6mm steel plate rolling technique

A steel plate and process technology, applied in the field of metallurgical industry plate rolling process, can solve the problems of unstable rolling, failure to form batch production capacity, rolling waste, etc., and achieve the effect of rolling stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Embodiment 1: First use more than 30 minutes to roll 13 steel plates whose thickness is between 20-7mm, arranged from thick to thin, and the thickness of the last 4 steel plates is successively 10, 9, 8, 7mm. The thickness of the slab is 120mm, and the rolling pass is set to 11 passes. The backup rolls have been used for 10 days, and the work rolls have been used for 13 hours. AGC gain setting: when the thickness of the rolled piece is ≥10mm, it is 90%, and when the thickness of the rolled piece is ≤6mm, it is 50%. The system oscillates. The rolling force of the last pass is set at 0.33 times of the maximum rolling force of the rolling mill. The adaptive coefficient of the last three passes is 0.39, and the proportional convexity is set to 0.8%. In the last three passes, the conveying roller table speed on the exit side is 3.5% faster than that of the working rolls of the rolling mill, and the conveying roller table speed on the entrance side is 3.5% slower than that...

Embodiment 2

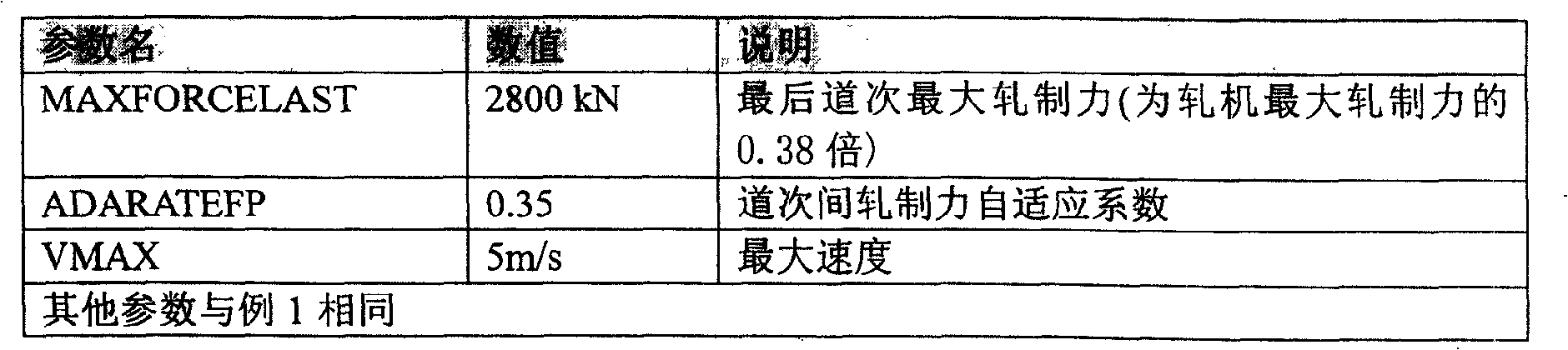

[0028] Embodiment 2: First use more than 30 minutes to roll 13 steel plates whose thickness is between 20-7mm, arranged from thick to thin, and the thickness of the last 4 steel plates is successively 10, 9, 8, 7mm. The thickness of the slab is 210mm, and the rolling pass is set to 13 passes. The backup rolls have been used for 3 days and the work rolls have been used for 15 hours. AGC gain setting: when the thickness of the rolled piece is ≥10mm, it is 90%, and when the thickness of the rolled piece is ≤6mm, it is 50%. The system oscillates. The rolling force of the last pass is set to 0.38 times the maximum rolling force of the rolling mill. The adaptive coefficient of the last three passes is 0.35, and the proportional convexity is set to 1.0%. In the last three passes, the conveying roller table speed on the exit side is 5% faster than that of the working rolls of the rolling mill, and the conveying roller table speed on the entrance side is 5% slower than that of the w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com