Electro-contact abrasion test bench for cylindrical conductive slip ring

A conductive slip ring and electrical contact technology, which is applied in the direction of testing wear resistance, can solve the problems of less design and development of electrical contact sliding friction and wear test equipment, and achieve the effects of flexible loading, convenient speed regulation, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

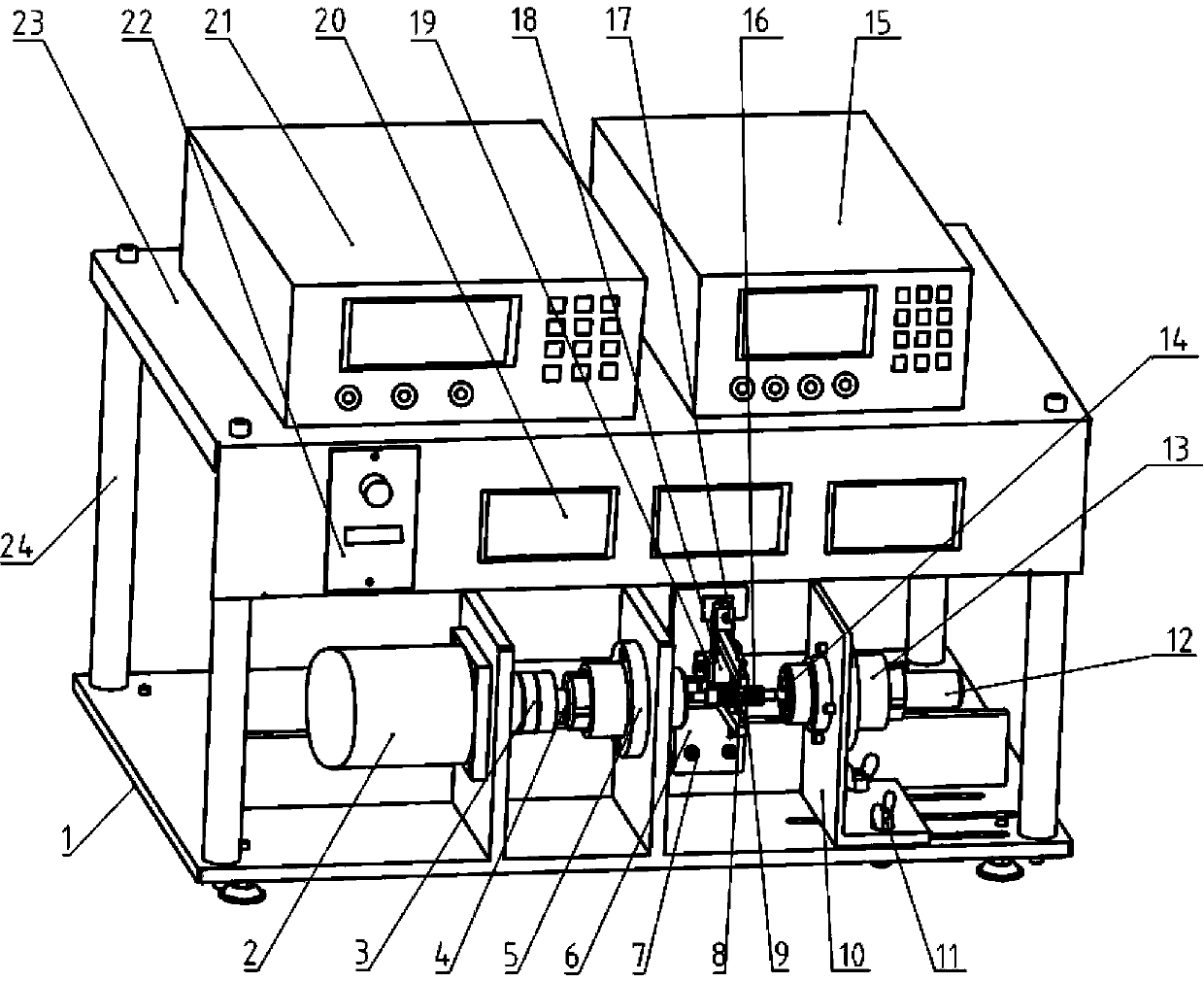

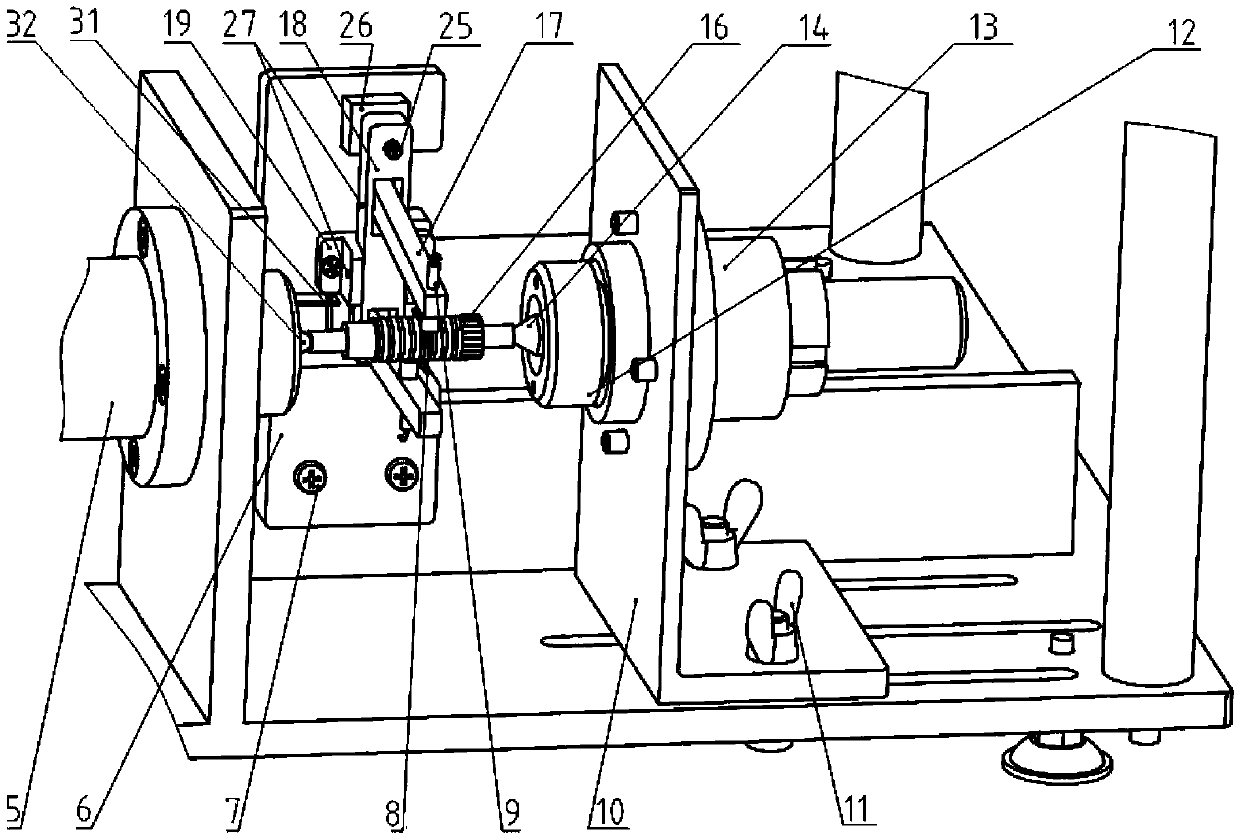

