Patents

Literature

43results about How to "Ensure homogeneity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

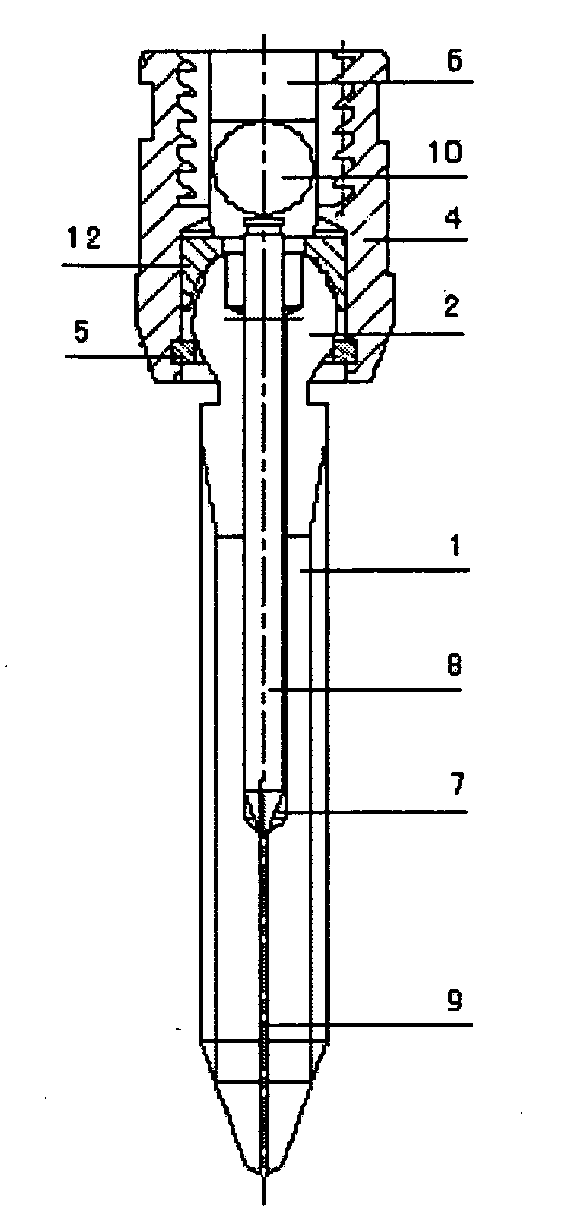

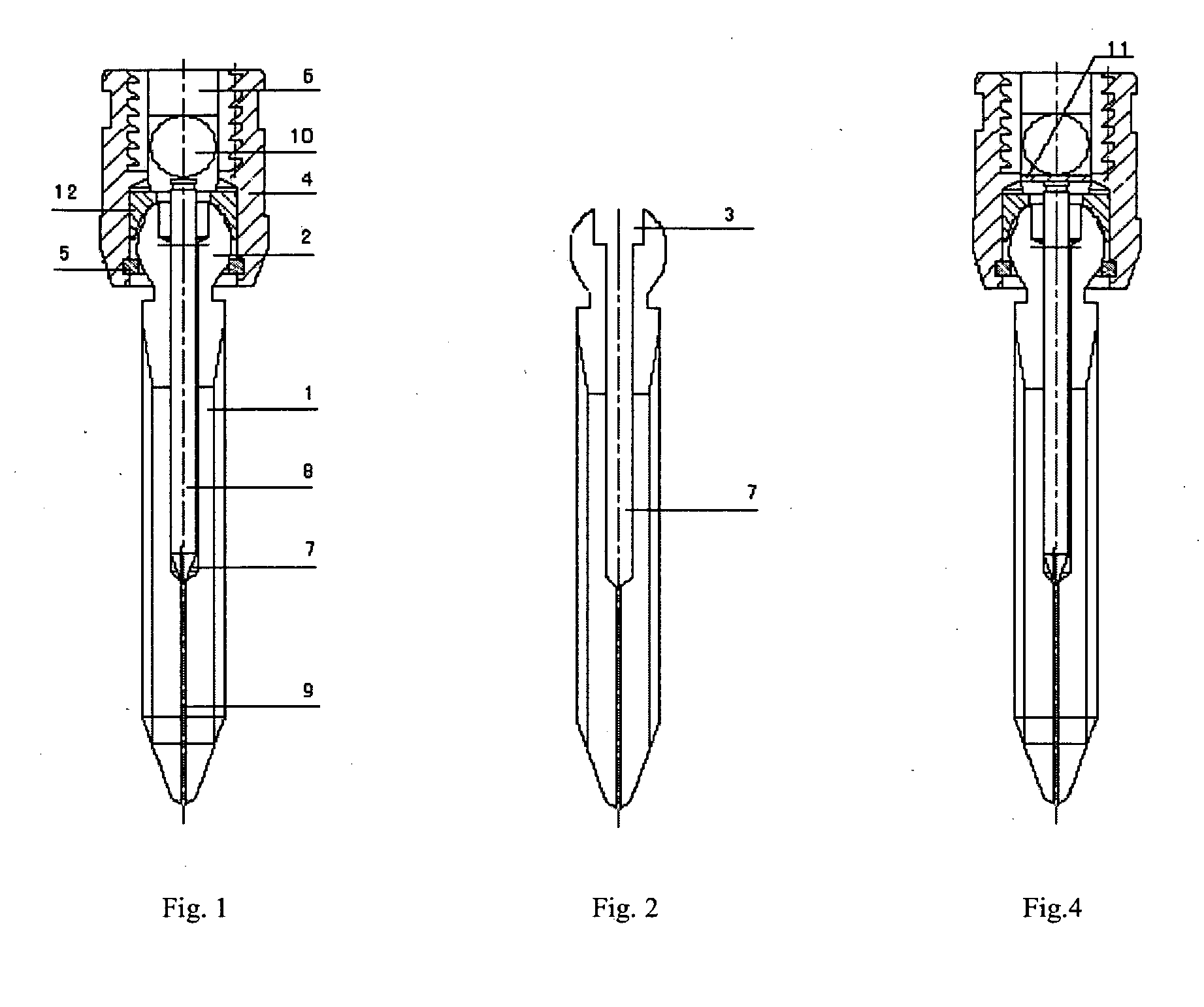

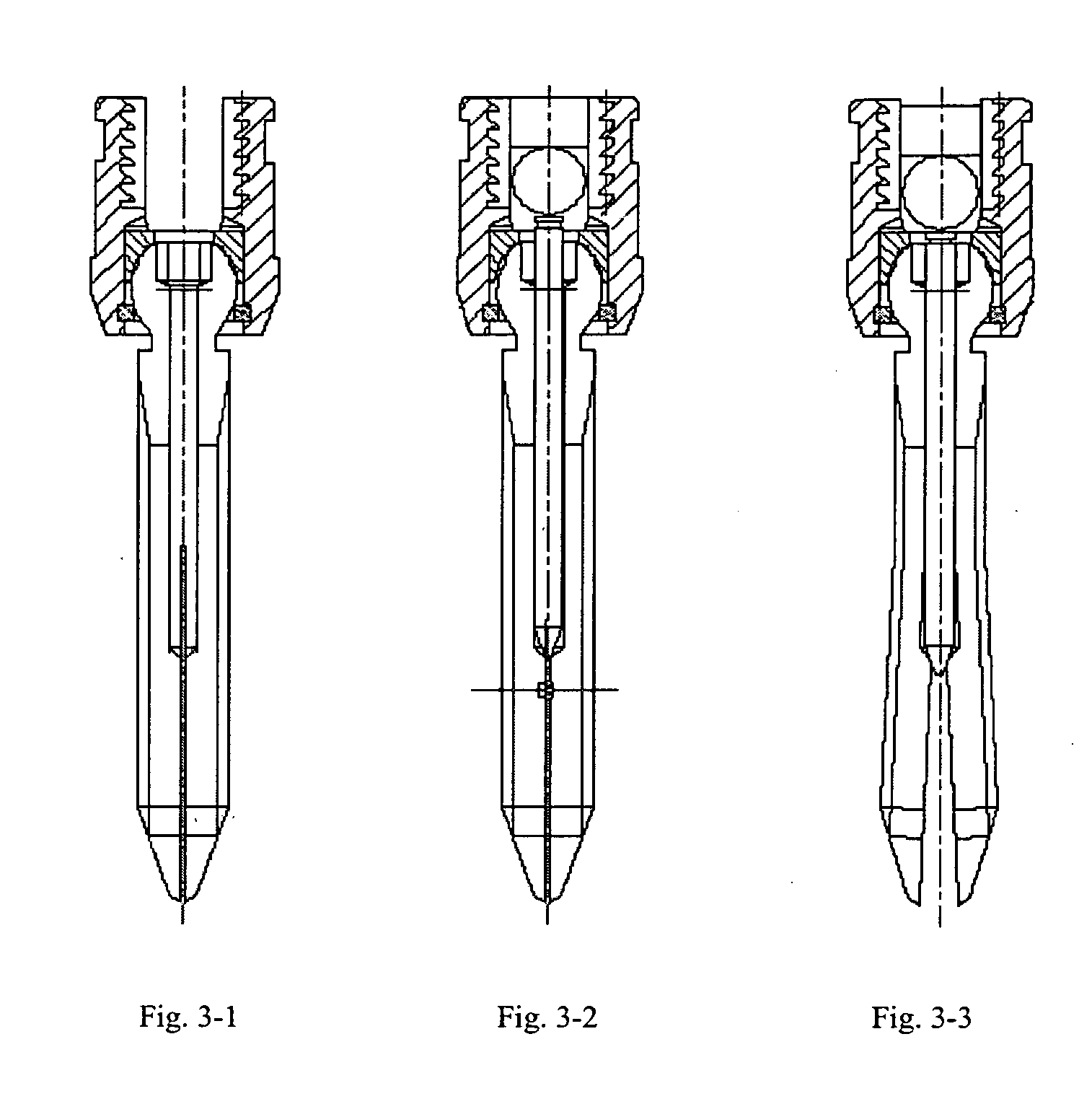

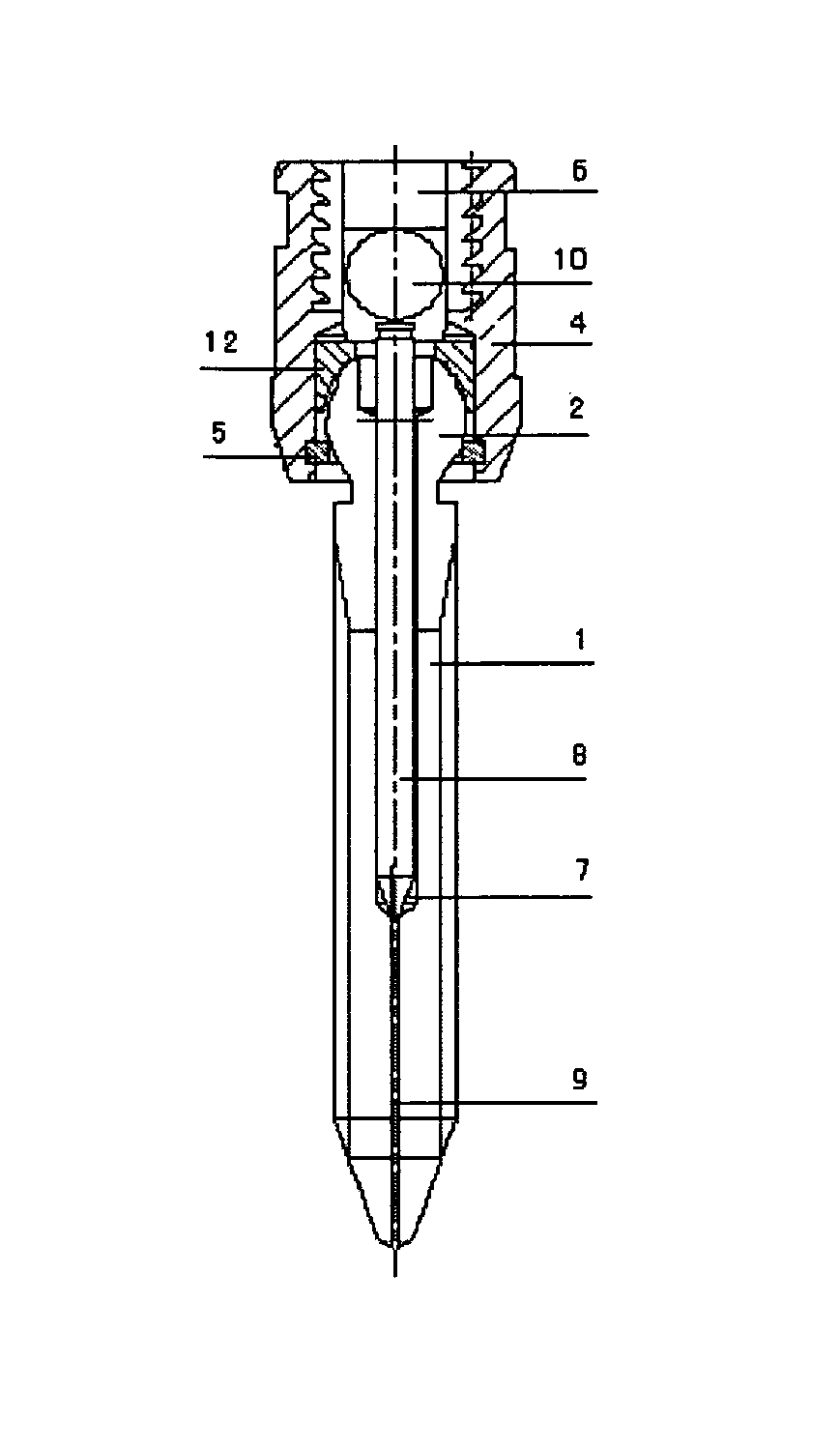

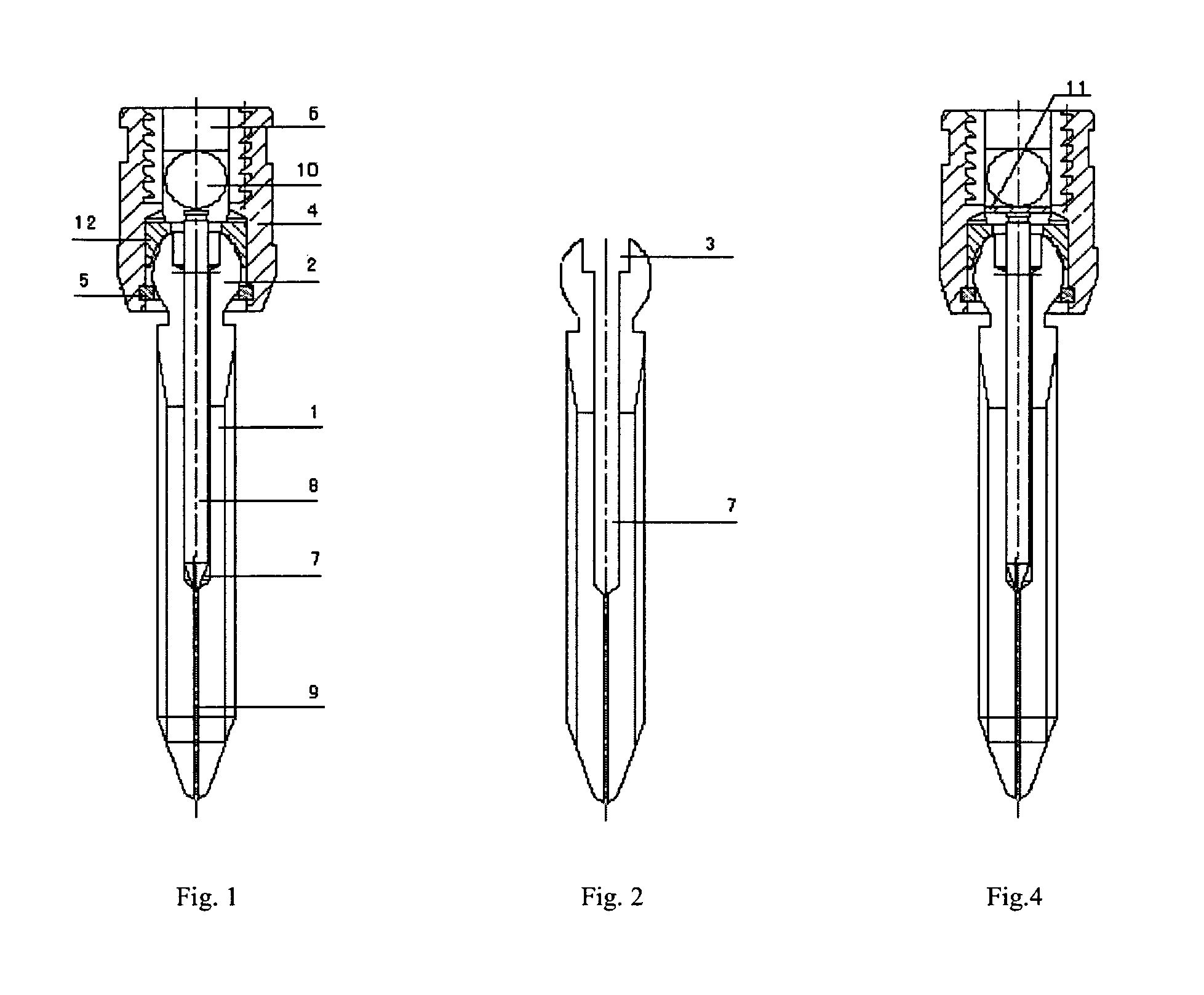

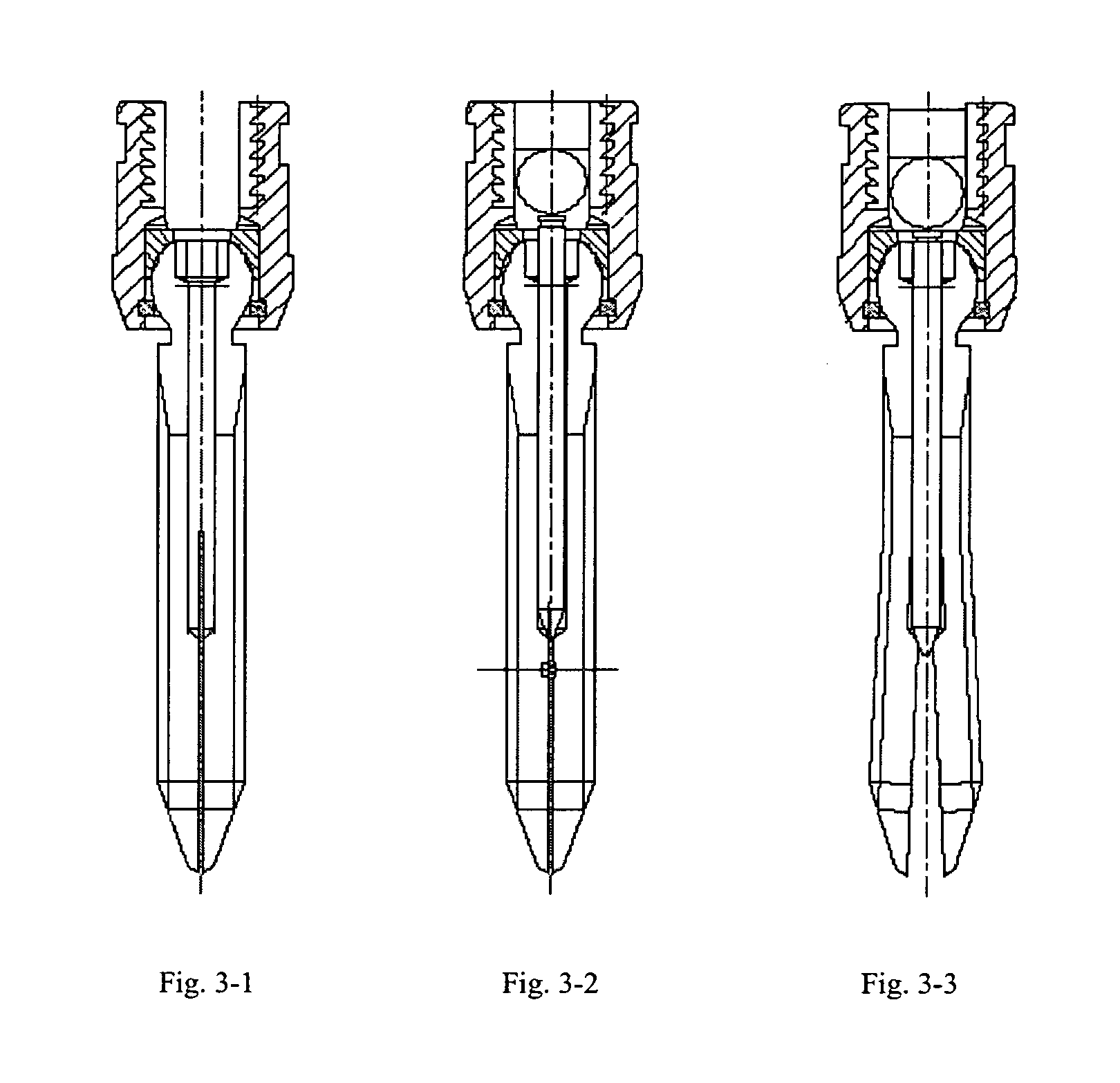

Multi-Axial Expandable Pedicle Screw and an Expansion Method Thereof

ActiveUS20090105771A1Reduce probabilityImprove stabilitySuture equipmentsInternal osteosythesisFailure rateUniversal joint

The invention disclosed a multi-axial expandable pedicle screw and an expansion method by using the same. Structure of the screw comprising a hollow screw being spherical shaped end connecting with an adapting piece, which is universal joint structure; an inner wall of the adapting piece connecting a lock bolt through screw threads; the hollow screw with sharp shaped on another end having a bore inside formed hollow structure in its entirety; the bore having taper shaped tip; expansion gaps uniformly setting up two, or three or four or more anterior fins on the hollow screw along its axial direction upward, prolonging from its tip to the bore; the inner needle is disposed in the bore. The invention can reduce the pedicle screw loose and even occurrence ratio of pull-out and increase the stability and reliability and reduce the failure rate of spinal surgeries at the same time. It is also easy to operate, and degree of expansion is of controllable level.

Owner:LEI WEI +1

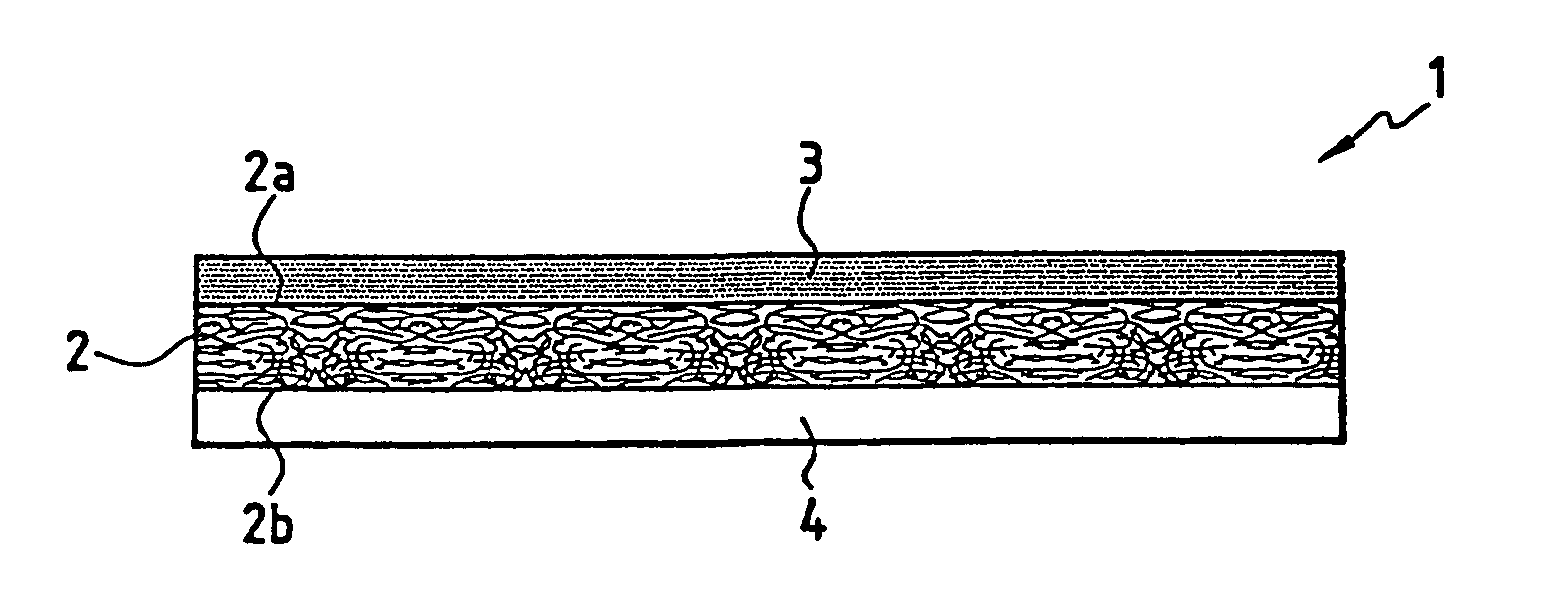

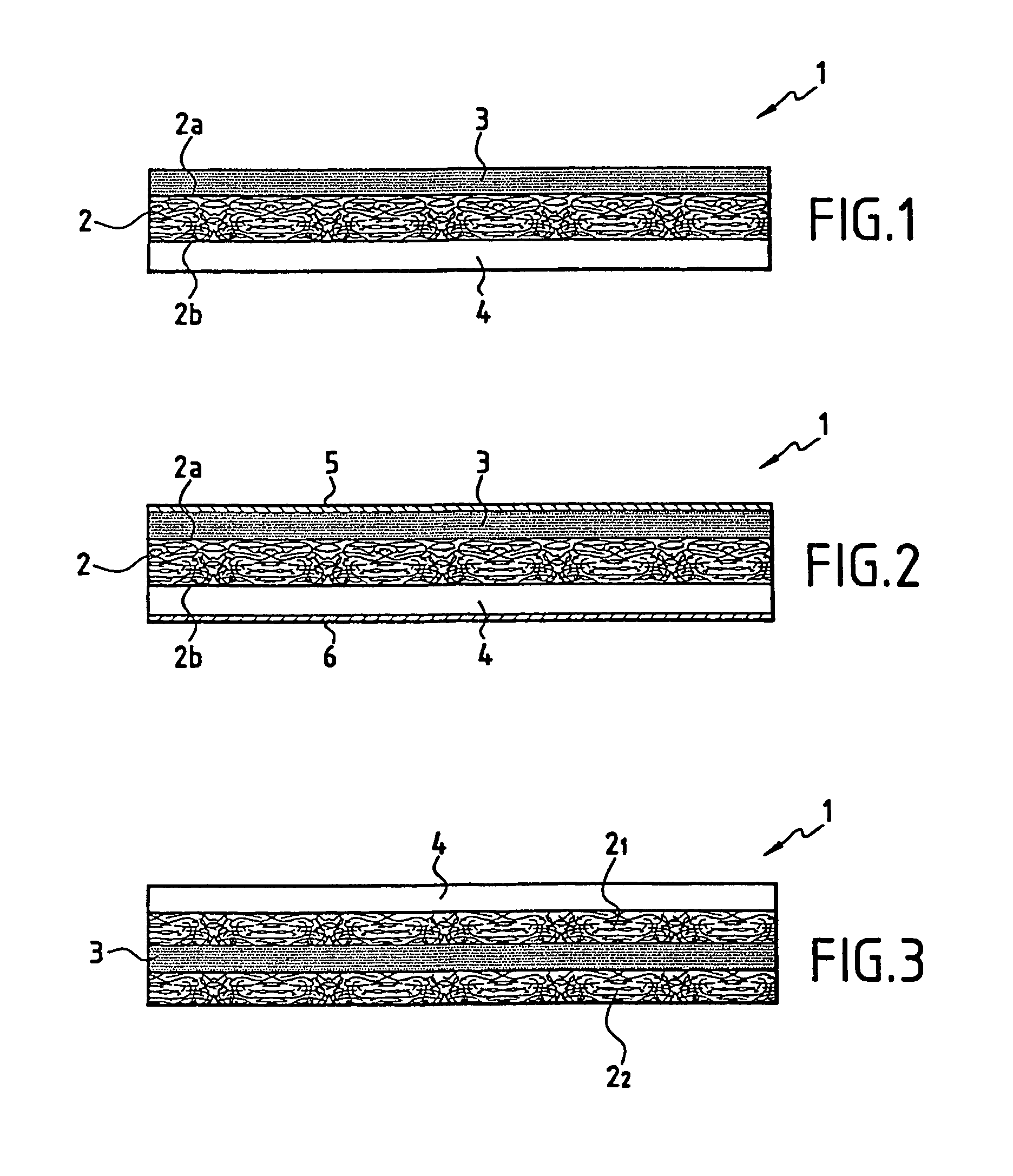

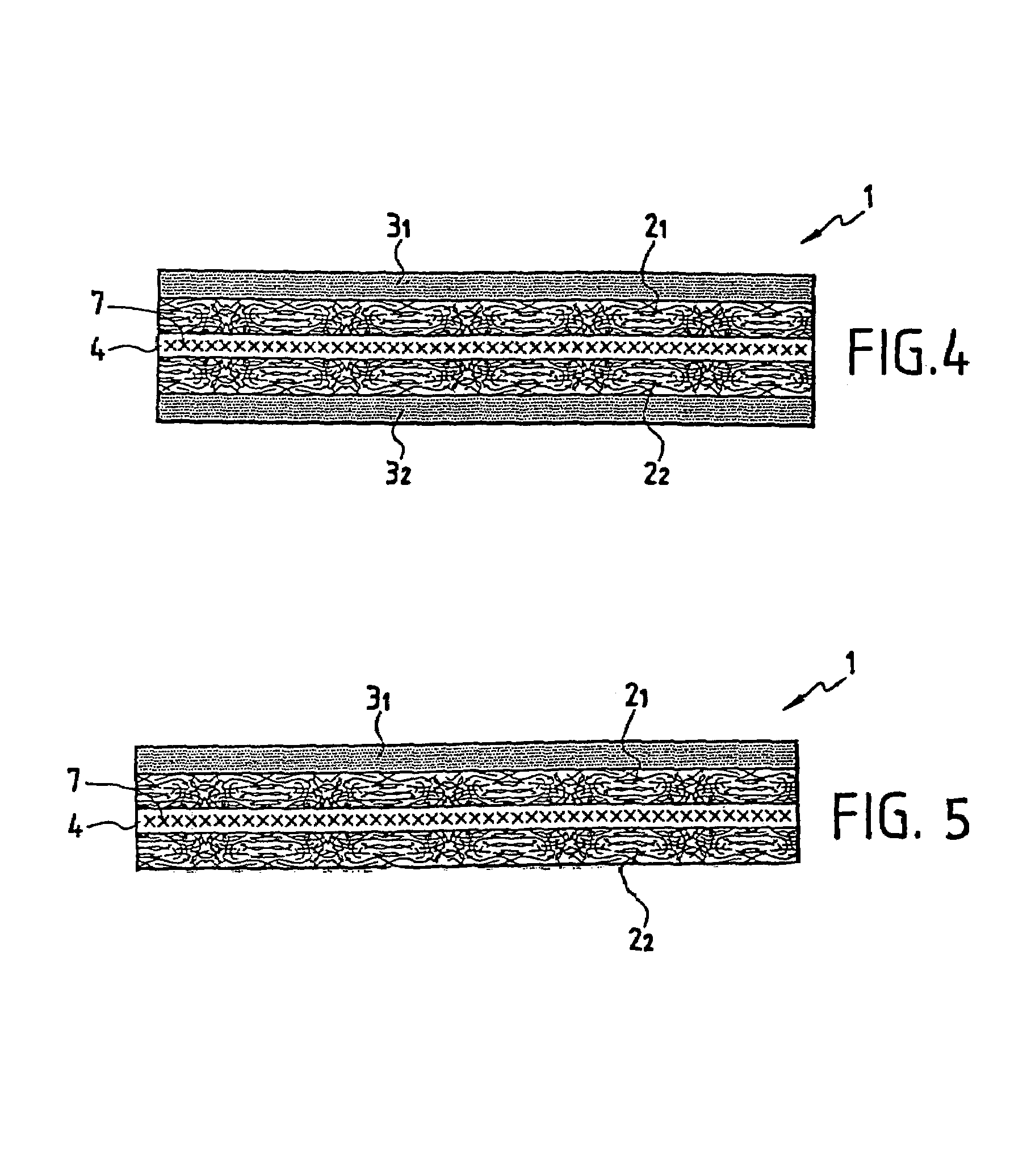

Composite products and molded articles obtained from said products

ActiveUS7267868B2Easy to implementEasy to handleBox making operationsPaper-makingPhysical BarrierFibre reinforcement

An uncured composite product having a middle fibrous reinforcement, a thermosetting-resin based layer and a hardening-agent based layer for the thermosetting resin. The thermosetting-resin based layer is placed on one side of the fibrous reinforcement and the hardening-agent based layer is placed on the other side so that the fibrous reinforcement forms a physical barrier between the thermosetting resin and the hardener. When heated, the thermosetting resin and / or hardener flows across the physical barrier to provide mixing and resultant curing.

