Method for rolling precision stainless steel strips with Sendzimir rolling mill

A technology of stainless steel and steel rolling mills, applied in the direction of rolling mill control devices, metal rolling, metal rolling, etc., can solve the problems of costing a lot of money, and achieve the effect of reducing investment costs, low cost, and competing for speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Embodiment one. the method for rolling stainless steel precision strip steel with Sendzimir rolling mill

[0018] On the basis of the existing rolling process regulations of the 20-high Sendzimir rolling mill, add the technical regulations for rolling thickness below 0.3mm, and carry out reasonable configuration of the roll system, and calibrate the inspection instruments such as thickness gauges and shape gauges , fully meet the requirements for the production of stainless steel precision strip below 0.3m. The method of rolling stainless steel precision strips with Sendzimir rolling mills in this example has been successfully used in a steel company to produce and roll 0.25mm stainless steel precision strips. The method it adopts is specifically:

[0019] 1. The deformation rate of each pass should be allocated reasonably, and the deformation rate of each pass is set as follows: 20% for the first pass, 15% for the second pass, 12% for the third pass, 10% for the fourth...

Embodiment 2

[0026] Embodiment two. The method for rolling stainless steel precision strip with Sendzimir rolling mill

[0027] The method of rolling stainless steel precision strip steel with a Sendzimir rolling mill in this example was successfully used in a certain steel company to produce and roll 0.2mm stainless steel precision strip steel. The method it adopted was specifically:

[0028] 1. The pass deformation rate is set as follows: 20% for the first pass, 15% for the second pass, 11% for the third pass, and 9% for the finished pass;

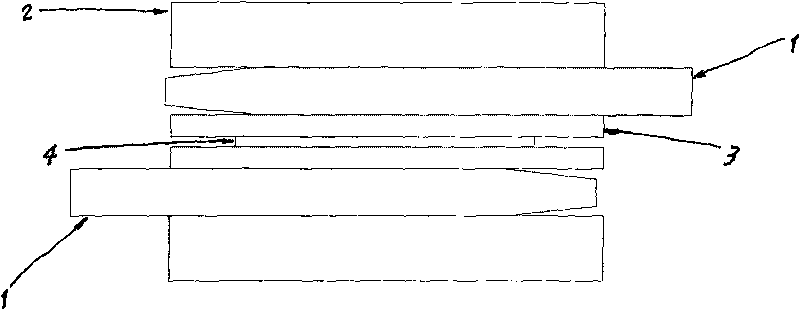

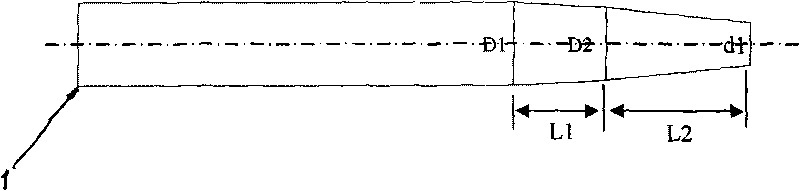

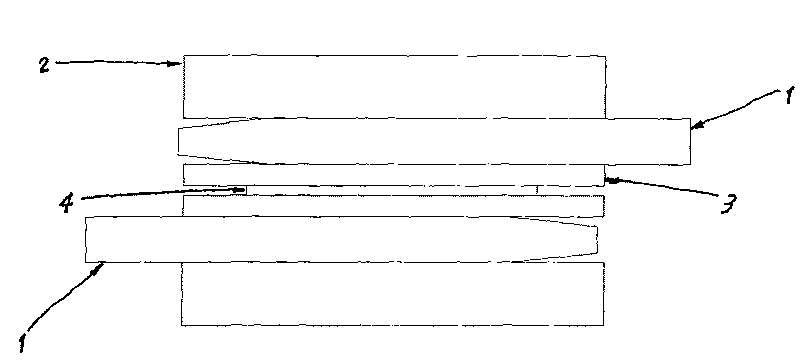

[0029] 2. The configuration of the roller system is: two intermediate free rollers with 12 upper and lower crowns, and one intermediate roller uses compound double taper. The grinding process is: the first section of the cone is 230mm long and the taper is 0.25%; the second section of the cone is 100mm long. Taper 0.14%, please refer to the attached manual figure 1 , 2 ;

[0030] 3. The operation of an intermediate roll after replacing the work ro...

Embodiment 3

[0033] Embodiment three. The method for rolling stainless steel precision strip with Sendzimir rolling mill

[0034]The method of rolling stainless steel precision strip steel with Sendzimir rolling mill in this example has been successfully used in a certain iron and steel enterprise to produce and roll 0.15mm precision strip steel. The method it adopts is specifically:

[0035] 1. The pass deformation rate is set as follows: 22% for the first pass, 18% for the second pass, 16% for the third pass, 13% for the fourth pass, and 11% for the finished pass;

[0036] 2. The configuration of the roller system is: two intermediate free rollers with 8 upper and lower crowns, and one intermediate roller uses compound double taper. The grinding process is: the first section of the cone is 220mm long and the taper is 0.18%; the second section of the cone is 100mm long, Taper 0.10%;

[0037] 3. The operation of an intermediate roll after replacing the work roll: After replacing the work ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com