Multi-tapered suspension component

a suspension component and multi-taper technology, applied in the direction of spring/damper functional characteristics, mechanical equipment, transportation and packaging, etc., can solve the problems of inacceptable stress concentration, complex challenges, and significantly higher lateral spring rate, and achieve constant stress, enhanced performance characteristics, and more lateral bending deflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

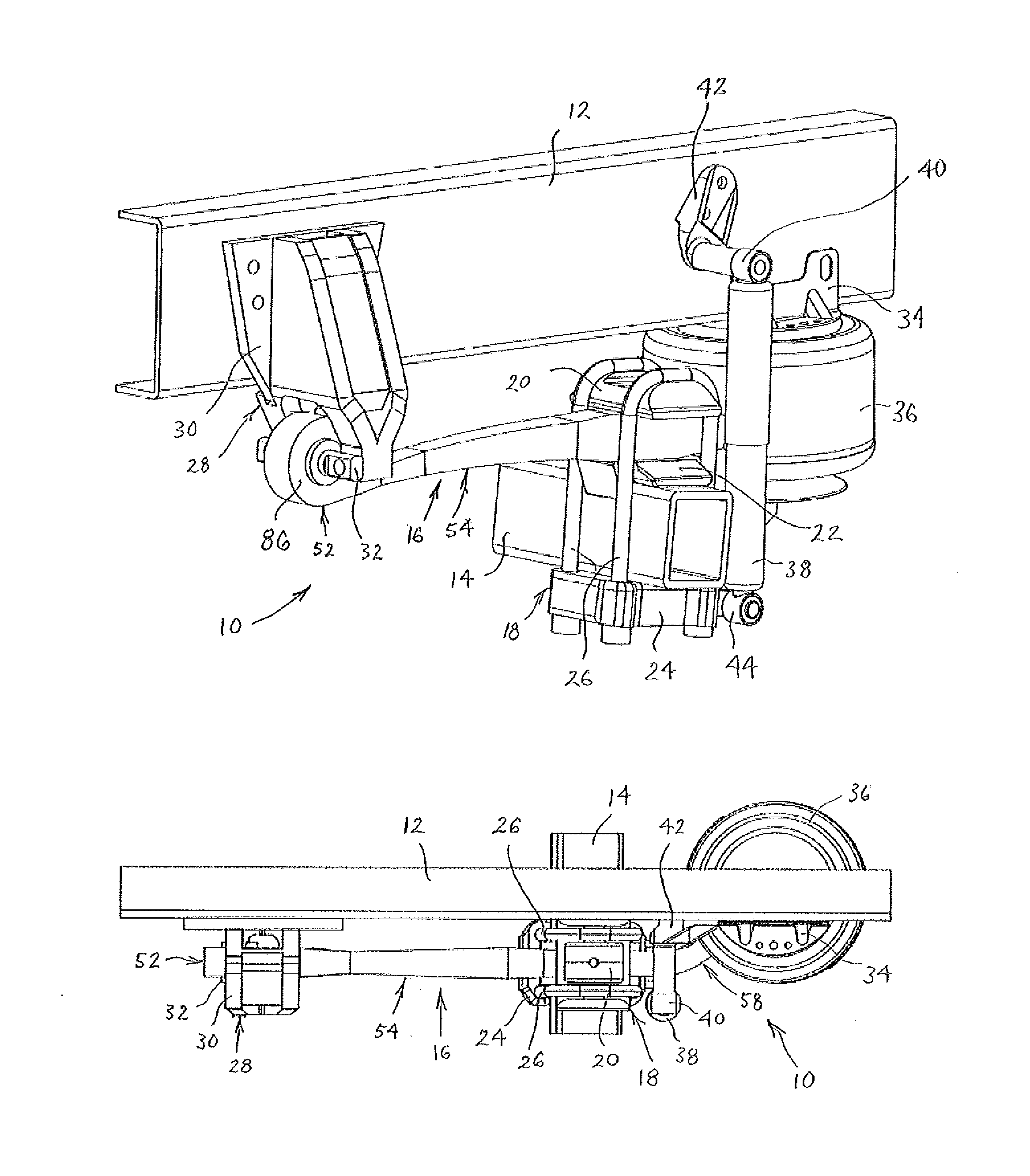

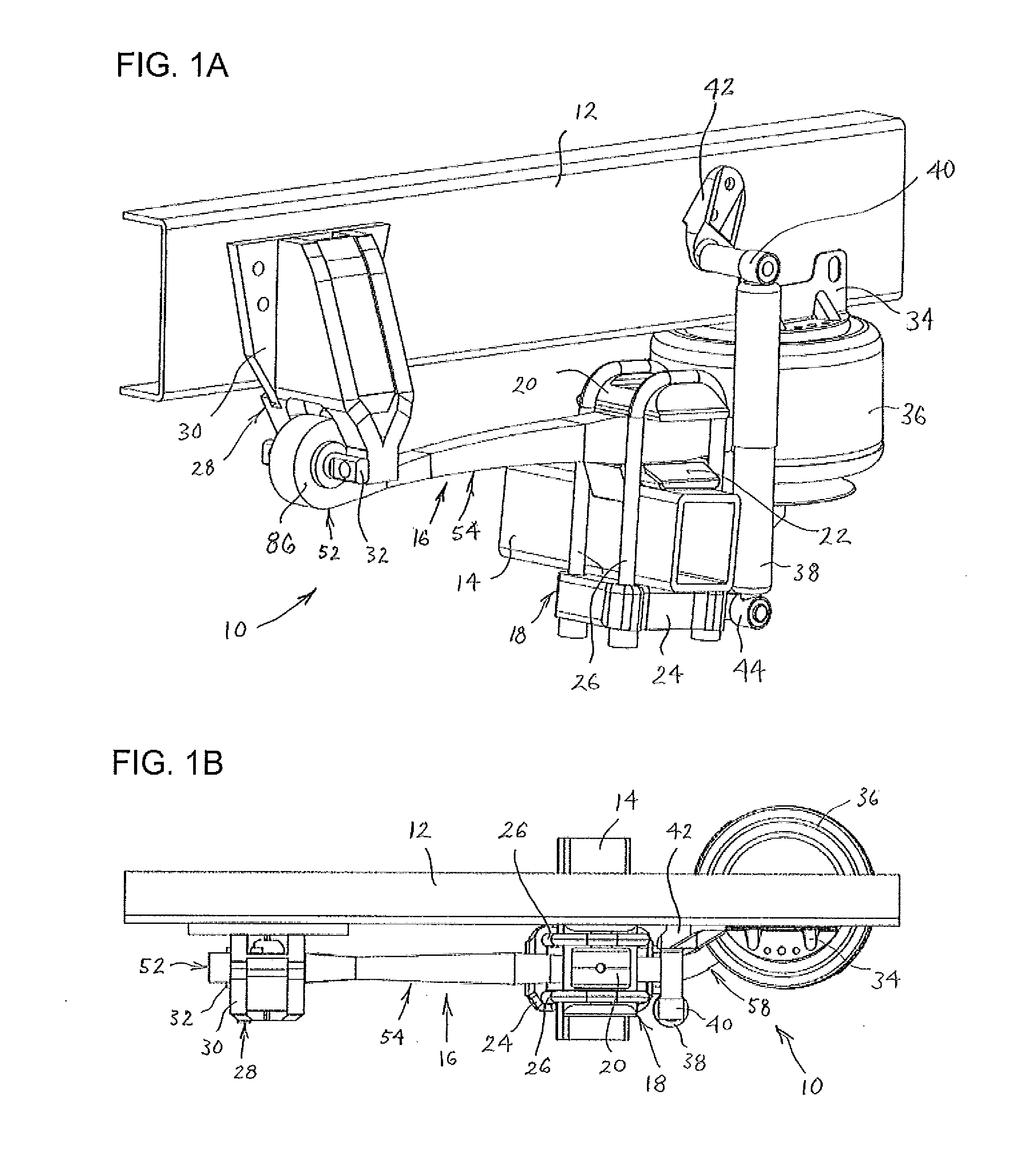