Owner:HEXCEL COMPOSITES SAS

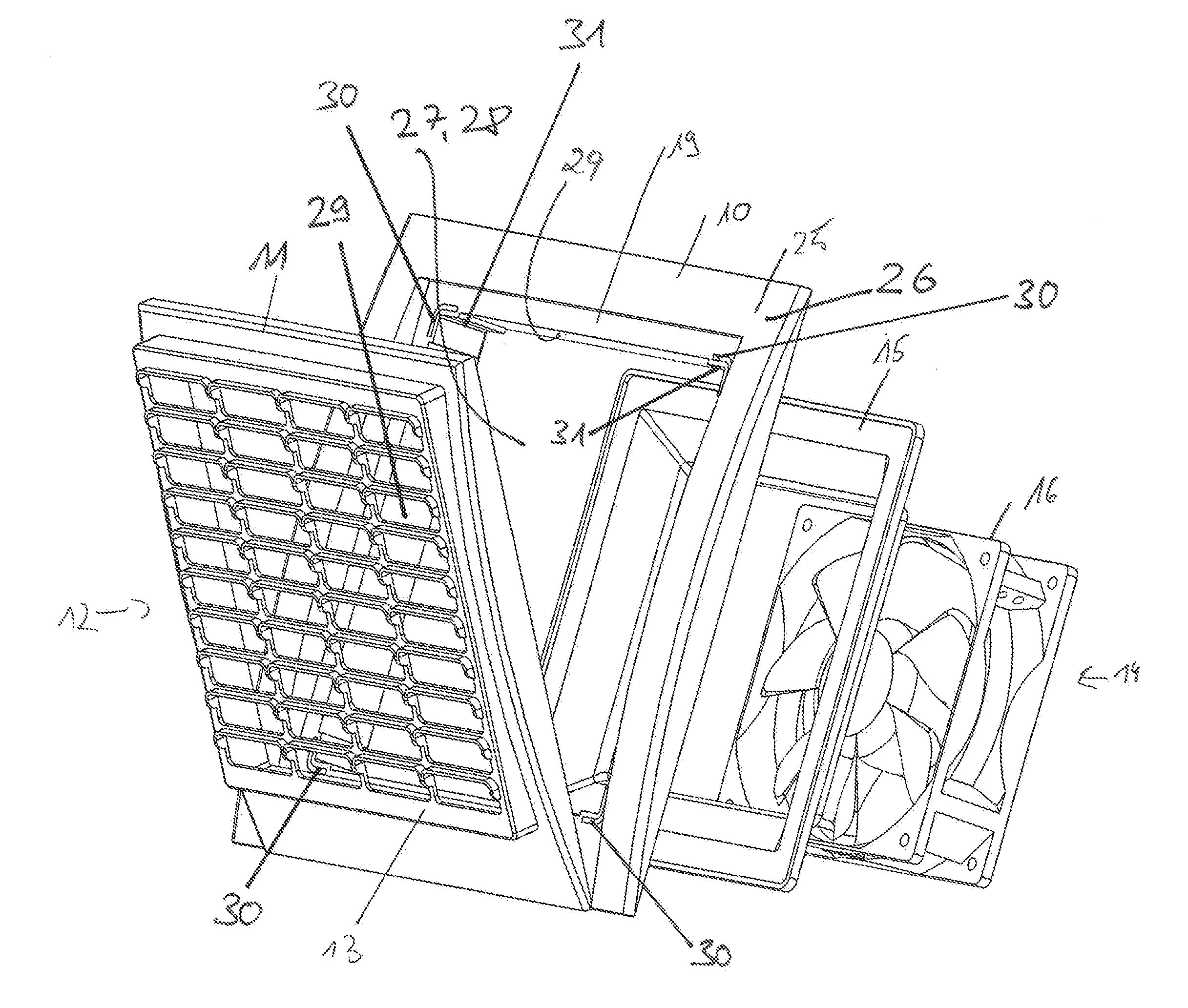

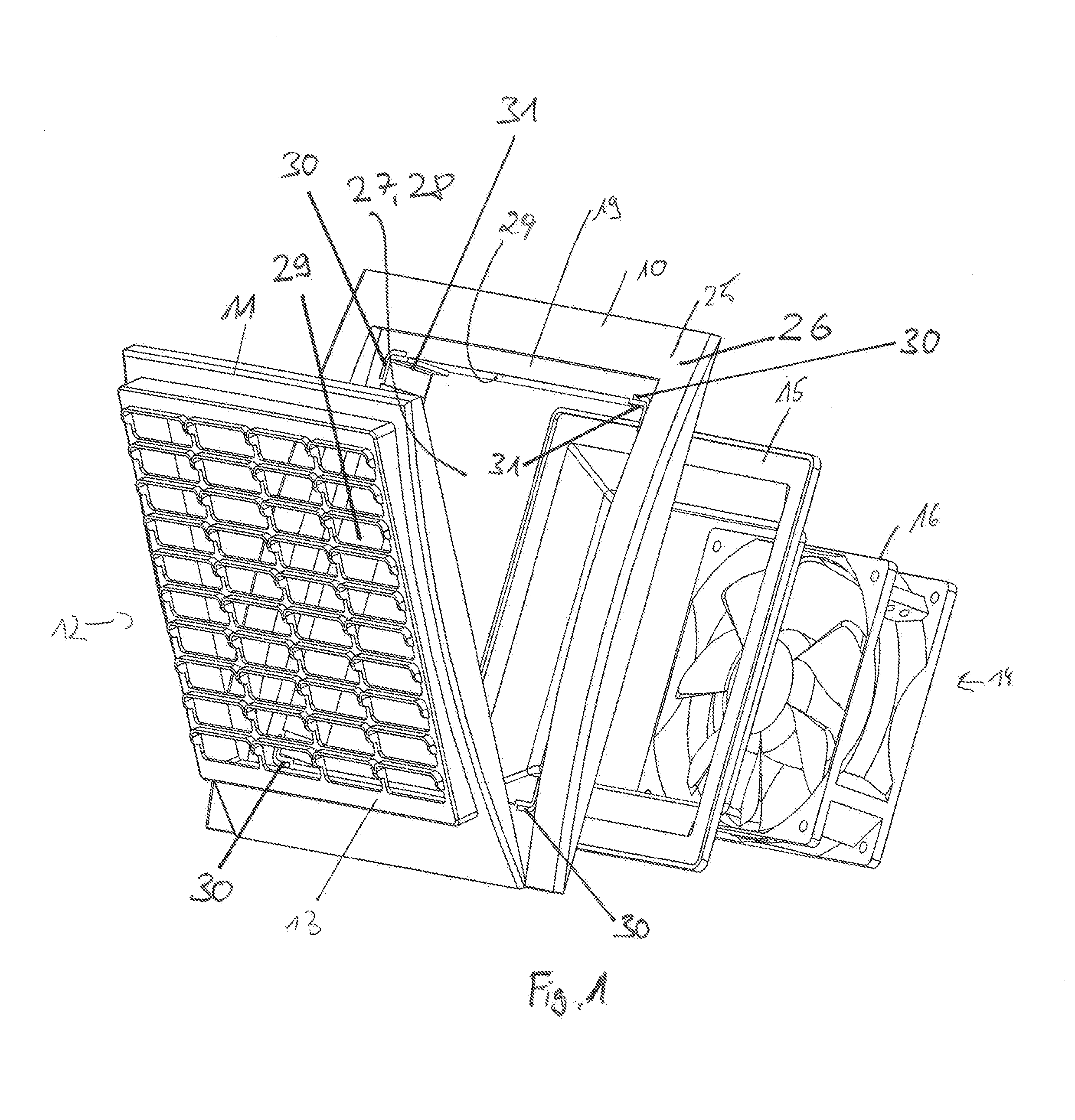

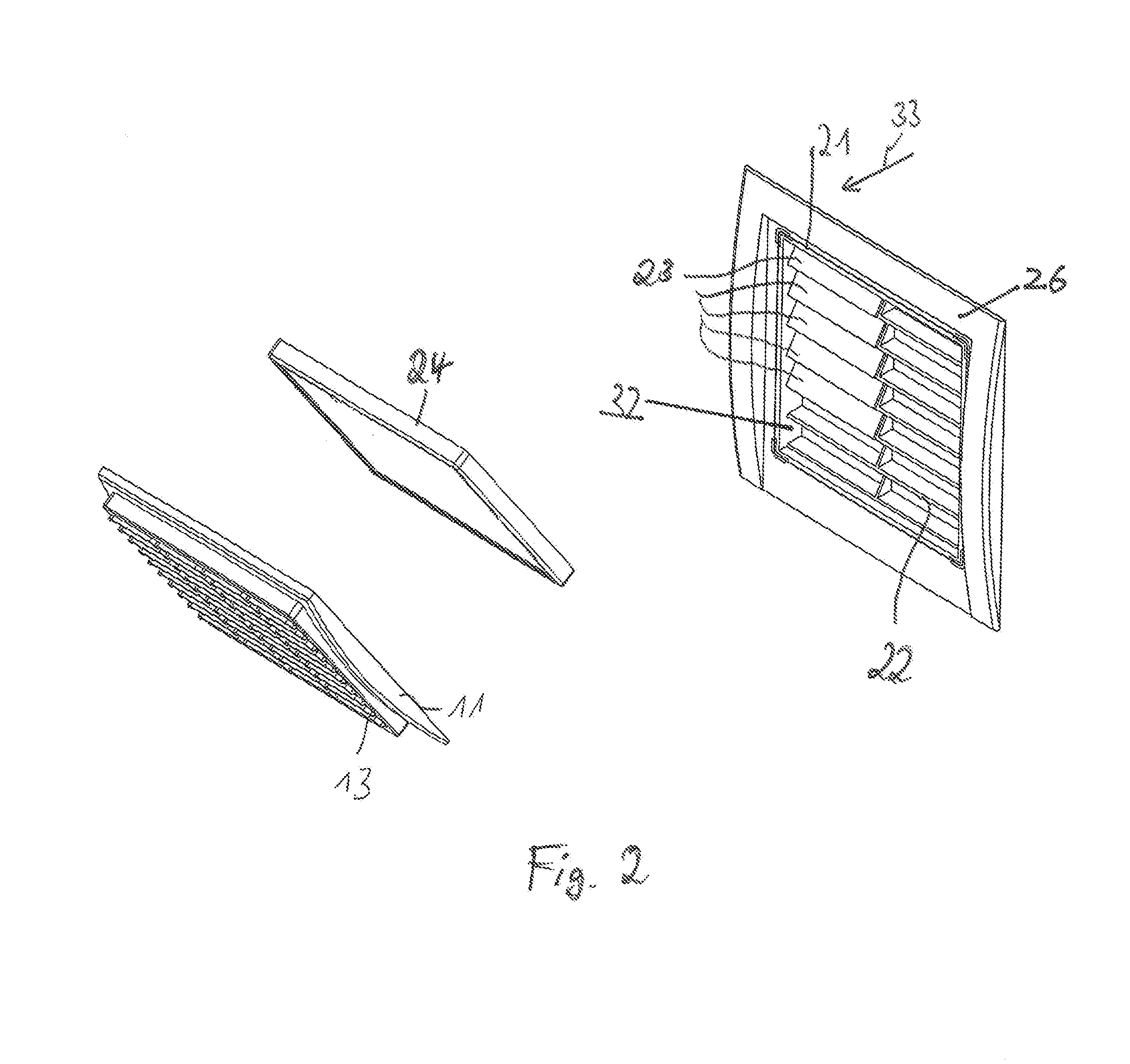

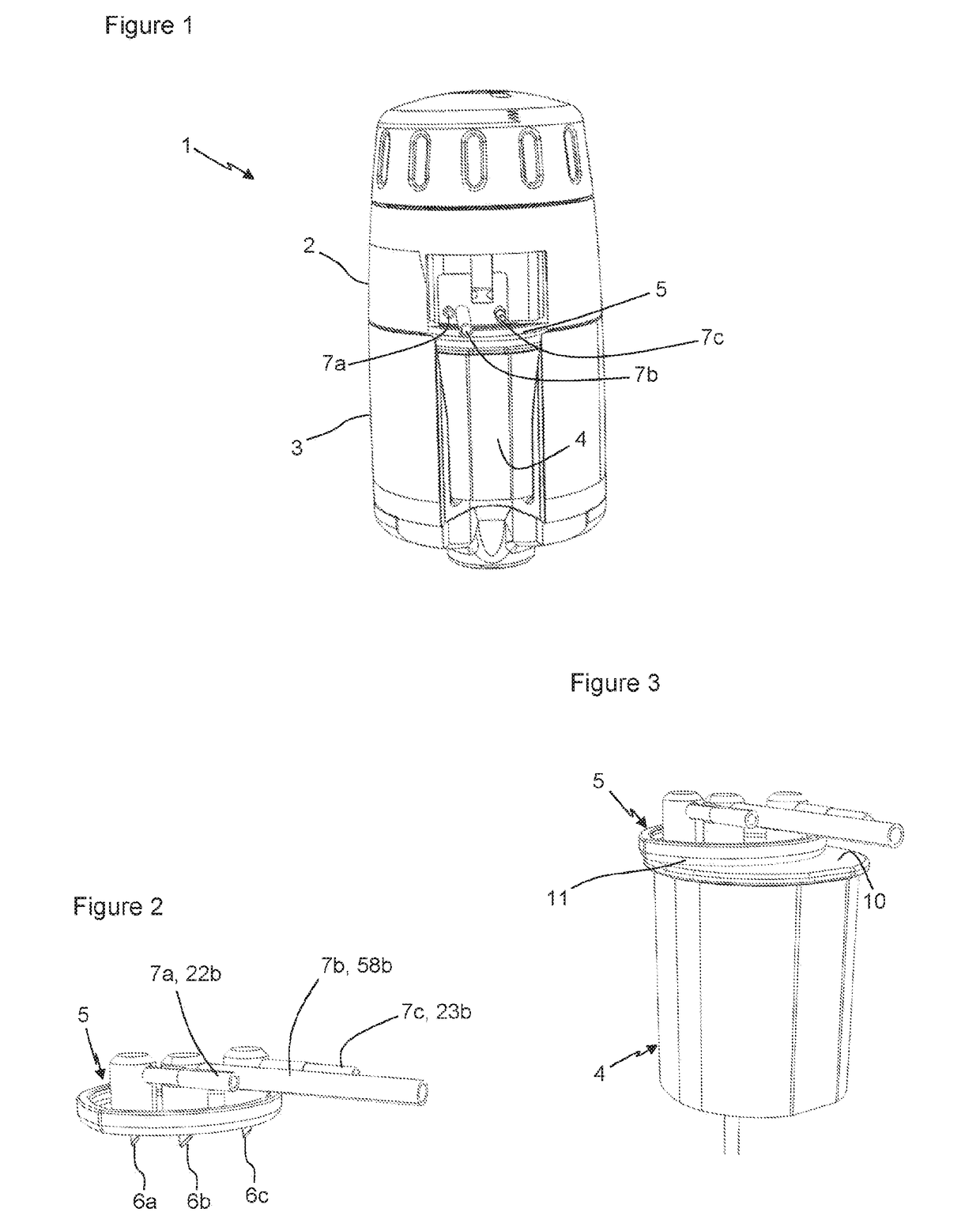

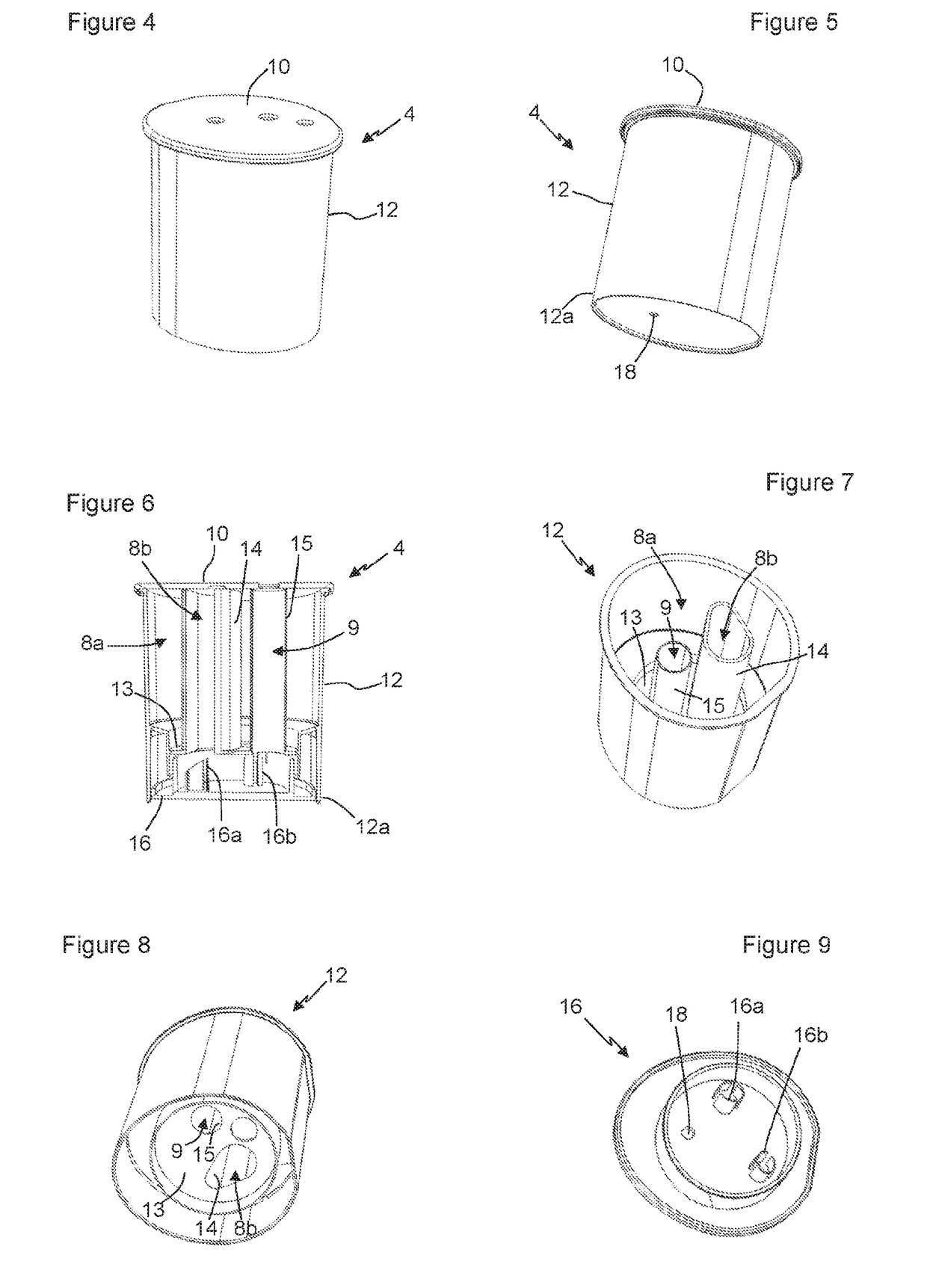

Fan holder for a fan, in particular of a switch cabinet

InactiveUS20160105996A1Improve cooling effectReduce throughputDispersed particle filtrationPump componentsEngineeringMechanical engineering

Owner:STEGO HLDG

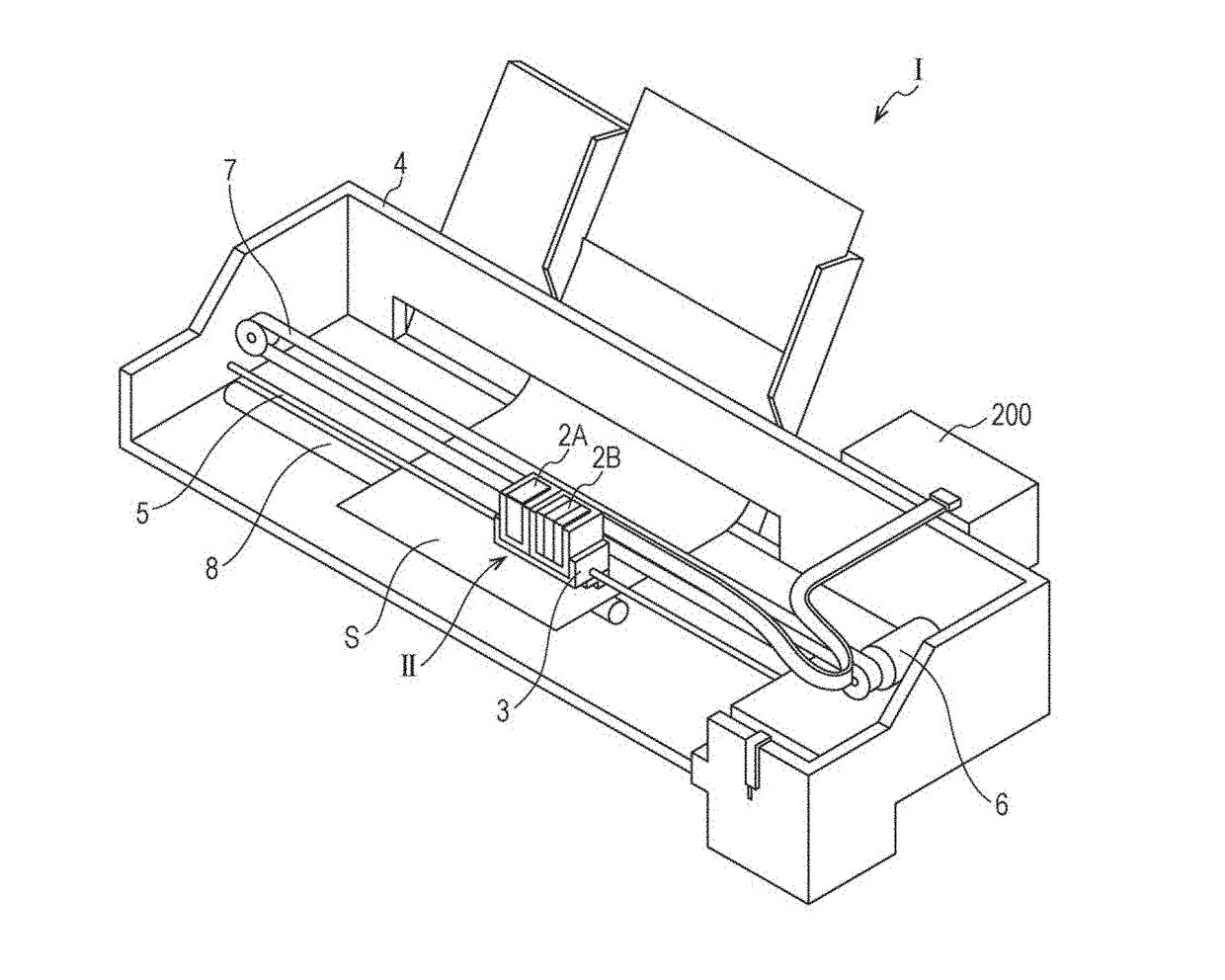

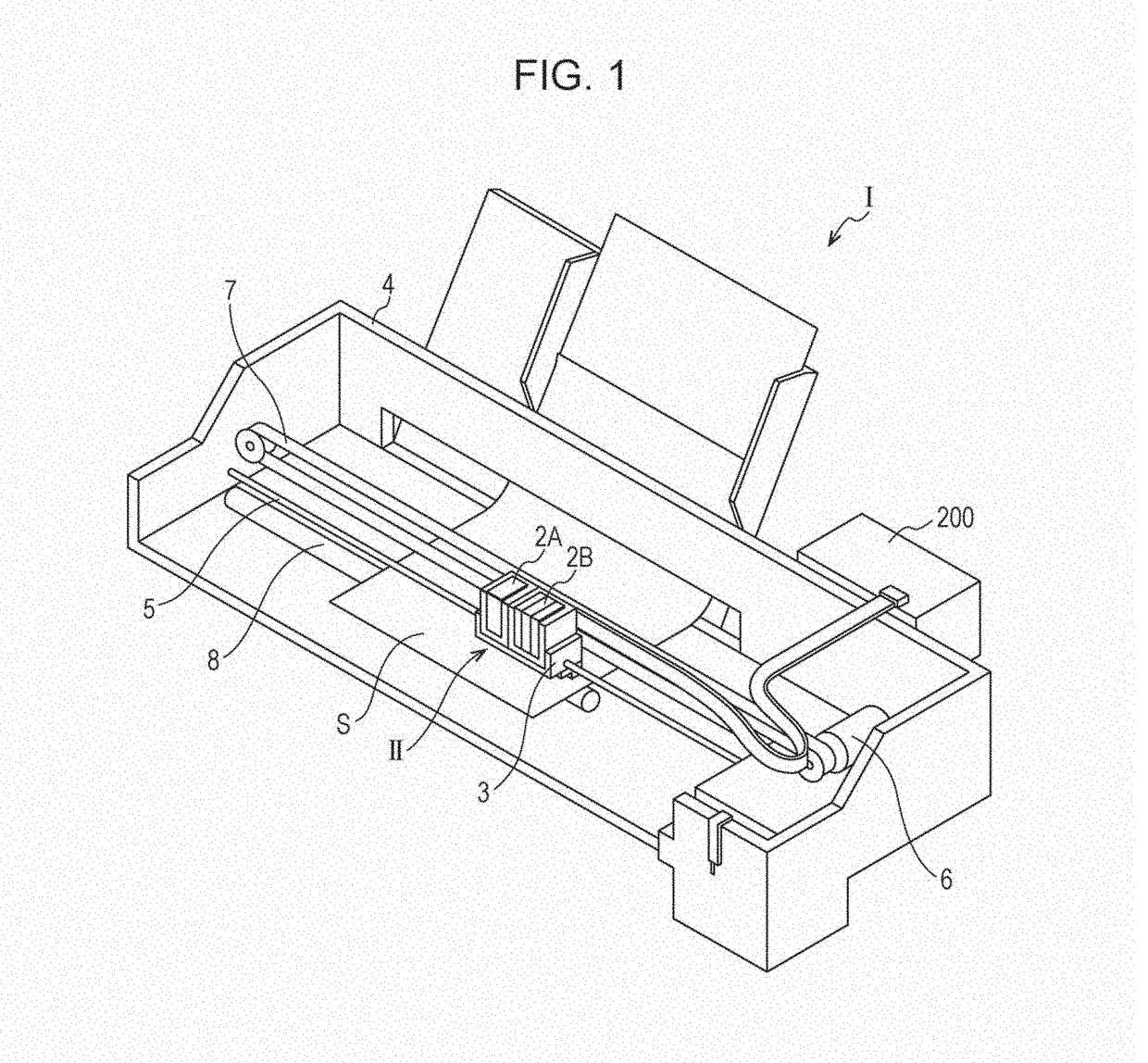

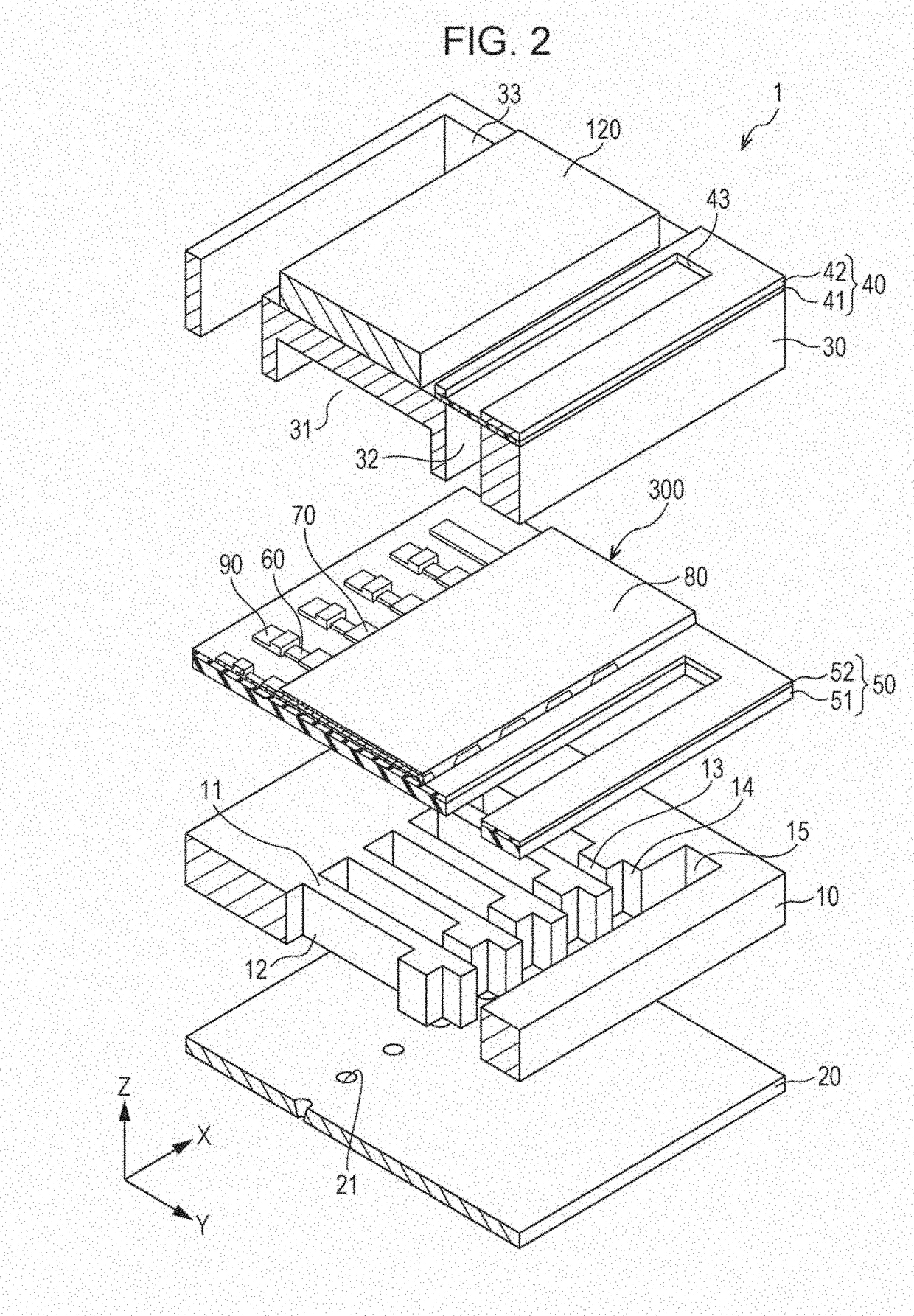

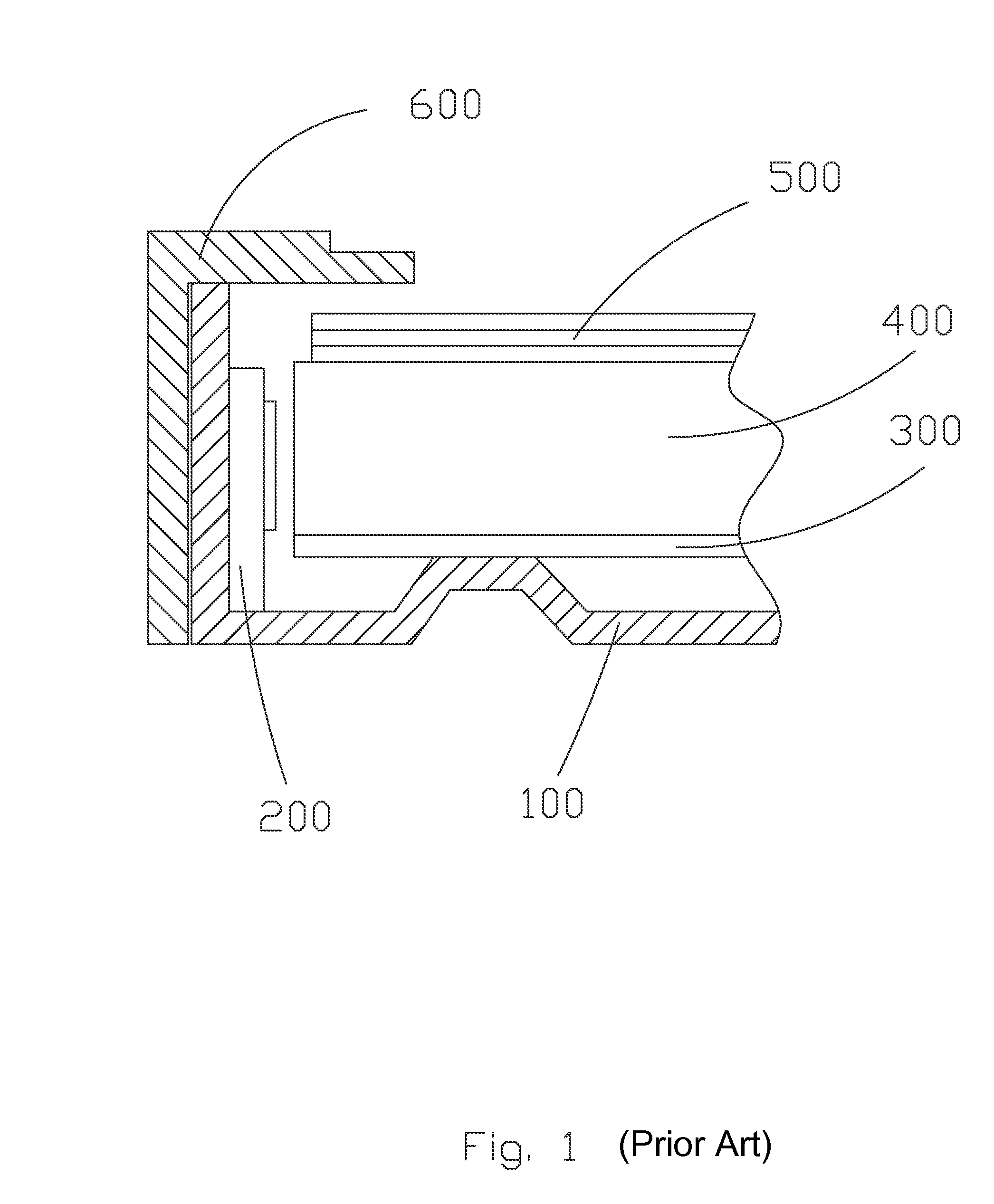

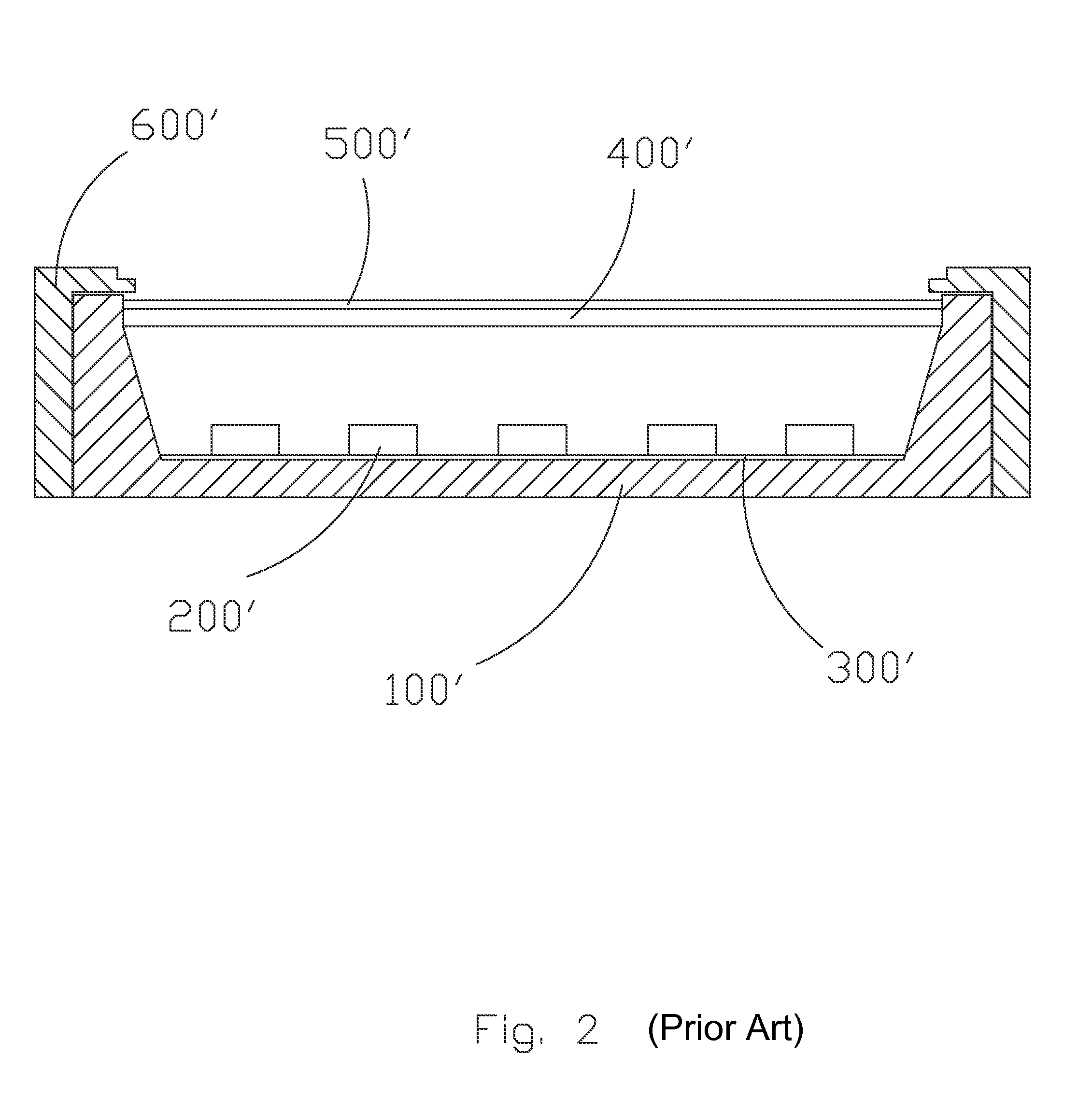

Piezoelectric element, piezoelectric element application device, and method of manufacturing piezoelectric element

ActiveUS20170229637A1Ensure homogeneityMaintain homogeneityPiezoelectric/electrostrictive device manufacture/assemblyInking apparatusNiobiumPotassium

A piezoelectric element includes a first electrode, a piezoelectric layer formed of a first piezoelectric film which is formed on the first electrode and which includes potassium, sodium, and niobium and a plurality of second piezoelectric films which are formed on the first piezoelectric film and which include potassium, sodium, and niobium, and a second electrode formed on the piezoelectric layer, in which the piezoelectric layer is a stack of a plurality of piezoelectric films, the first piezoelectric film has a thickness of 30 nm to 70 nm, a concentration of sodium in each of the piezoelectric films is along a gradient in the film thickness direction with the first electrode side being high and the second electrode side being low.

