Offshore platform hydraulic self-lifting device

A self-elevating technology for offshore platforms, applied in water conservancy projects, artificial islands, underwater structures, etc., can solve problems such as long construction work time, inconvenient operation, and inability to guarantee synchronous take-off and landing of pile legs, so as to save investment costs , fast locking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to the following embodiments.

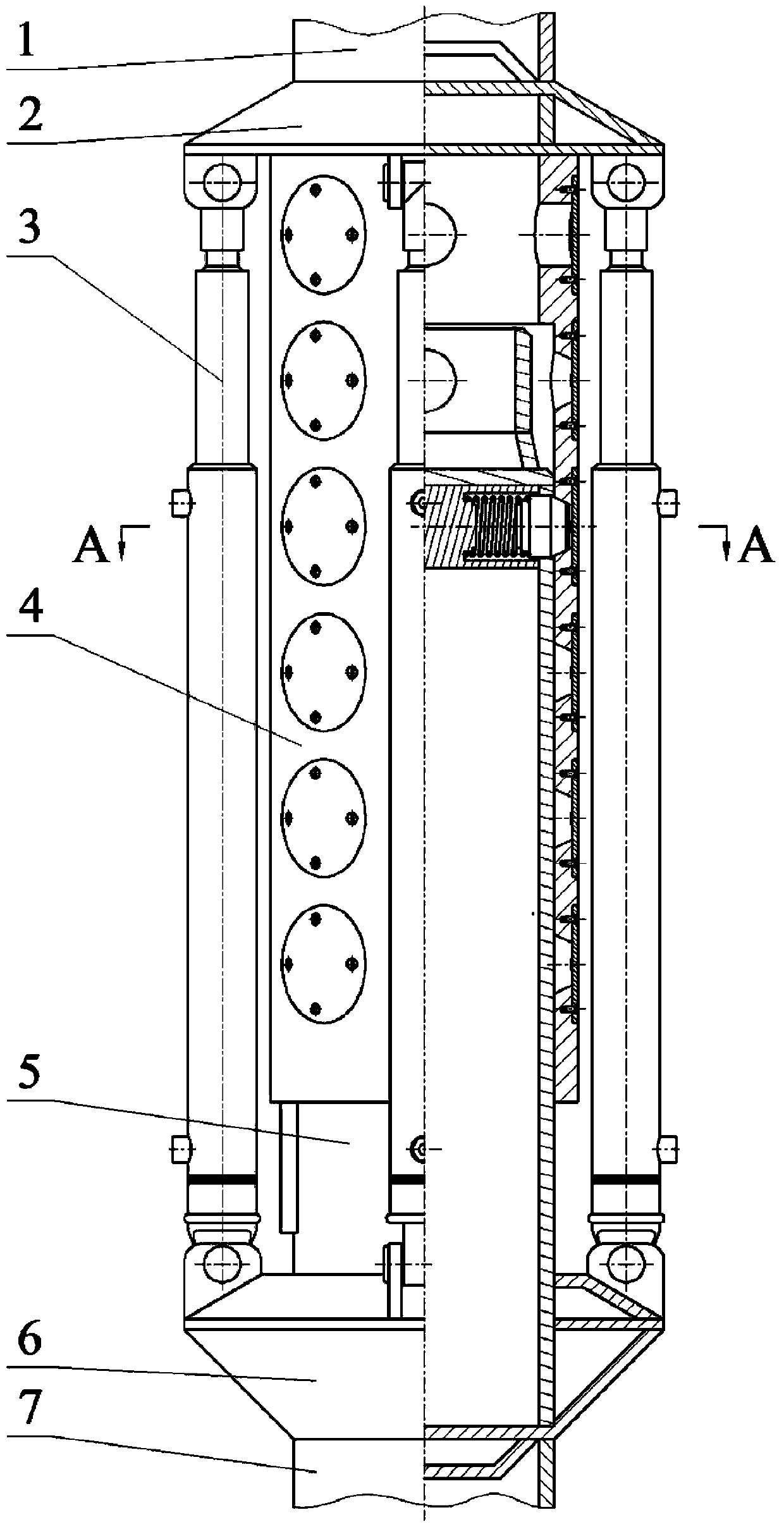

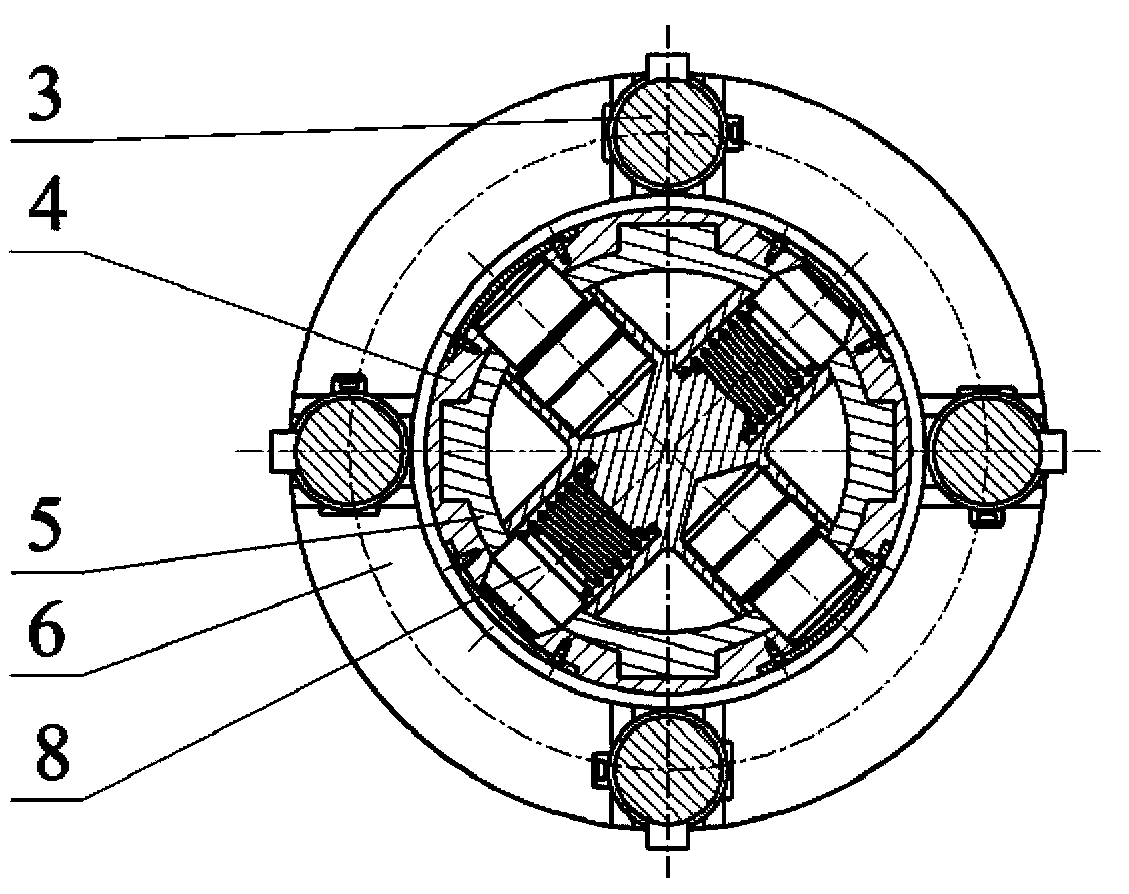

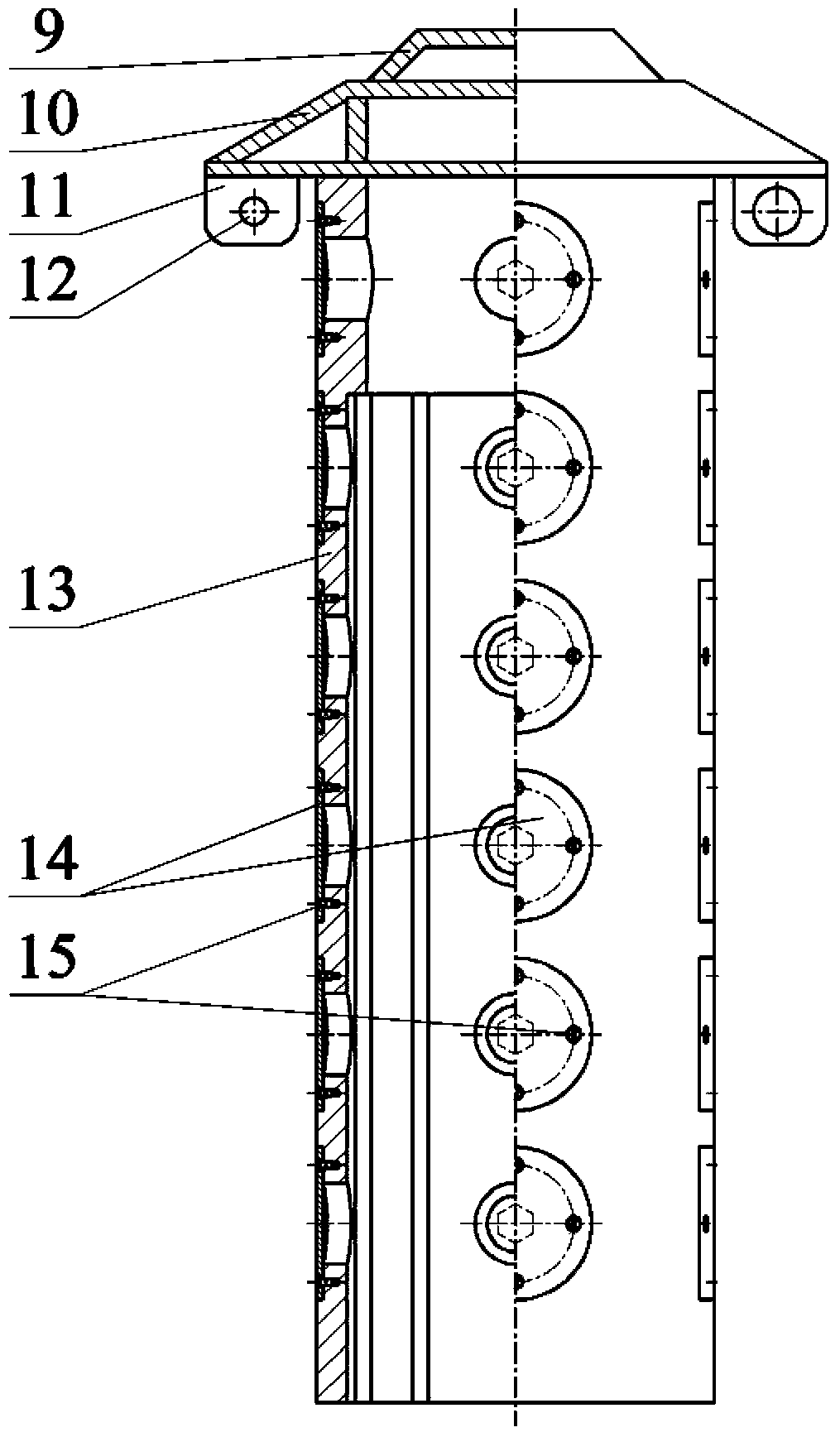

[0039] Such as figure 1 and figure 2 As shown, the offshore platform hydraulic self-elevating device provided by the present invention is the upper support 2, the hydraulic system 3, the sleeve assembly 4, the main body 5, the lower support 6 and the support body 8 on the upper part of the main body 5 from top to bottom. The upper support 2 and the sleeve assembly 4 are directly welded to the lower end of the platform leg 1 , and the body 5 and the support body 8 are directly welded to the upper end of the jacket leg 7 through the lower support 6 . Before the hydraulic self-elevating device is assembled, the outer surfaces of the upper support 2, the sleeve assembly 4, the body 5 and the lower support 6 are sprayed with paint to prevent corrosion of the device; the body 5 is placed in the sleeve a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com