A valve and a wheel

A wheel and valve technology, applied in the direction of wheels, valve details, diaphragm valves, etc., can solve the problems of increasing the running resistance and noise of the wheel, increasing the air resistance of the spoke, and increasing the surface area of the spoke, so as to reduce the wind resistance and increase the rim dispersion. , the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

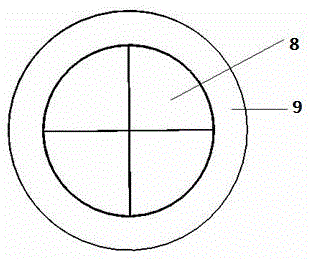

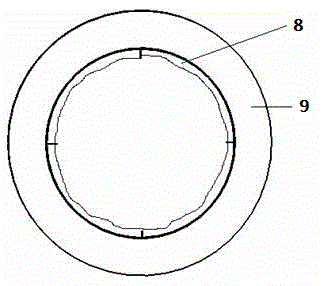

[0027] Embodiment 1: as figure 1 , figure 2 As shown, the valve provided by the present invention is composed of a shape memory metal sheet 8 and a frame 9, the shape memory metal sheet 8 is fixedly connected to the inner ring of the frame 9, and the number of shape memory metal sheets is multiple, for example figure 1 with Figure 7 As shown, the number of shape memory metal sheets 8 is four. The fixed connection method adopts welding, metal glue or clamping method. Such as figure 1 , when the ambient temperature is at or below a specific temperature, the shape memory metal sheet 8 remains closed, such as figure 2 , when the temperature exceeds a specific temperature, the shape memory metal sheet 8 is heated and shrinks to the surroundings, and the valve is opened, so as to achieve the function of controlling the fluid flow. It should be pointed out that the concept of low temperature, critical temperature and high temperature mentioned in the present invention is not ...

Embodiment 2

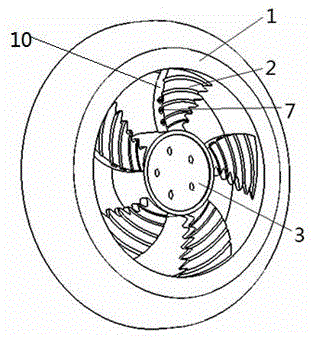

[0028] Embodiment 2: as image 3 , Figure 4 with Figure 5 As shown, in a wheel, the air inlet 5 of the ventilation hole 4 is arranged on the side of the spoke in the windward direction, and the air outlet 6 is arranged behind the spoke, and the air inlet 5 and the air outlet 6 communicate with each other to form the ventilation hole 4 . A ventilation hole 4 is provided on the side of the spoke 2, and a valve 7 provided by the present invention is provided at the air inlet 5 of the ventilation hole 4. The valve 7 is set at the air inlet 5 of the ventilation hole 4 through two technical schemes: the first scheme is that the valve 7 is directly fixedly connected with the air inlet 5; Figure 7 The second solution shown is that the valve 7 is fixedly connected to one end of a sleeve 11 and then the sleeve 11 and the valve 7 are inserted into the ventilation hole 4 as a whole. As a preferred technical solution, such as image 3 , Figure 4 with Figure 5 As shown, the venti...

Embodiment 3

[0029] Embodiment 3: as Image 6 As shown, the spoke 2 is connected to the hub 3, and the spoke 2 of the wheel forms an angle β with respect to the bottom surface of the hub 3, and the technical features of the angle range greater than 0° and less than 90° can reduce the windward area of the spoke 2 as a whole, and correspondingly The windward area of the air inlet 5 on the side surface 10 of the spoke 2 is increased to increase the heat dissipation performance. The spoke 2 is designed as a wing-shaped structure, and the preferred solution is to have a streamline groove structure on the surface of the spoke. During the operation of the car, the air flows through the rim groove of the spoke 2 through the asymmetric wing-shaped spoke 2. The technical features of asymmetry, wing shape or rim groove can reduce the air resistance and noise of the car running, and improve the driving performance of the car. . In this embodiment, the fixed connection method adopts welding, meta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com