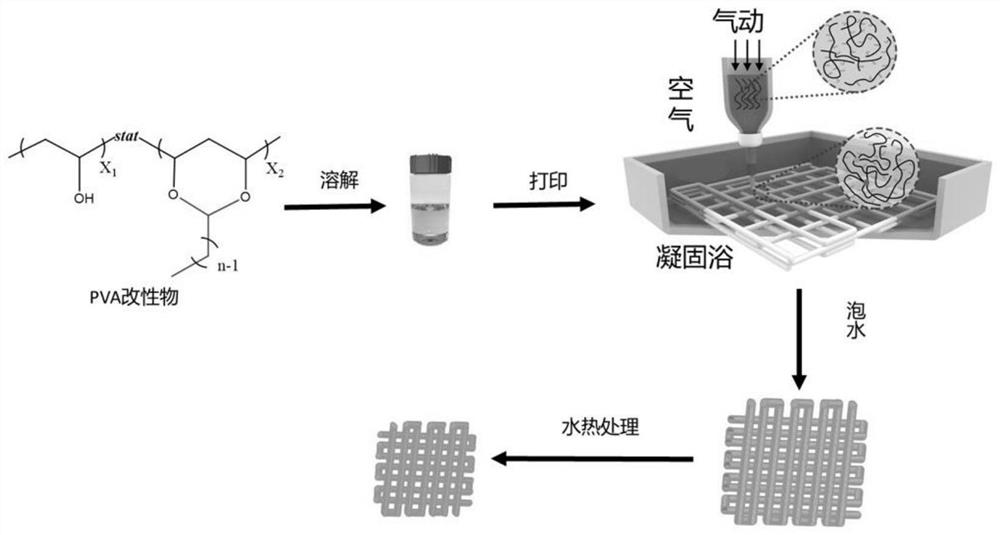

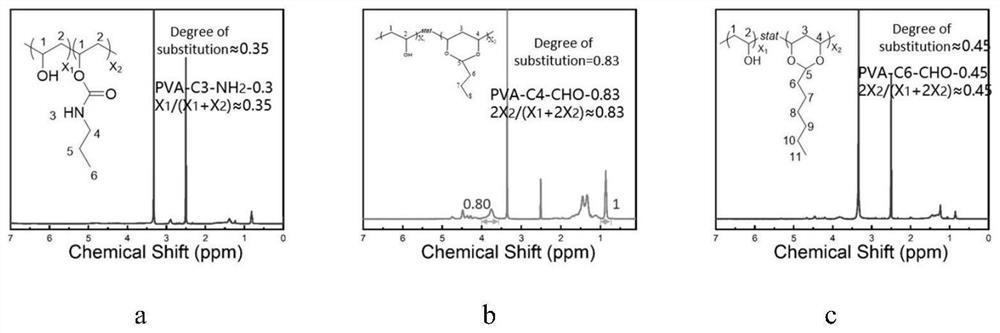

[0061] Take PVA-C3-NH 2 -0.3 (the modification rate can be determined by nuclear magnetic resonance spectrum (hydrogen spectrum)) is the printing substrate, and the sample printing is carried out. The specific process is as follows:

