Support roll with high abrasion resistant performance and manufacturing method thereof

A manufacturing method and back-up roll technology, which is applied in the field of metallurgical roll manufacturing, can solve the problems affecting the surface quality of the plate and product qualification rate, can not meet the low roll consumption, long rolling cycle, affect the contact state of the work roll, etc., to achieve a variety of , enhance the wrapping ability, improve the effect of wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the examples.

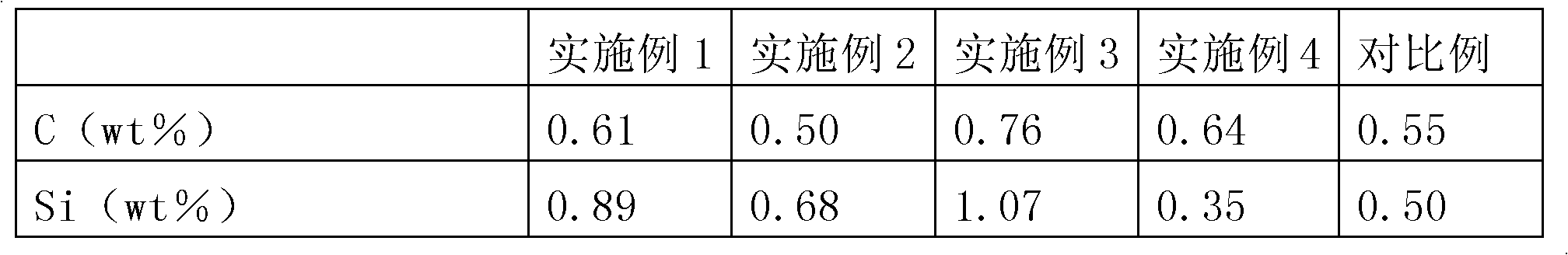

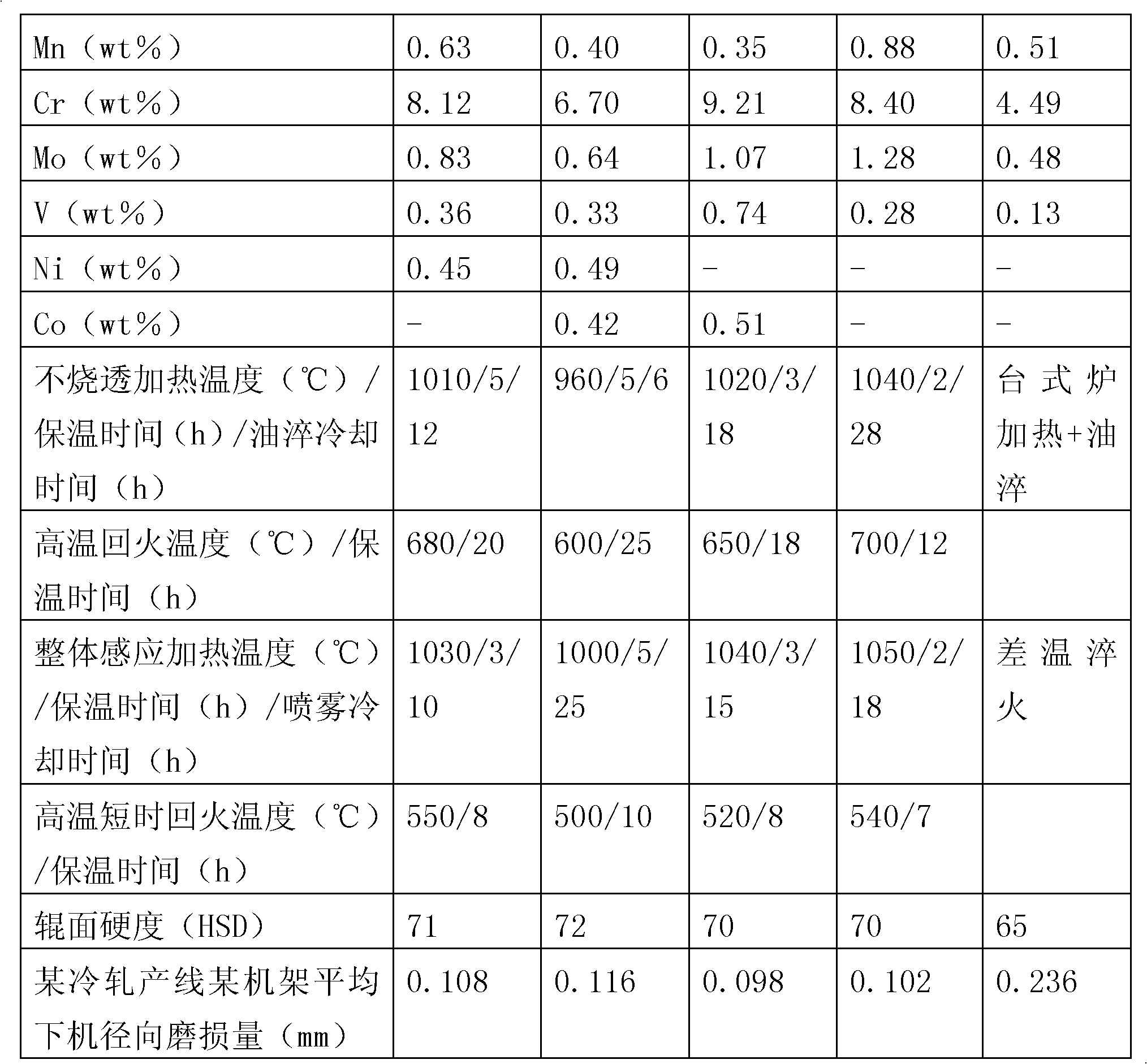

[0033] The process steps of the manufacturing method of each embodiment are basically the same as that of Embodiment 1, and the differences are shown in Table 1.

[0034] Table 1

[0035]

[0036]

[0037] According to the material and manufacturing process of the above examples, a physical support roll of φ1300mm×1550mm was produced. The average hardness value of the roll surface is 71HSD. It is used on a cold rolling production line. The amount of wear is 0.108mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com