Bridging arrangement of vehicle beam and left-right longeron

A joint structure, left and right technology, applied in the field of automobile beam lap joint structure, can solve the problems of process notch cracking, lap edge flanging stress concentration, poor transmission effect, etc., to increase the effective area, to ensure the overall strength and stiffness requirements, Delivery and decomposition of improved effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

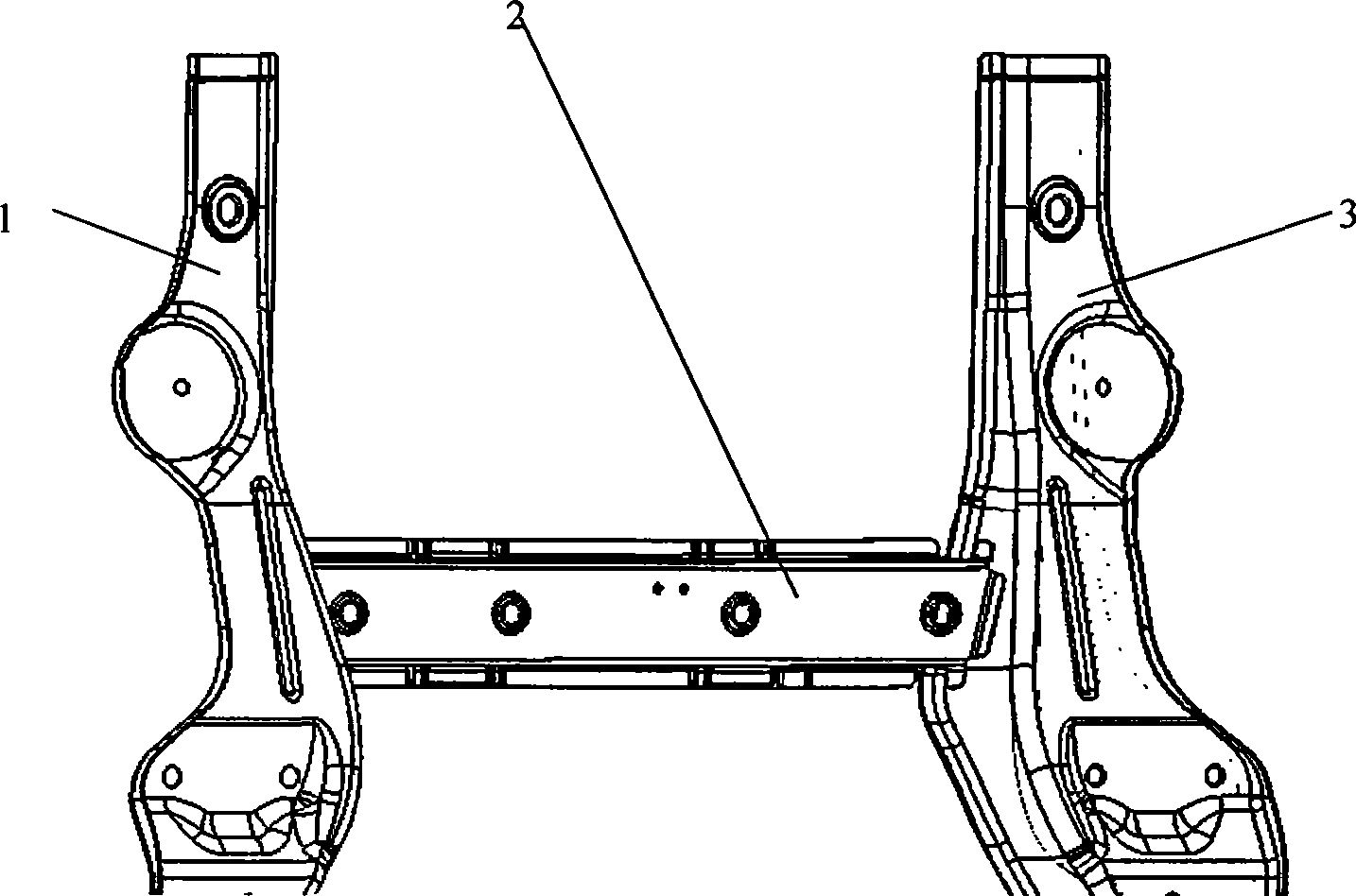

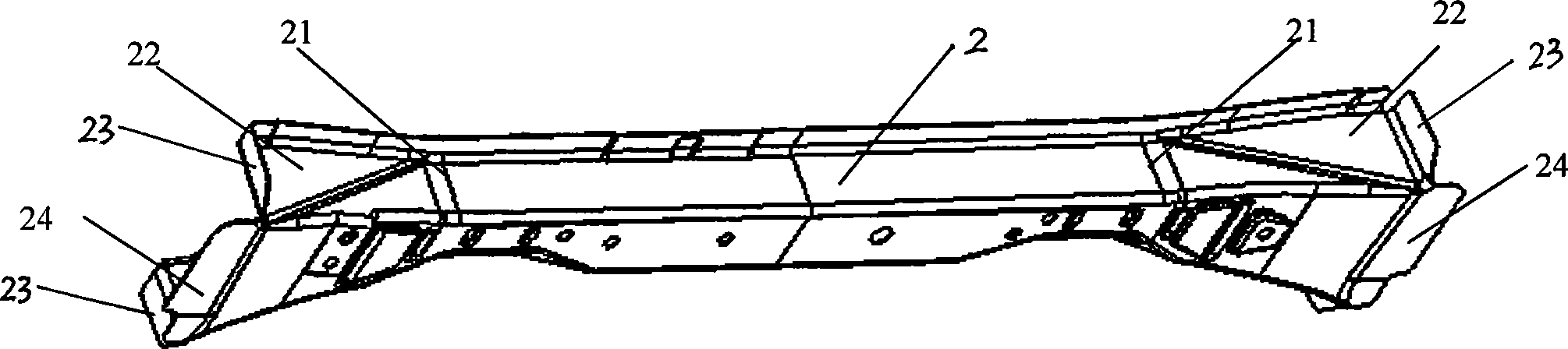

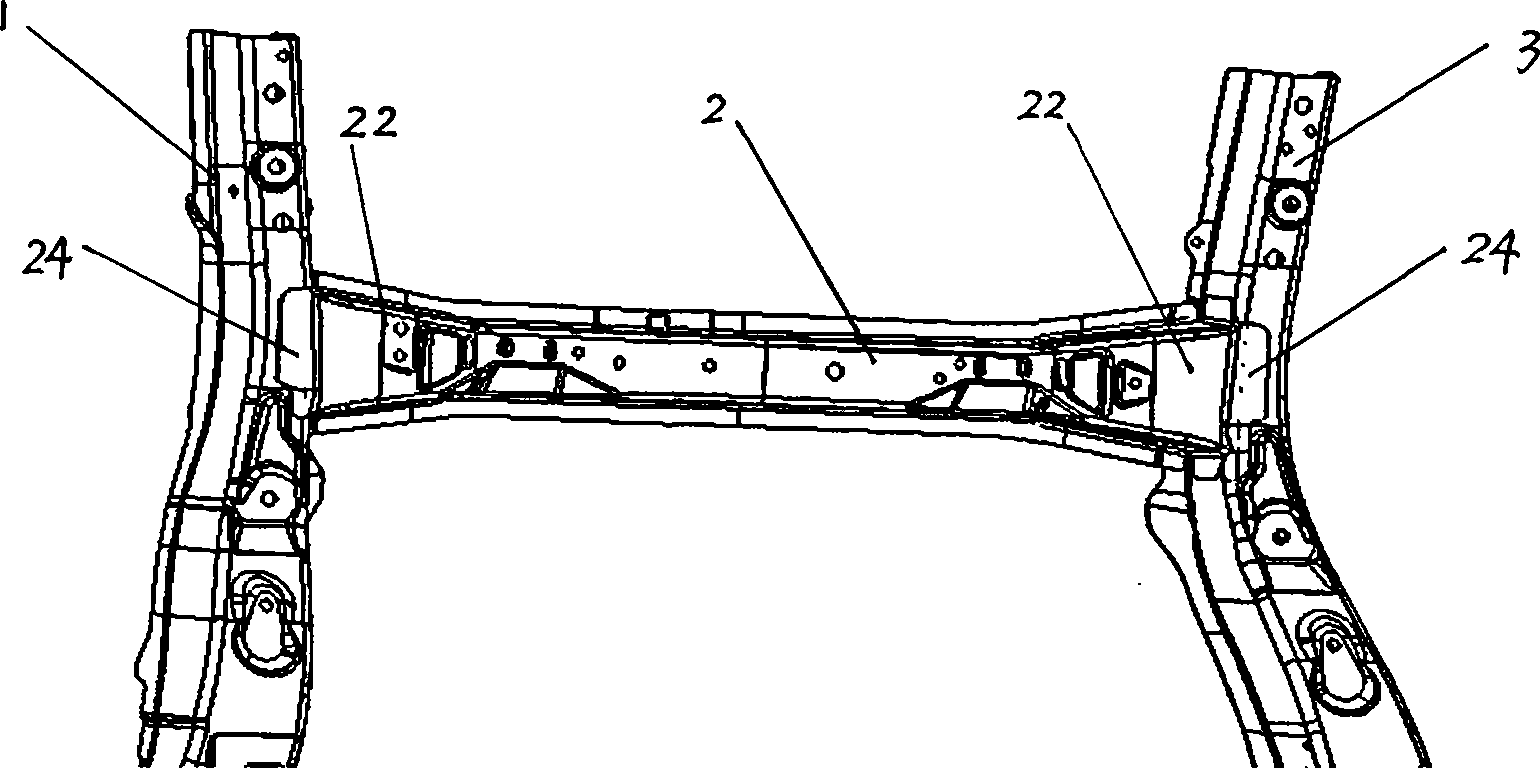

[0009] Such as figure 2 As shown, the cross-beam 2 of the car cross-beam lap structure is a "U"-shaped cross-section part, and the middle of the cross-beam 2 is small. As the cross-beam gradually extends to both ends, the cross-section continues to increase, and a gradually-increasing bell-mouth structure is formed at both ends. 21. The specific position on the beam that gradually increases, that is, the block line 21 in the figure, needs to be finally determined according to the surrounding structure and CAE verification analysis. The end edge of crossbeam 2 is formed with two symmetrical flanging laps 23 and straight edge lapping 24, and two flangings lapping 23 are lapped on the inner surface of left and right longitudinal beam 1 and 3 namely with automobile. On the Z-direction plane based on the coordinate system, the straight side overlapping edge 24 is overlapped on the upper surfaces of the left and right longitudinal beams 1 and 3, that is, on the X-direction plane ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com