Owner:SEIKO EPSON CORP

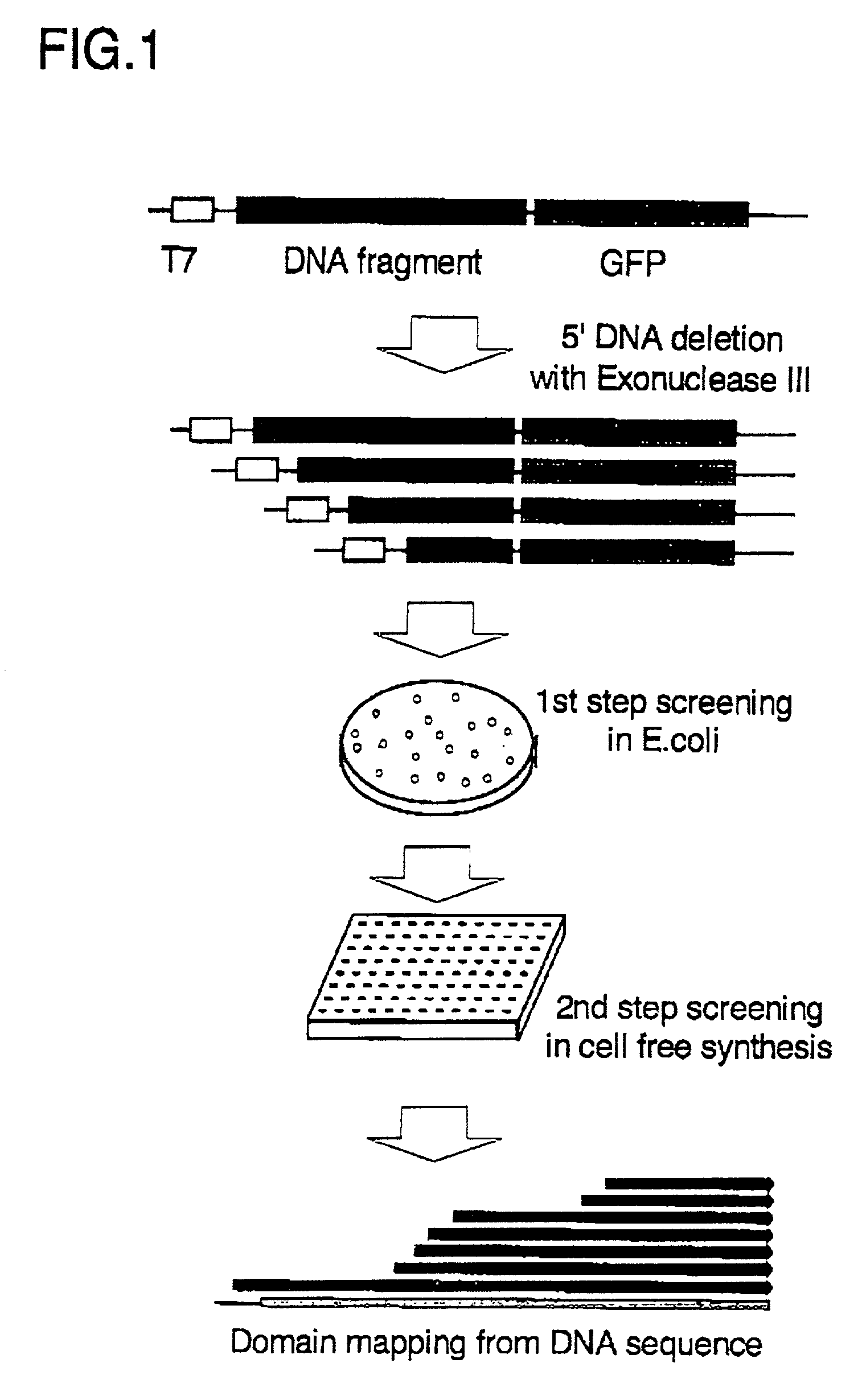

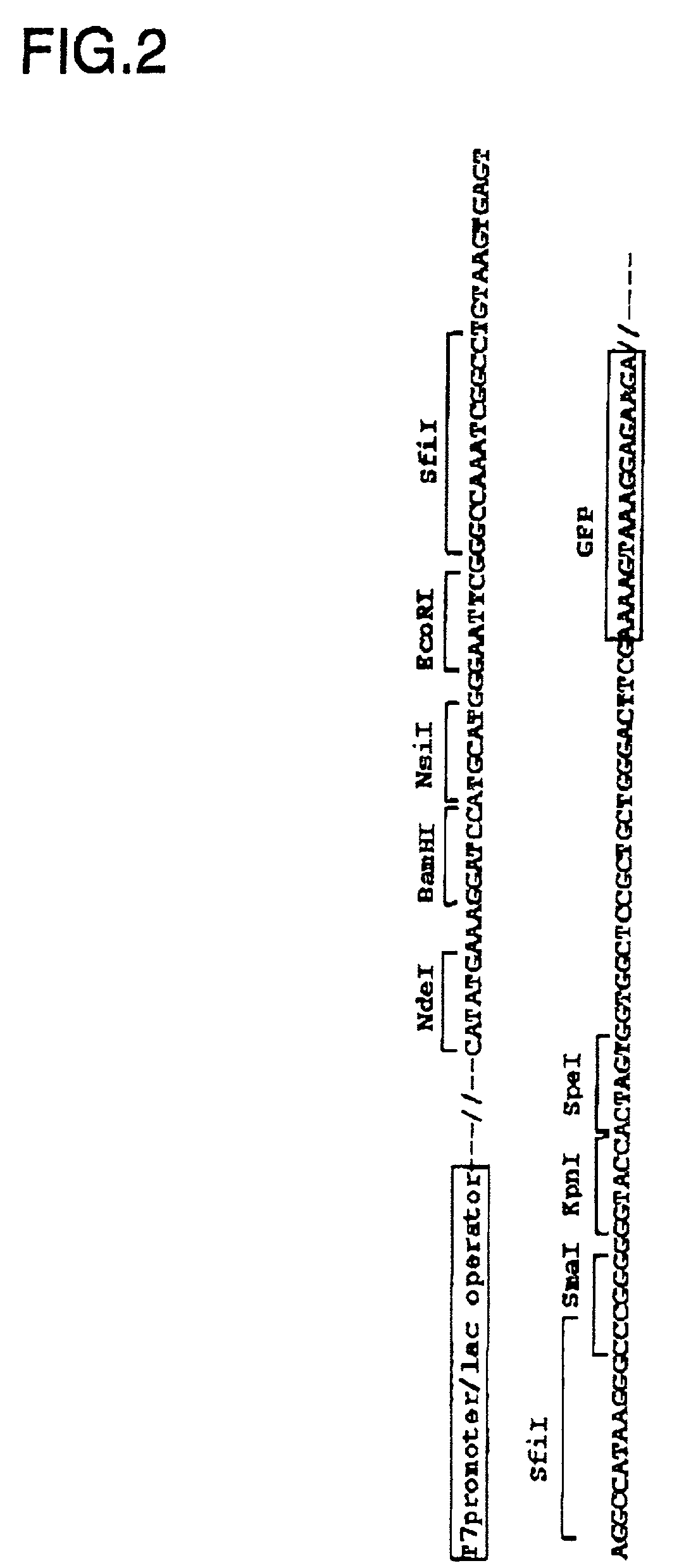

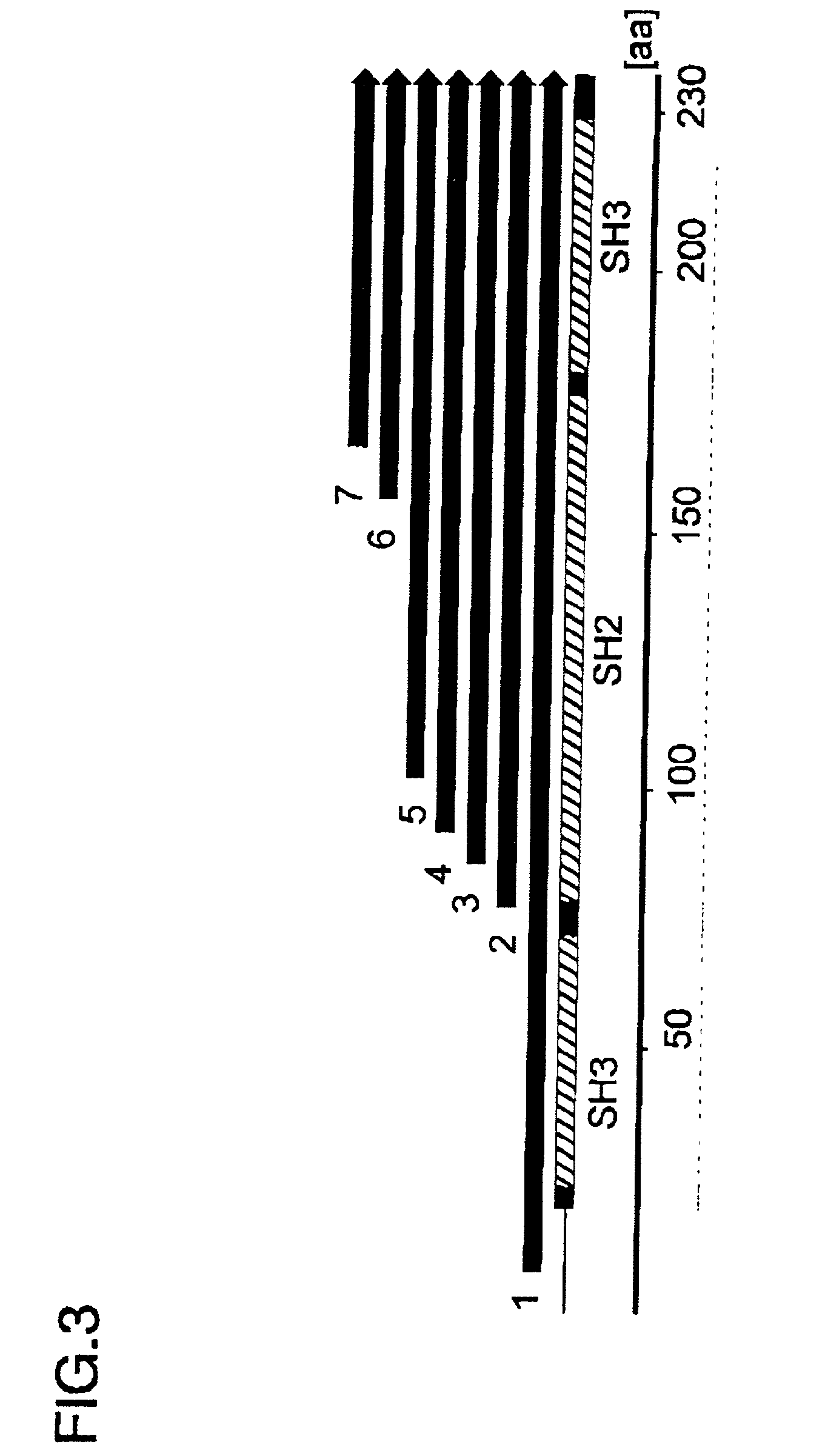

Methods for producing protein domains and analyzing three dimensional structures of proteins by using said domains

InactiveUS20020142387A1Easy and rapid methodEfficient preparationBacteriaPeptide/protein ingredientsDNA fragmentationA-DNA

There is provided a method for producing a soluble protein domain comprising: (a) preparing two or more DNA fragments by partially digesting a DNA coding for a protein; (b) expressing the protein which is coded on each of said DNA fragments, as a fusion protein with a functional protein; (c) selecting the fusion protein exhibiting said function among two or more fusion proteins synthesized in step (b); and, (d) synthesizing the soluble protein domain which is coded on said DNA fragment in a cell-free system, wherein said soluble protein domain is included in said fusion protein selected in step (c). By using this method, it can be easy and efficient to analyze the three dimensional structure of proteins of many clones.

Owner:RIKEN

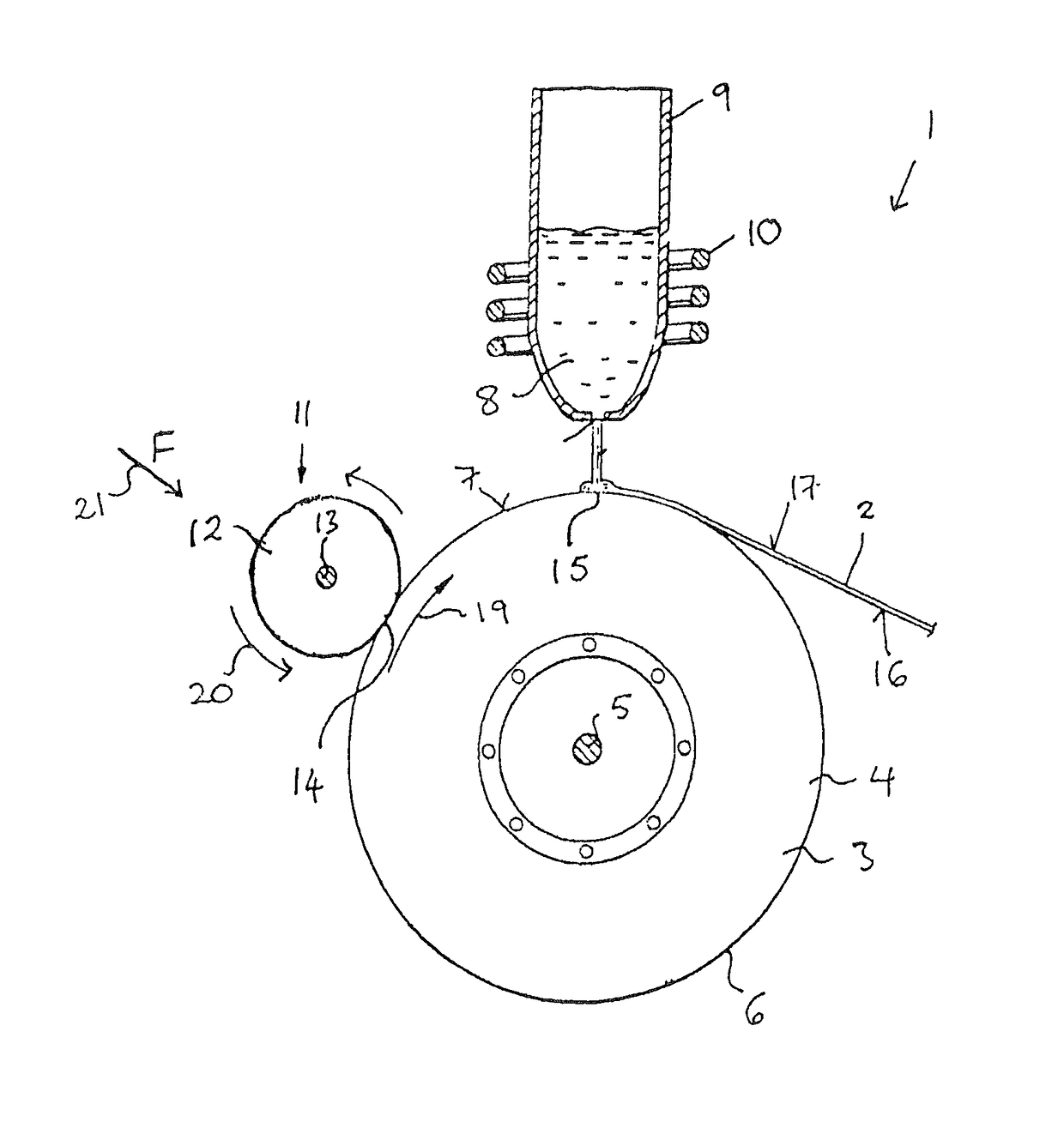

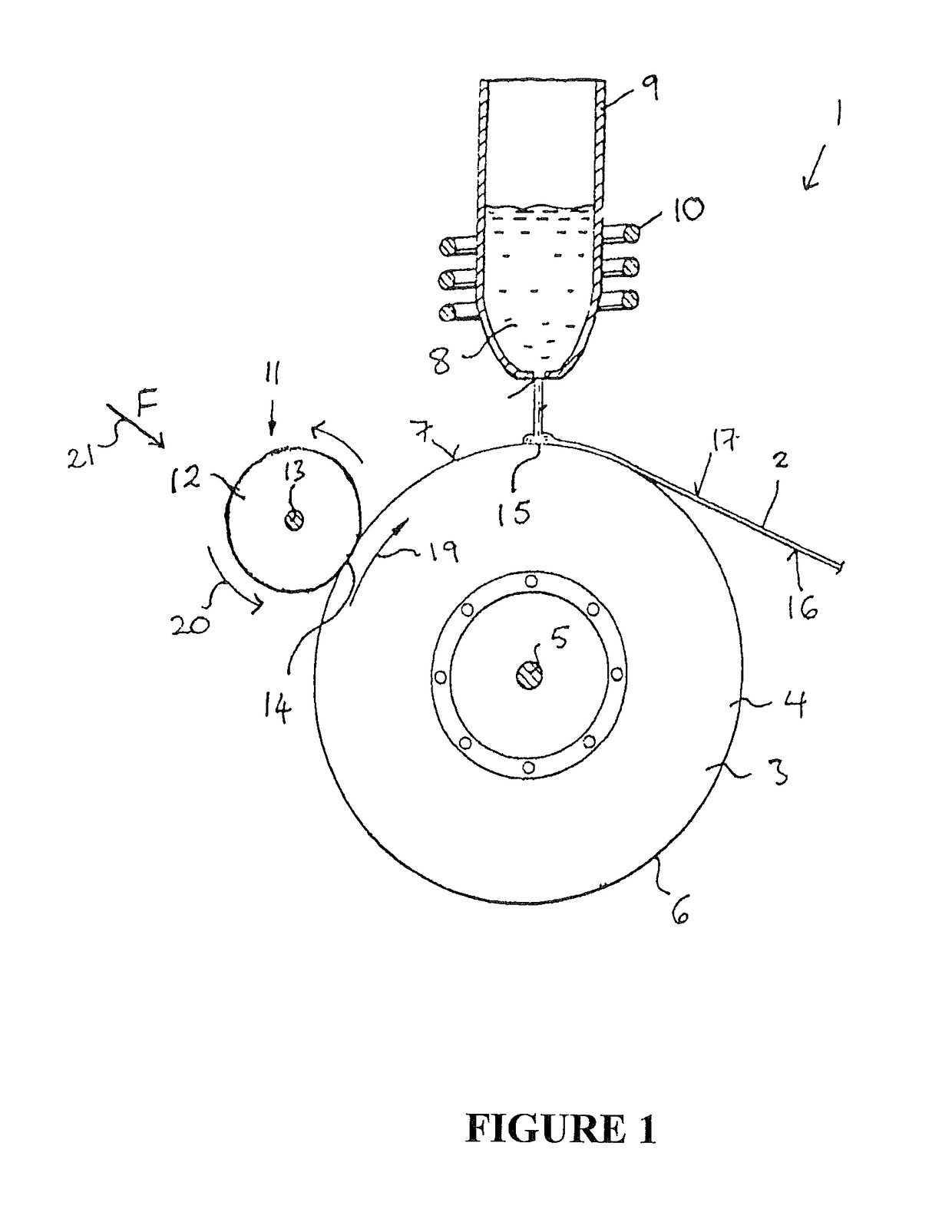

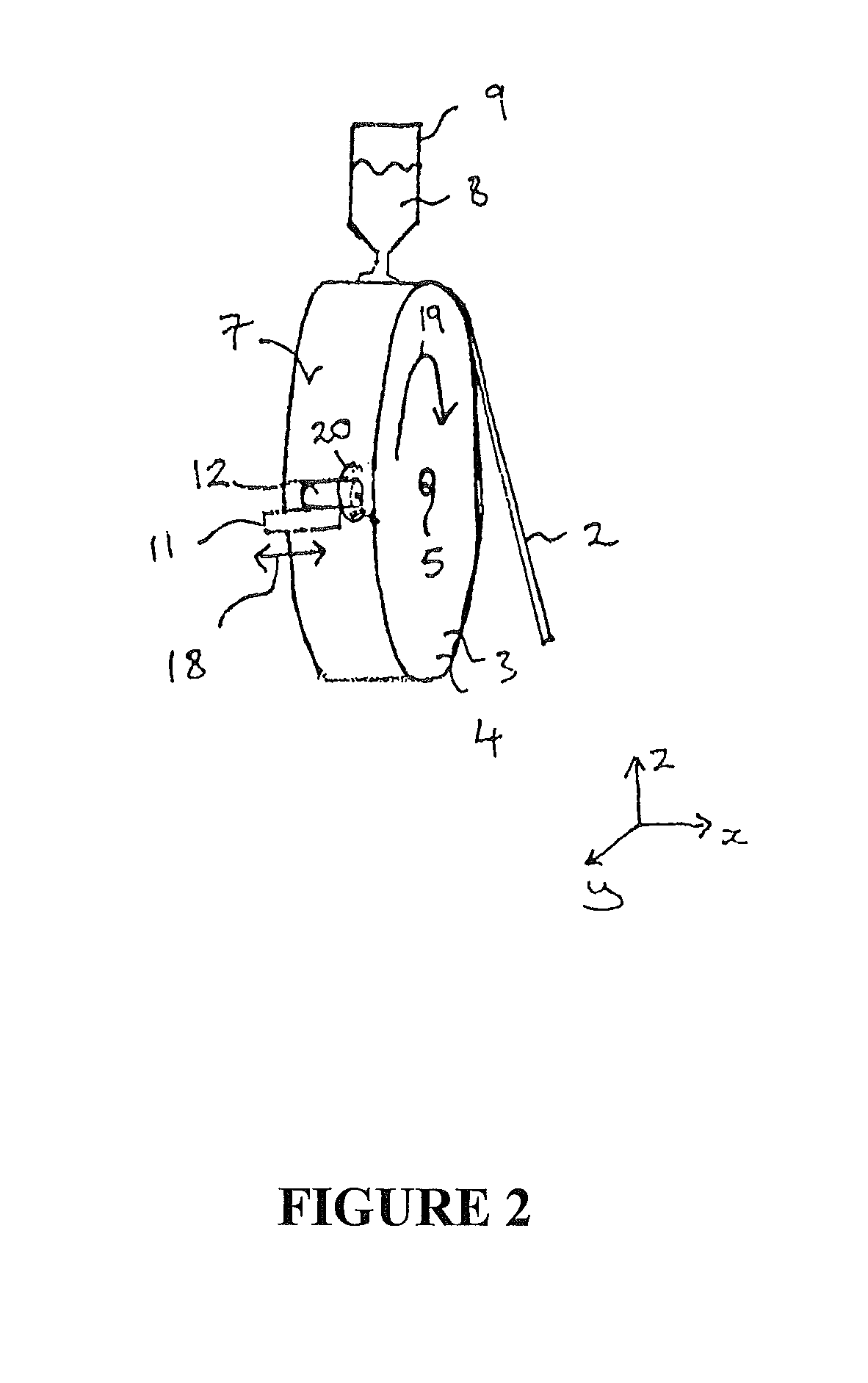

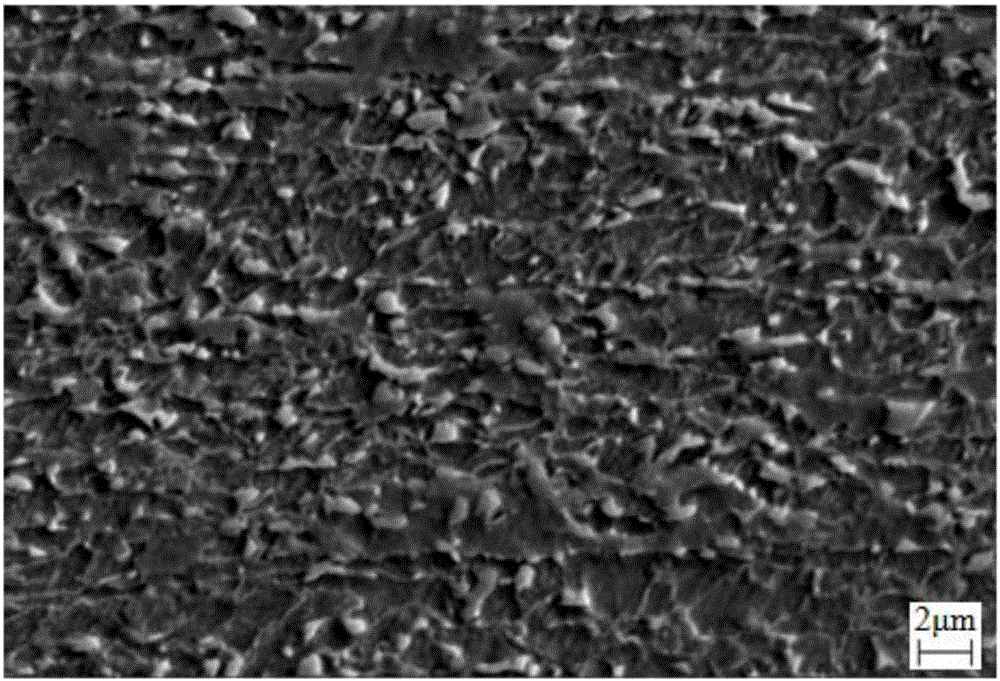

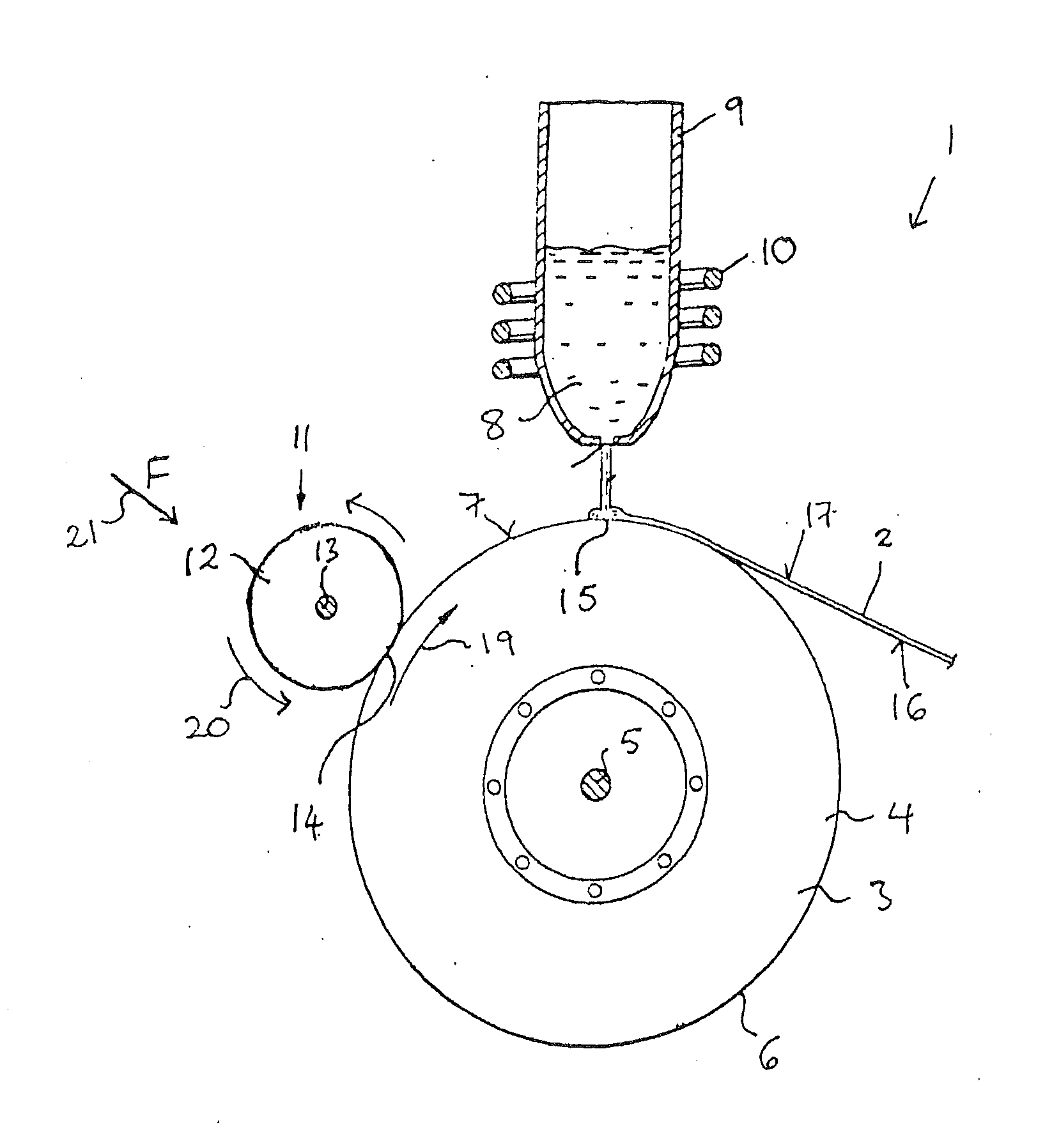

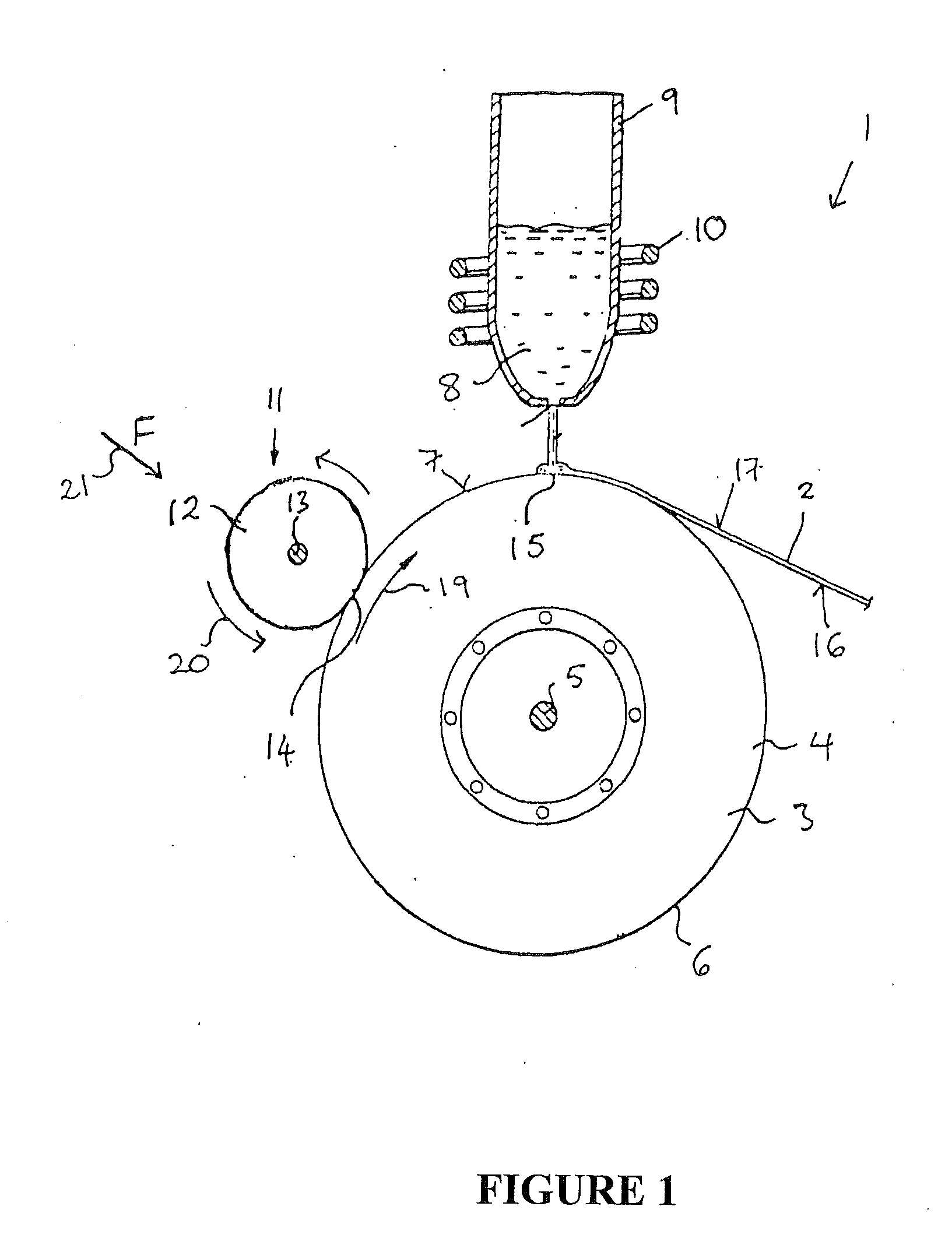

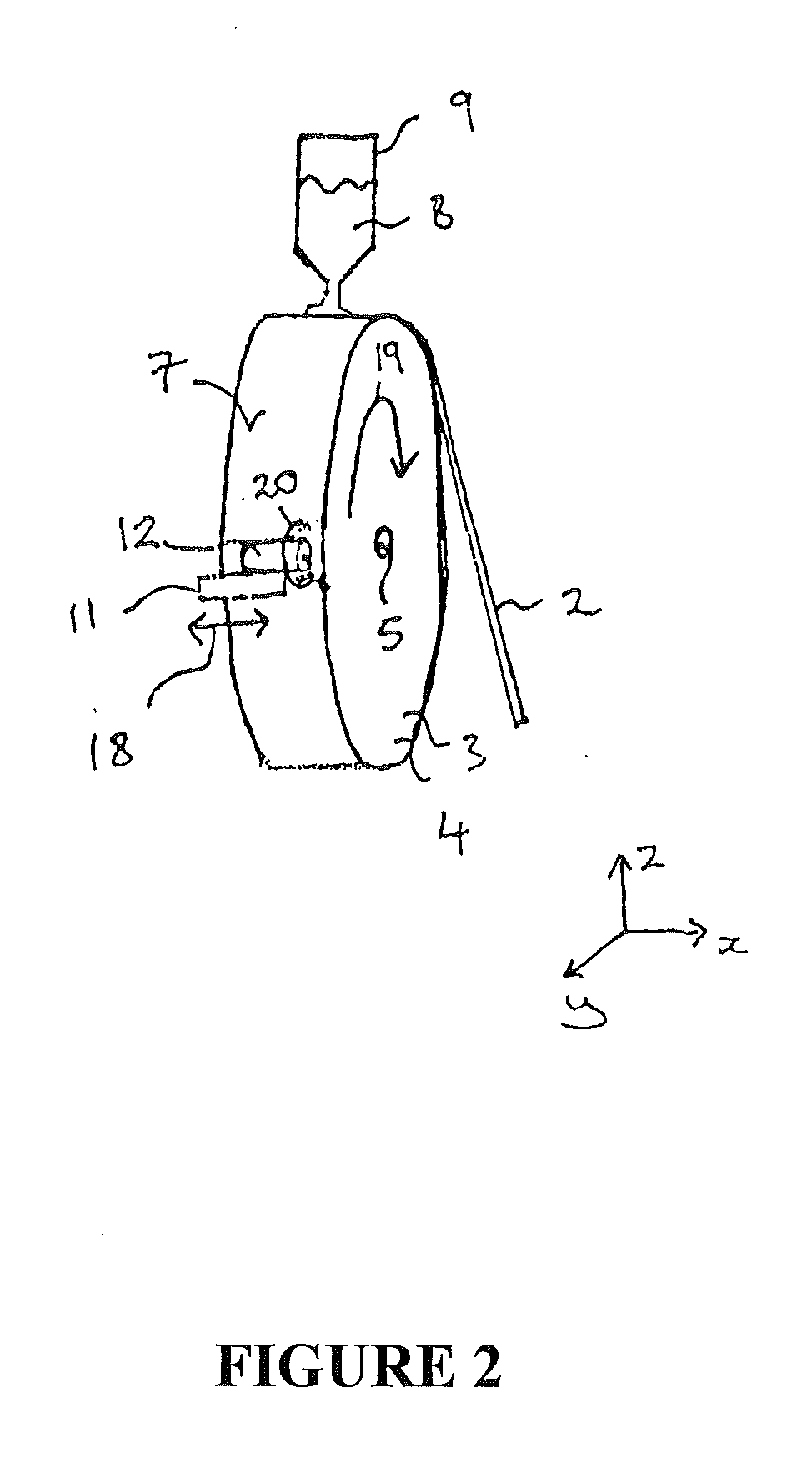

Device and method for the production of a metallic strip

ActiveUS9700937B2Roughness of and in particularSurface roughnessFurnace typesThin material handlingMaterials scienceMetal

A device for the production of a metallic strip using a rapid solidification technology is specified, which device includes a movable heat sink with an external surface onto which a melt is poured and on which the melt solidifies to produce the strip, and which device includes a rolling device which can be pressed against the external surface of the movable heat sink while the heat sink is in motion.

