Multilayer condom containing modified polyurethane raw material and preparation method of multilayer condom

A technology of polyurethane and condoms, which is applied in the direction of male contraceptives, etc., can solve the problems of unresolved natural rubber sensitization, low tolerance of oil-based lubricants, life-threatening problems, etc., and achieve excellent adhesion Adhesion performance, improvement of surface performance and water resistance, effect of improving surface performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Synthesis of modified polyurethane chain extender:

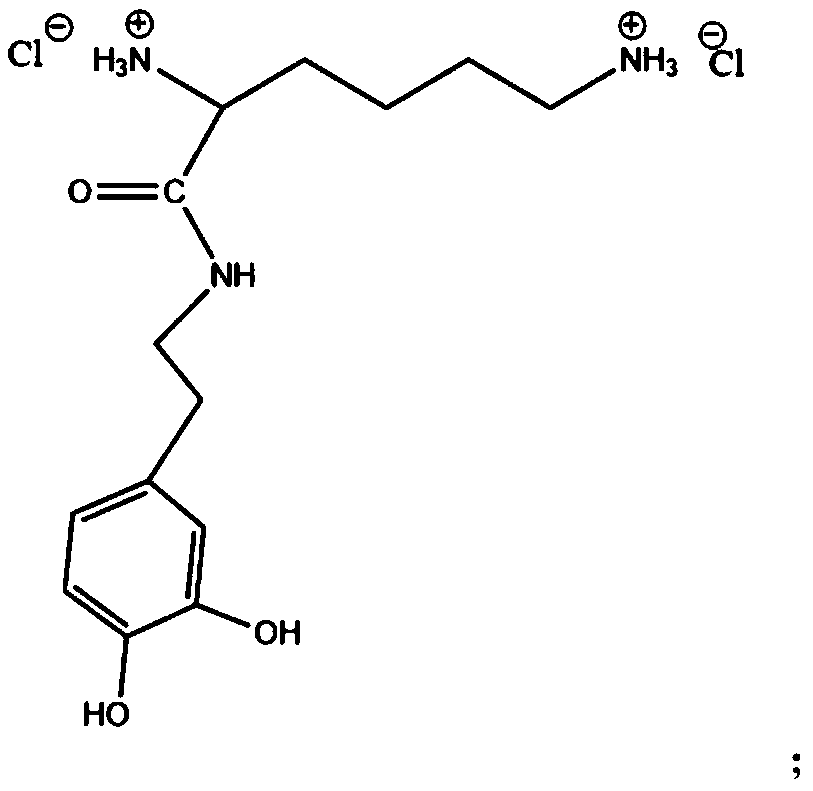

[0048] Amino protection of lysine by tert-butoxycarbonyl group and reaction with N-N-hydroxysuccinimide in dichloromethane solvent with coupling agent EDC-HCl at room temperature for 5 h to obtain intermediate product 1, and the obtained intermediate product One reacts with dopamine hydrochloride with methanol as a solvent at normal temperature for 10 hours to obtain intermediate product two, and reacts intermediate product two with hydrochloric acid / ethyl acetate for 2 hours at normal temperature to remove the amino protecting group to obtain a modified polyurethane chain extender, the reaction formula as follows:

[0049]

