Plate rolling mill and plate rolling method

A flat rolling mill and flat rolling technology, applied in the direction of rolling mill control device, metal rolling stand, metal rolling stand, etc., can solve the problem of inability to suppress the change of work roll offset and the inability to suppress the work roll offset , changes and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

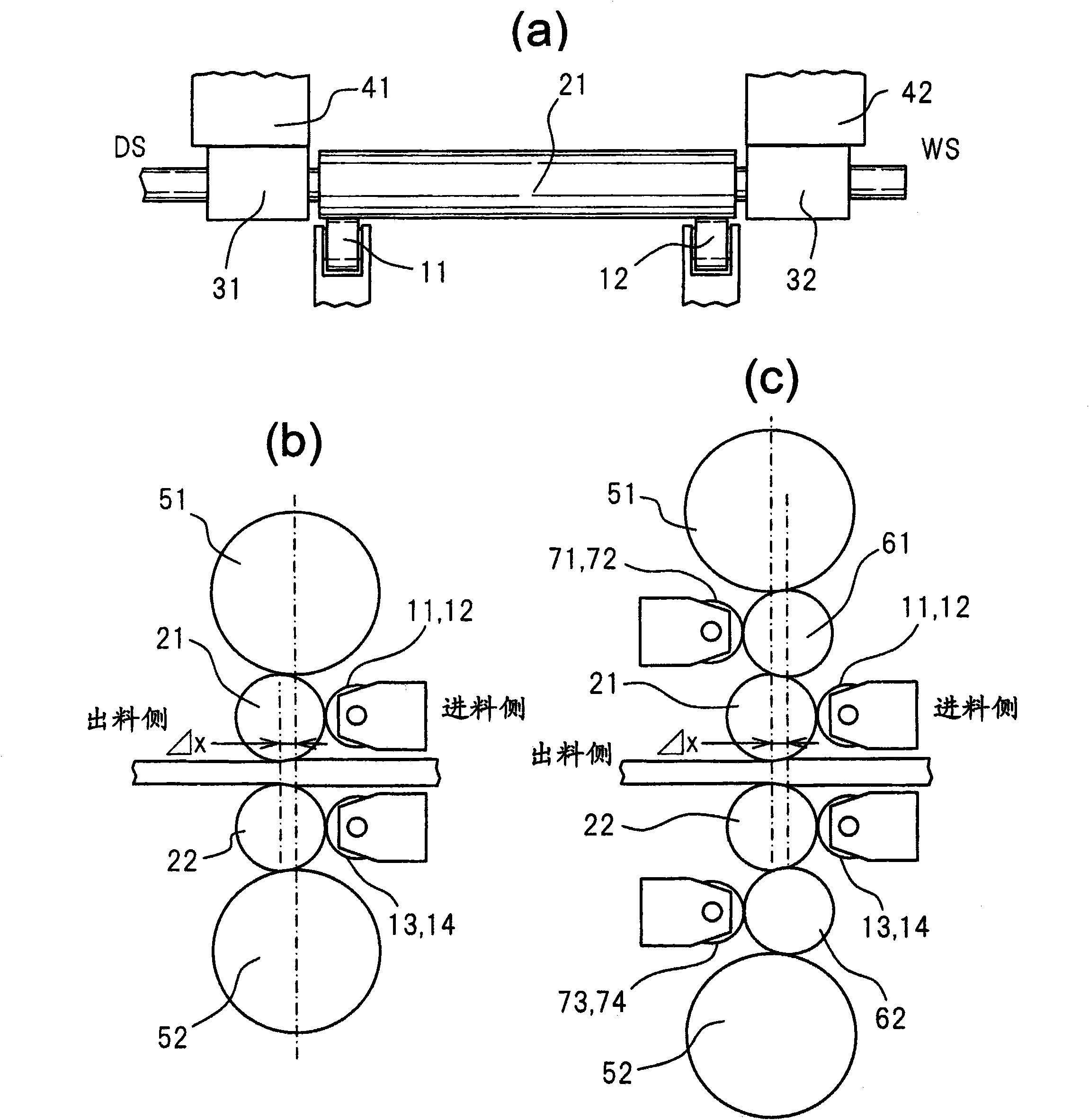

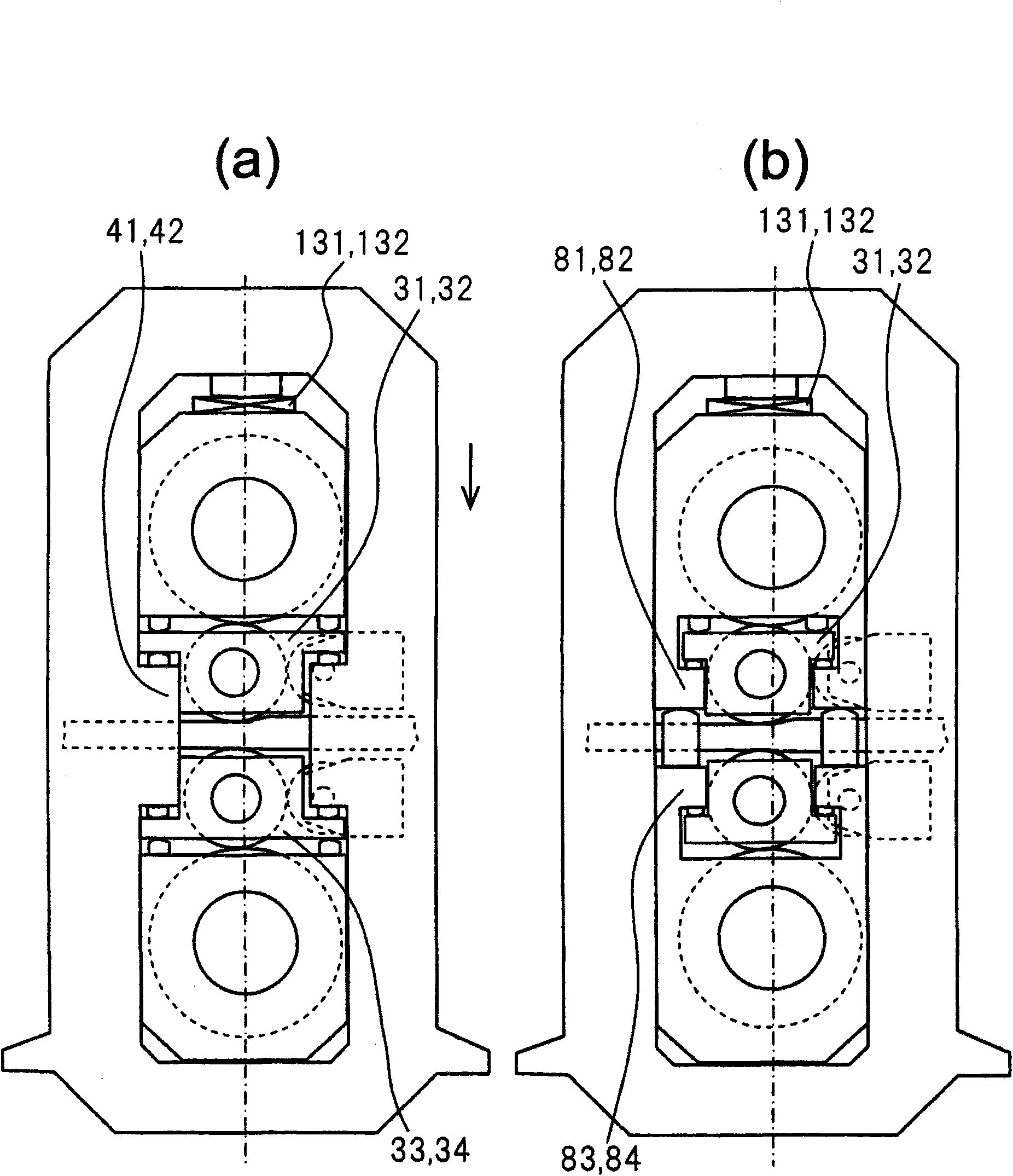

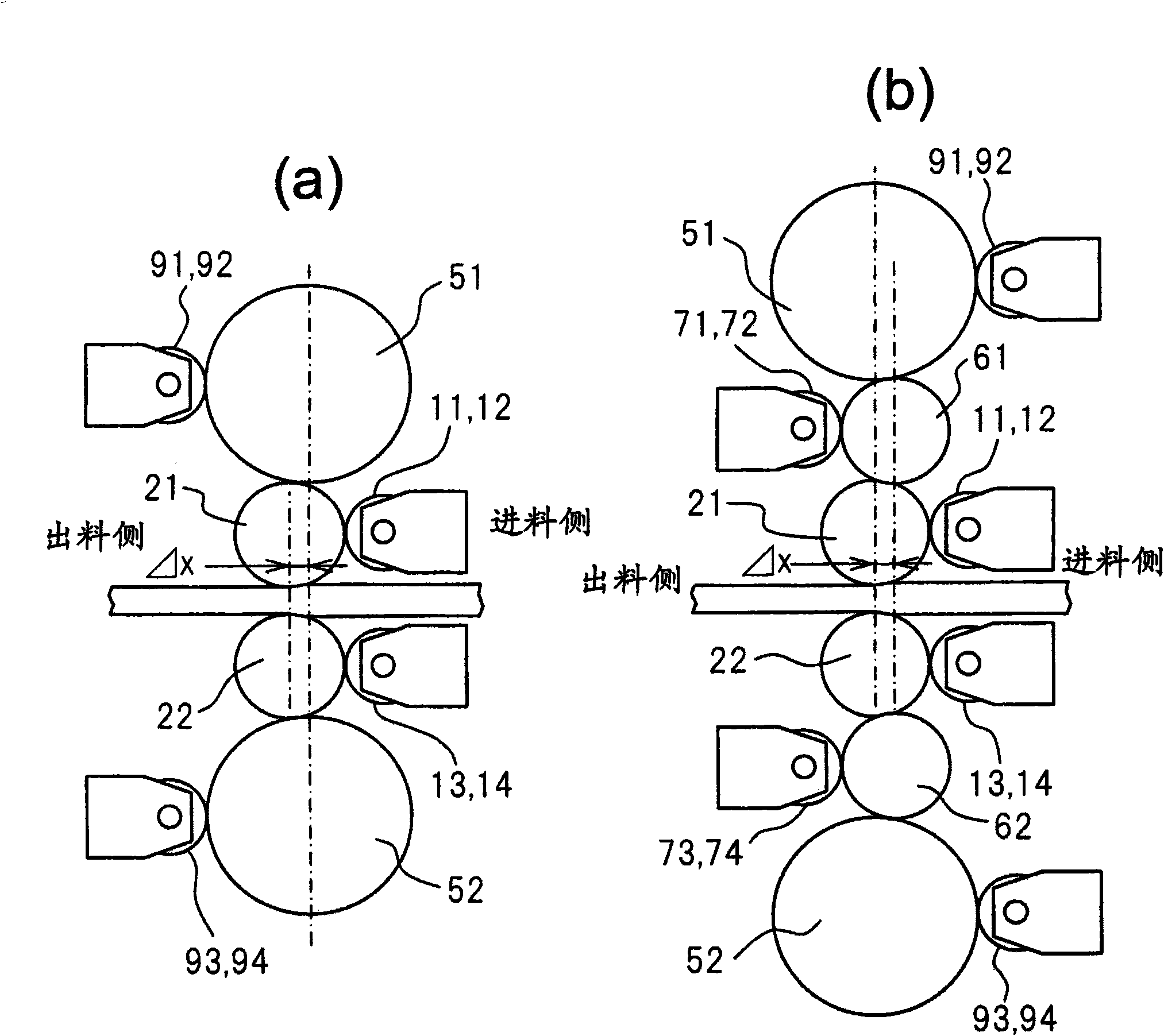

[0068] according to Figure 1 to Figure 10 The best mode for carrying out the present invention will be described in detail.

[0069] exist Figure 1 to Figure 10 , the reference signs are as follows:

[0070] 11, 12, 13, 14 work roll push rollers (11, 12 are upper work roll push rollers, 13, 14 are lower work roll push rollers. The same below, from the rolling line of the rolled material Start referring to the upper side as "upper" and the lower side as "lower")

[0071] 21, 22 work roll

[0072] 31, 32, 33, 34 work roll chocks

[0073] 41, 42 balance weight (rolling mill stand)

[0074] 51, 52 support roller

[0075] 61, 62 middle roller

[0076] 71, 72, 73, 74 middle roller pushing roller

[0077] 81, 82, 83, 84 Work roll chock support members connected to backup roll chocks

[0078] 91, 92, 93, 94 support roller push roller

[0079] 101, 102 work roll horizontal direction load detection device

[0080] 111, 112 push roller load detection device

[0081] 121, 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com