Owner:VACUUMSCHMELZE GMBH & CO KG

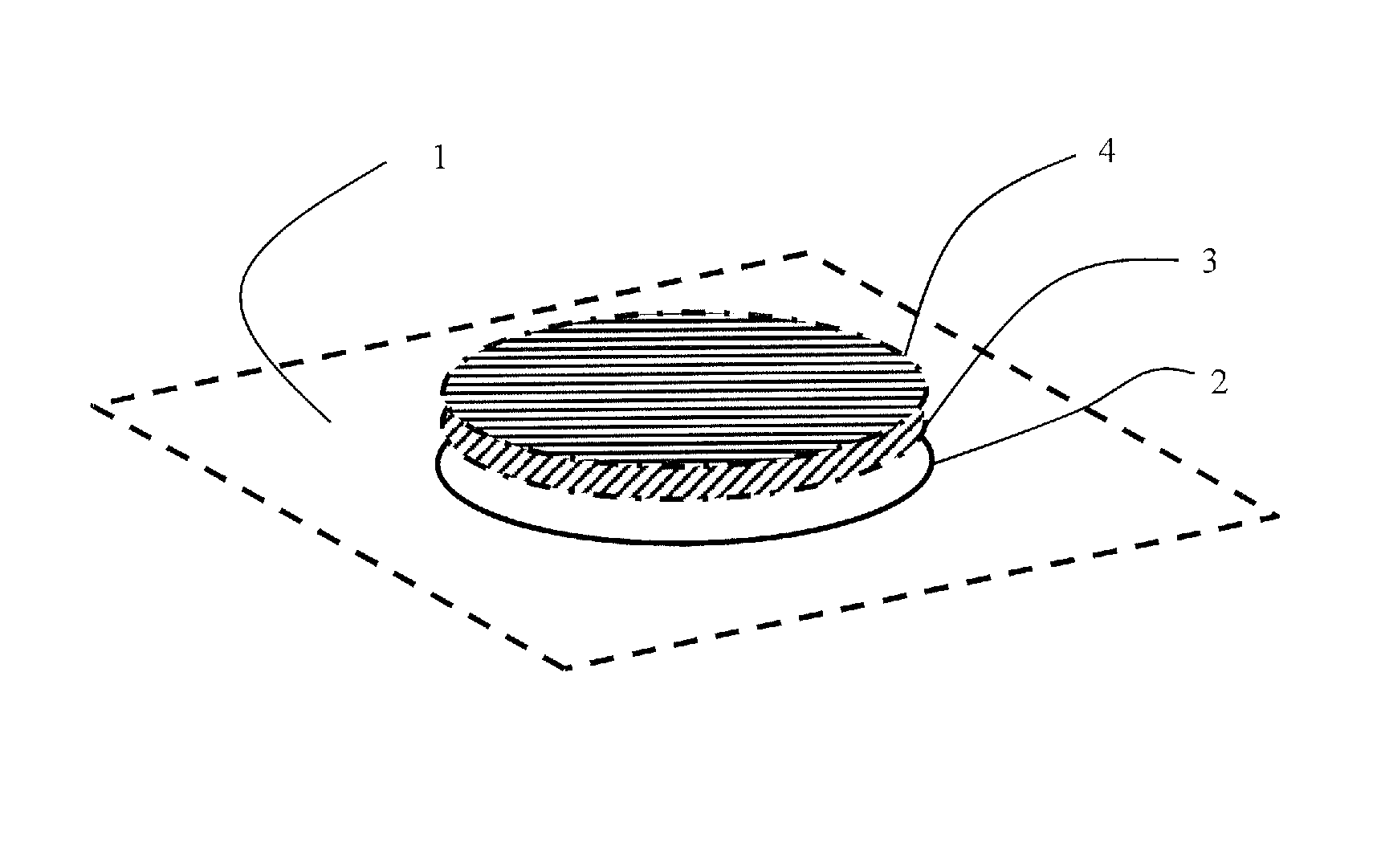

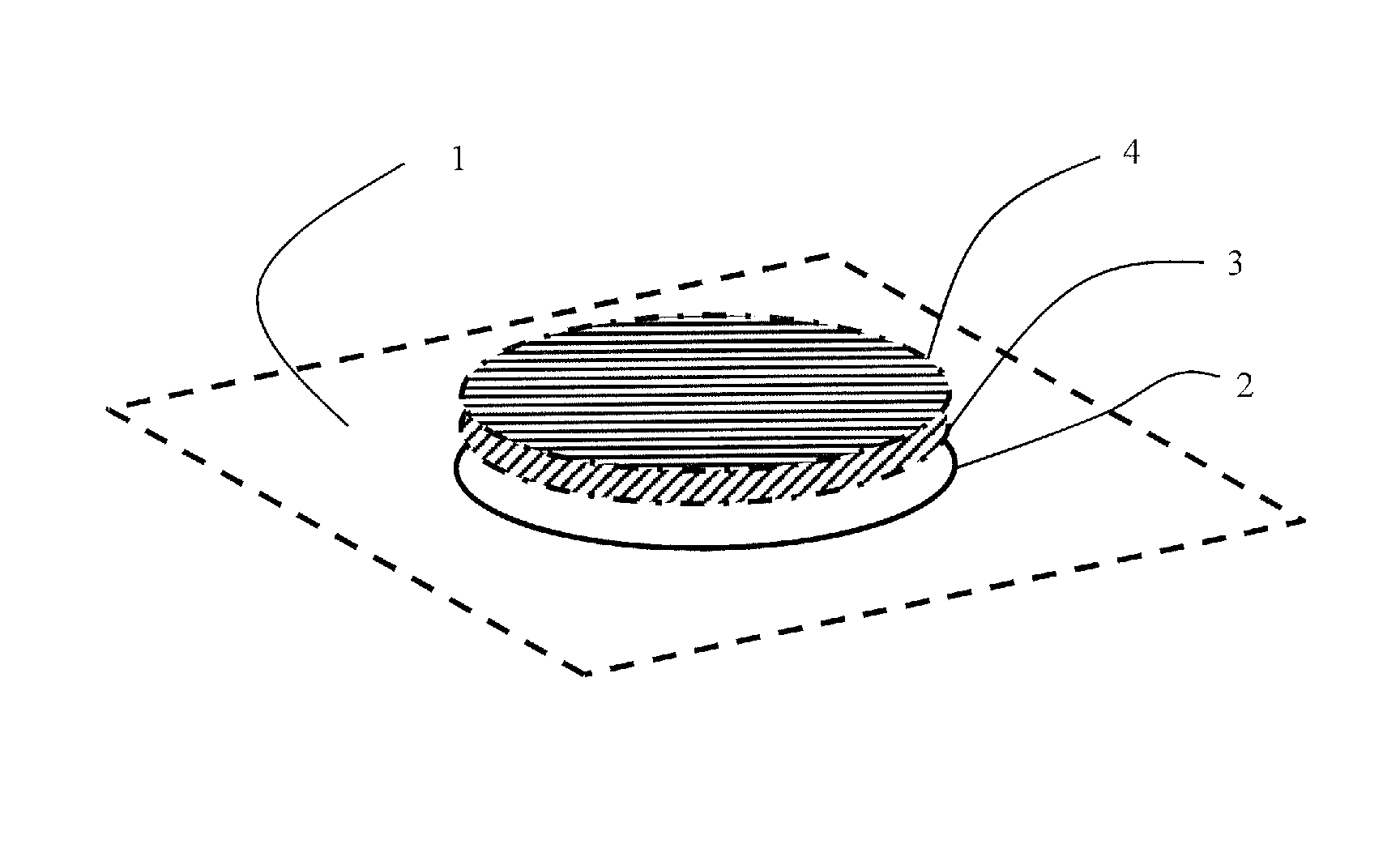

Brachytherapy method of treating skin tumors using a tailor-made radioactive source

ActiveUS20110201866A1Easy to controlPrevent skinAntineoplastic agentsRadiation therapyMedicineBrachytherapy

The present invention refers to a method of treating a cancerous or non-cancerous skin lesion of a subject, e.g. a human patient, by epidermal radioisotope therapy, a specialized type of brachytherapy, comprising the steps of (a) defining and marking an area of skin to be treated; (b) covering said area with a protective layer, e.g. a protective film or foil; (c) applying a tailor-made radioactive source by applying a layer of a radioactive source material on said protective layer, such that said area is covered by said material while any area not to be treated is spared; and (d) removing the radioactive source after a predetermined time period of irradiation.

Owner:ONCOBETA INT GMBH

Polyimide-based carbon molecular sieve membrane for ethylene/ethane separations

ActiveUS20130333562A1Effective membraneStable weightMembranesSemi-permeable membranesHollow fibreFiber

Carbon molecular sieve membranes having desirable selectivity for ethylene / ethane separations are prepared from a 3,3′,4,4′-benzophenonetetracarboxylic acid dianhydride 5(6)-amino-1-(4′-aminophenyl)-1,3,3-trimethylindane 4,4-bismaleimidodiphenyl-methane (BTDA-DAPI) precursor solution that is then formed into films or hollow fibers which are pyrolyzed under vacuum or an inert atmosphere to form carbon molecular sieve membranes. Pyrolysis condition variables, including ramp rate, thermal soak time and temperature, are used to optimize the membrane's separation performance.

Owner:GEORGIA TECH RES CORP

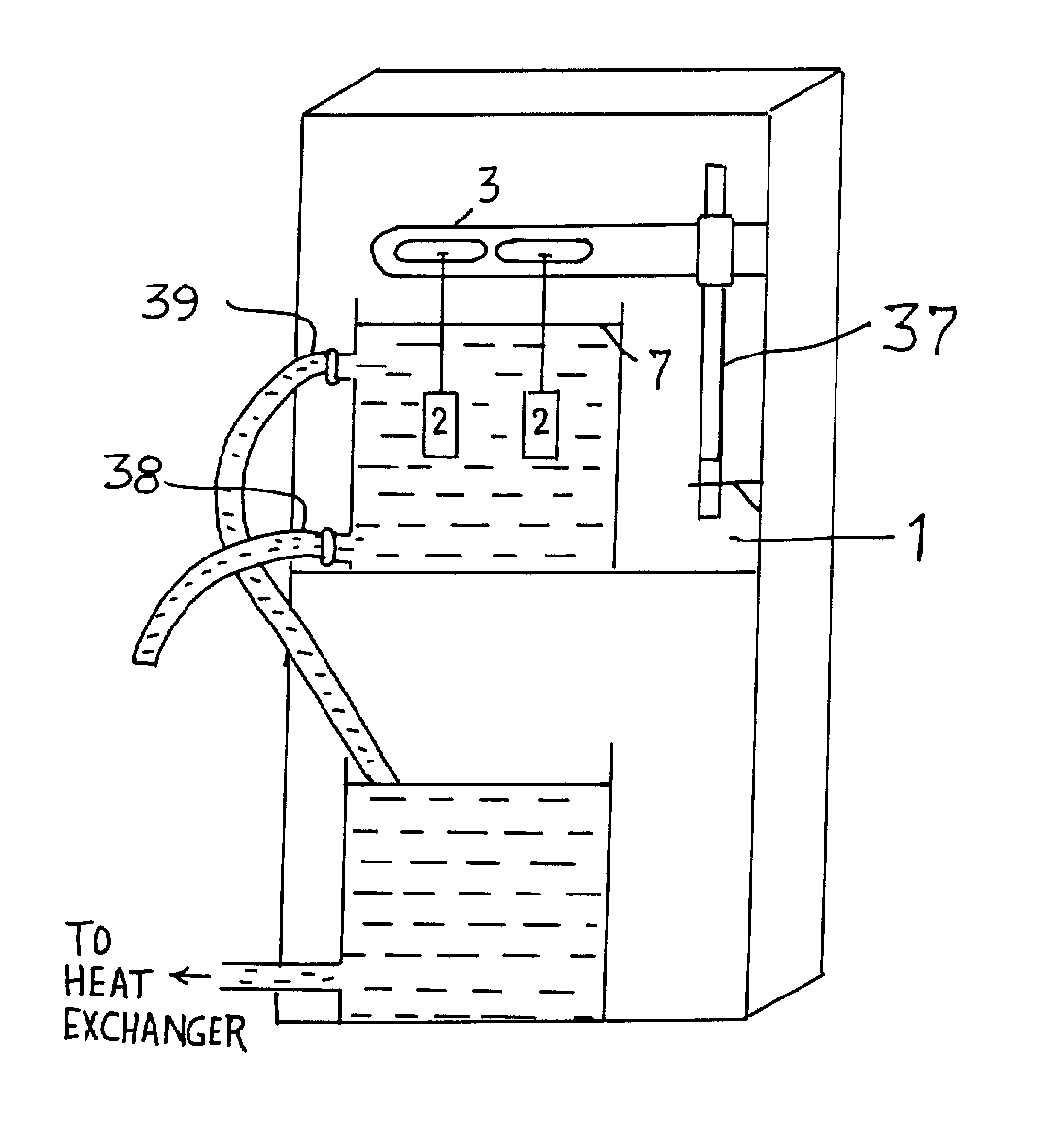

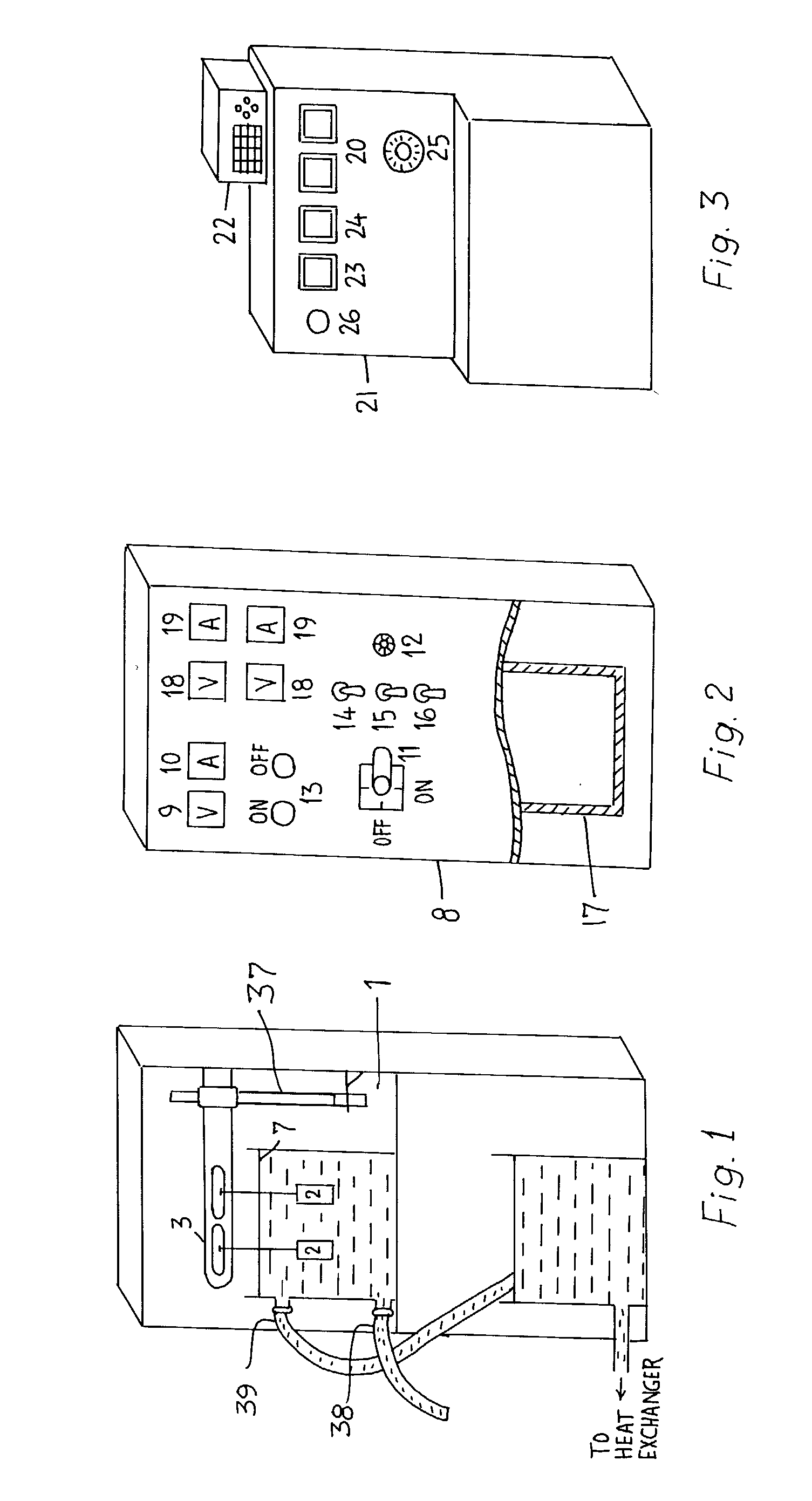

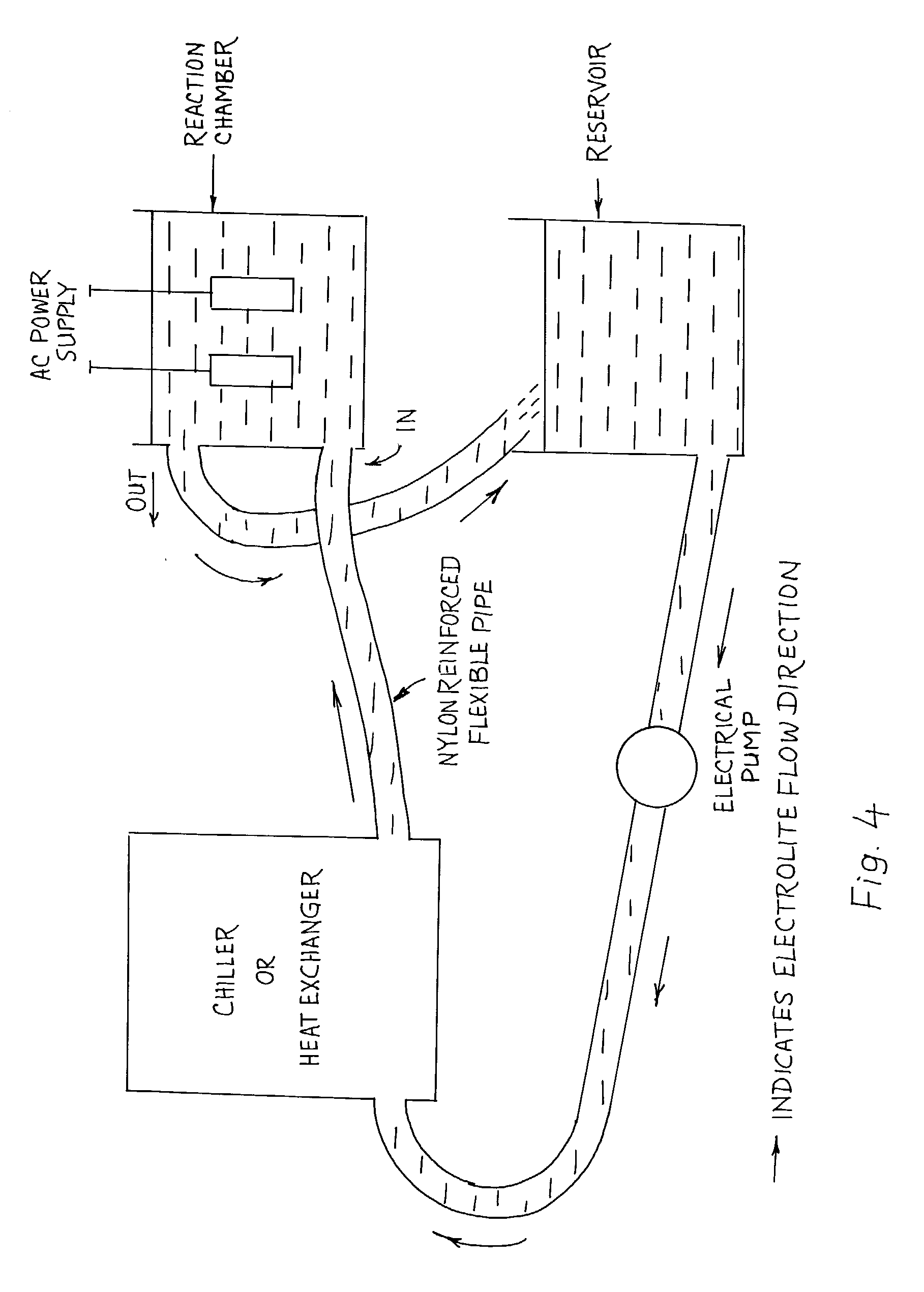

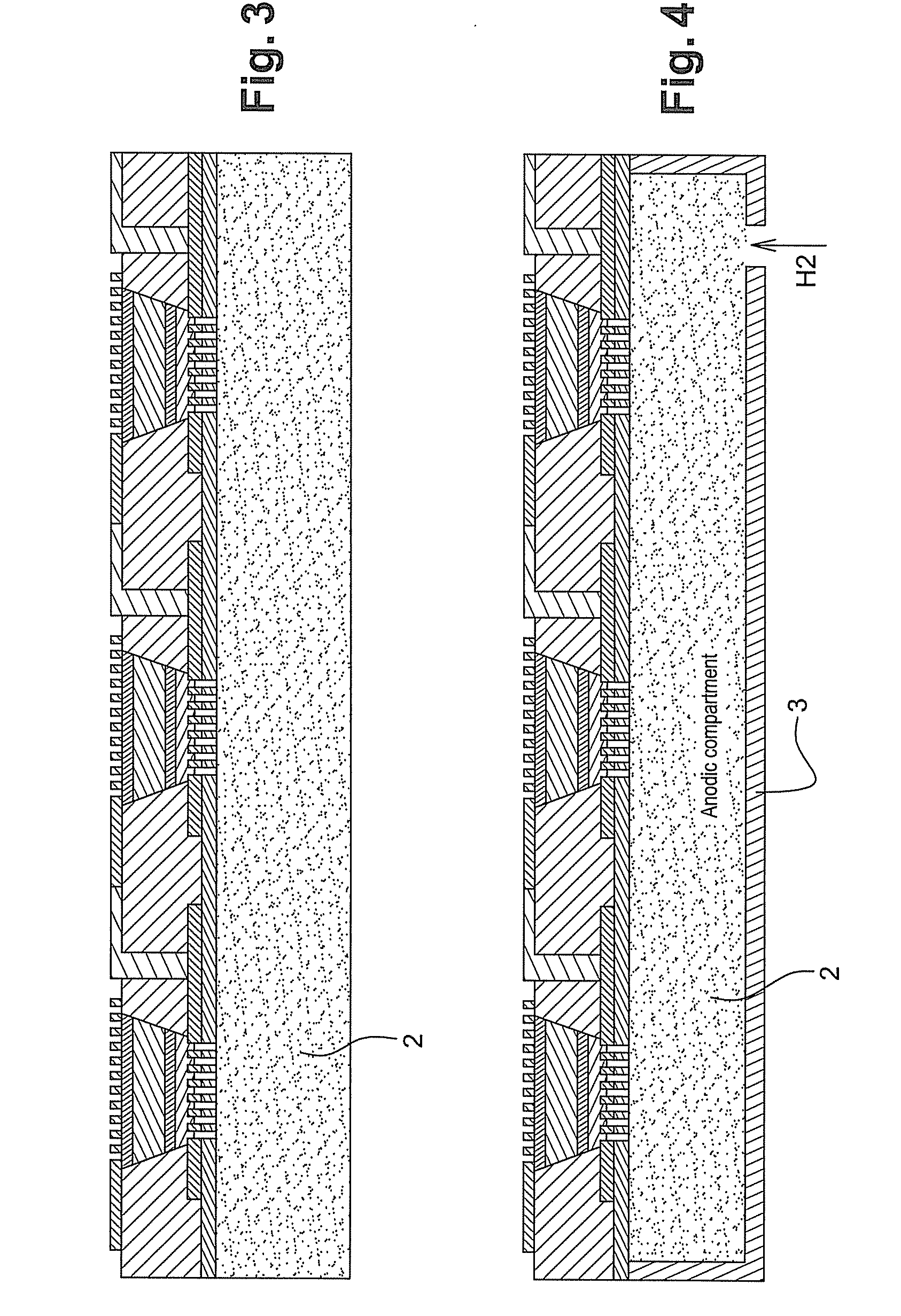

Process for forming coatings on metallic bodies and an apparatus for carrying out the process

InactiveUS20030094377A1Protect the surfaceEconomical and simpleCellsAnodisationCeramic compositeVolumetric Mass Density

This invention disclosed in this application relates to a process for forming oxide based dense ceramic composite coatings on reactive metal and alloy bodies. The process involves suspension of at least two reactive metal or alloy bodies in a non-metallic, non-conducting, non-reactive chamber in such a way that it causes either partial or full immersion of the said bodies in a continuously circulating electrolyte. Thyristor controlled, modified shaped wave multiphase alternating current power supply is applied across the said bodies where in each body is connected to an electrode. Electric current supplied to the said bodies where in each body is connected to an electrode. Electric current supplied to the said bodies is slowly increased to a particular value till the required current density is achieved and the maintained at the same level throughout the process. Visible arcing at the surface of the immersed regions of the said bodies is identified when the applied electric potential crosses 60V. Electric potential is furthr increased gradually to compensate the increasing resistance of the coating. Electrolyte composition is regulated through the changes in pH and conductivity of the electrolytic solution. Thickness of the coating formed on the said bodies is monitored by the time for which the electrical power at constant current density is supplied to the said bodies. The invention also relates to an apparatus for carrying out the above defined process. The coatings obtained according to the present invention are found to exhibit higher density and excellent wear resistance.

