Vehicle transporting center axle train

A central axle and vehicle technology, which is applied in the field of transport vehicles, can solve the problems of unsatisfactory transportation efficiency, excessive external dimensions, hidden dangers of vehicle safety, etc., and achieve the effect of light weight, small turning radius and flexible loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

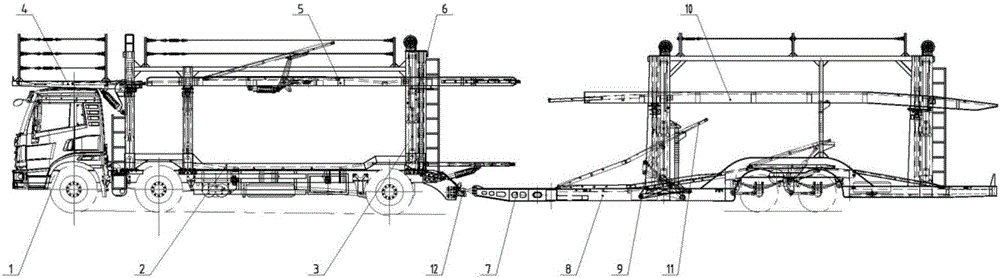

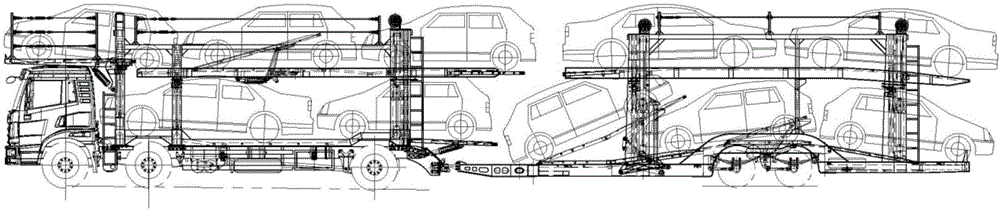

[0046] see figure 1 , figure 2 , the present invention discloses a vehicle transport center axle train, said train comprising: traction main car part, center axle trailer part, connecting coupler 12, hydraulic system, air system, circuit system;

[0047] The traction main vehicle part includes chassis 1, sub-frame 2, main vehicle side panel 3, main vehicle front upper turning platform 4, main vehicle rear upper platform 5, rear turning springboard 6; center axle trailer part includes traction rod 7 , the trailer frame 8, the trailer side piece 9, the trailer upper platform 10, the flipping springboard mechanism 11, the traction main vehicle part and the central shaft trailer part are hinged together with the drawbar through the connecting coupler 12;

[0048] The rear axle of the chassis 1 adopts air suspension, and a control switch is installed in the cab to control the air suspension airbag lifting of the rear axle to realize the height adjustment of the main vehicle;

[...

Embodiment 2

[0061] see figure 1 , the present invention discloses a vehicle transport center-axle train, the train includes: a traction main car part, a center-axle trailer part, and a connecting coupler 12;

[0062] The traction main vehicle part includes chassis 1, auxiliary frame 2, main vehicle side panel 3, main vehicle front upper turning platform 4, main vehicle rear upper platform 5, tail turning springboard 6, and the central axle trailer part is formed by a traction rod 7 , trailer frame 8, trailer side piece 9, trailer upper platform 10, flip springboard mechanism 11, traction main vehicle part and central axle trailer part are connected with drawbar by connecting coupler 12.

[0063] To sum up, the vehicle transport center axle train proposed by the present invention realizes the stacking of vehicles through multiple sets of overturned springboards, effectively utilizes the loading space, and makes loading more flexible and compact, which can meet the requirements of different...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com