Ultralow-temperature woven/wound outer rubber mixed material for hydraulic rubber hoses

A technology of rubber hoses and mixed materials, applied in the field of rubber materials, can solve the problems of poor pulse performance of hydraulic hoses, poor low temperature resistance performance of rubber hoses, and insufficient performance, so as to improve physical and mechanical properties and pulse performance, and improve cold and aging resistance. Excellent weather resistance and aging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0010] The invention discloses an outer rubber mixed material for ultra-low temperature braided / wound hydraulic rubber hose, which is prepared from the following raw materials in parts by weight: 0-35 parts of polyvinyl chloride, 30-45 parts of nitrile 26, and 322 parts of neoprene 40-55 parts, 8-12 parts of chlorinated polyethylene, 0.6-1.0 parts of sulfur, 1.2-3.2 parts of zinc oxide, 1-3 parts of stearic acid, 3-5 parts of magnesium oxide, 0.5-0.7 parts of accelerator DM, 1.7-1.9 parts of microcrystalline wax, 4-6 parts of coumarone, 15-25 parts of high wear-resistant carbon black, 45-70 parts of semi-reinforcing carbon black, 10-20 parts of white carbon black, 18-28 parts of clay, Antiaging agent BLE 1.7-2.1 parts, dioctyl sebacate (DOS) 10-15 parts, dibutoxyethyl adipate (DEBA) 8-12 parts, adhesive AS-88 20-27 parts , Antiaging agent 4010NA 12-18 parts.

[0011] The experimental formula has been screened and optimized many times, and the final formula is confirmed from m...

Embodiment 2-10

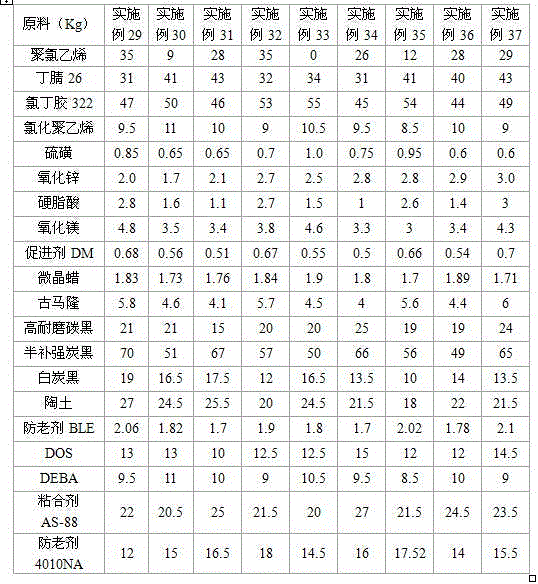

[0025] Table 1 List of Embodiments 2-10 of the present invention

[0026]

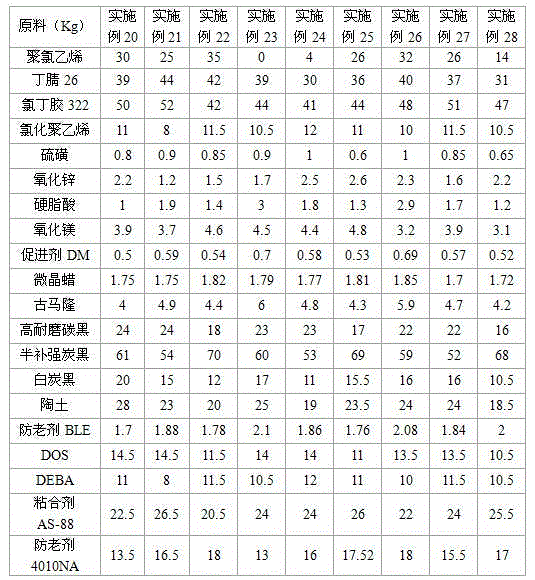

[0027] Table 2 List of Embodiments 11-19 of the present invention

[0028]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com