Owner:M S INT ADVANCED RES CENT FOR POWDER METALLURGY & NEW METERIALS ARCI

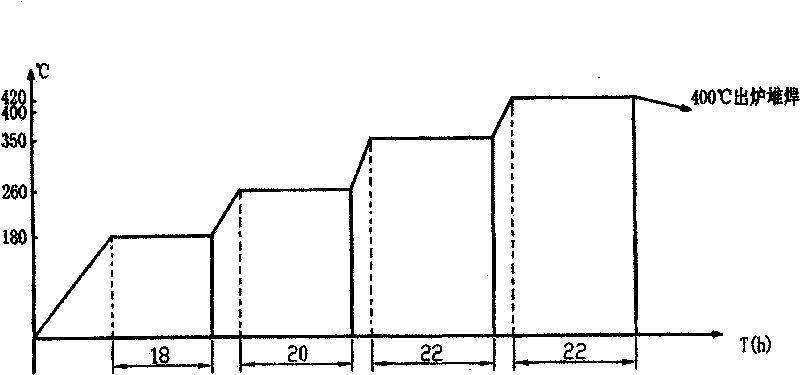

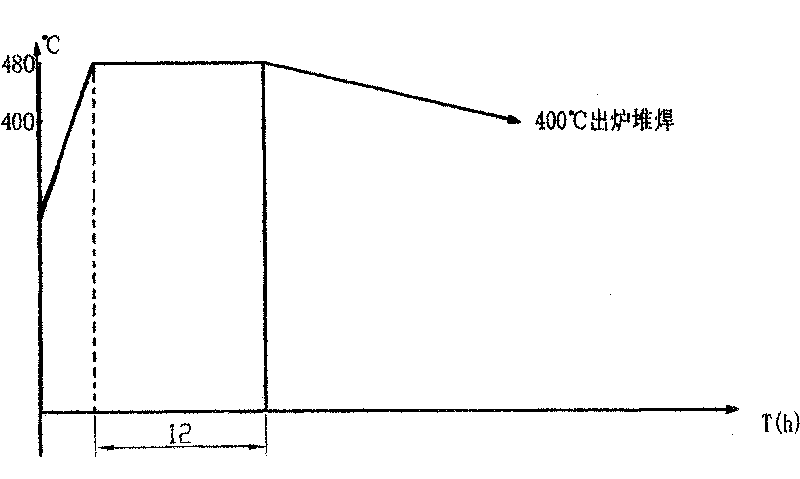

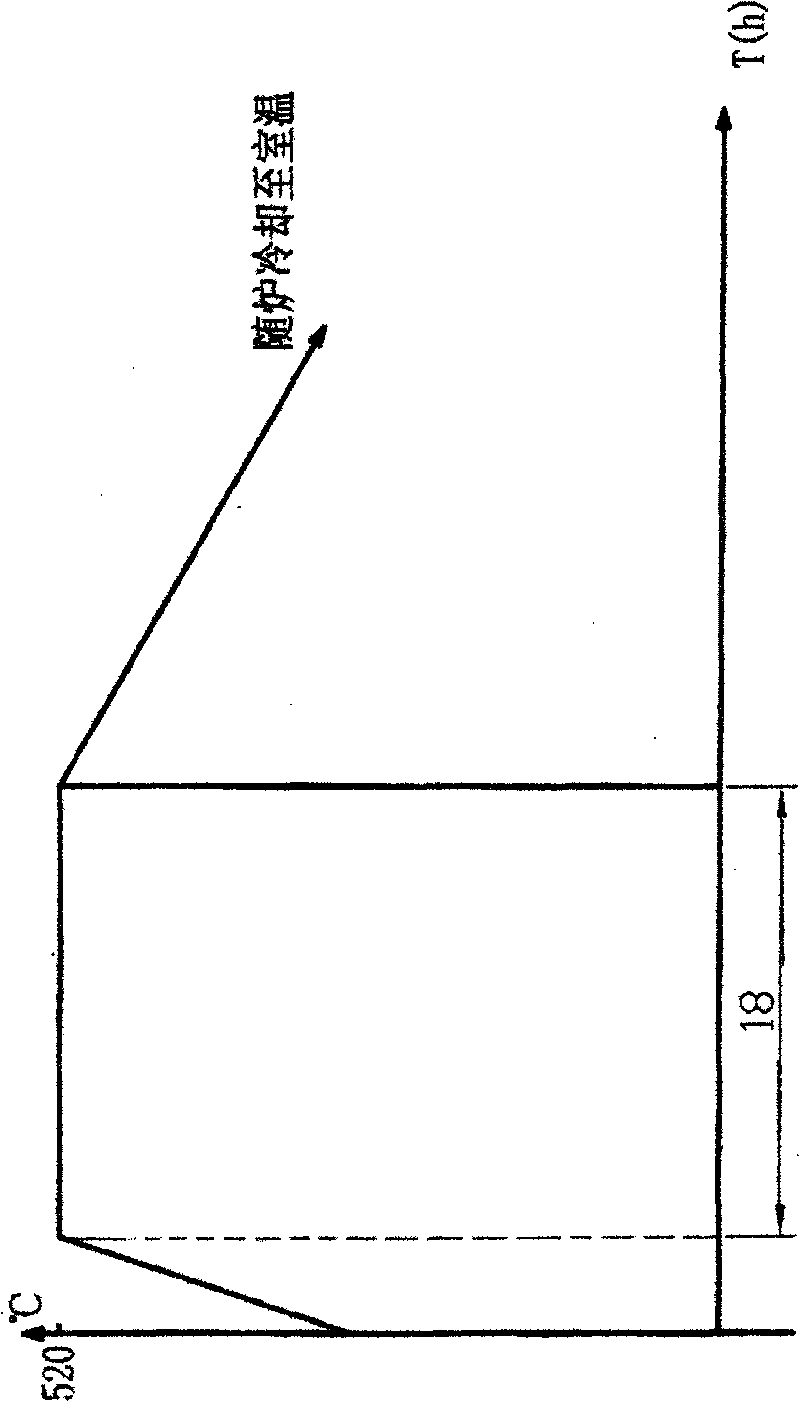

Renovation technique for phi2100í3400mm wrought steel support roll

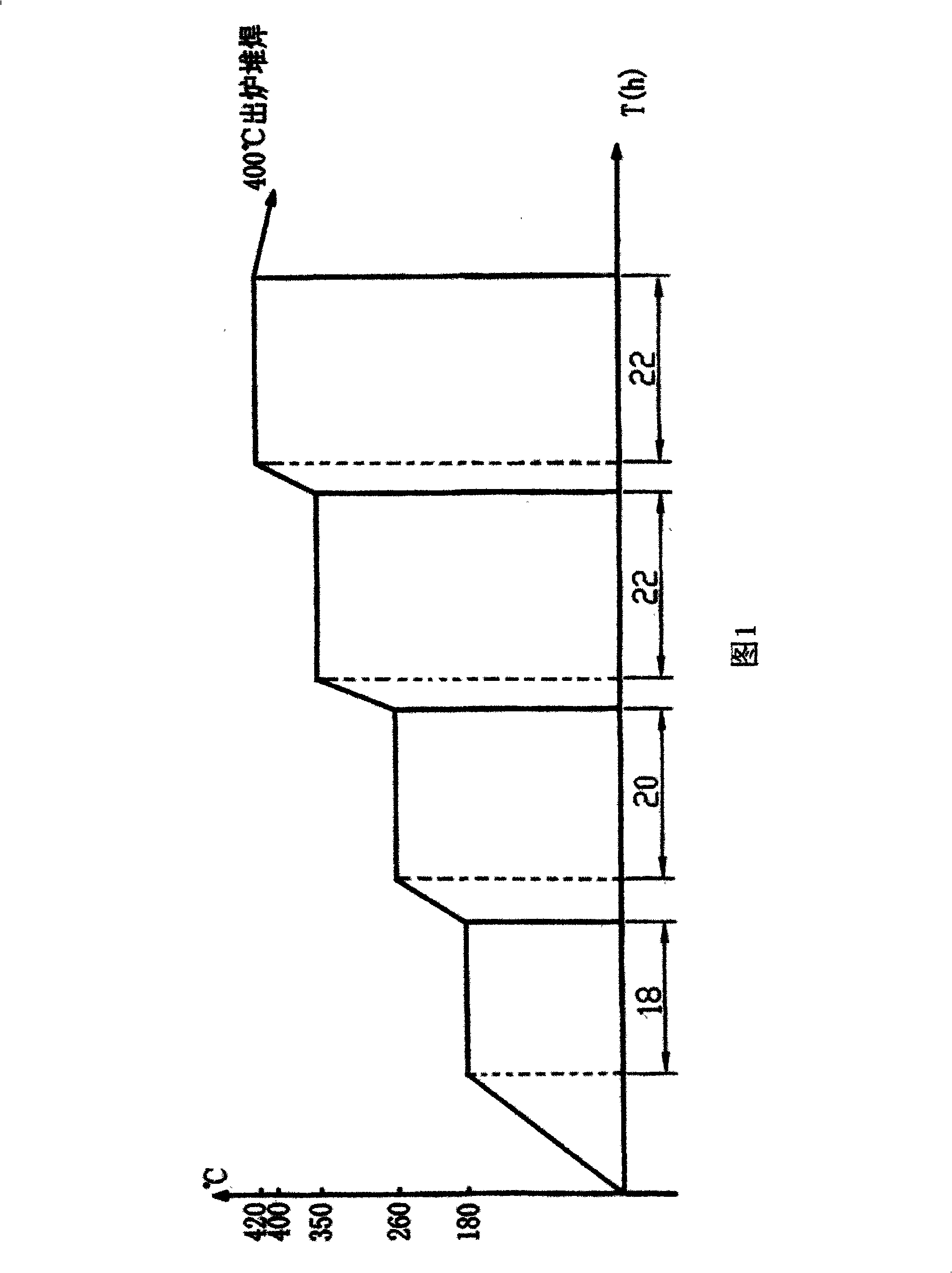

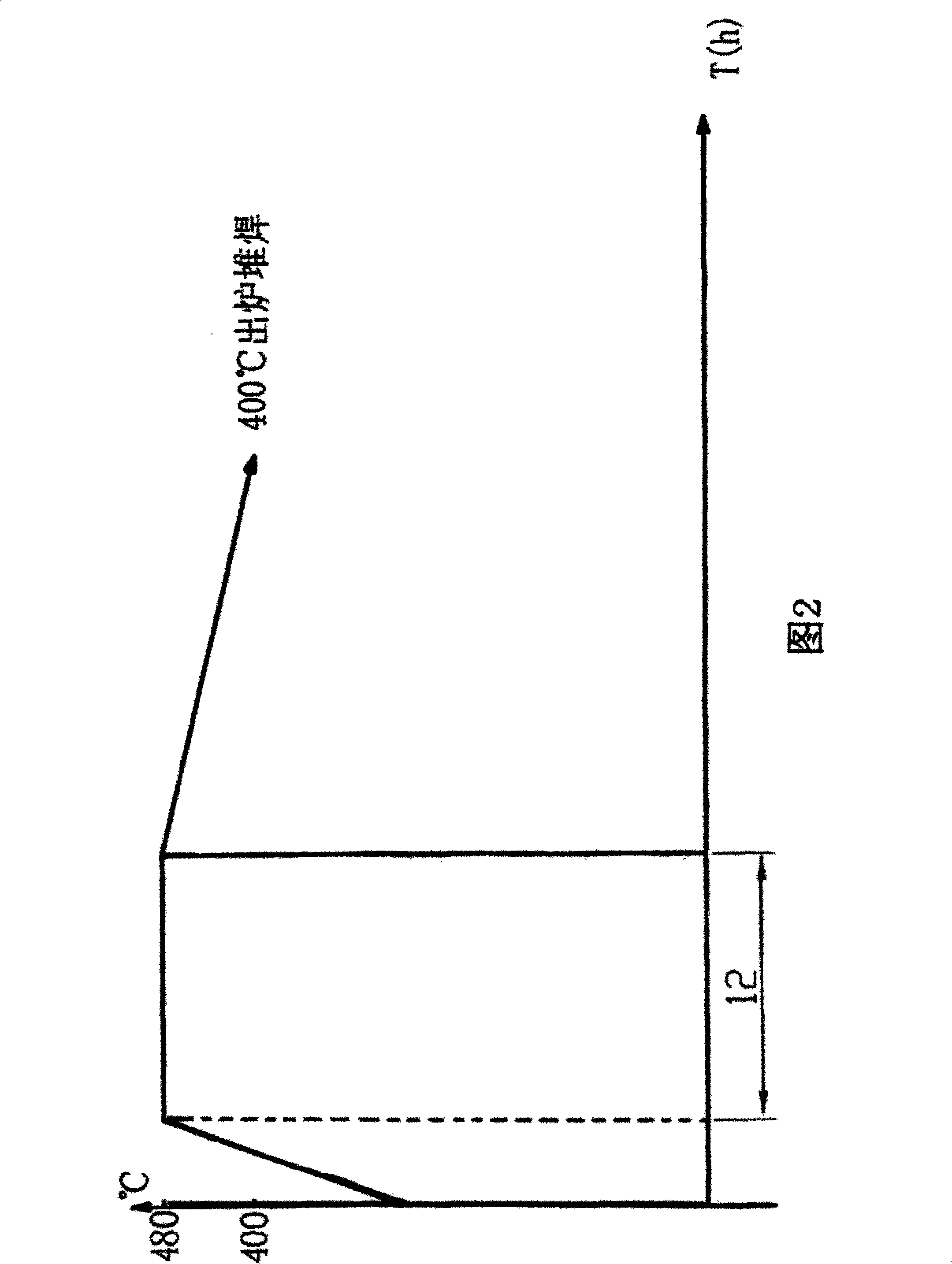

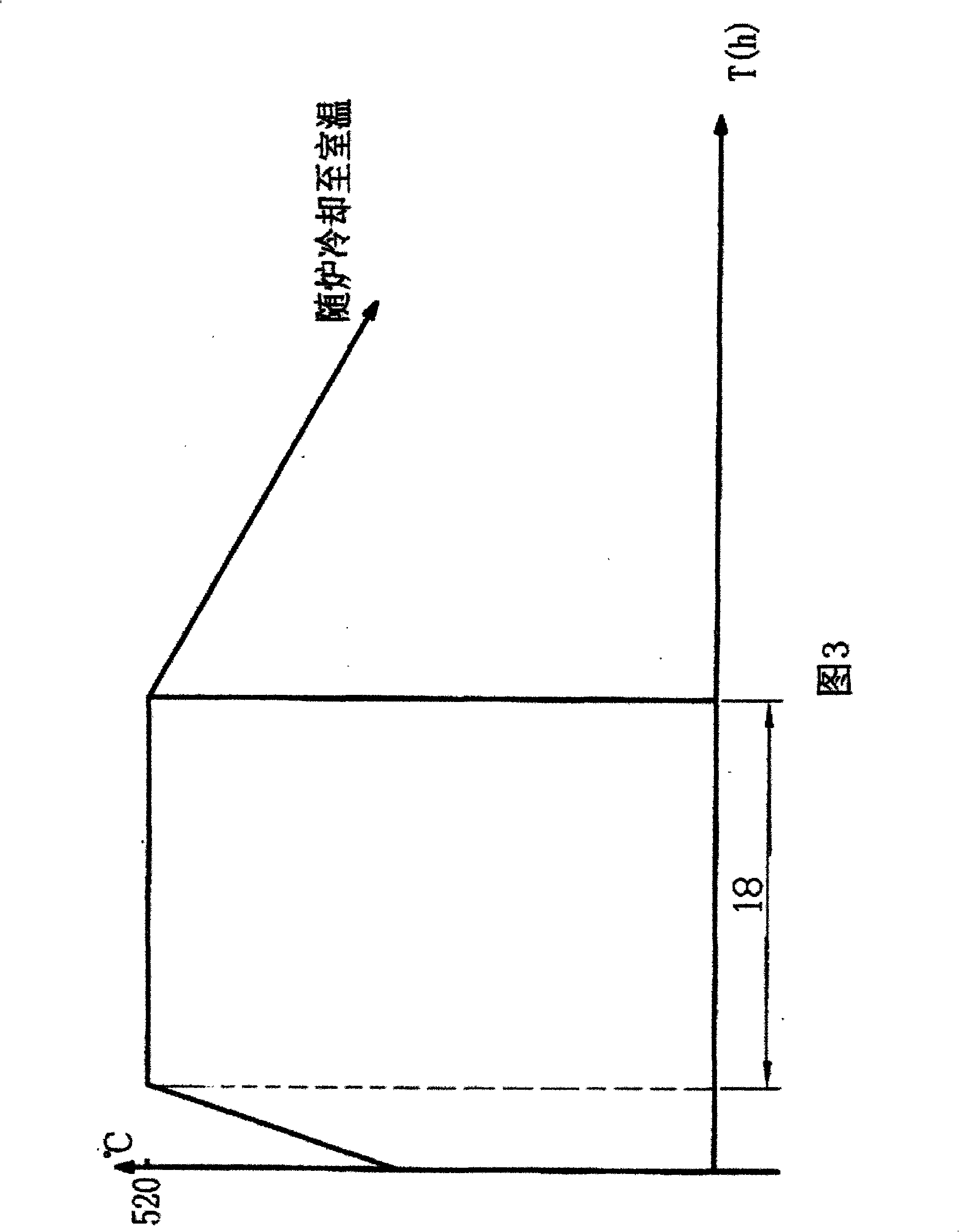

InactiveCN101293300AEnsure homogeneityPreserve the quality of restorationCounter-pressure devicesArc welding apparatusHeat-affected zoneEngineering

The invention relates to the technical field for repairing an ultra-large type backup roll, in particular to a repair process of a forging steel backup roll with Phi2100* 3400mm. Firstly, welding is carried out on the rib of the backup roll: the roll body of the backup roll which needs to be welded is preheated to 250 DEG C, and the temperature is preserved for 10 hours; then the door of a furnace is opened, rib welding is carried out, zigzag welding is carried out every 100mm, and the length of the weld pass is 50-60mm; oxygen is used on the welded part immediately, and ethyne is used for warming the welded part until the welded part becomes blue. After the rib welding is finished, preheating treatment, temperature preservation treatment and destressing treatment are carried out respectively according to a heat treatment curve when the roll body of the backup roll is overlaid for making a bottom layer, a transition layer and a working layer. Compared with the prior art, in the technology of the invention, the influence on the service performance caused by the temperature circulation and change of a heat influencing region during the overlaying is considered, uniformity and penetration of preheating workpieces and uniformity of temperature between layers are guaranteed in the repair process, the blank in the repair rebirth field of the domestic ultra-large type backup roll is filled in. The time for repair is short, the service life is prolonged, and the cost is saved.

Owner:SHANGHAI SHIWEI WELDING IND

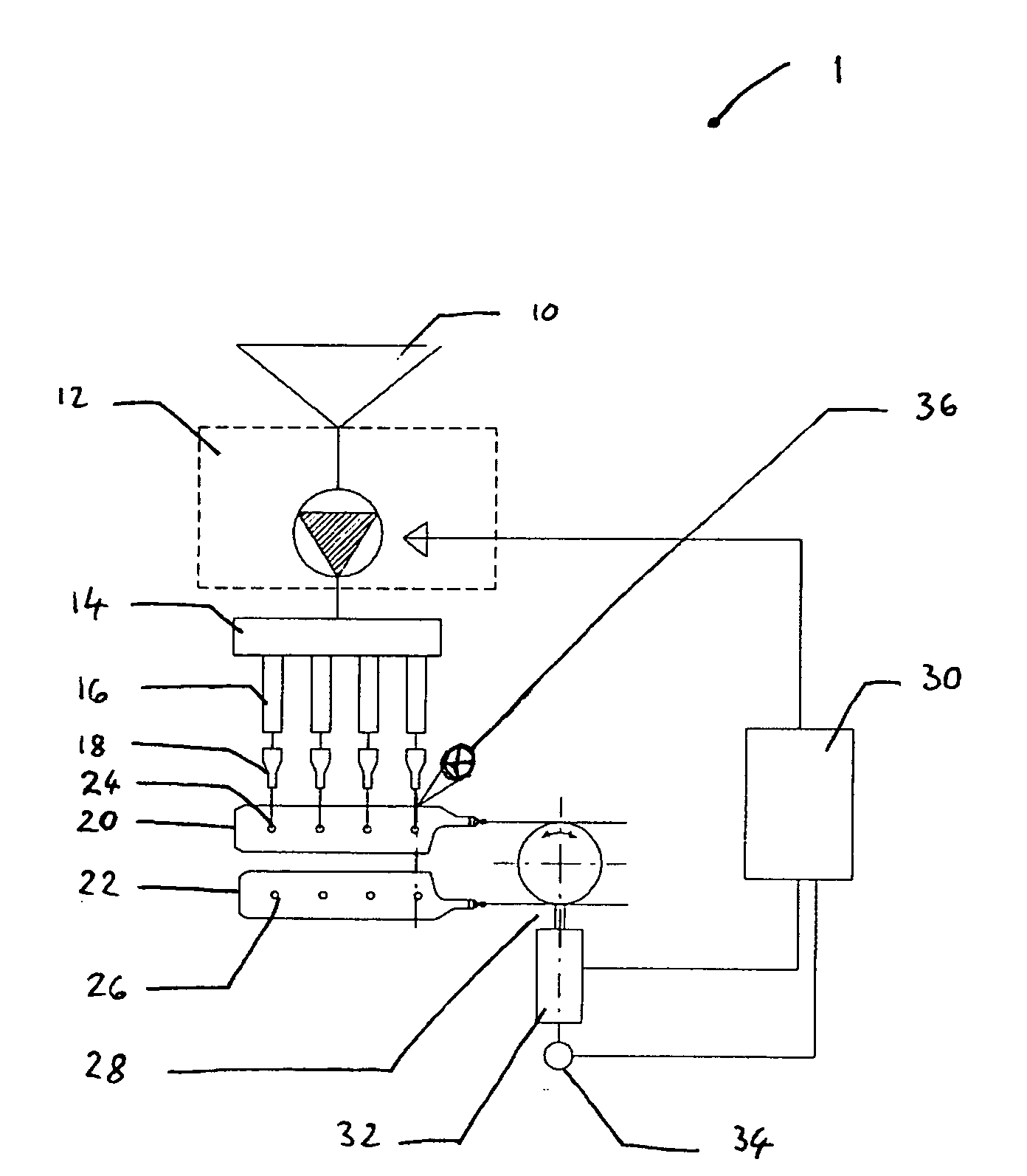

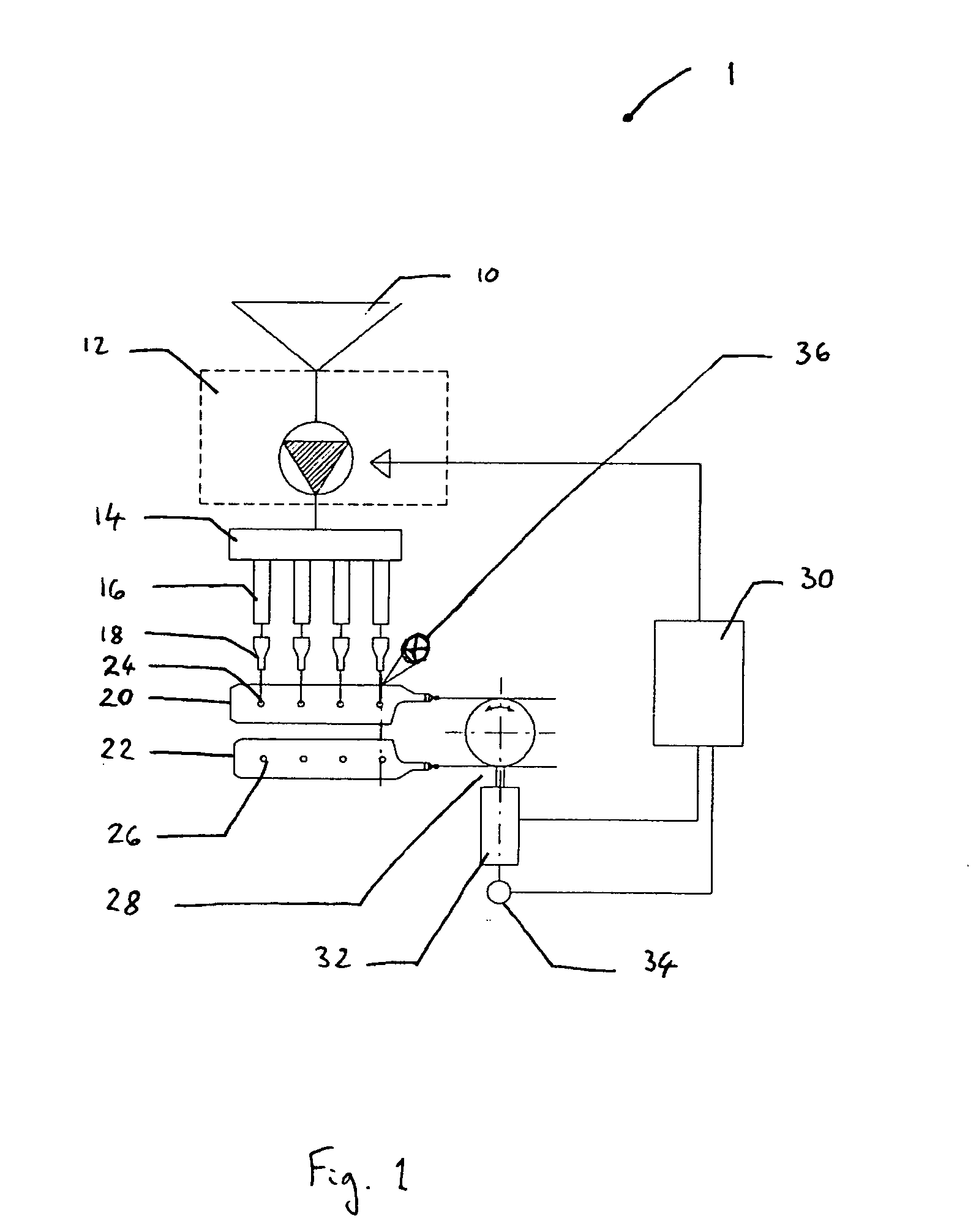

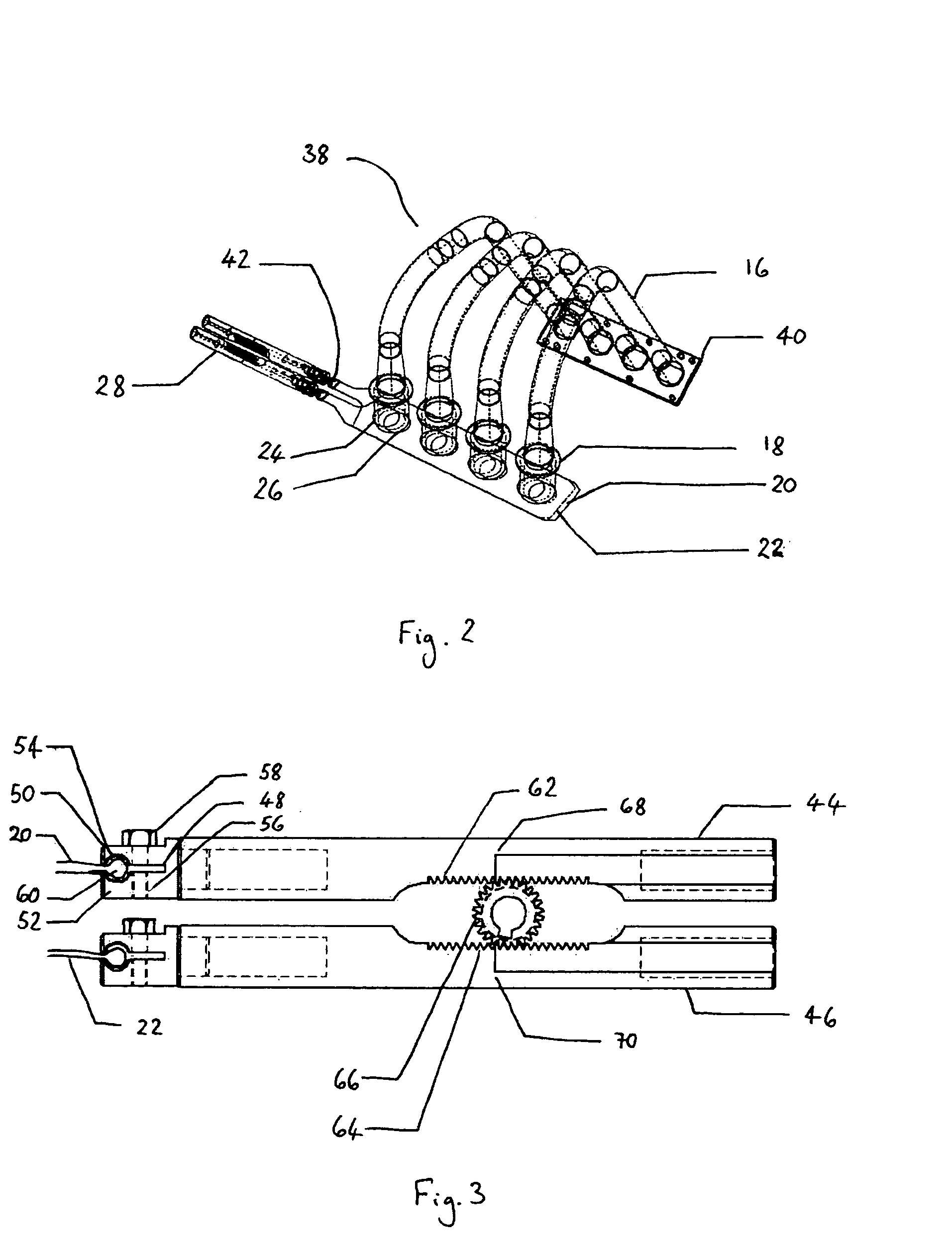

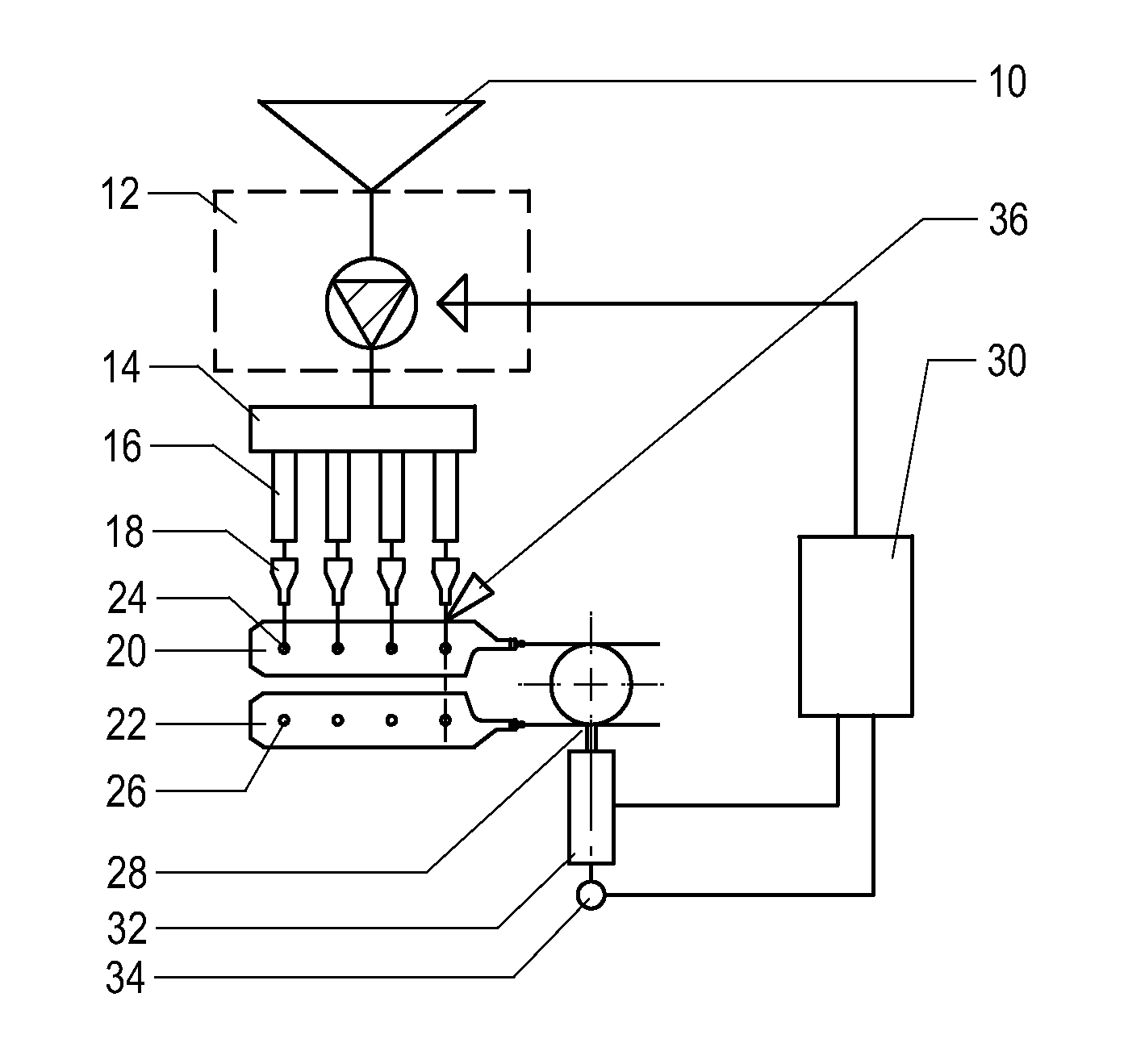

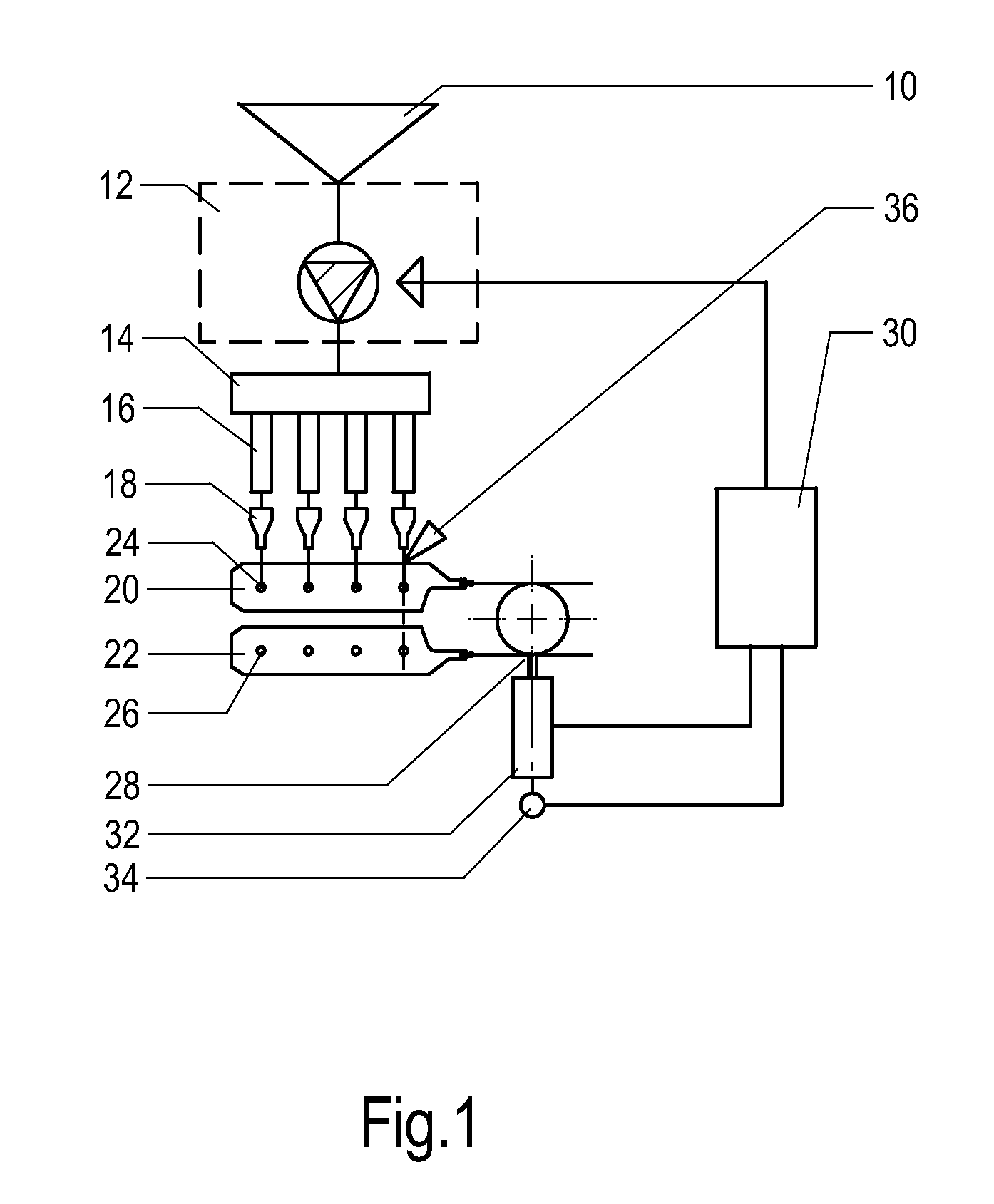

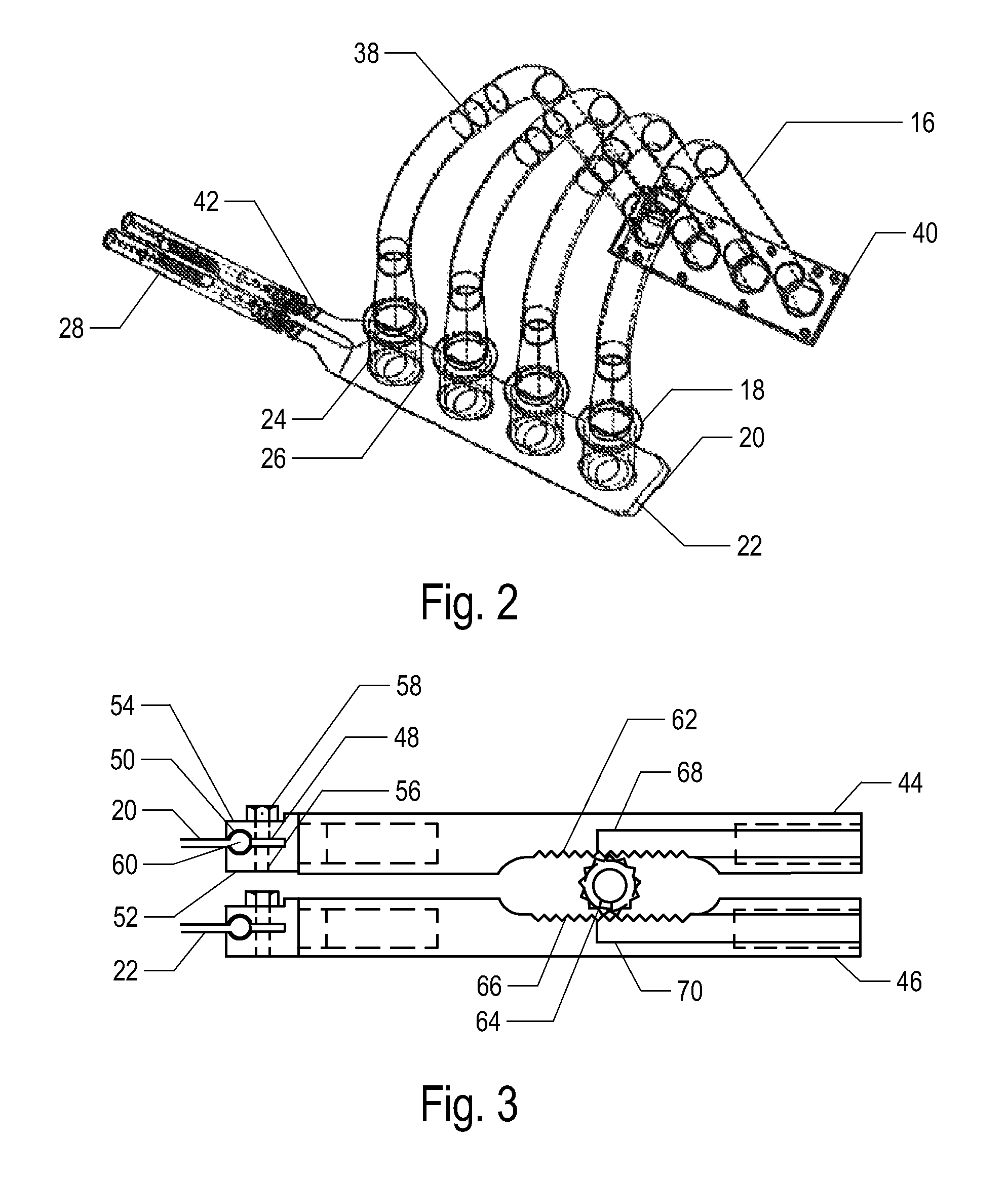

Food processing device

ActiveUS20070295222A1Improve cutting performanceReduce actionLinked sausage separationFood shapingElectricityLine tubing

A food processing device comprises a paste reservoir, a feed pump and a flow divider. The flow divider is provided with outlets to four supply lines all of which receive a substantially equal supply of paste as a result of the operation of the flow divider. Each of the outlets is connected to a nozzle. A pair of knives is located ahead of the nozzles, each being provided with four apertures. The knives are provided with an actuating mechanism and a controller. Controller registers and controls operation of the meatball forming device and is electrically connected to the feed pump, to a servomotor and to a shaft encoder.

