Mandrel used for digital printing on can members

An axial and integrated technology, applied in the direction of printing, printing presses, rotary printing presses, etc., can solve the problem of not providing the information of the clamping device, etc., and achieve the effect of reducing permanent deformation and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

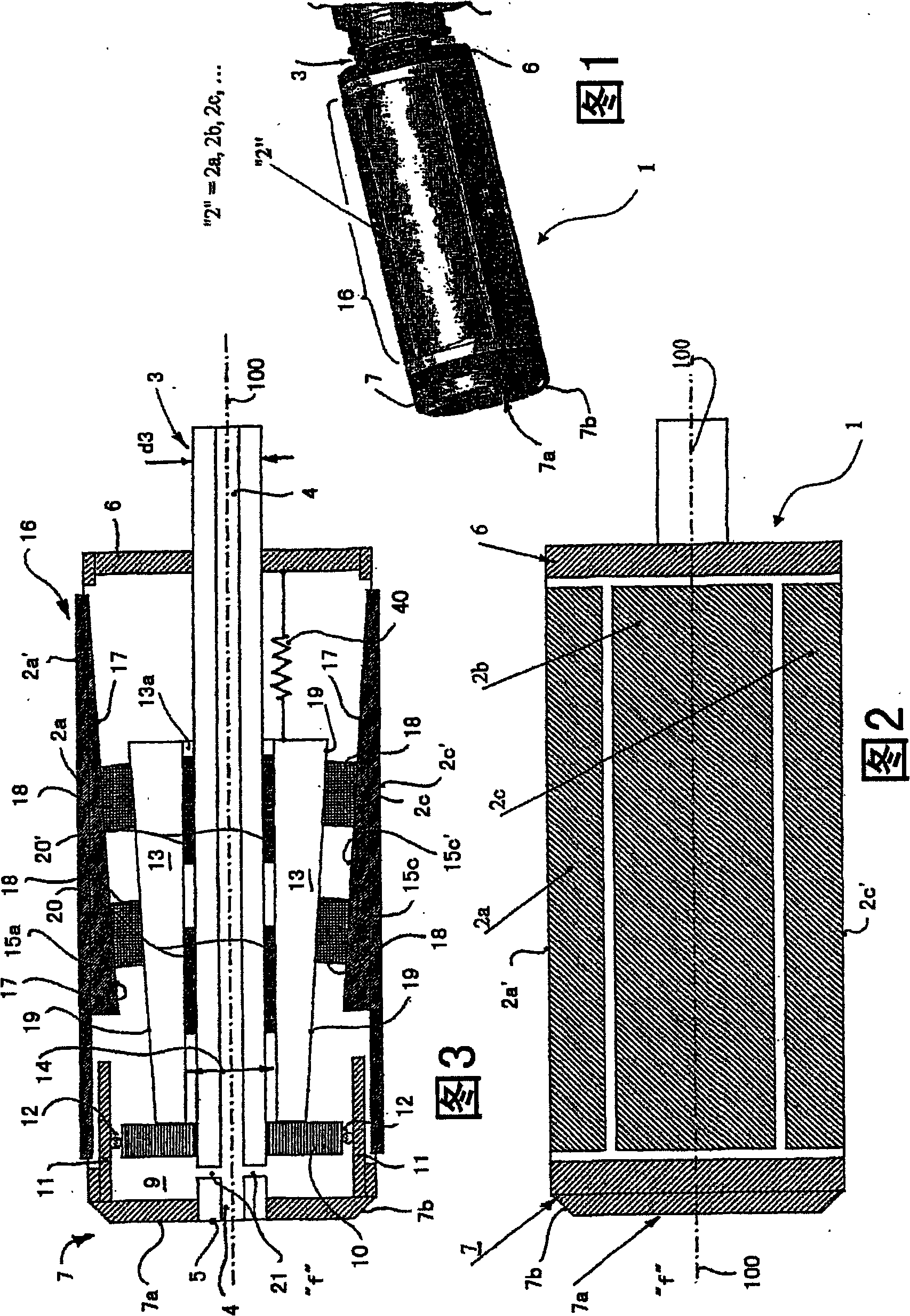

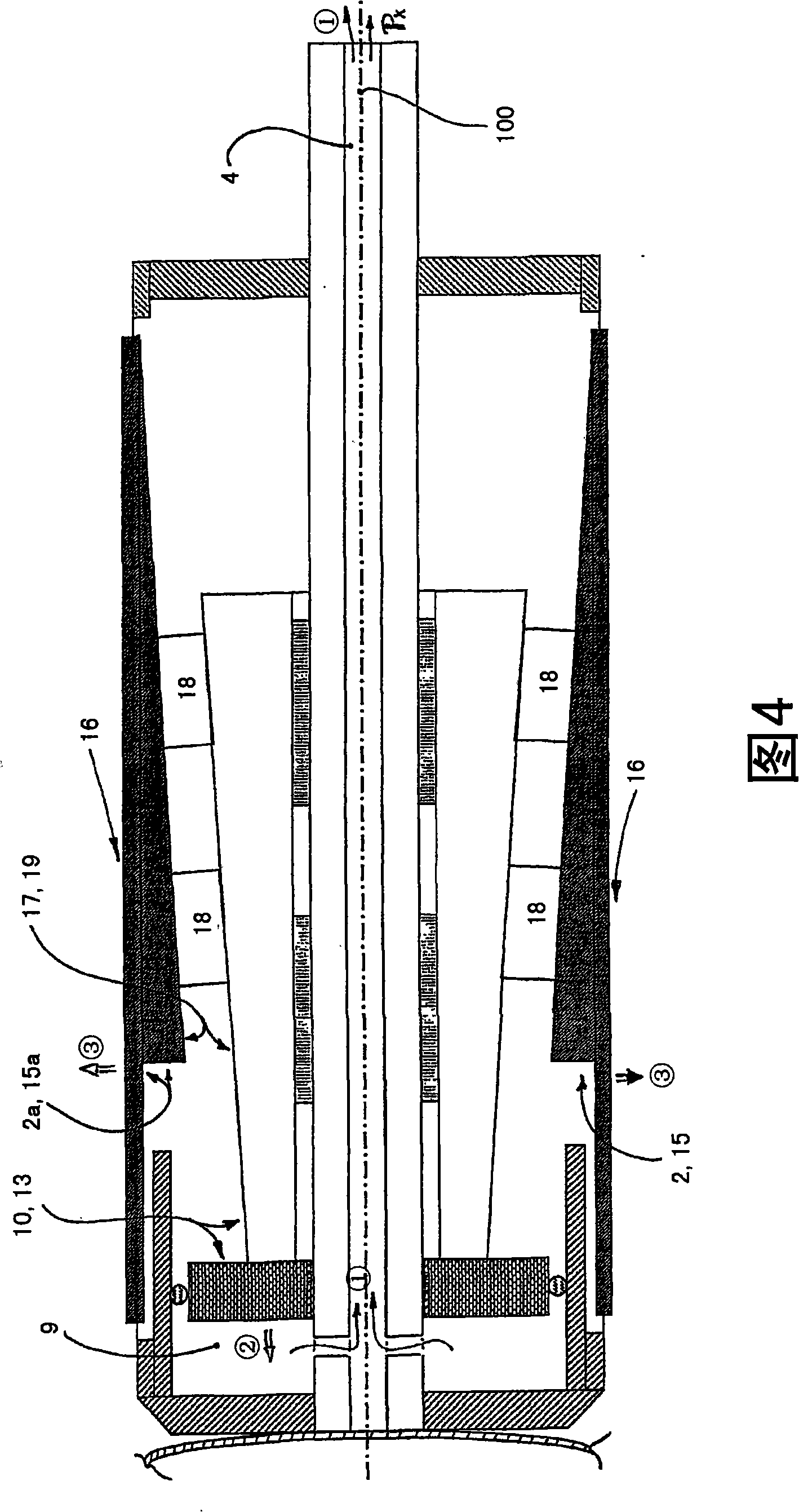

[0024] The actual clamping surface 16 of the clamping device in the form of a clamping mandrel 1 passes through a plurality of preferably identical clamping segments 2a, 2b, 2c etc. (also referred to for short by reference number 2), each of which has a clamping surface The corresponding part-cylindrical outer surfaces of the parts are thus connected together to form the cylindrical clamping surface 16 . The clamping sections extend practically over the entire length of the clamping device 1 and are radially displaceably guided on the main body of the clamping device.

[0025] One embodiment is a clamping surface portion 2a' associated with the clamping section 2a. Corresponding structures also apply to the clamping section 2c and the clamping surface portion 2c'.

[0026] The body comprises a central shaft 3 extending over the entire length of the holding device and beyond one end of the holding device and on which two end wall elements 6 and 7 are fixed at suitable axial sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com