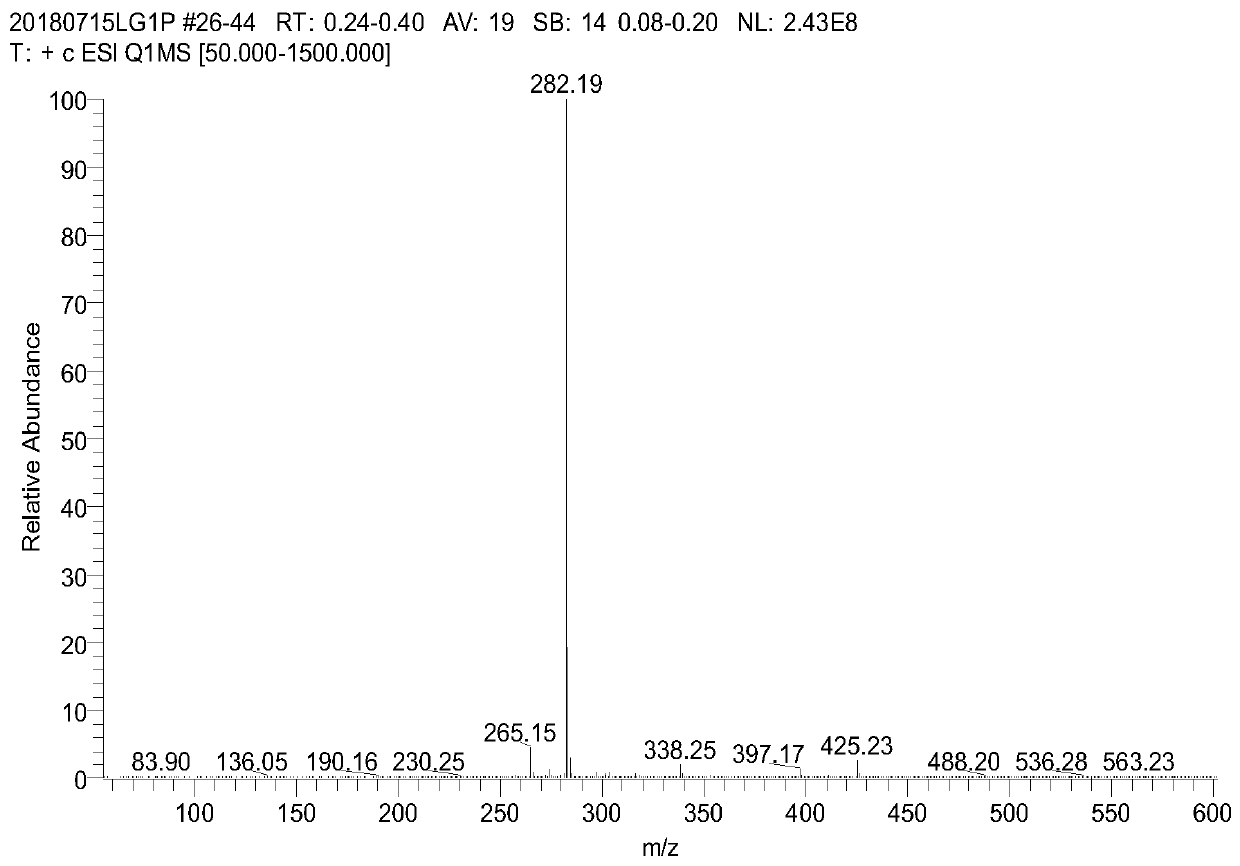

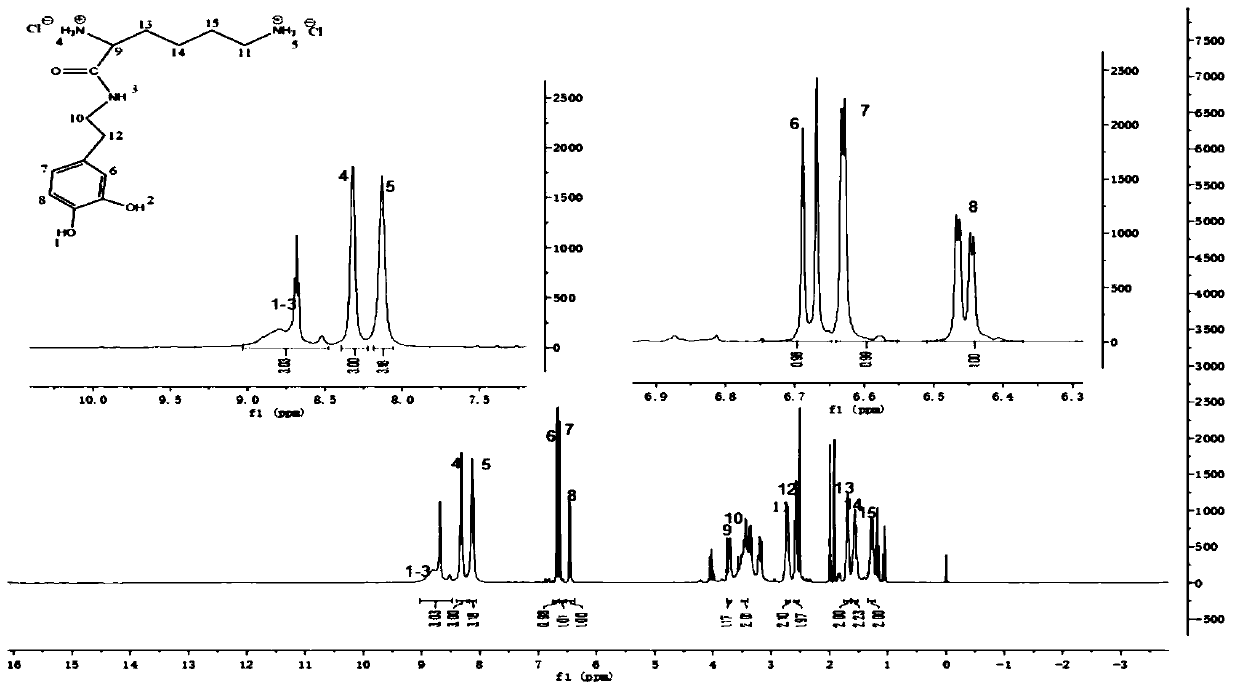

[0050] The mass spectrometry data of test gained modified polyurethane chain extender is as figure 1 As shown, the H NMR spectrum is as figure 2 shown.

Embodiment 2

[0052] Synthesis of modified polyurethane:

[0053](1) React with isophorone diisocyanate, polytetrahydrofuran ether diol and hydrophilic chain extender 2,2-dimethylolpropionic acid (DMPA) according to the molar ratio of 3:2:1 to prepare modified polyurethane , denoted as PU-LDA00, its molecular weight is measured as M n =93215.

[0054] (2) React with isophorone diisocyanate, polytetrahydrofuran ether glycol, and mixed chain extender at a molar ratio of 3:2:1, wherein the mixed chain extender follows: ①Modified polyurethane chain extender and hydrophilic extender Chain agent DMPA molar ratio = 0.3:0.7; ② modified polyurethane chain extender and hydrophilic chain extender DMPA molar ratio = 0.5:0.5; prepared modified polyurethane, respectively marked as PU-LDA30, PU-LDA50, measured its The molecular weights are ①M n =108864; ②M n =112350.

[0055] The modified polyurethane emulsion obtained above was cast into a film to obtain a film with a thickness of 0.1mm, and the wat...

Embodiment 3

[0064] The synthesis of the multilayer condom containing modified polyurethane raw material, its preparation method comprises the following steps:

[0065] (1) Preparation of inner film:

[0066] In terms of solid mass percentage, it is polymerized and emulsified from the following components: 19.2% diisocyanate, 68.9% polymer diol, 6.4% polysiloxane diol, 1.67% fluorine-containing chain extender, and chain extender I1. 13%, hydrophilic chain extender 2.7%; Wherein, diisocyanate is isophorone diisocyanate (IPDI); Polymer diol is polybutylene adipate diol (PBA molecular weight 2000); Siloxane diol is dimethyl siloxane with active end group, the end group of siloxane is connected with the active terminal hydroxyl group through ether carbon chain, and its molecular weight is 2500; the fluorine-containing chain extender is a side chain fluorine-containing carbon chain Segment of dihydric alcohol, the fluorocarbon chain of the side chain is a non-perfluorocarbon chain of 5 carbons...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com