Spatial box type cabin structure

A space and cabin technology, applied in the aerospace field, can solve the problems of poor adaptability of later mechanism and equipment installation and adjustment, increase the difficulty of accuracy guarantee and development cost, and complex assembly form of space truss, so as to ensure structural rigidity and light weight. Design requirements and the effect of meeting structural precision design requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

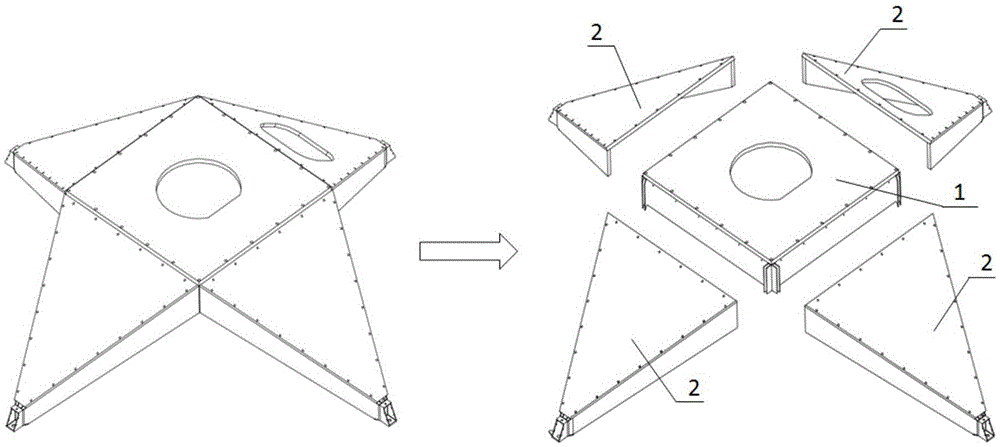

[0024] See figure 1 , figure 1 It is a schematic configuration diagram of the space box type cabin structure of the present embodiment; wherein,

[0025] The space box-type cabin structure includes a square box (1) and four triangular boxes (2), the square box (1) is located at the center of the space box-type cabin structure, and the triangular boxes (2) are evenly distributed on The four sides of the square box (1), and the four triangular boxes (2) are in the form of space angles with the square box (1); the overall configuration of the space box-type cabin structure is from top to bottom through the triangle The box (2) is gradually drawn together to finally realize a four-point support structure. Such a structure effectively simplifies the connection and separation design of cabin sections, and reduces the structural space occupation requirements.

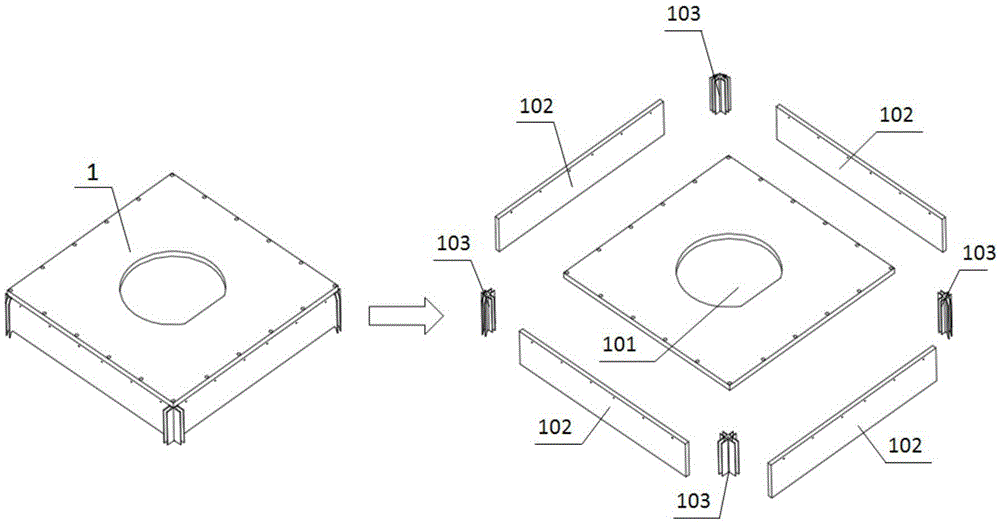

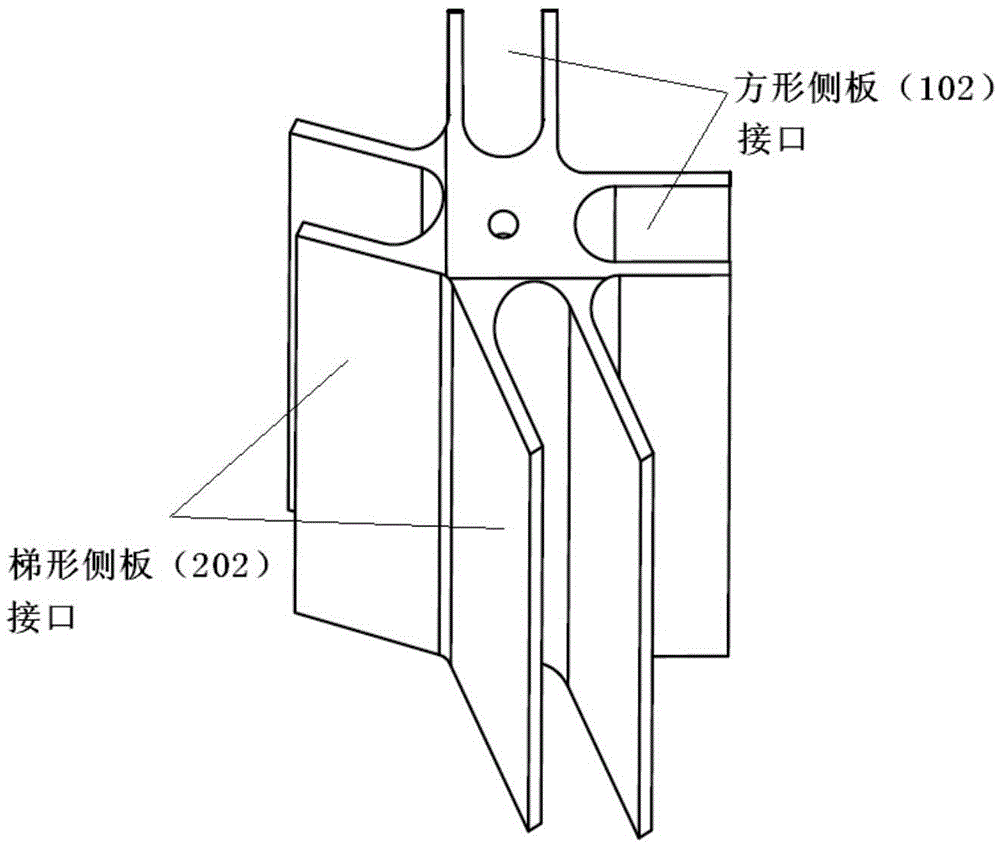

[0026] See figure 2 and image 3 ,in figure 2 is a schematic diagram of the structural composition of the square box...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com