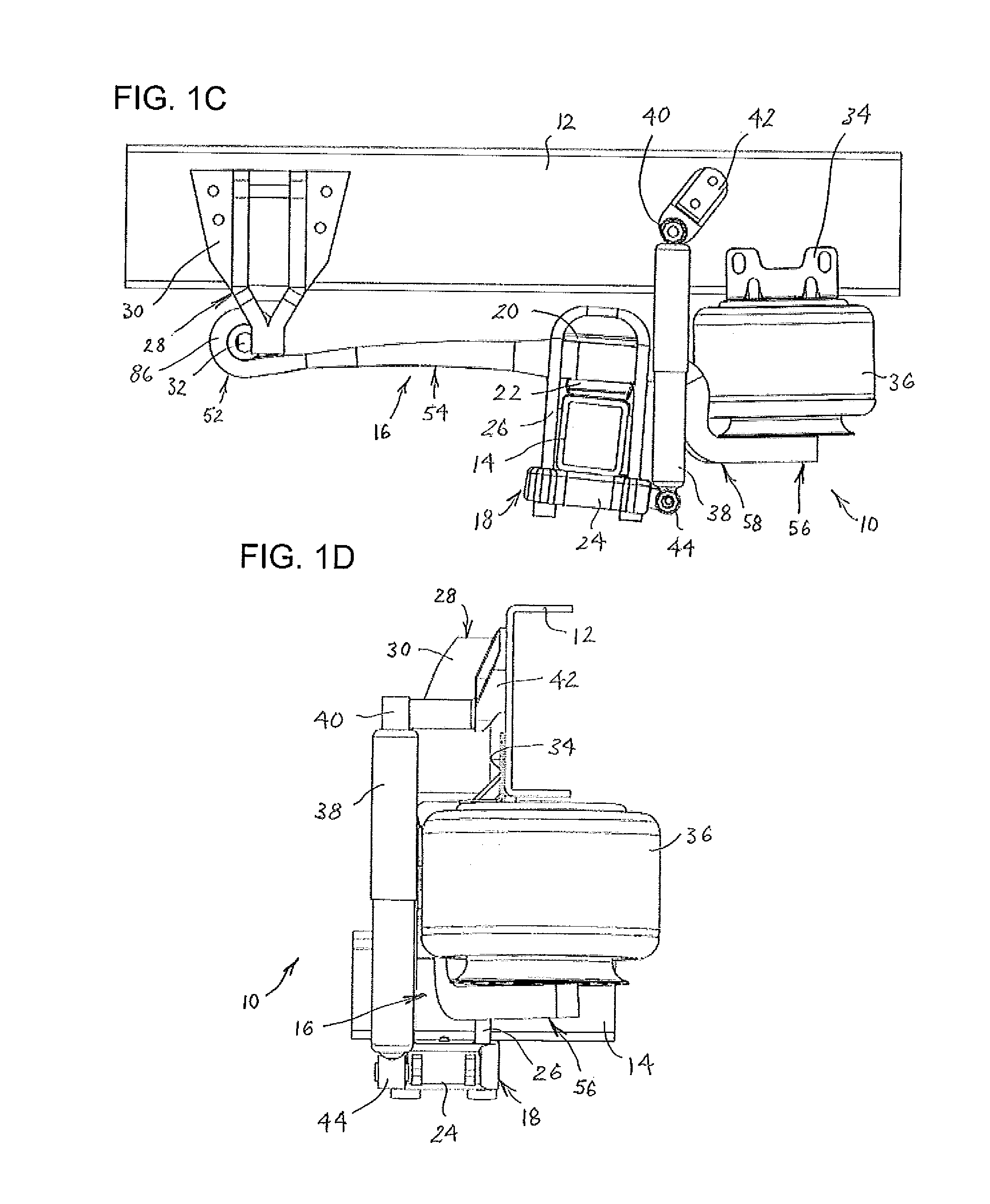

[0044]This disclosure presents energy storing suspension components, such as support members, spring members, and the like, that may be used in suspension systems on chassis, on the front or rear of wheeled vehicles or trailers. Several example energy storing suspension components for use in the suspension systems are disclosed herein, as well as a particularly advantageous bushings for use in combination with one of the example energy storing suspension components having an end configured to include an eye. It will be apparent that each example energy storing suspension component includes an axle seat portion, an end, and a limb extending between the axle seat portion and the end, with the limb including a first taper wherein the limb decreases in width as the limb extends toward the end, a second taper wherein the limb decreases in thickness as the limb extends toward the end, wherein along the limb there is at least a portion where both the first taper and second taper are presen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com