Owner:MACHINEFAB GEURTSEN DEVENTER

Multi-axial expandable pedicle screw and an expansion method thereof

ActiveUS8911484B2Reduce probabilityEasy to controlSuture equipmentsInternal osteosythesisFailure rateUniversal joint

Owner:LEI WEI +1

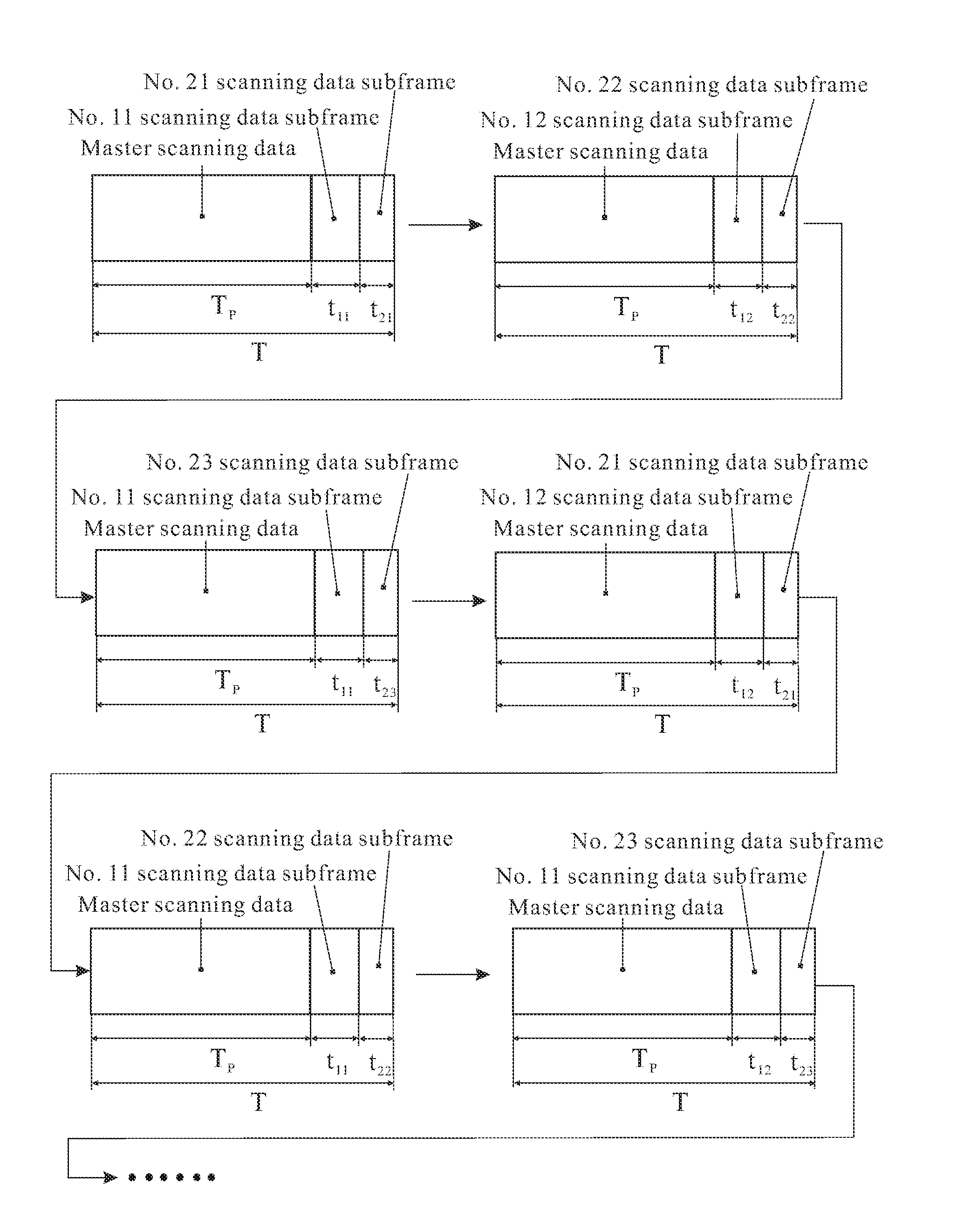

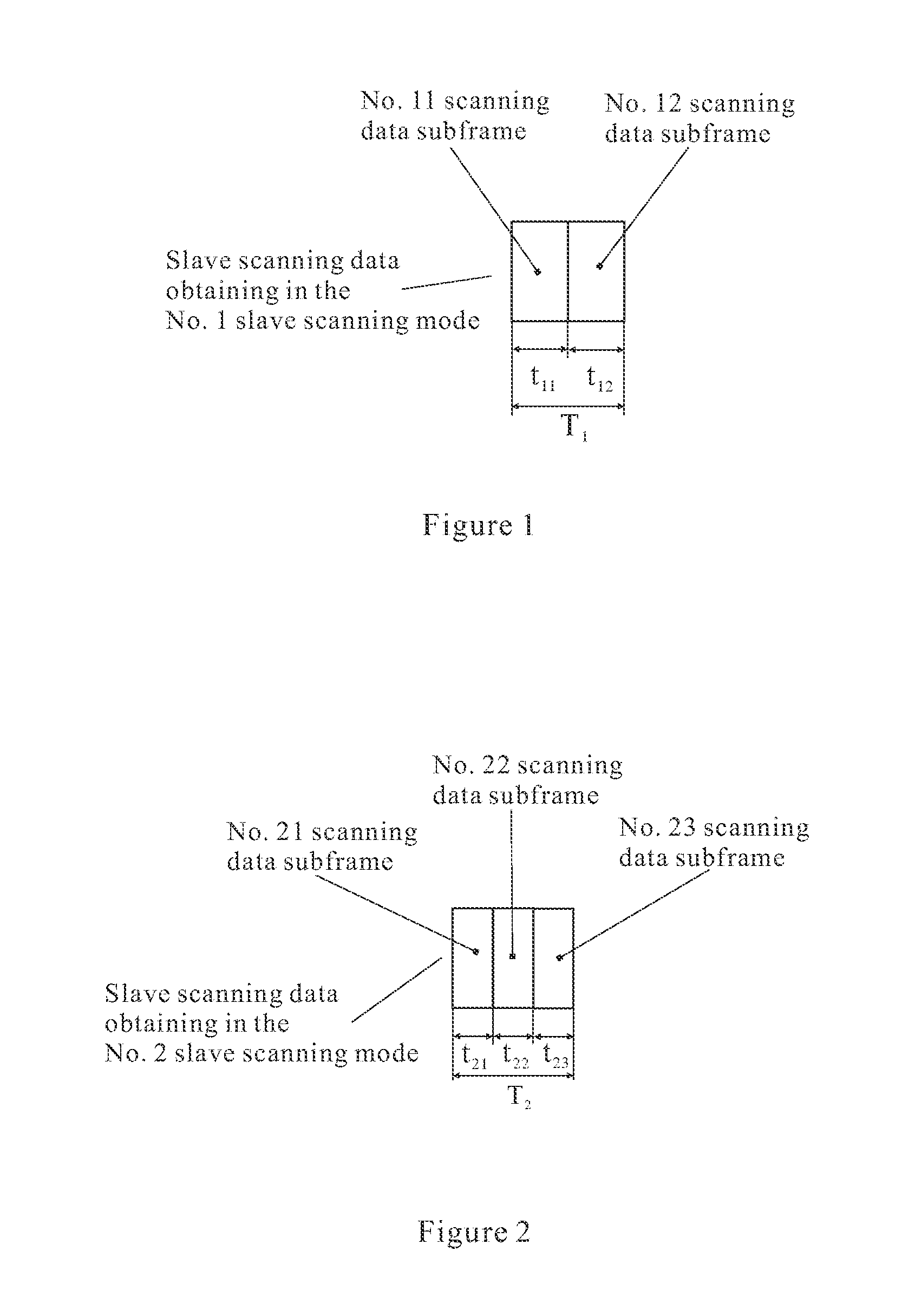

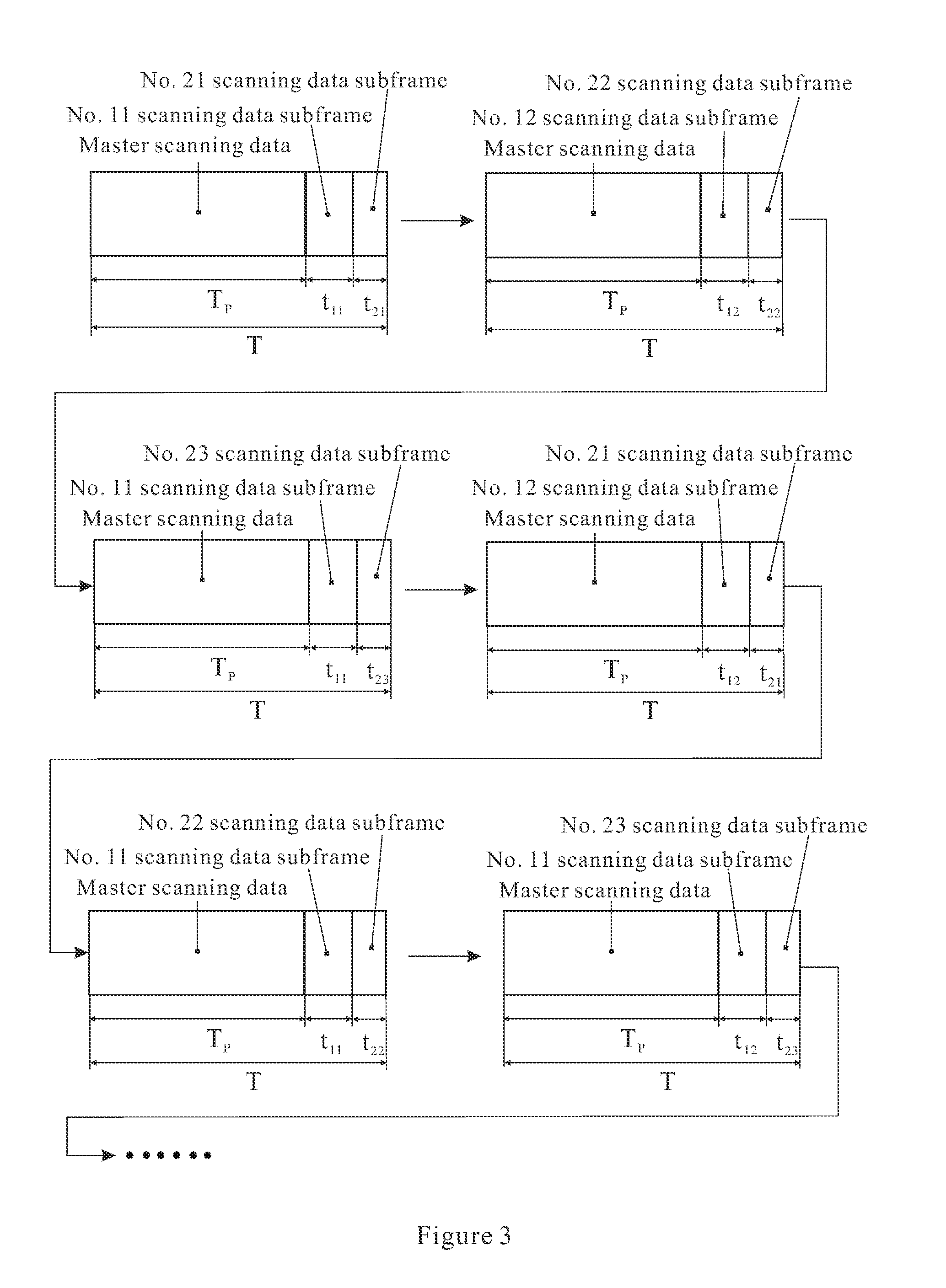

Time slot scanning method enabling the capacitive touch screen to implement multiple scanning modes

InactiveUS20140160065A1Enabling reliability of dataMinimize consumptionInput/output processes for data processingCapacitanceLaser scanning

A time slot scanning method that enables the capacitive touch screen to implement multiple scanning modes, where the said capacitive touch screen comprises the capacitance matrix and data processing modules that are electrically connected thereto; the said scanning method refers to a data acquisition mode where the signal scanning is initiated in a cycle and the received data generated due to scanning are acquired. The present invention enables the touch screen to execute multiple scanning modes with the time slot scanning method. Under the circumstances where the master scanning mode is executed, the scanning course of the slave scanning mode will be inserted in sections into the scanning course of the master scanning mode. Through the alternate use of the master scanning mode and slave scanning mode, the present invention is able to utilize the strengths of the master scanning and slave scanning are utilized to solve the issue that fails to be resolve by only one scanning mode used; in the meantime, the alternate use of the master scanning mode and slave scanning mode ensures the homogeneity of the data acquisition time, thus enabling the reliability of data; only part of the slave scanning mode is executed, so as to minimize the additional time consumption.

Owner:FOCALTECH SYSTEMS LTD

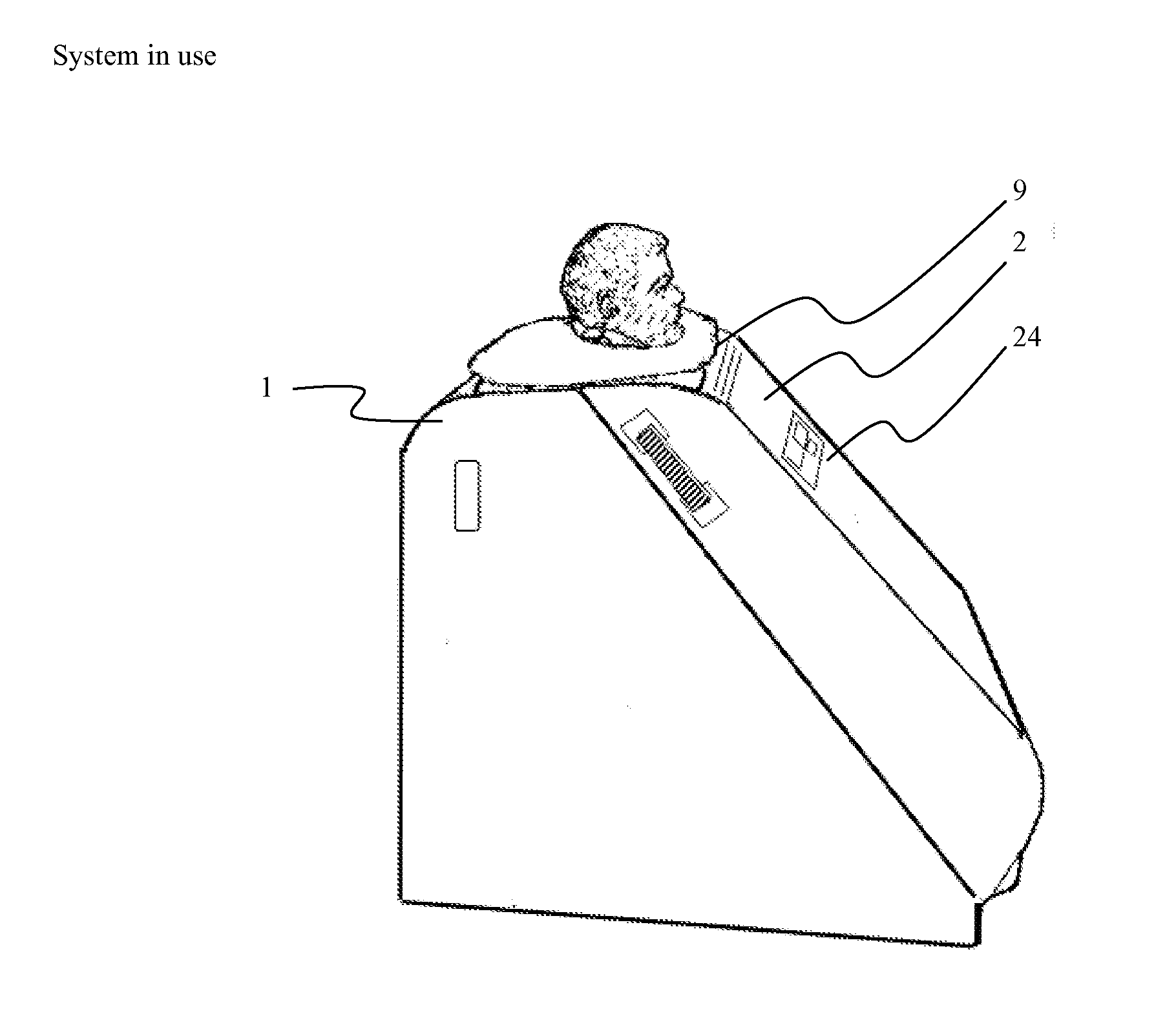

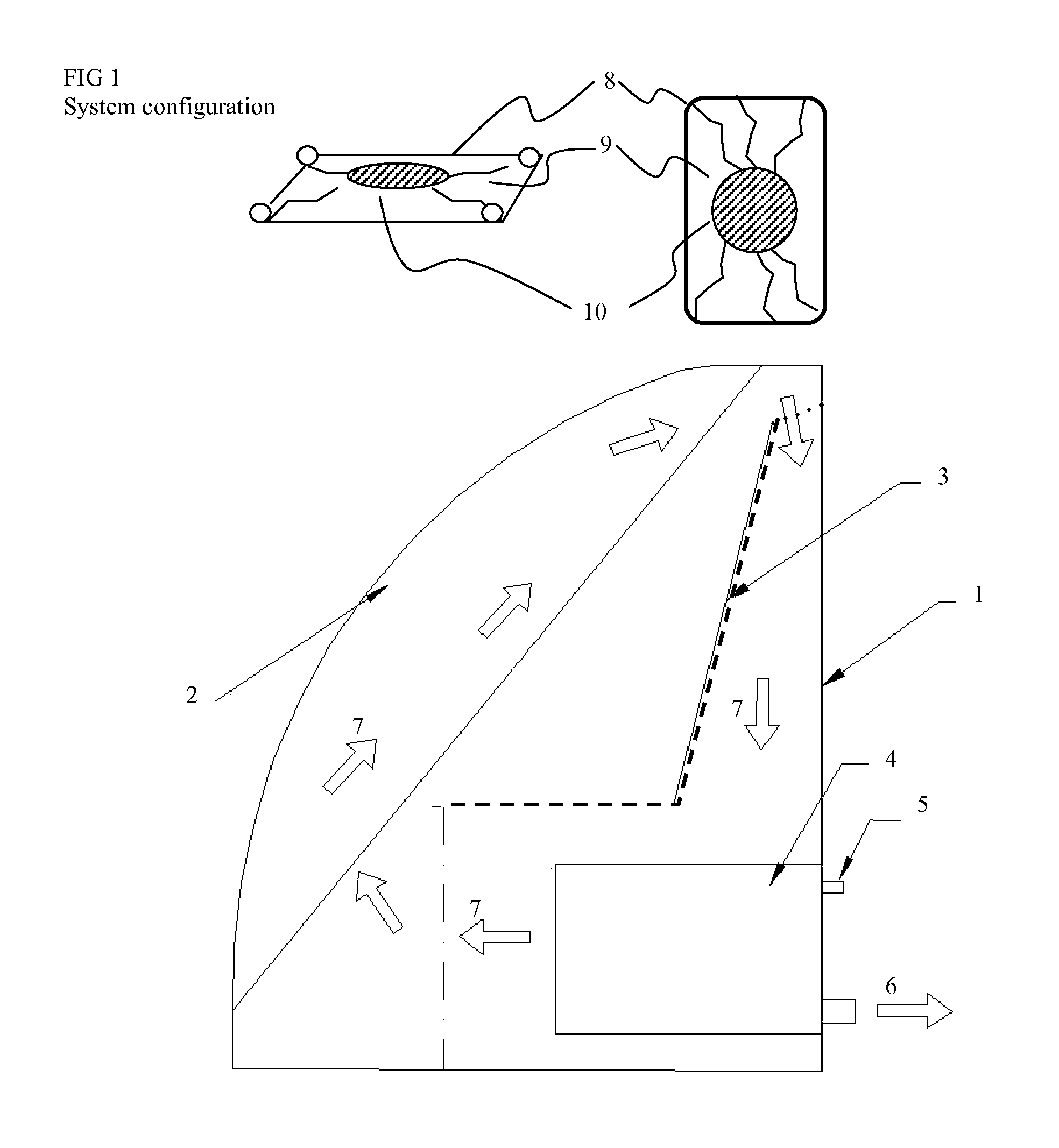

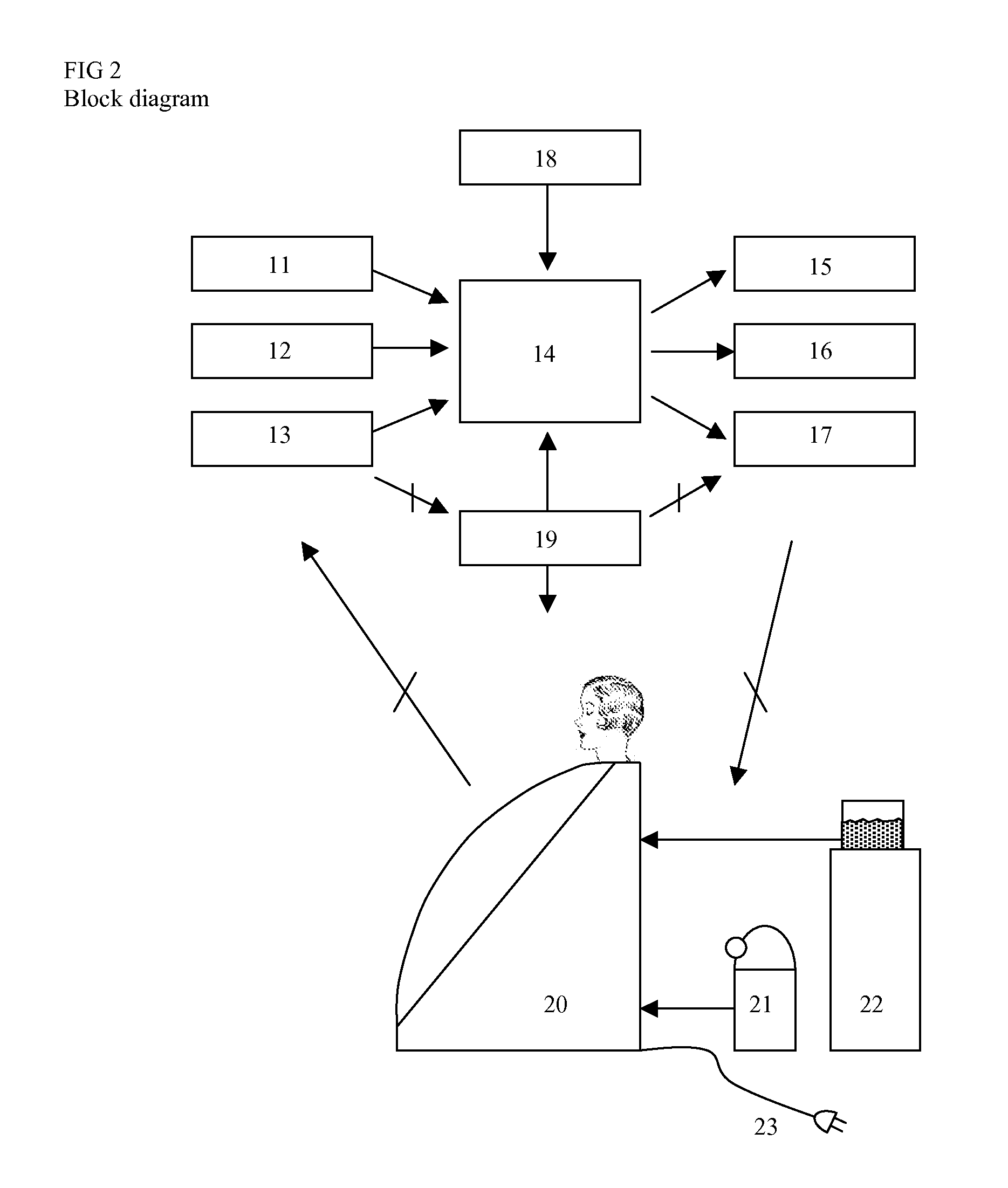

Method and System for the Therapeutic Application of Dry Carbon Dioxide Gas

ActiveUS20110125083A1Improve distributionWell mixedMedical devicesMedical applicatorsWater vaporEngineering

A sealable cabinet that permits a human or animal to experience a dry bath for carbon dioxide or other gases, with said cabinet fitted with gas, water, and power connections, and a controller to optimize the temperature, gas concentrations, and water vapor content of the interior, plus a switchable means for selecting between a sauna environment and said carbon dioxide bath, with a business method that enables a provider of services involving such equipment to achieve a profitable interface with patients and customers.

Owner:BELKIN SAM

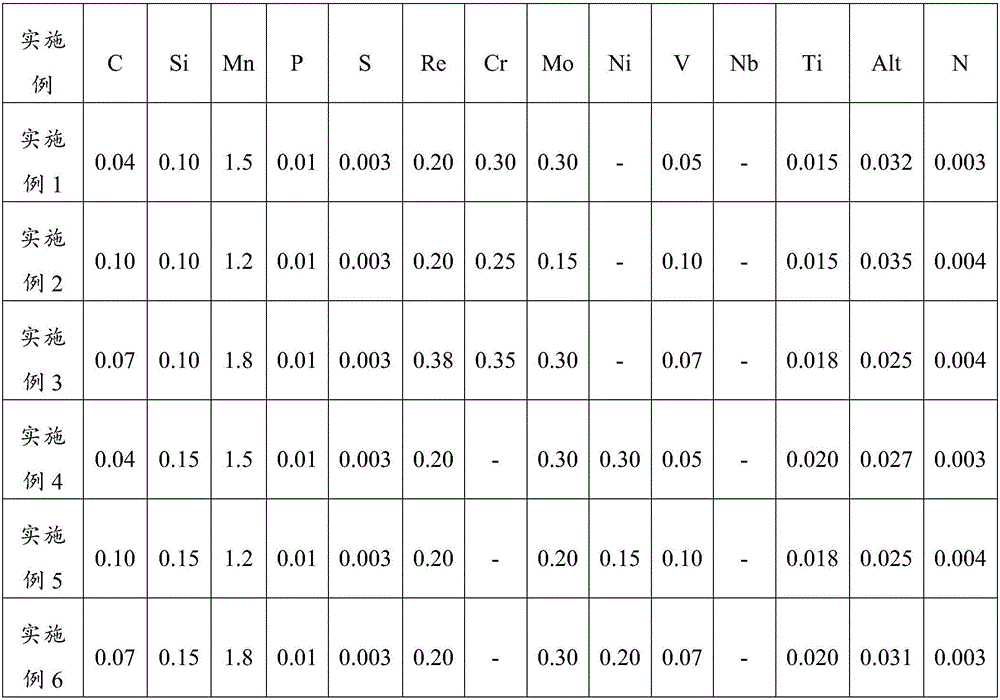

Hot-rolled multi-phase steel with excellent flangability and production method thereof

The invention discloses a hot-rolled multi-phase steel with excellent flangability and production method thereof, belonging to technical field of steelmaking. The hot-rolled multi-phase steel comprises the following chemical components by mass: 0.04 to 0.10% of C, 0.1 to 0.2% of Si, 1.0 to 2.0% of Mn, no more than 0.015% of P, no more than 0.004% of S, no more than 0.04% of Al, no more than 0.0050% of N, 0.1 to 0.4% of Re, any two selected from a group consisting of 0.25 to 0.45% of Cr, 0.1 to 0.4% of Mo and 0.1 to 0.4% of Ni, and any one selected from a group consisting of 0.04 to 0.06% of Nb and a mixture of 0.05 to 0.10% of V and 0.010 to 0.03% of Ti, with the balance being Fe and unavoidable impurities. The interior microscopic structure of the hot-rolled multi-phase steel is granular bainite. The hot-rolled multi-phase steel in the invention has good flangability, surface quality and comprehensive mechanical properties.

Owner:SHOUGANG CORPORATION

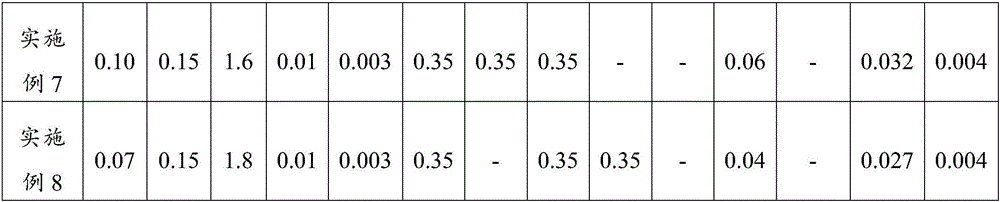

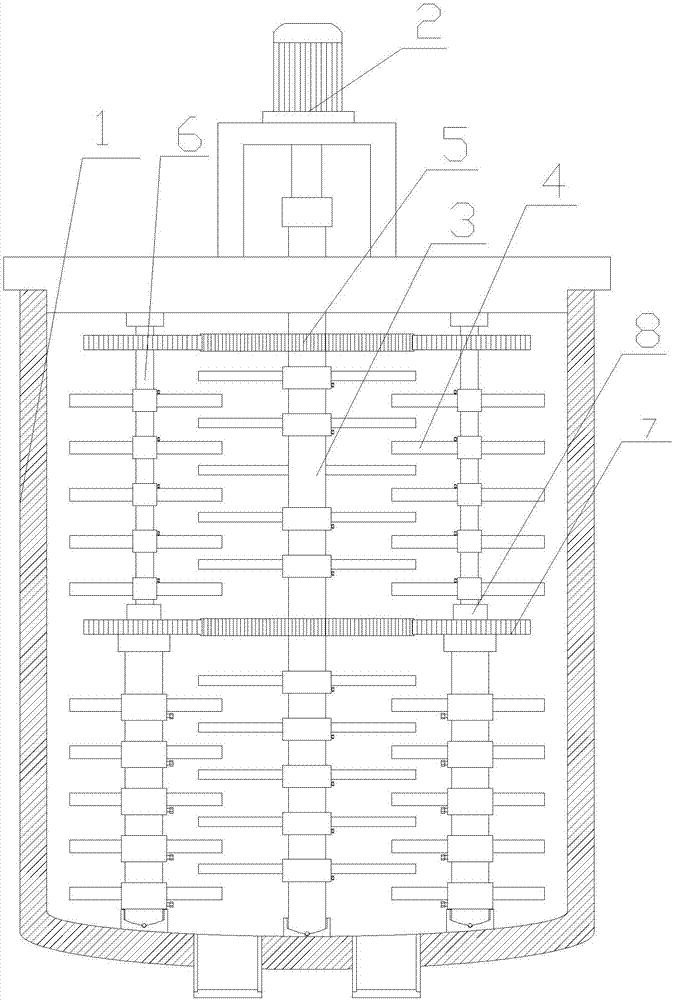

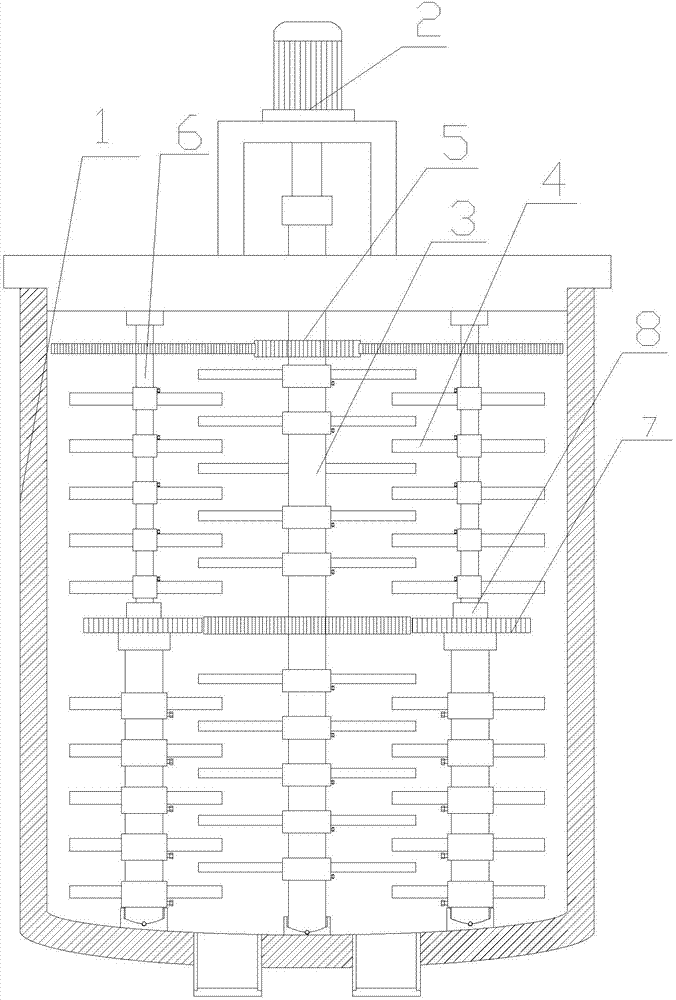

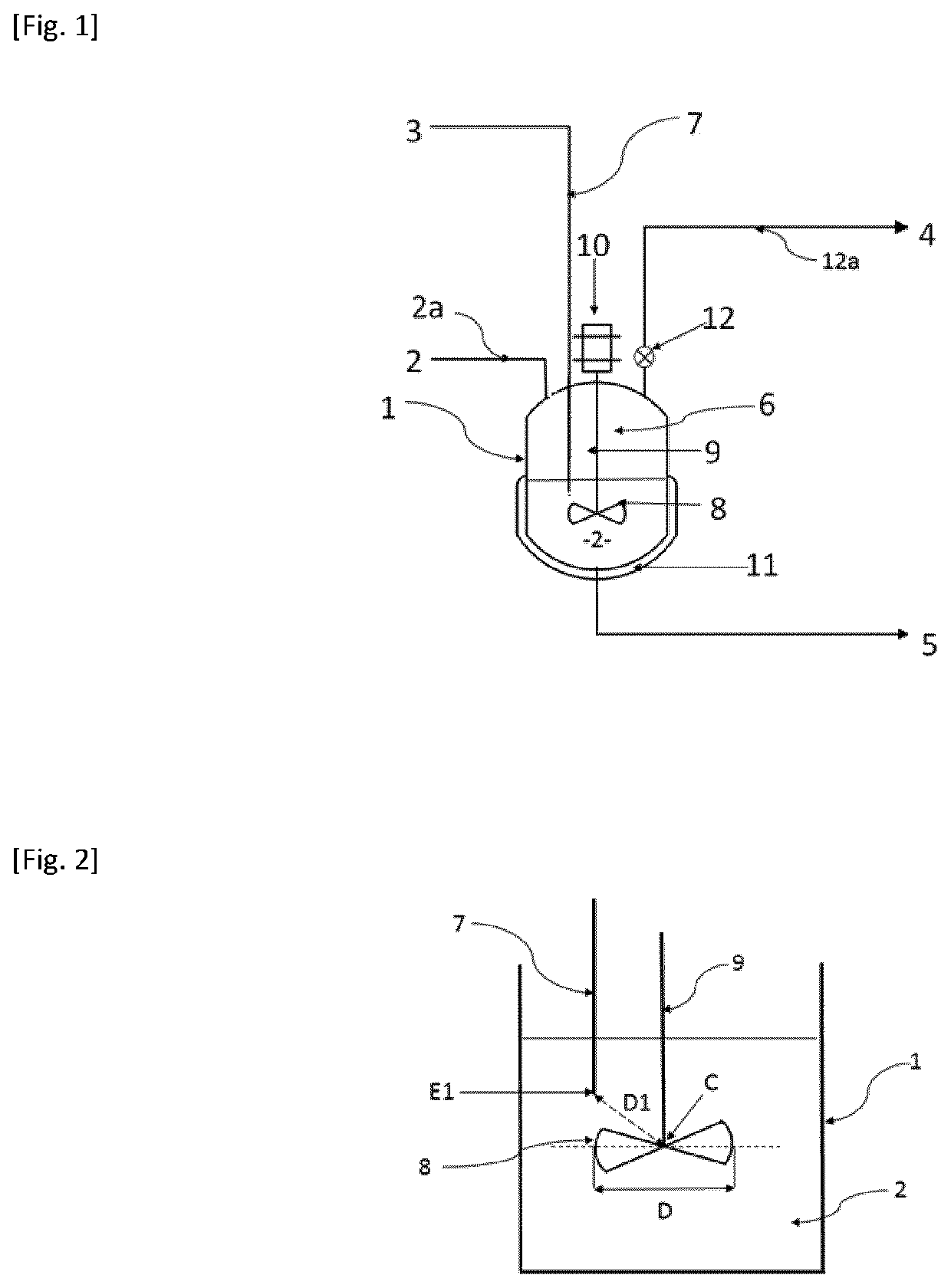

Multistage driving type material stirring mechanism

PendingCN106914175ADifferent stirring speedImprove uniformityRotary stirring mixersTransportation and packagingEvaporationEngineering

A multistage driving type material stirring mechanism comprises a stirring tank, a driving motor arranged on the top of the stirring tank, a middle driving shaft arranged in the stirring tank, and stirring blades arranged on the middle driving shaft. The top of the middle driving shaft penetrates the stirring tank and is connected to the shaft of the driving motor. Active driving gears are arranged on the middle driving shaft. Two ends of the middle driving shaft are both provided with a lateral driving shaft. Inactive driving gears are arranged on the lateral driving shafts. The active driving gears and the inactive driving gears are engaged with each other. The lateral driving shafts are provided with stirring blades, which axially intersect with the middle driving shaft. The structure is simple, the design is novel, a set of driving motor can drive multiple mechanisms to work at the same time, a solution can be stirred efficiently and stably at a high speed, the solution uniformity in evaporation and crystallization is guaranteed, the production efficiency is improved, the energy consumption is low, and the design cost is low.

