Automobile energy absorption box structure

An energy-absorbing box and automobile technology, which is applied to the substructure, vehicle parts, transportation and packaging, etc., can solve the problem that the energy-absorbing box cannot be fully crushed to absorb energy, so as to improve the energy-absorbing effect of collapse, save costs, and improve production. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

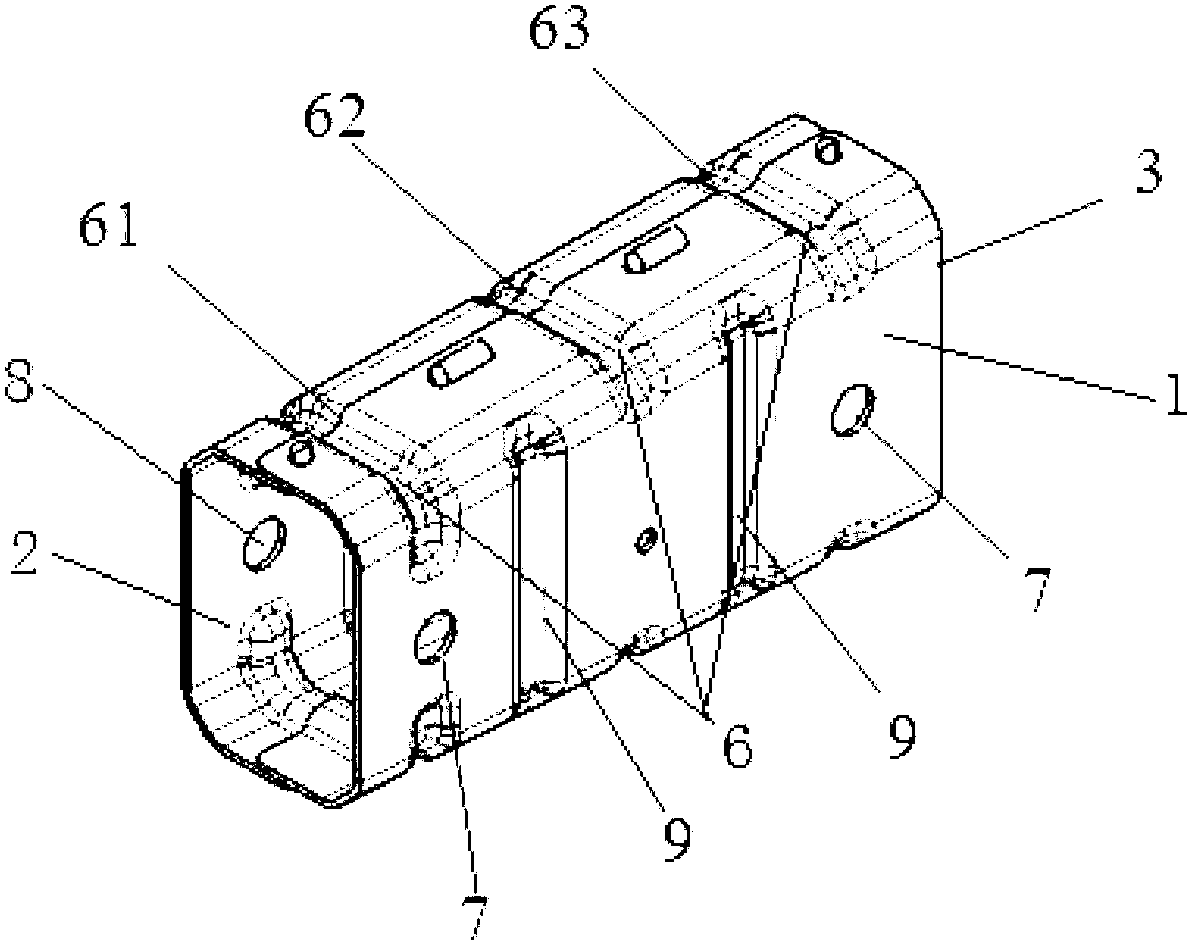

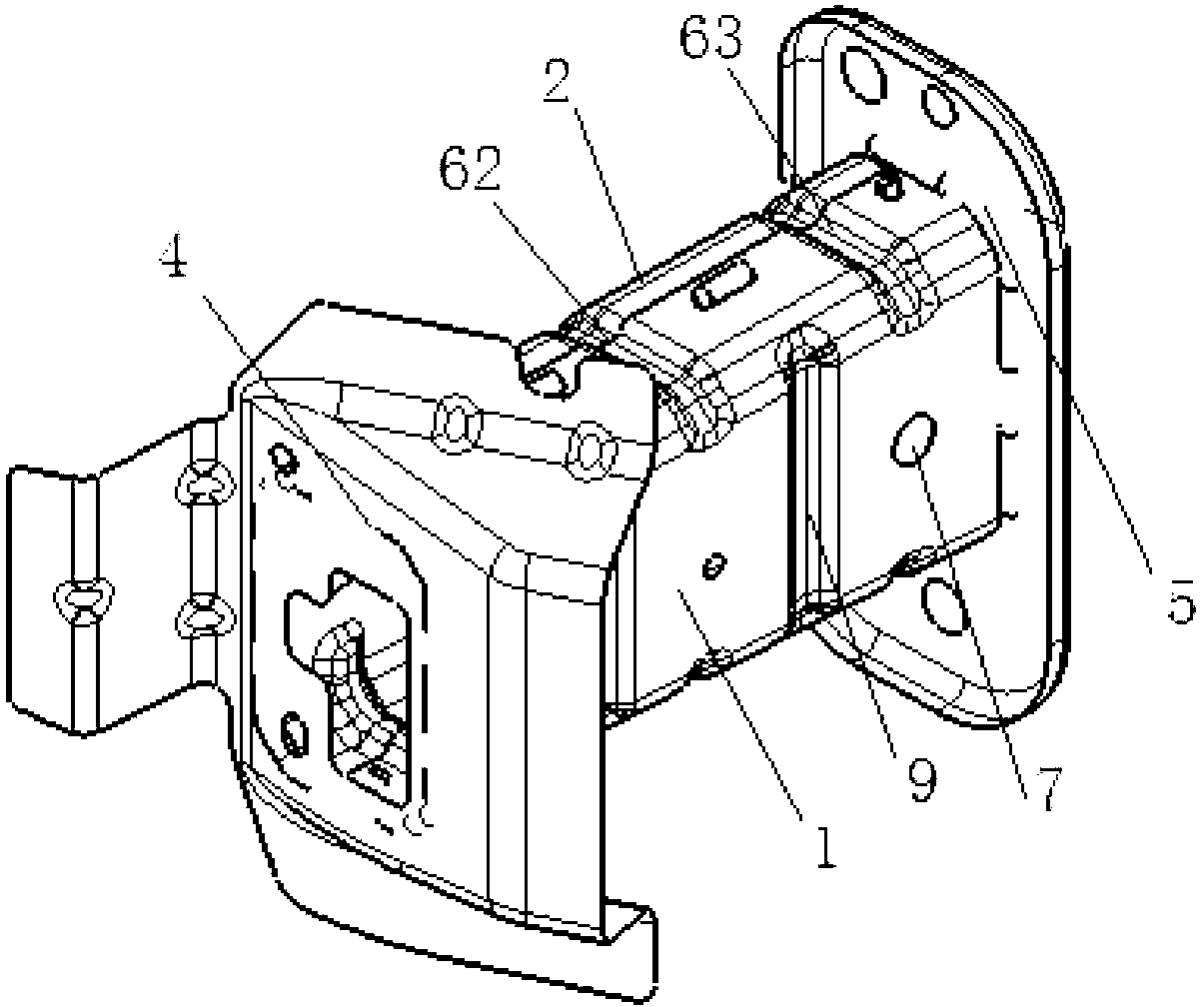

[0017] Example: such as figure 1 , figure 2 As shown, an automobile crash box structure includes a crash box body 3 composed of overlapping U-shaped crash box outer panels 1 and U-shaped crash box inner panels 2, and the front end of the crash box body 3 is fixedly arranged There is a front end plate 4, and a rear end plate 5 is fixedly arranged at the rear end of the energy absorbing box body 3; a group of energy absorbing plates are arranged symmetrically on the overlapping surfaces of the U-shaped energy-absorbing box outer plate 1 and the U-shaped energy-absorbing box inner plate 2 Rib 6; the crash box body 3 is a conical structure with a cross-sectional area increasing along the direction from the front to the rear of the vehicle. The arrangement position of the energy-absorbing ribs 6 overlaps with the waveform of the crush wave; the width of the energy-absorbing ribs 6 is equal to the half-wavelength of the crush wave. The group of energy-absorbing ribs 6 includes a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com