Novel device and method for testing minimum bend radius of ocean engineering flexibility pipeline and cable

A technology for marine engineering and testing devices, which is applied to measurement devices, mechanical measurement devices, and mechanical devices. It can solve the problems of inconvenient data processing, waste of experimental samples, inaccurate measurement results, etc. Load flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

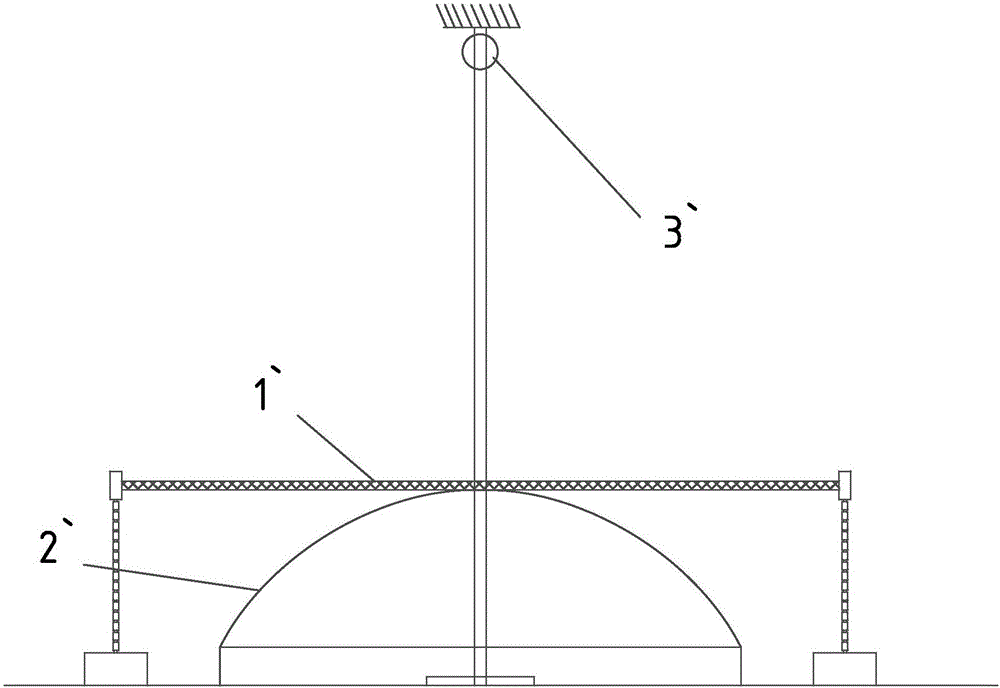

[0075] like Figure 5-Figure 14 As shown, a new type of minimum bending radius test device for flexible umbilical cables in marine engineering,

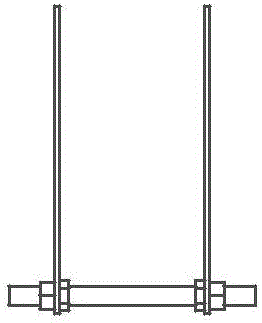

[0076] It includes an anvil, a horizontal slide rail 2, a rack 3 positioned on the horizontal slide rail 2, an actuator 4 that pushes the rack 3 to move along the horizontal slide rail 2, and an actuator 4 that cooperates with the rack 3. The pinion 5, the bull gear 6 cooperating with the pinion 5, the gear holder 7 and the rope 9 for fixing the bull gear 6 and the pinion 5,

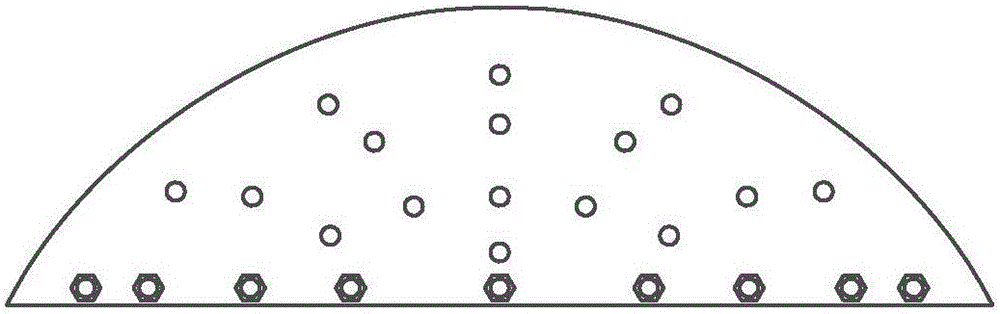

[0077] The anvil comprises an arc plate 1, a pipe cable bending support plate 8 and a supporting truss structure 20 for fixing the arc plate 1,

[0078] The gear end surface on one side of the bull gear 6 has a cylindrical winding part 10 coaxial with the bull gear 6, and one end of the rope 9 is fixed on the side wall of the cylindrical winding part 10,

[0079] The radius of curvature of the outer edge of the horizontal section of the arc plate 1 changes li...

Embodiment 2

[0092] A new method for testing the minimum bending radius of flexible umbilical cables in marine engineering has the following steps:

[0093] S1, design a kind of novel marine engineering compliance pipe cable minimum bending radius testing device as described in embodiment 1;

[0094] S2. Connect one end of the umbilical cable 13 vertically to the joint fixing device 12 through the umbilical cable joint, the free end of the umbilical cable 13 is connected to the rope 9, and the rope 9 passes through the horizontal through hole 11, and wound on the side wall of the cylindrical winding part 10;

[0095] S3. On the busbar of the umbilical cable 13 farthest from the arc plate 1, a plurality of openings are densely arranged, capable of leaking the armored steel wire inside the umbilical cable 13, and capable of accommodating strain gauges, Bond the strain gage to the armored steel wire with glue, and fix one end of the cable connected to the strain gage to the umbilical cable 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com