Owner:ANHUI JINLONG MACHINERY

Device and Method for the Production of a Metallic Strip

ActiveUS20120040206A1Roughness of and in particularSurface roughnessLayered productsRecord information storageMaterials scienceHeat spreader

A device for the production of a metallic strip using a rapid solidification technology is specified, which device comprises a movable heat sink with an external surface onto which a melt is poured and on which the melt solidifies to produce the strip, and which device comprises a rolling device which can be pressed against the external surface of the movable heat sink while the heat sink is in motion.

Owner:VACUUMSCHMELZE GMBH & CO KG

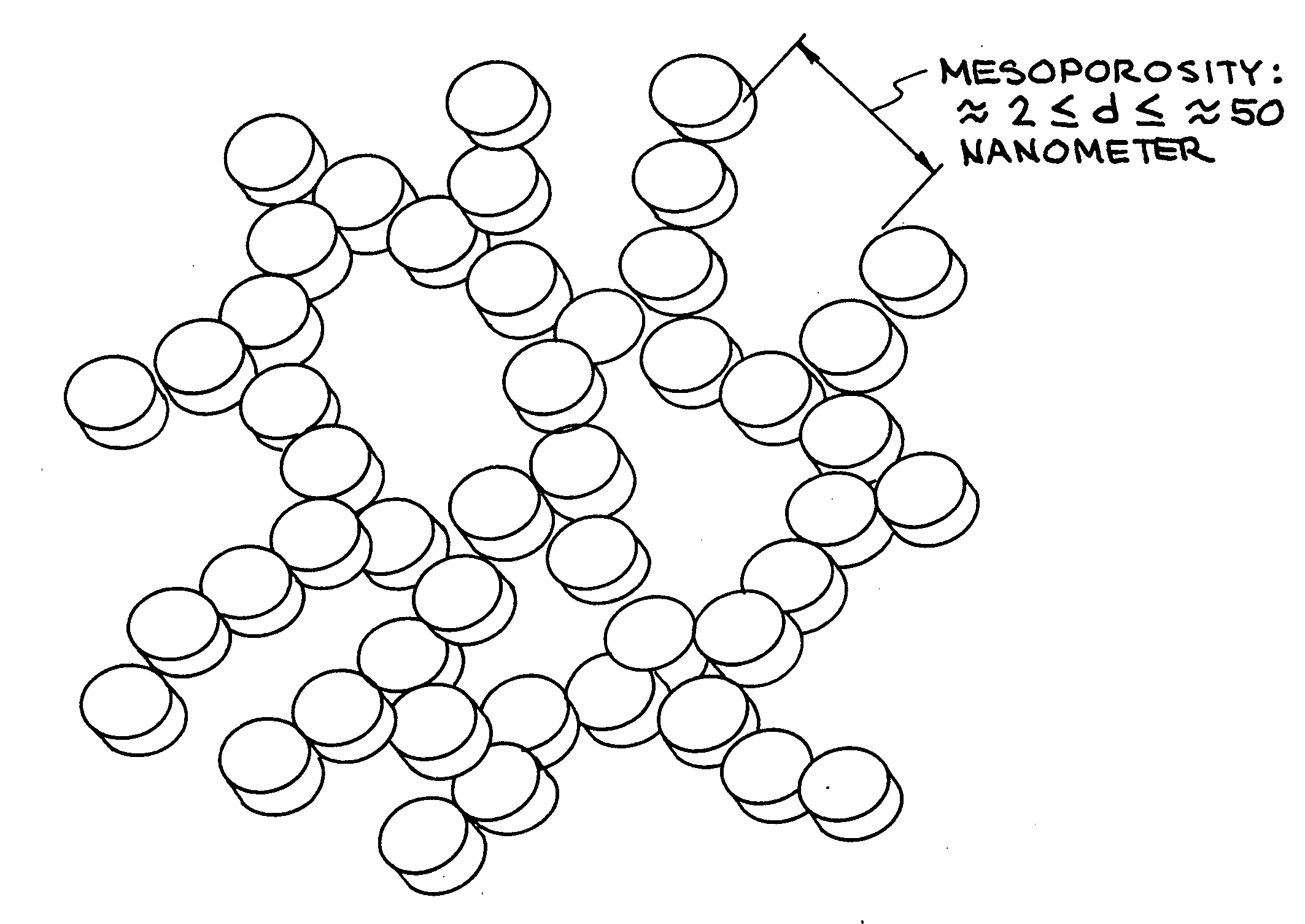

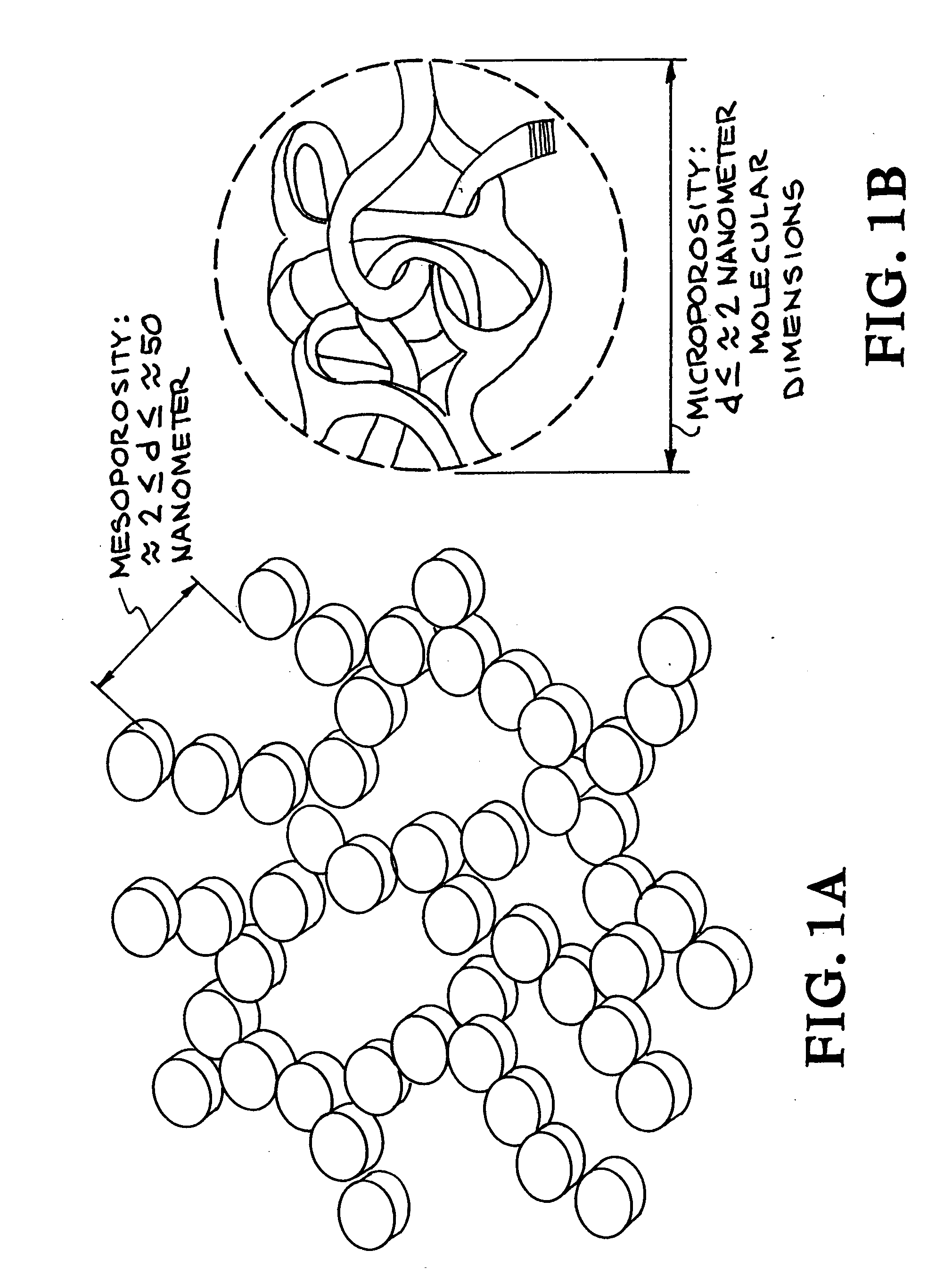

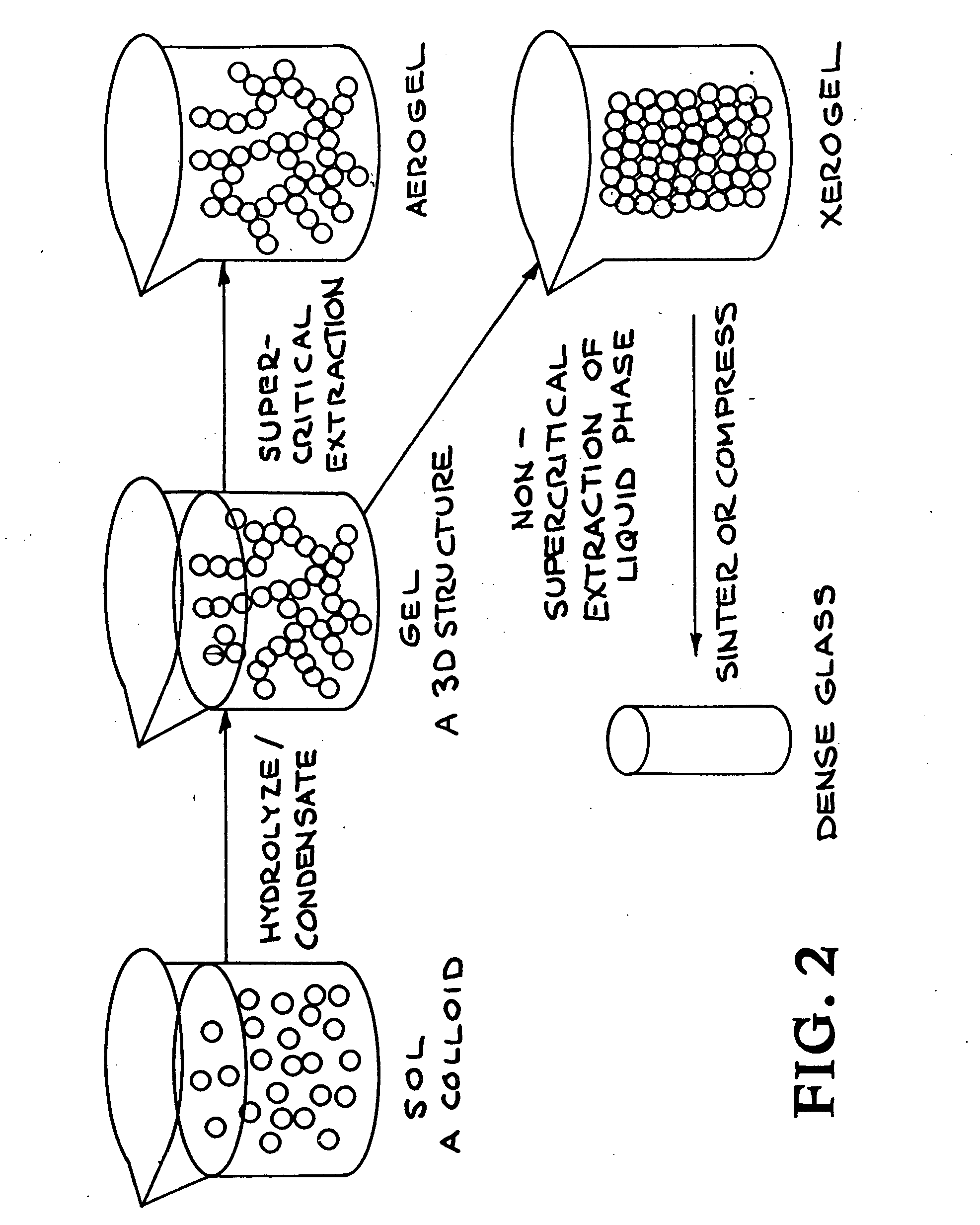

Sol-gel manufactured energetic materials

Sol-gel chemistry is used for the preparation of energetic materials (explosives, propellants and pyrotechnics) with improved homogeneity, and / or which can be cast to near-net shape, and / or made into precision molding powders. The sol-gel method is a synthetic chemical process where reactive monomers are mixed into a solution, polymerization occurs leading to a highly cross-linked three dimensional solid network resulting in a gel. The energetic materials can be incorporated during the formation of the solution or during the gel stage of the process. The composition, pore, and primary particle sizes, gel time, surface areas, and density may be tailored and controlled by the solution chemistry. The gel is then dried using supercritical extraction to produce a highly porous low density aerogel or by controlled slow evaporation to produce a xerogel. Applying stress during the extraction phase can result in high density materials. Thus, the sol-gel method can be used for precision detonator explosive manufacturing as well as producing precision explosives, propellants, and pyrotechnics, along with high power composite energetic materials.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

Method for Manufacturing LED Light Bar and LED Light Bar and Backlight Module

InactiveUS20130272027A1Reduce manufacturing costReduce wasteMechanical apparatusLighting support devicesLuminous intensityEngineering

The present invention provides a method for manufacturing LED light bar, which includes the following steps: (1) providing light-emitting dies of different sizes; (2) measuring luminous intensities of the light-emitting dies; (3) selecting among the light-emitting diodes ones of which the luminous intensities are different from each other by less than 5%; (4) encapsulating the selected ones of the light-emitting dies to form LED lights, which are of substantially identical encapsulated size; and (5) mounting and electrically connecting the LED lights to a printed circuit board to form an LED light bar. The method for manufacturing LED light bar according to the present invention uses light-emitting dies of different sizes so as to improve utilization rate of an entire wafer and effectively reduce the manufacture cost.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

Brachytherapy method of treating skin tumors using a tailor-made radioactive source

ActiveUS9486642B2Accurate calculationEasily adheres to surfaceAntineoplastic agentsX-ray/gamma-ray/particle-irradiation therapyMedicineRadioactive waste

Embodiments of the invention relate to a method of treating a cancerous or non-cancerous skin lesion of a subject, e.g. a human patient, by epidermal radioisotope therapy, a specialized type of brachytherapy. The method can include defining and marking an area of skin to be treated; covering the area with a protective layer, e.g. a protective film or foil; applying a tailor-made radioactive source by applying a layer of a radioactive source material on the protective layer, such that the area is covered by the material while any area not to be treated is spared; and removing the radioactive source after a predetermined time period of irradiation.

Owner:ONCOBETA INT GMBH

Food processing device

ActiveUS7845271B2Reduce actionImprove cutting performanceLinked sausage separationFood shapingElectricityLine tubing

A food processing device comprises a paste reservoir, a feed pump and a flow divider. The flow divider is provided with outlets to four supply lines all of which receive a substantially equal supply of paste as a result of the operation of the flow divider. Each of the outlets is connected to a nozzle. A pair of knives is located ahead of the nozzles, each being provided with four apertures. The knives are provided with an actuating mechanism and a controller. Controller registers and controls operation of the meatball forming device and is electrically connected to the feed pump, to a servomotor and to a shaft encoder.

Owner:MACHINEFAB GEURTSEN DEVENTER

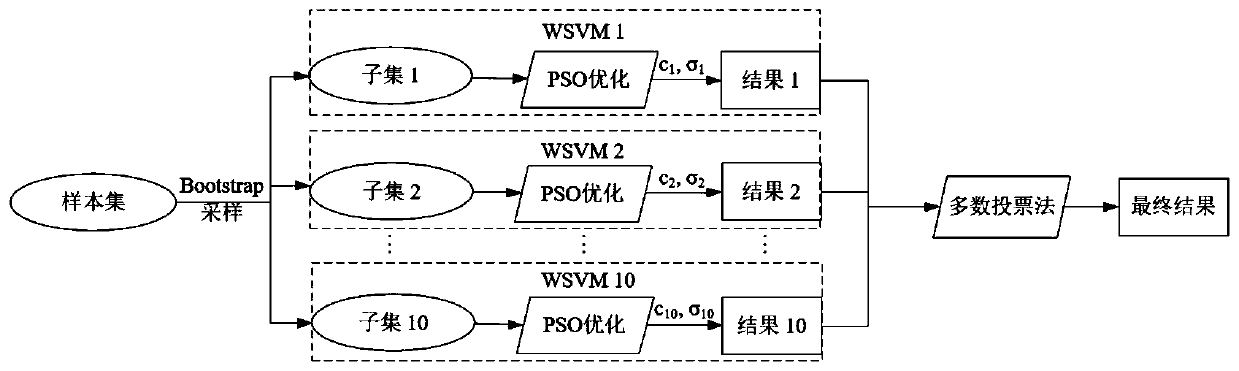

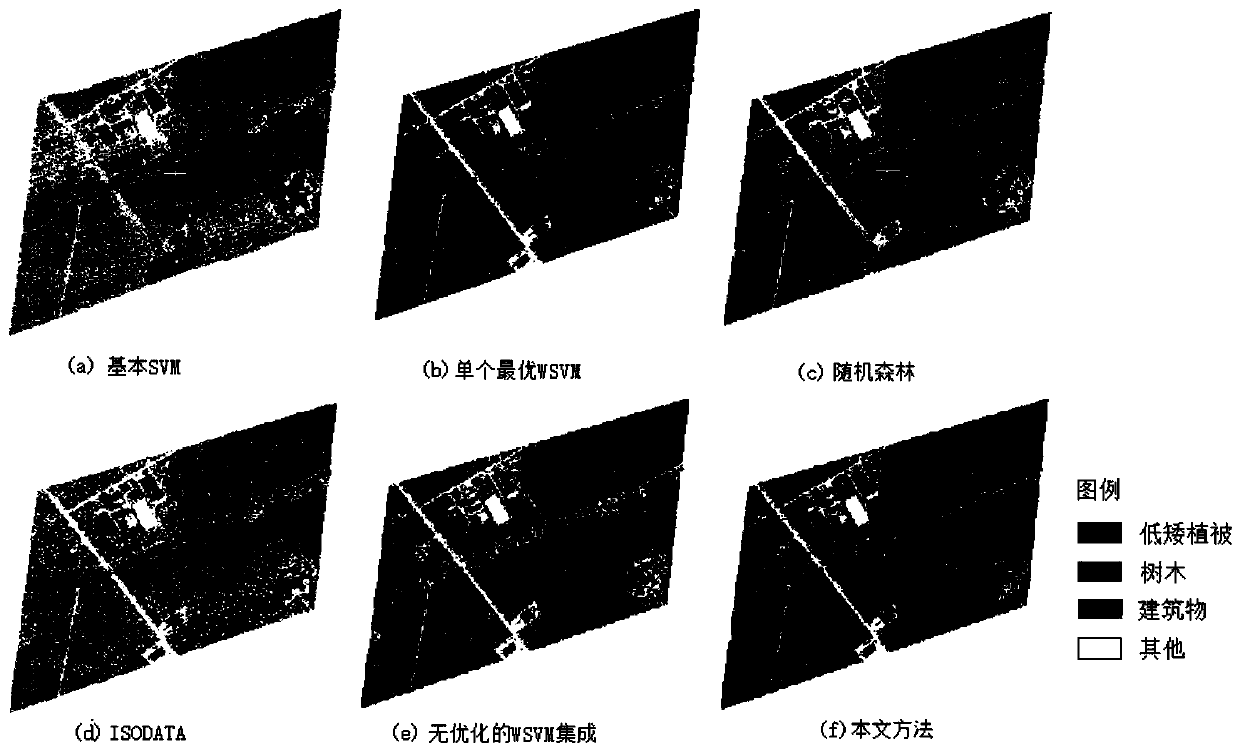

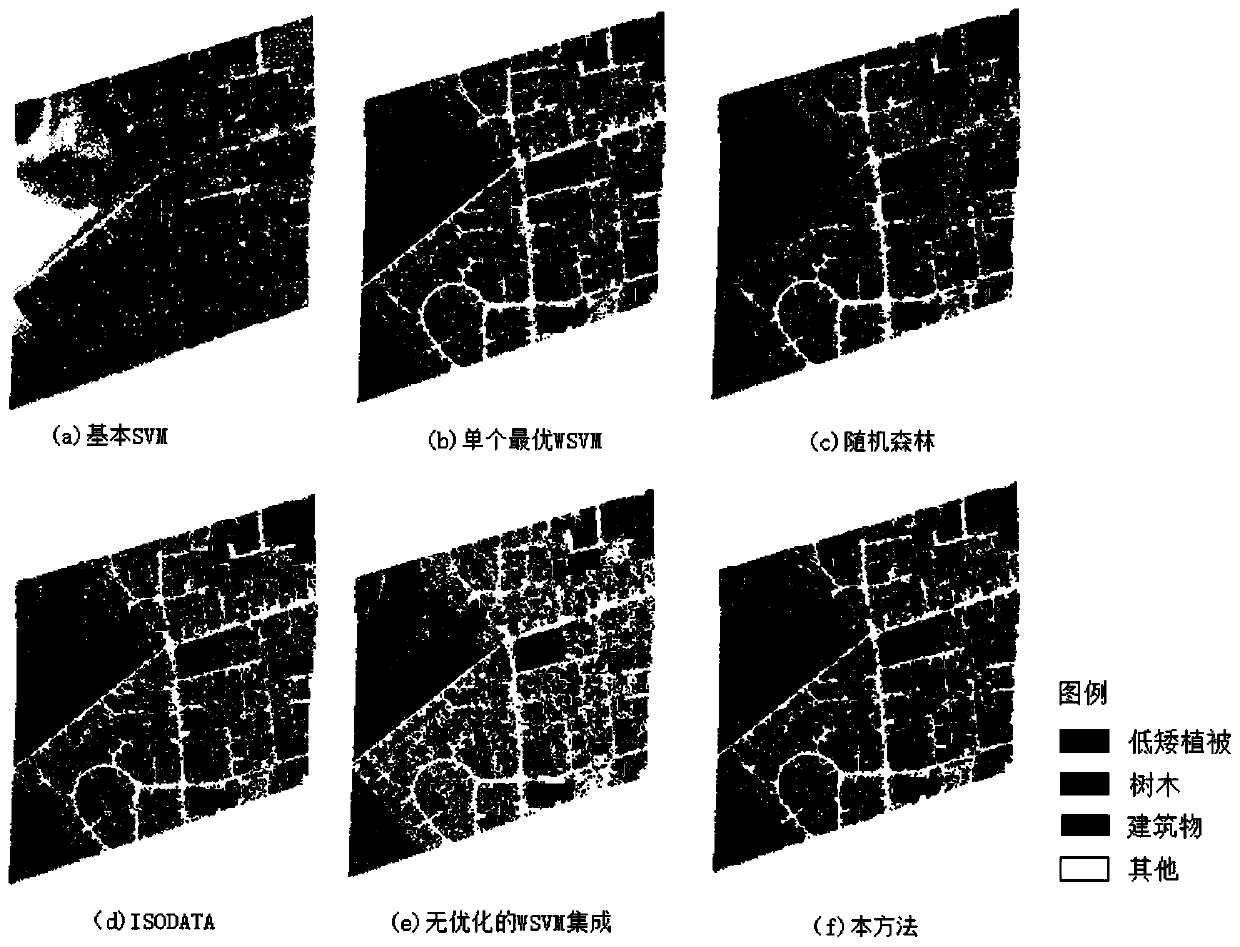

Full-waveform LiDAR point cloud classification method based on multi-wavelet support vector machine WSVM integration

PendingCN110503132AEnsure heterogeneityEnsure homogeneityCharacter and pattern recognitionParticle swarm optimization pso algorithmSupport vector machine

The invention discloses a full-waveform LiDAR point cloud classification method based on multi-wavelet support vector machine WSVM integration. The method comprises the following steps: firstly, decomposing full-waveform LiDAR data, extracting geometric and waveform characteristics of point cloud, constructing a plurality of wavelet support vector machine (WSVM) classifiers by utilizing differentwavelet kernel functions, and constructing an integrated system by taking the WSVM classifiers as base classifiers; performing parameter optimization in each WSVM classifier by adopting a particle swarm optimization PSO algorithm, and integrating the WSVM classifiers by adopting a bagging algorithm; and finally, adopting a wavelet support vector machine (WSVM) classifier integrated system to classify point clouds decomposed from the original full-waveform LiDAR data, and outputting a result. According to the invention, a good point cloud classification result can be obtained.

Owner:WUHAN UNIV

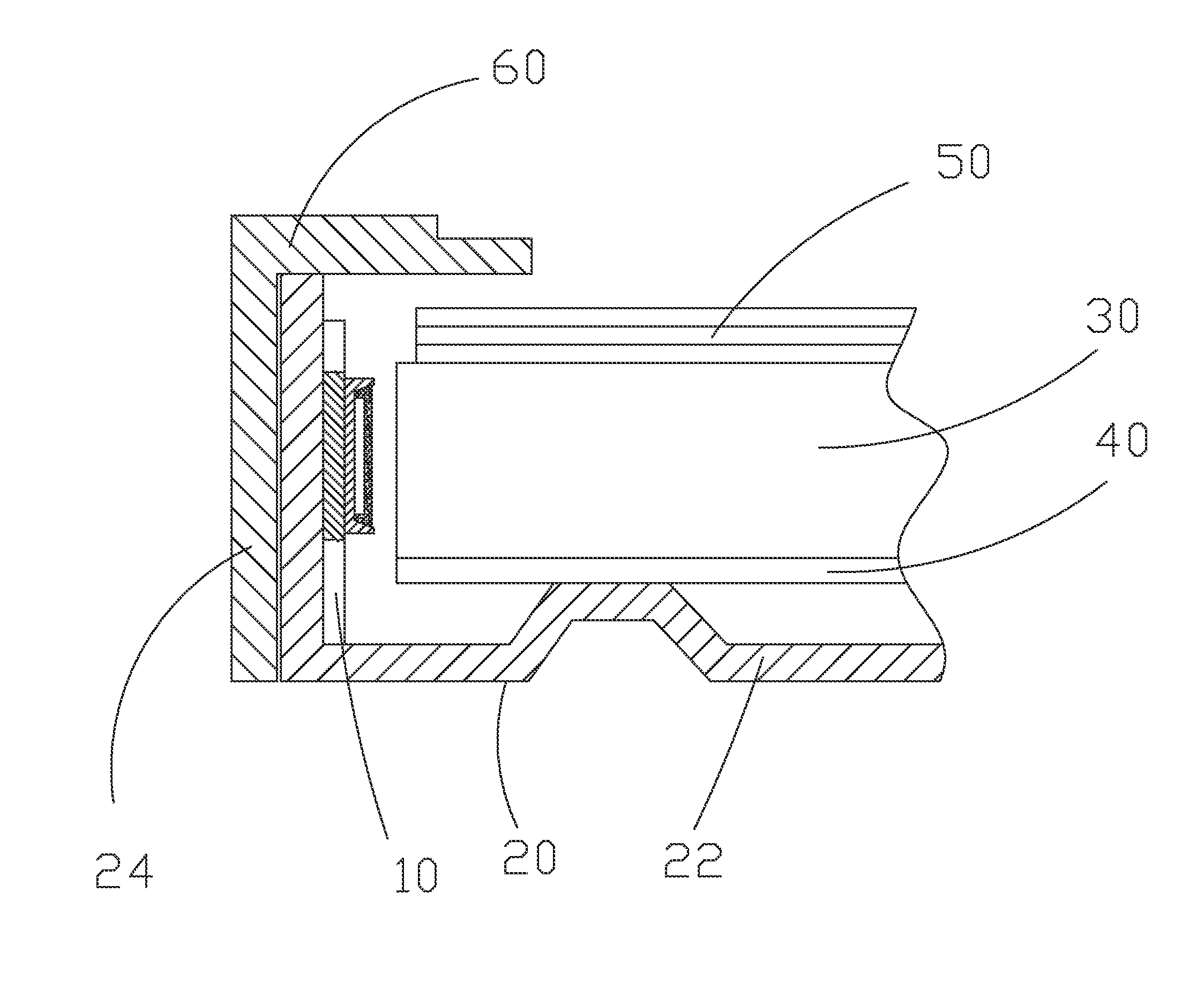

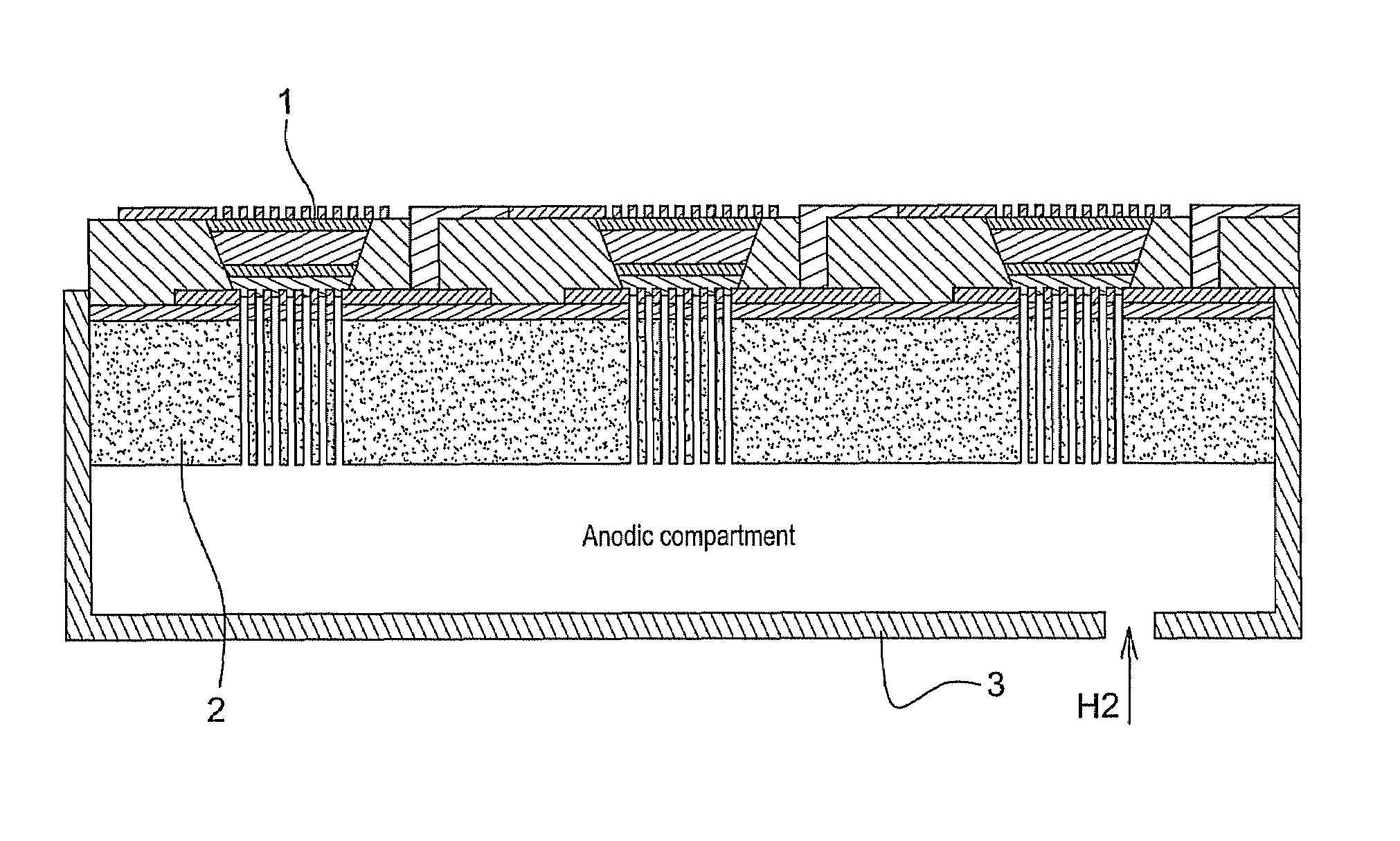

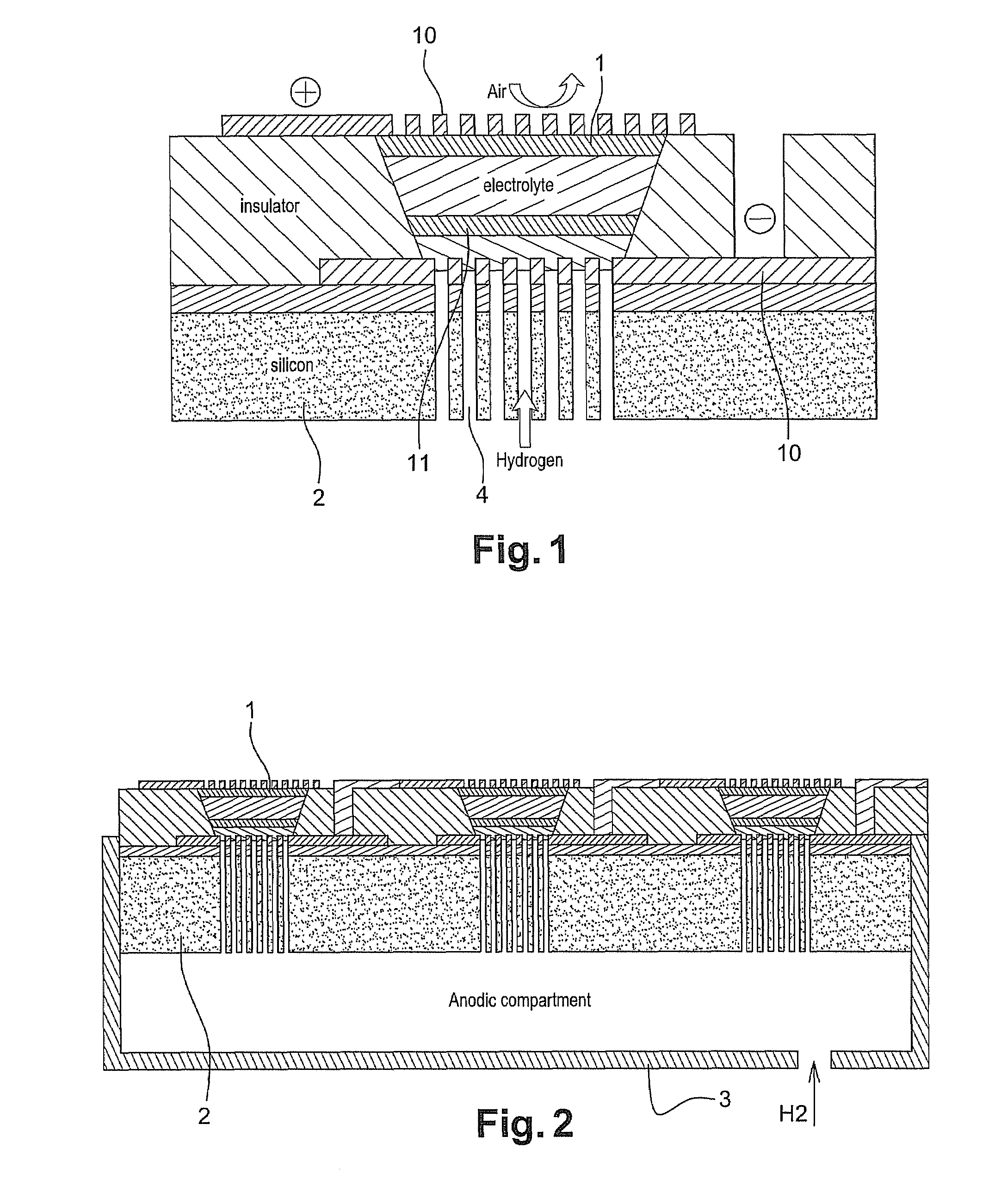

Impermeable porous substrate for planar fuel cells and integrated packaging

InactiveUS20100098993A1Compact aspectImprove power densityPrimary cellsElectrode carriers/collectorsPorous substrateFuel cells