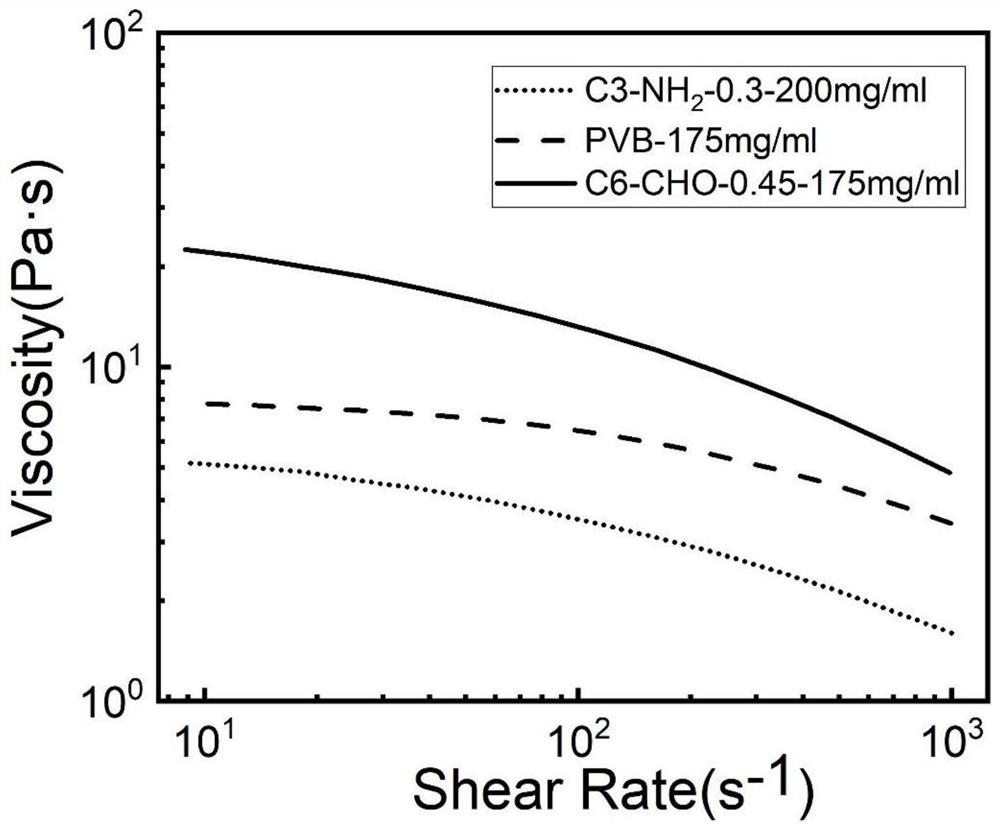

[0062] PVA-C3-NH 2 -0.3 dissolved in N,N-dimethylformamide to prepare PVA-C3-NH 2 -0.3 3D printing solution with a concentration of 200mg / ml (for the prepared 3D printing solution see Figure 4 );

[0063] 3D printing was performed with 30% ethanol aqueous solution as a coagulation bath (printing parameters: needle diameter 0.26mm, barrel temperature 20-30°C, air pressure 0.05Mpa, speed 6mm / s) to obtain printed samples;

[0064] Place the obtained printed samples in pure water at room temperature, soak for 7 days, change the water every 12 hours during this period, until the residual organic solvent is completely removed, put the bracket into a glass bottle filled with water, and place it in an oven for hydrothermal treatment ( Set the water ...

Embodiment 2

[0066] Same as Example 1, the difference is that the side chain uses PVA-C4-CHO-0.83 (i.e. PVB) grafted with n-butyraldehyde to polyvinyl alcohol (the molecular weight and hydrolysis rate of polyvinyl alcohol are constant) as the printing substrate; carry out sample printing , the specific process is as follows:

[0067] Dissolve PVB in N,N-dimethylformamide to prepare a 3D printing solution with a concentration of 175 mg / ml ( Image 6 It is the solubility parameter diagram of the aldehyde group series, the abscissa is the modification rate, and the ordinate is the solubility parameter; two completely parallel straight lines, the upper one is the solubility parameter curve of the organic solvent DMSO, and the lower one is the solubility parameter curve of the organic solvent DMF ;The other six curves from top to bottom are the solubility curves of aldehyde-based samples whose carbon chains are C3, C4, C5, C6, C7, and C8 aldehyde-modified. The solubility is similar, which prove...

Embodiment 3

[0073] Same as Example 1, the difference is that the side chain uses PVA-C6-CHO-0.45 of n-hexanal grafted polyvinyl alcohol (the molecular weight and hydrolysis rate of polyvinyl alcohol are constant) as the printing substrate, and the sample printing is carried out. The specific process is as follows:

[0074] Dissolve PVA-C6-CHO-0.45 in N,N-dimethylformamide to prepare a 3D printing solution with a PVA-C6-CHO-0.45 concentration of 175 mg / ml (see Figure 12 );

[0075] Use water as a coagulation bath for 3D printing (printing parameters: needle diameter 0.26mm, barrel temperature 20-30°C, air pressure 0.05Mpa, speed 4.5mm / s) to obtain a printed sample; place the printed sample in pure water at room temperature In the medium, soak for 7 days, change the water every 12 hours until the residual organic solvent is completely removed, put the bracket into a glass bottle filled with water, and place it in an oven for hydrothermal treatment. Also in order to achieve the best shrinka...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Young's modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com