Body-like node aluminum alloy space truss structure

A network frame structure and aluminum alloy technology, which is applied to building structures, bridge parts, bridge materials, etc., can solve the problems of undiscovered aluminum alloy network frame structure, reduced strength of welded aluminum alloy materials, and high requirements for aluminum alloy welding technology. It achieves the effects of convenient processing and manufacturing, construction and installation, load reduction, and low project life and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0078] The present invention is further described below in conjunction with accompanying drawing.

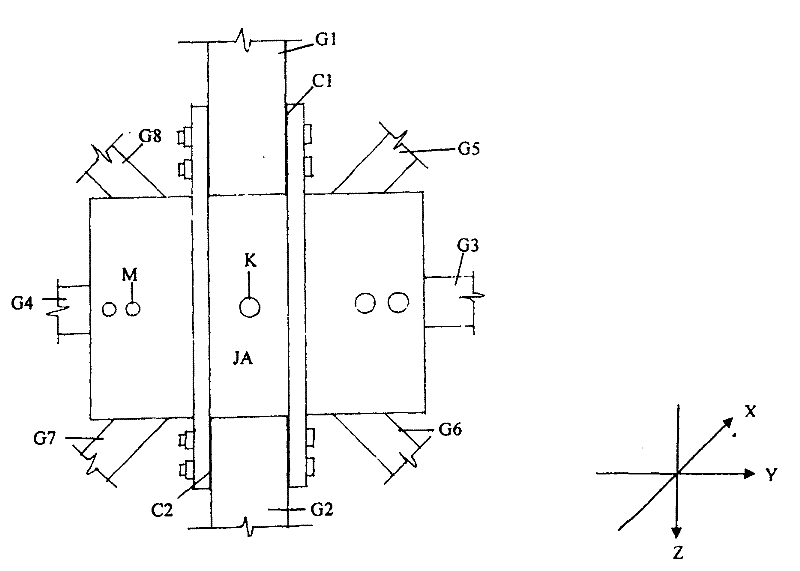

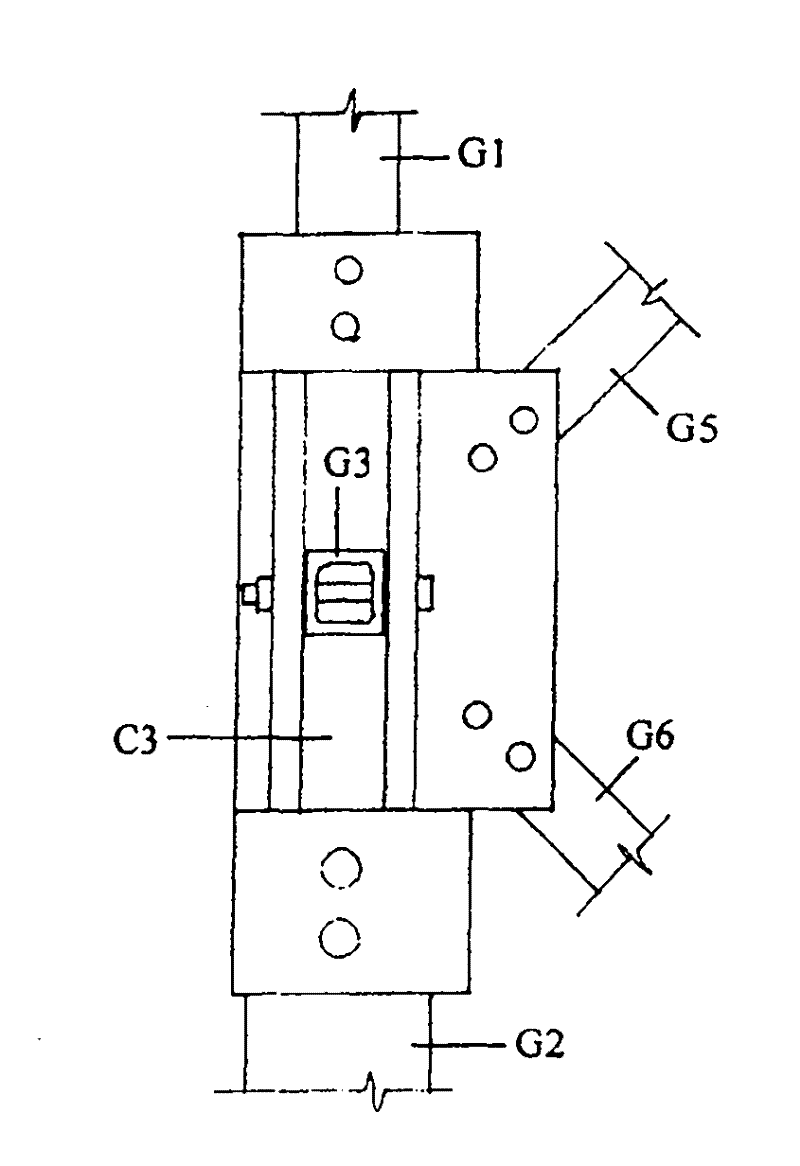

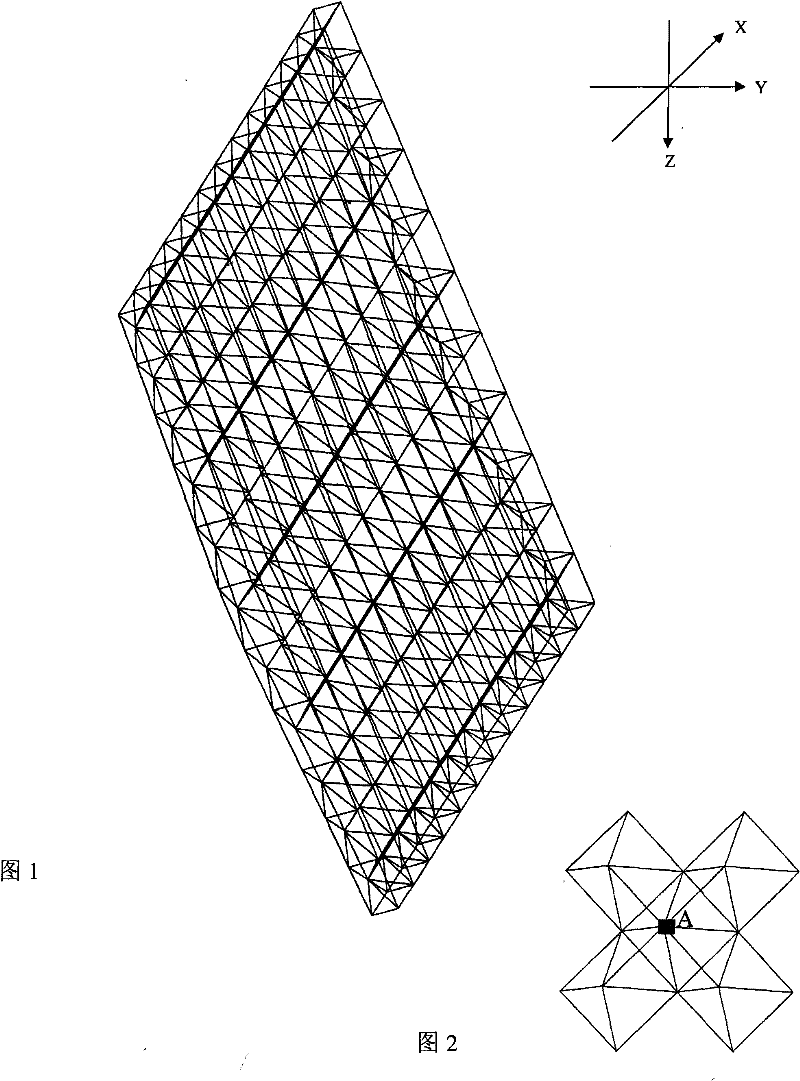

[0079] According to the composition of grid units, the grid structure is generally divided into: plane truss system grid, quadrangular pyramid system grid, and triangular pyramid system grid. figure 1 It is an example of a body-node aluminum alloy orthogonally placed quadrangular pyramid grid structure, figure 2 It is a partial enlargement of the grid structure. All chords, webs and all nodes of the grid frame are made of aluminum alloy. The node structure of the grid structure can all use the planted plate type body nodes, can also use all the planted pole type body nodes, can also use all the planted plate, planted pole hybrid type body nodes, or can be the above three types of body nodes. Nodes are used together. All the rods of the network frame are connected with the node bodies with stainless steel or aluminum alloy bolts or rivets. Rods, node bodies and bolts must b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com