Eighteen-roller rolling mill structure

An 18-high rolling mill frame technology, applied in the field of 18-high rolling mill structure, can solve the problems of poor lubrication of rolls and strips, inconvenient equipment maintenance, and small opening of the rolling mill, so as to achieve good lubrication conditions and save equipment investment , increase the effect of rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in detail below in conjunction with the accompanying drawings.

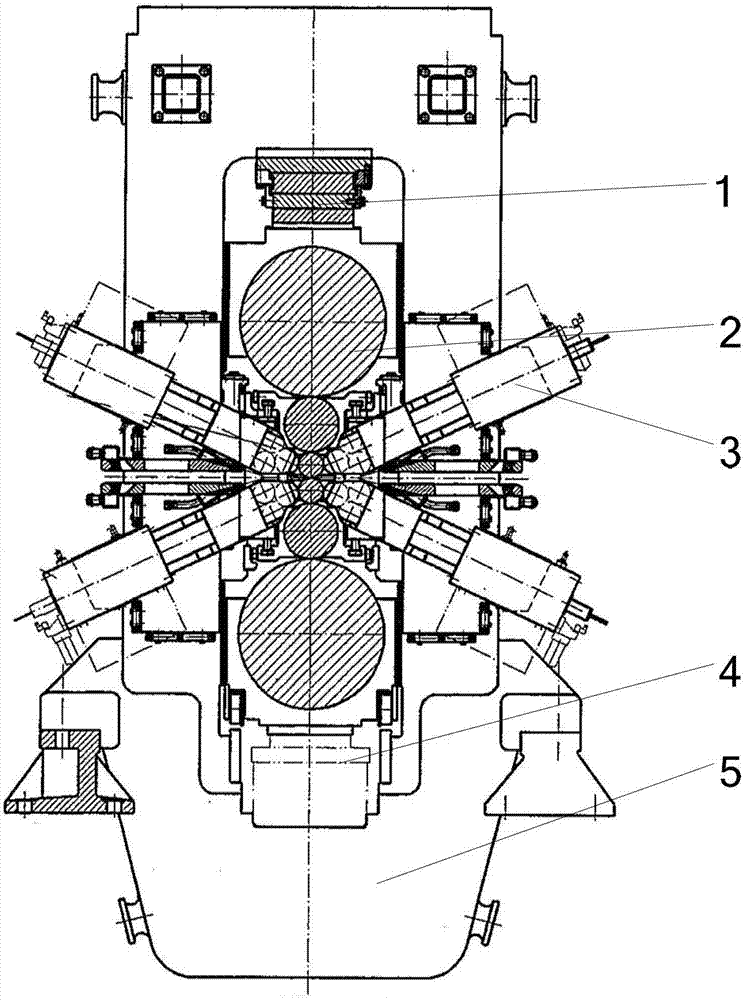

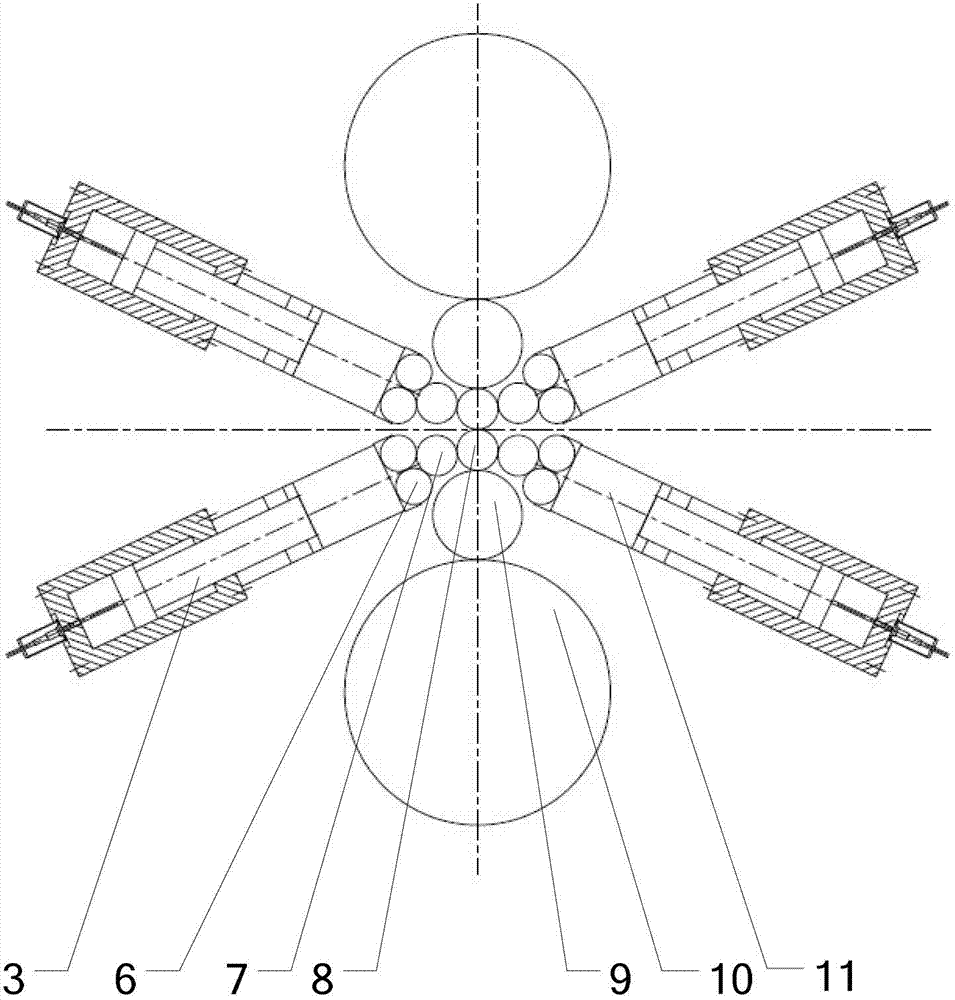

[0013] refer to figure 1 and figure 2 , an eighteen-high rolling mill structure, including a rolling line adjustment device 1, a roll assembly 2, a side push cylinder 3, a pressing oil cylinder 4, a frame assembly 5, side support rolls 6, side rolls 7, work rolls 8, and intermediate rolls 9. Backup roll 10, two work rolls 8, two intermediate rolls 9, two support rolls 10, eight side support rolls 6 and four side rolls 7 form an eighteen-roll type, and the work roll 8 passes through the intermediate roll 9 by Back-up roll 10 is supported, and back-up roll 10 is connected with pressing oil cylinder 4, and the side support device of work roll 8 is contained in the front and back of rolling mill frame assembly 5 respectively, and is arranged up and down.

[0014] The side support device includes a side roller 7, a side support roller 6, and a side support bearing seat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com