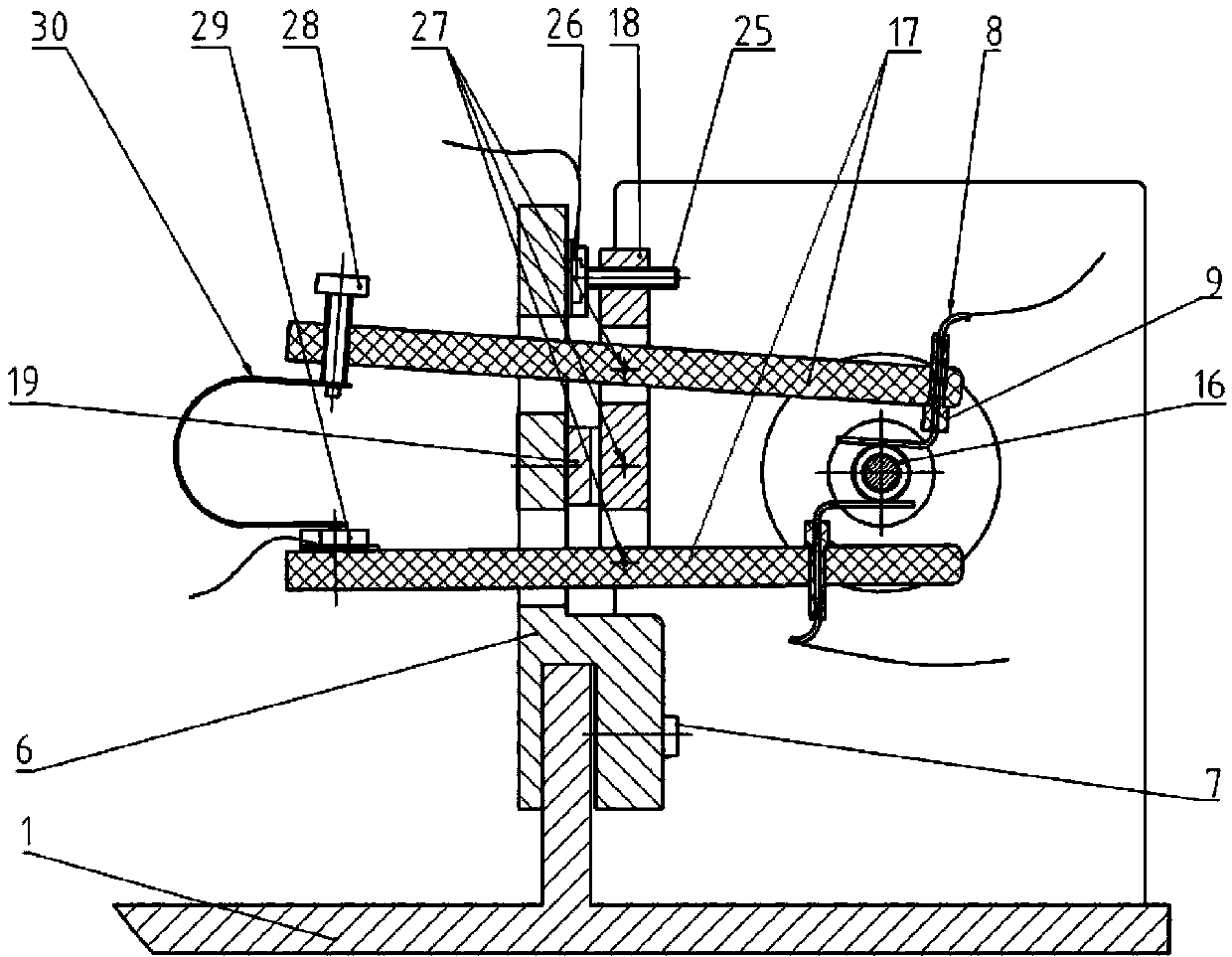

[0016] The specific embodiment of the present invention is described in detail in conjunction with technical scheme and accompanying drawing: figure 1 It is an overall structure of a cylindrical conductive slip ring electrical contact wear test bench, and its layout is as follows: four supporting columns 24, a driving motor 2, an adjustable bracket 10, a sliding seat 6, and a left belt seat bearing 5 are installed on the base 1 And right belt seat bearing 12. An upper supporting plate 23 is installed on the support column 24 so as to place a standard driving voltage and current source 15 and a contact resistance measuring instrument 21 , and the front panel is equipped with a digital display head 20 and a motor governor 22 . The driving motor 2 is fixed on the base 1, and the rotation is transmitted to the driving shaft 4 through the coupling 3. The driving shaft 4 is mounted on the left bearing 5 with a seat, and the driven shaft 12 is mounted on the right bearing 13 with a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com