Intensified POE (Polyolefin Elastomer) photovoltaic packaging adhesive film as well as preparation process and application thereof

An encapsulation film, enhanced technology, applied in photovoltaic power generation, adhesives, film/flake adhesives, etc., can solve the problem of low POE strength and bonding performance, affecting the application of photovoltaic encapsulation film, and the light transmittance of materials It can not meet the requirements and other problems, and achieve the effect of simple preparation method, low cost and excellent aging resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

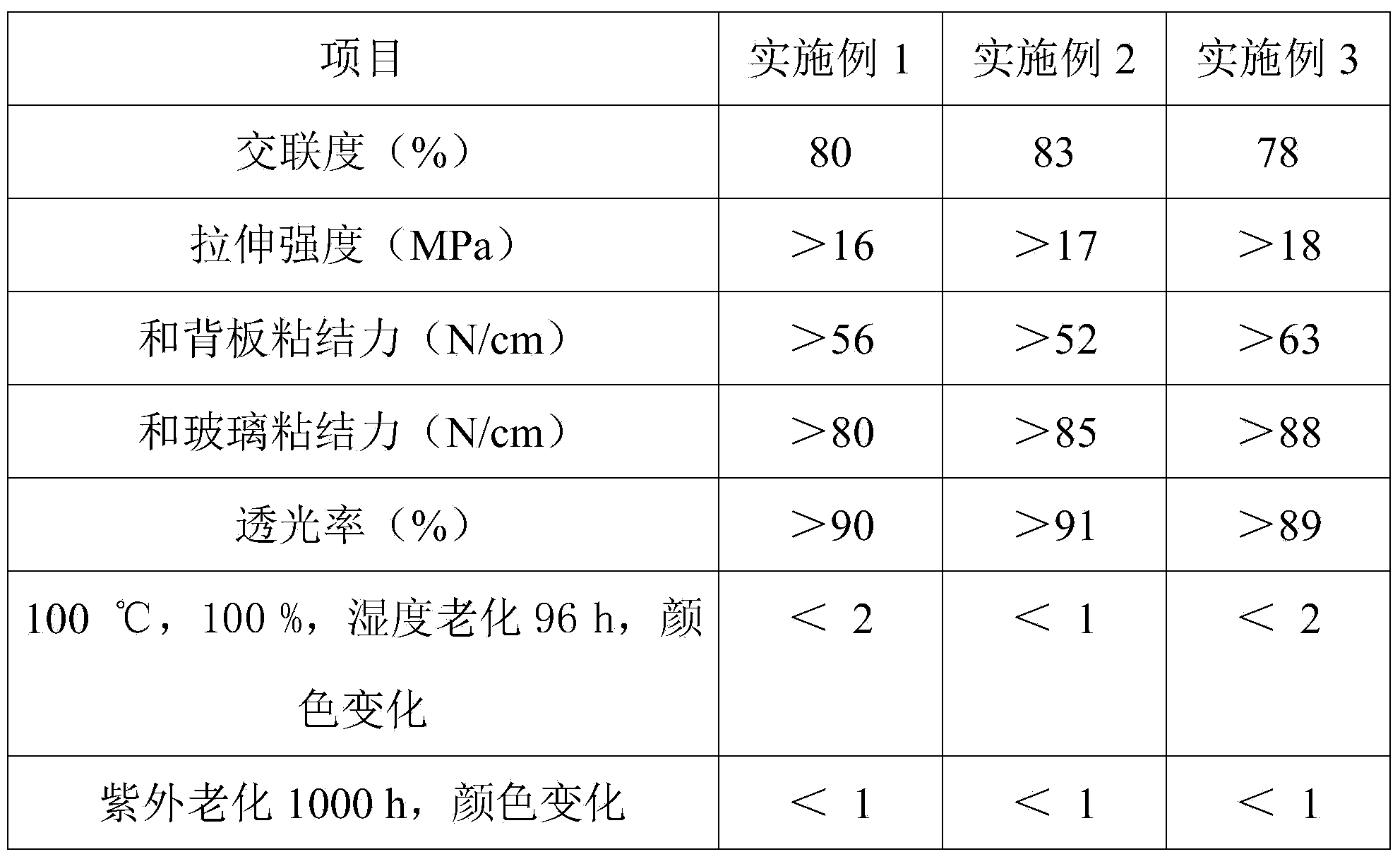

Examples

Embodiment 1

[0032] The above materials were granulated in a twin-screw extruder to prepare reinforced resin-modified POE granules A, and the processing temperature was 120°C. Then extrude through the T-die of the clothes hanger according to the following formula, and the film-forming temperature is 90° C. The thickness of the film is 0.3 mm.

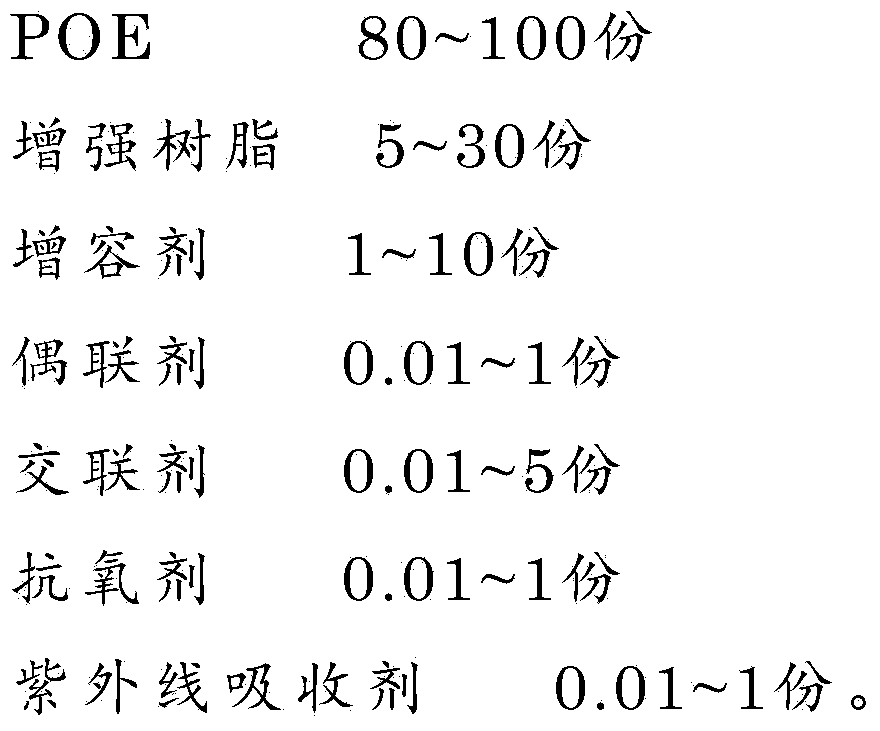

[0033] raw material

Embodiment 2

[0035] raw material

[0036] The above materials were granulated in a twin-screw extruder to prepare reinforced resin-modified POE granules A, and the processing temperature was 130°C. Then extrude into a film through the T-die of a clothes hanger according to the following formula, the temperature is 100° C., and the thickness of the film is 0.5 mm.

[0037] raw material

[0038] Reinforced resin modified POE particles A

Embodiment 3

[0041] The above materials were granulated in a twin-screw extruder to prepare reinforced resin-modified POE granules A, and the processing temperature was 150°C. Then extrude into a film through the T-die of a clothes hanger according to the following formula, the temperature is 110° C., and the thickness of the film is 0.6 mm.

[0042] raw material

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com