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

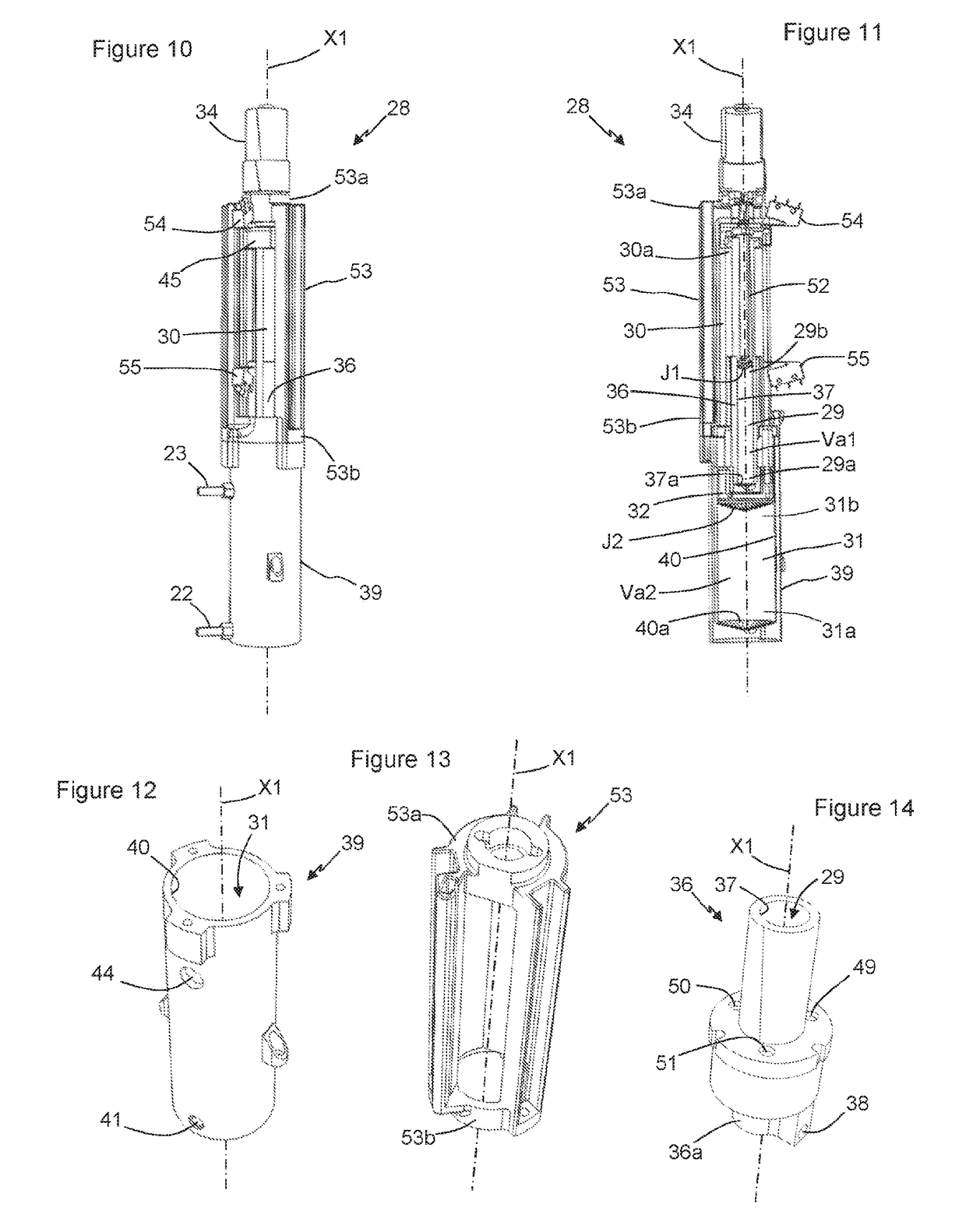

Machine for dispensing beverages from a pod, comprising a device for the synchronized injection of two volumes of air

ActiveUS20190045967A1Avoid wasting waterGuaranteed homogeneityBeverage vesselsPumpsAdditive ingredientEngineering

A machine for dispensing beverages includes a pod including at least two cavities each cavity containing a volume of ingredients forming part of a composition of the beverage, the machine further including an air injection device configured to supply at least two volumes of air in a synchronized manner, the at least two volumes of air being adapted respectively to the volumes of ingredients in the at least two cavities, the injection device including an air pump including two chambers and two pistons slidably mounted respectively in the two chambers, and an actuator configured to actuate the two pistons in a synchronized manner.

Owner:SEB SA

Reduced sodium salt

InactiveUS20130196049A1Enhanced experienceSufficient hardnessConfectionerySweetmeatsCoordination complexChloride sodium

There is provided a process for preparing a reduced sodium salt composition, the process comprising the steps of mixing sodium chloride with one or more sodium chloride substitute complexes, heating the so-formed mixture to form a melt, and cooling the melt to form a solid. The so-formed solid is a fused granular matrix of sodium chloride and one or more sodium chloride substitute complexes. An alternative process is provided in which the sodium chloride and the sodium chloride substitute complex are heated to the liquid phase before they are combined. A reduced sodium salt composition is also provided, in particular a reduced sodium chloride salt obtained from these processes.

Owner:KLINGE CHEM

Process for preparing bis(fluorosulfonyl) imide

PendingUS20220041448A1Ensure homogeneityPreclude obtainingNitrosyl chlorideImidodisulfonic/nitrilotrisulfonic acidImidePolymer science

The invention relates to a process for preparing bis(fluorosulfonyl) imide, comprising the steps of: i) providing a stream A1 containing HF and a reactor containing a liquid phase A2 that contains bis(chlorosulfonyl) imide; ii) in said reactor, bringing said liquid phase A2 into contact with said stream A1 to produce bis(fluorosulfonyl) imide, said process being characterized in that said stream A1 is injected into said liquid phase A2.

Owner:ARKEMA FRANCE SA

Renovation technique for phi2100x3400mm wrought steel support roll

InactiveCN101293300BEnsure homogeneityPreserve the quality of restorationCounter-pressure devicesArc welding apparatusHeat-affected zoneEngineering

The invention relates to the technical field for repairing an ultra-large type backup roll, in particular to a repair process of a forging steel backup roll with Phi2100* 3400mm. Firstly, welding is carried out on the rib of the backup roll: the roll body of the backup roll which needs to be welded is preheated to 250 DEG C, and the temperature is preserved for 10 hours; then the door of a furnaceis opened, rib welding is carried out, zigzag welding is carried out every 100mm, and the length of the weld pass is 50-60mm; oxygen is used on the welded part immediately, and ethyne is used for warming the welded part until the welded part becomes blue. After the rib welding is finished, preheating treatment, temperature preservation treatment and destressing treatment are carried out respectively according to a heat treatment curve when the roll body of the backup roll is overlaid for making a bottom layer, a transition layer and a working layer. Compared with the prior art, in the technology of the invention, the influence on the service performance caused by the temperature circulation and change of a heat influencing region during the overlaying is considered, uniformity and penetration of preheating workpieces and uniformity of temperature between layers are guaranteed in the repair process, the blank in the repair rebirth field of the domestic ultra-large type backup roll is filled in. The time for repair is short, the service life is prolonged, and the cost is saved.

Owner:SHANGHAI SHIWEI WELDING IND

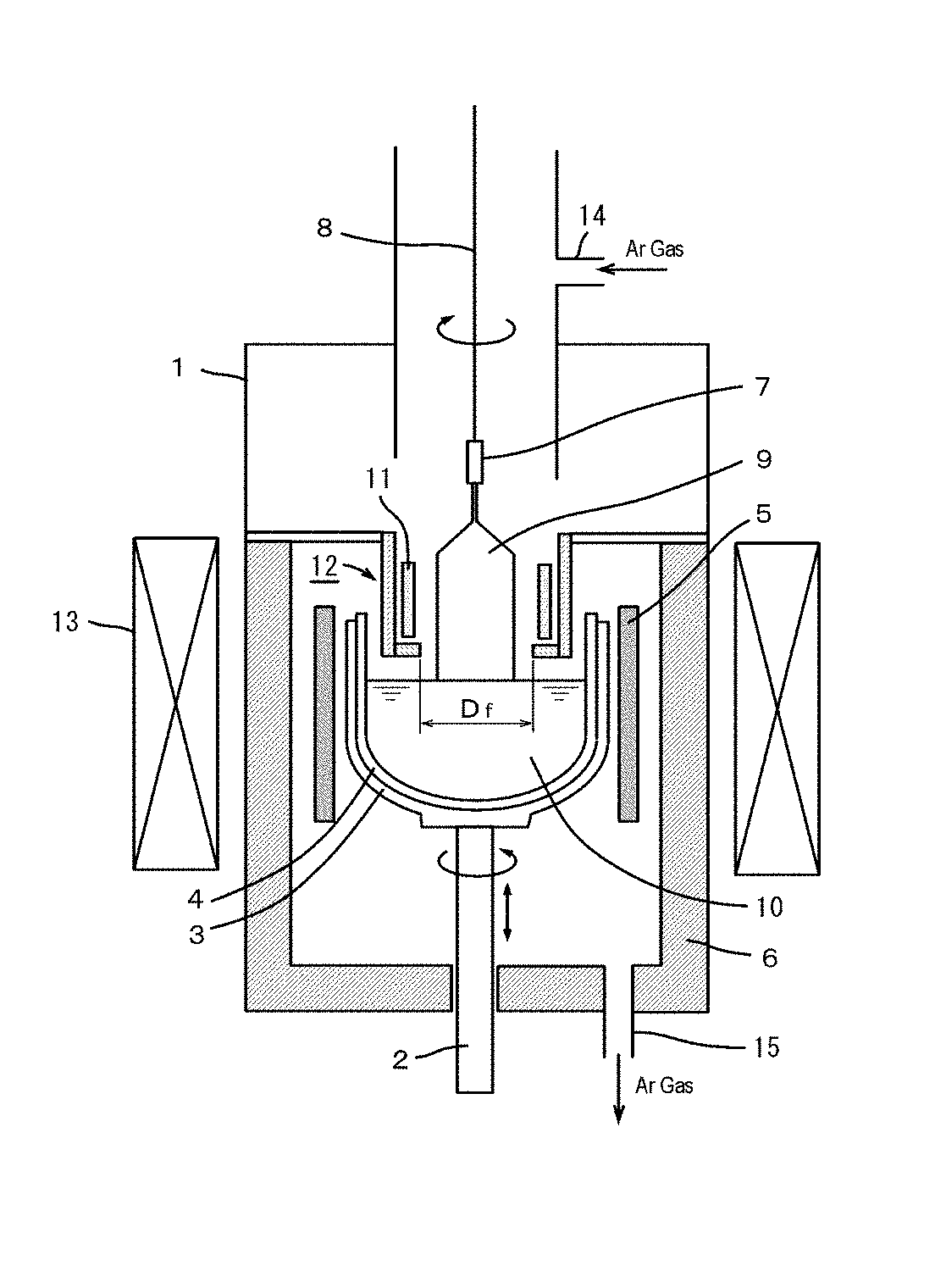

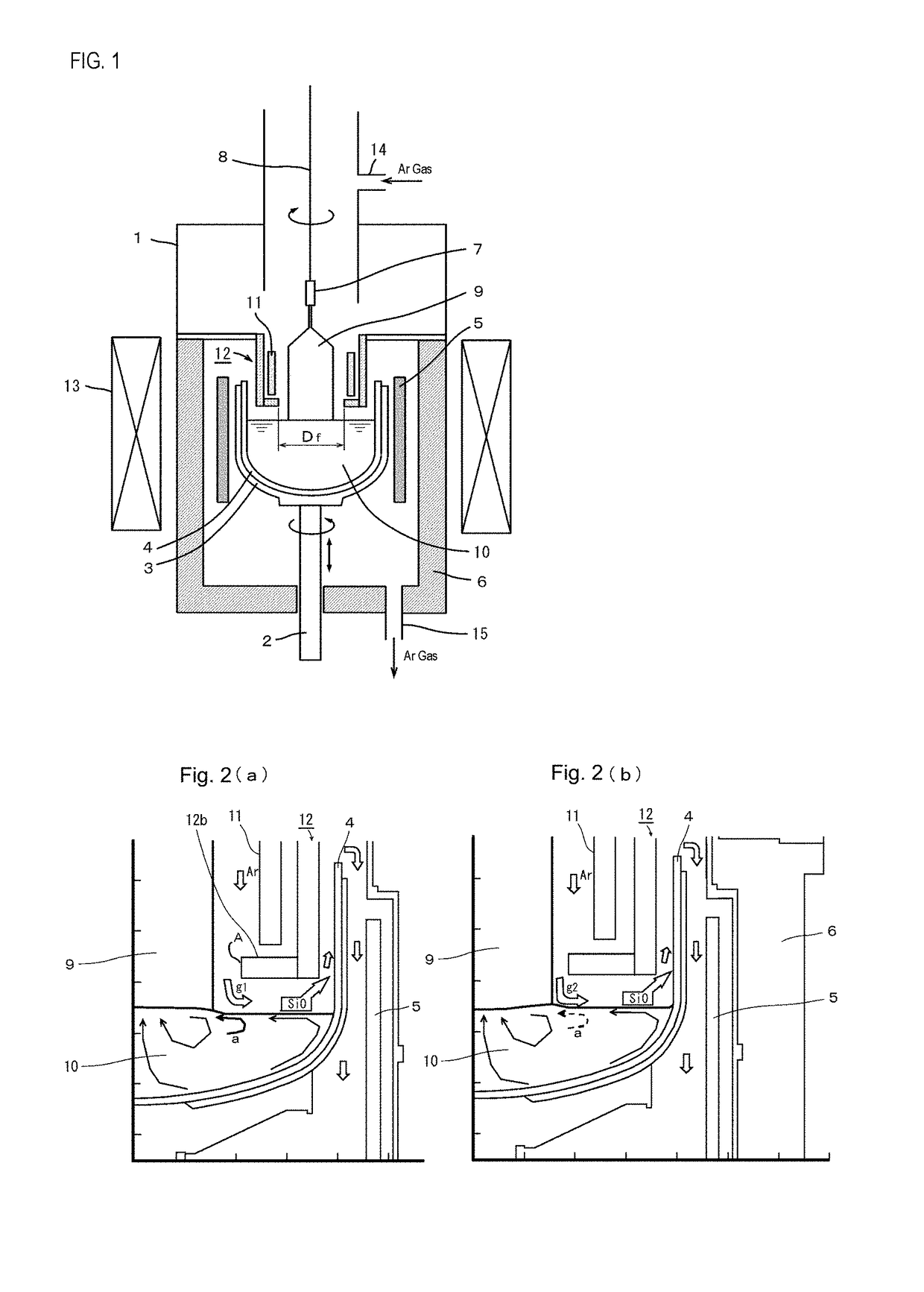

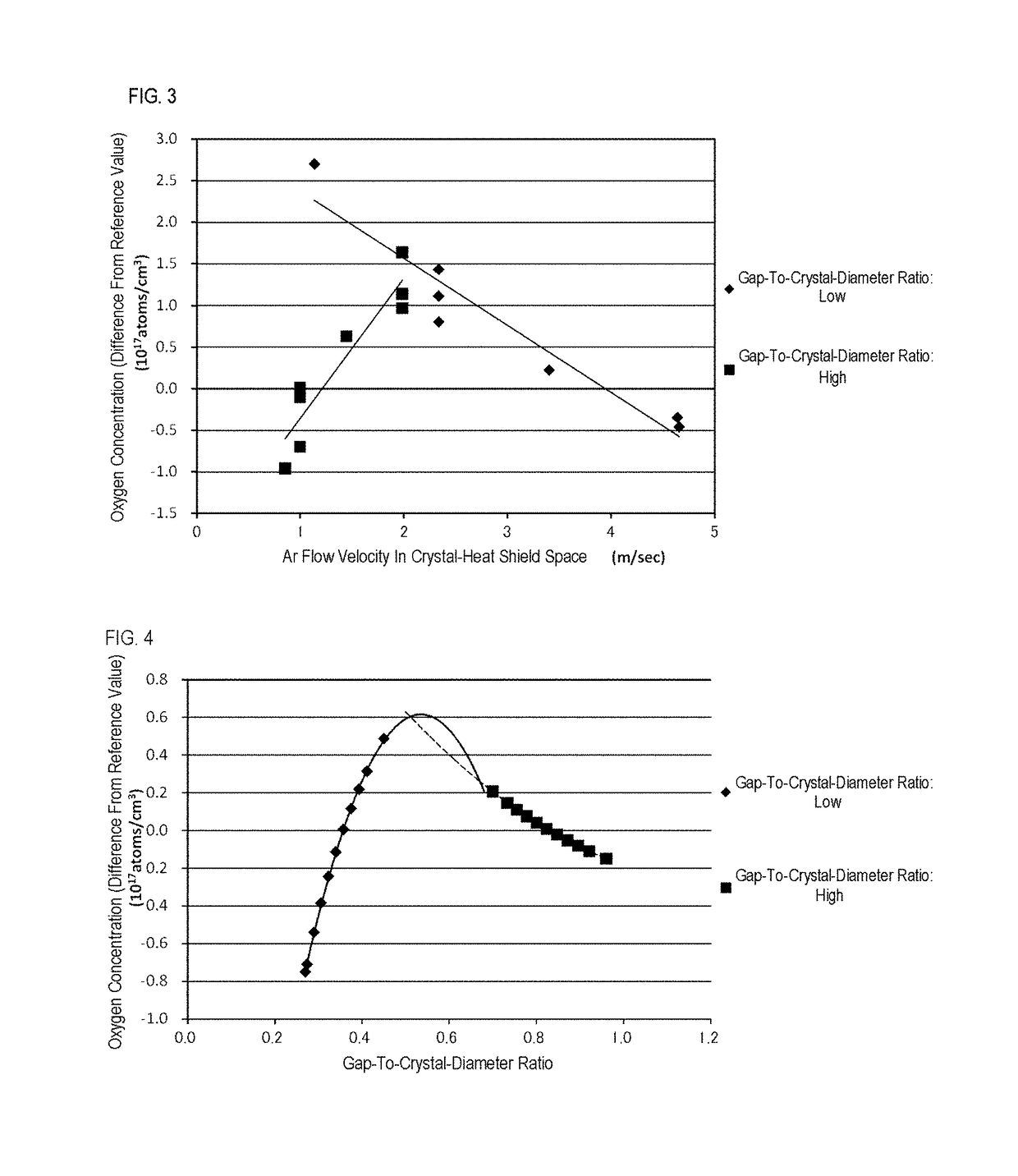

Silicon single crystal producing method

ActiveUS9903044B2Easy to controlEnsure homogeneityPolycrystalline material growthBy pulling from meltCzochralski methodDiameter ratio

Owner:SUMCO CORP

Composition for solid tires and a non-marking solid tire

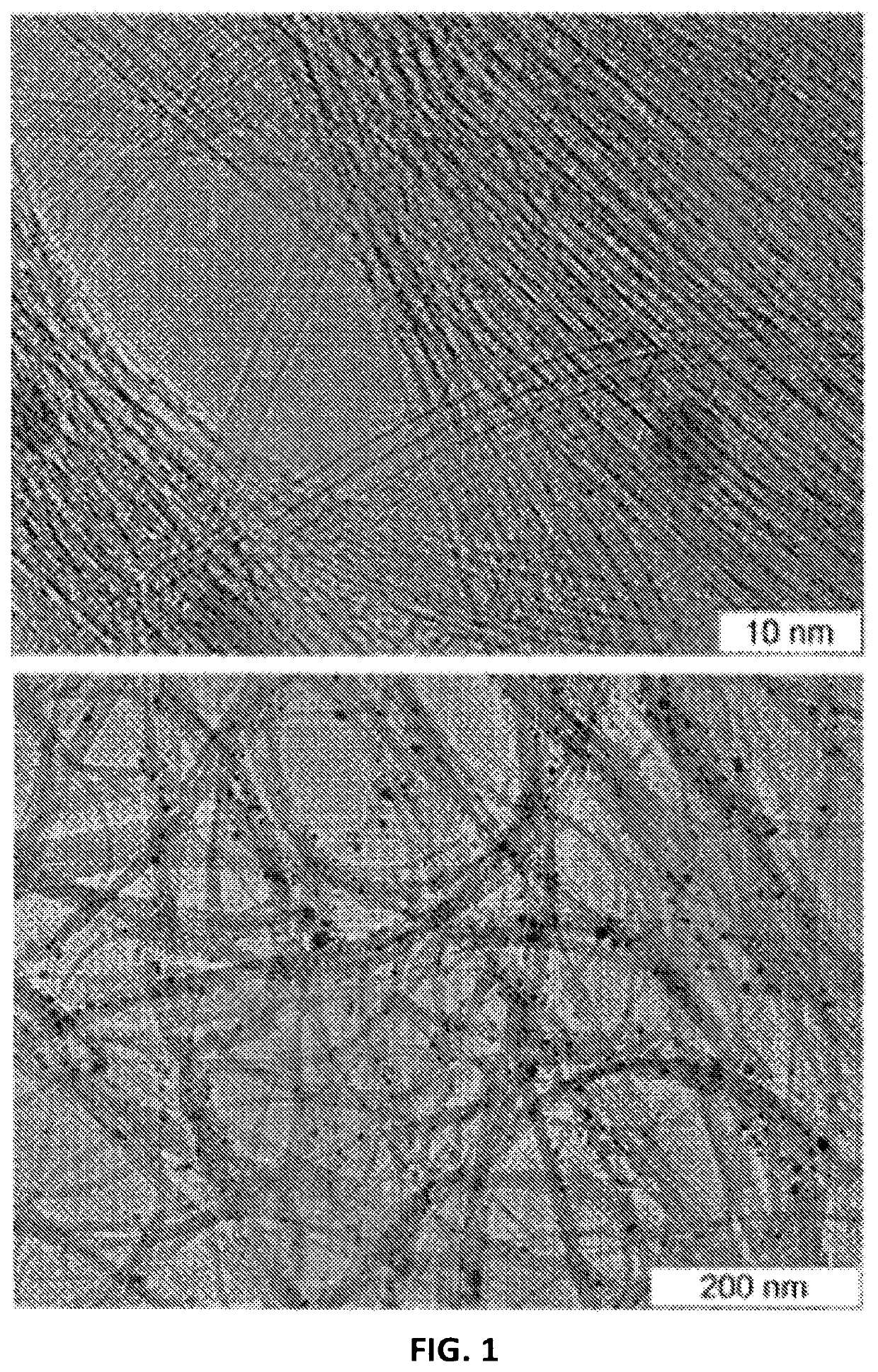

PendingUS20220325080A1Simple designSimple processabilityNon-inflatable tyresSpecial tyresPolymer scienceCarbon nanotube

The invention solves the problem of creating a rubber composition that can be used in a solid tyre of an extremely simple and manufacturable design to provide safe and hygienic operation of the tyre without accumulating a static electric charge and without leaving black marks on a floor surface. An electrically conductive rubber composition for non-marking solid tyres is proposed, which composition comprises (1) a rubber or a mixture of at least two rubbers, (2) oxide fillers and modifiers, (3) organic plasticisers and modifiers, (4) a curing system and (5) carbon nanotubes, wherein the total amount of carbon nanotubes and carbon of other allotropic modifications constitutes from 0.05 to 1.5 wt % relative to the amount of rubber. A non-marking solid tyre made from the electrically conductive rubber composition is also proposed.

Owner:MCD TECH SARL

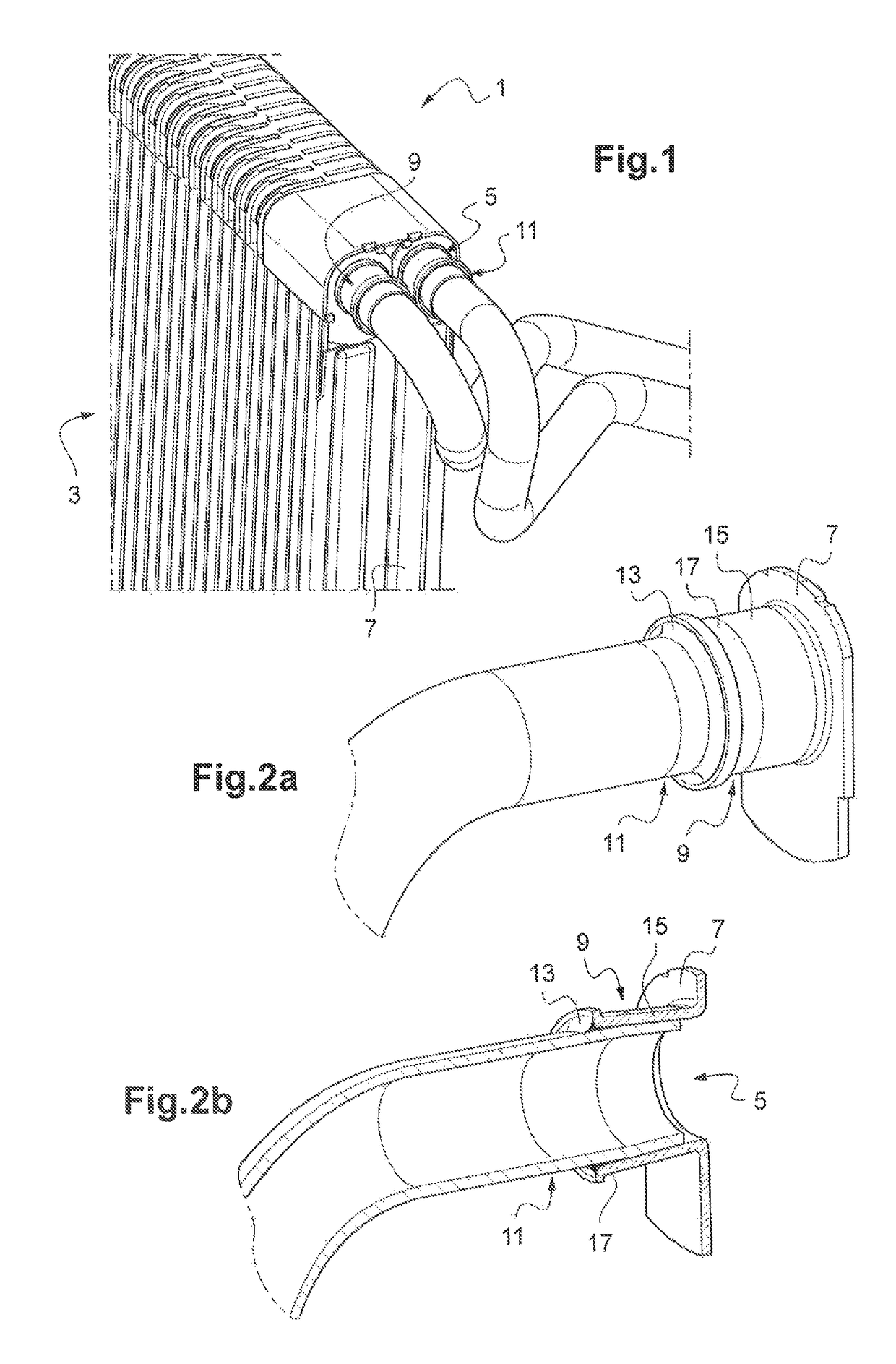

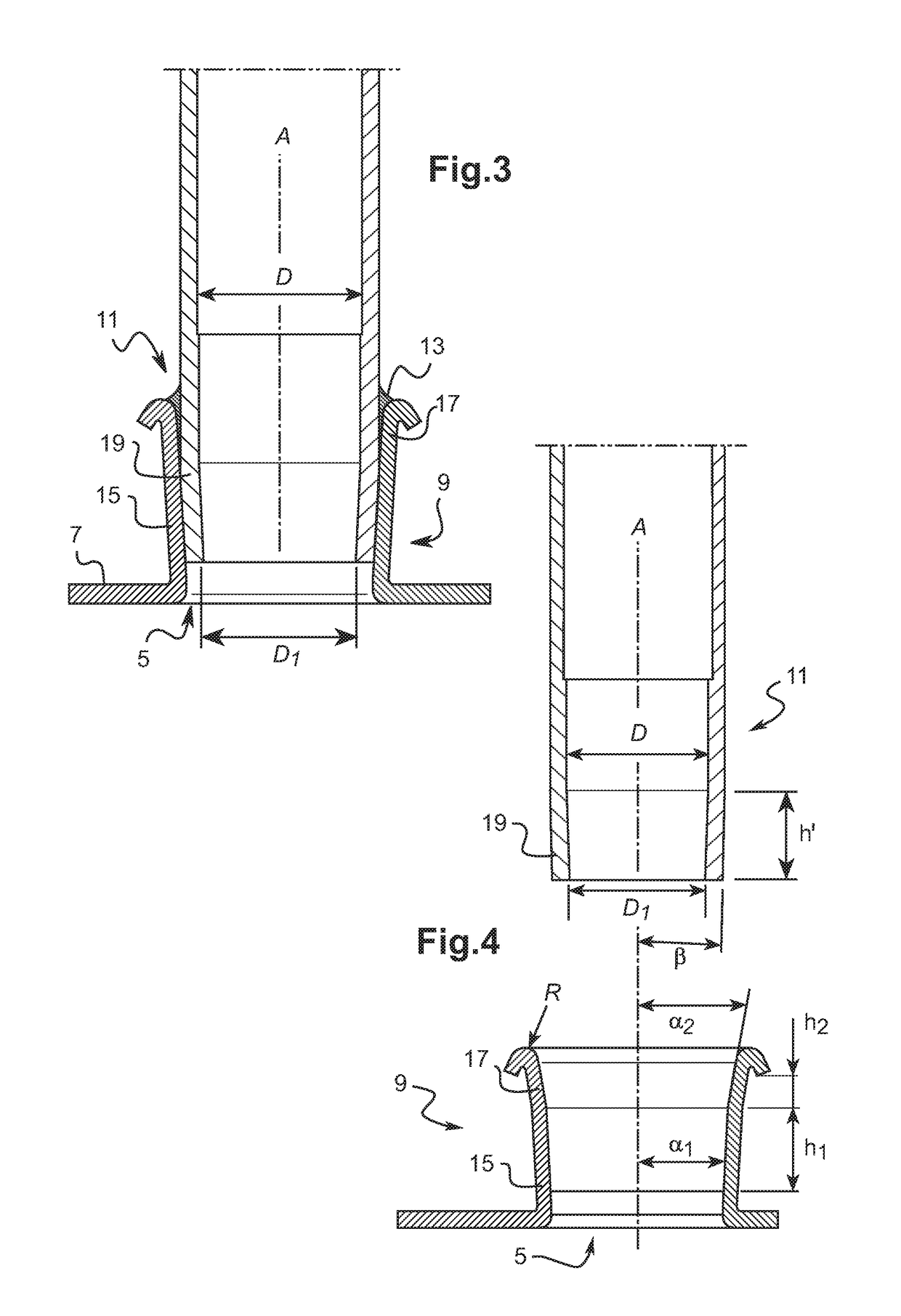

Connecting device, and corresponding thermal exchanger, particularly for a motor vehicle

ActiveUS9920864B2Simplify brazed connectionOptimized brazing conditionSoldering apparatusStationary conduit assembliesCircular coneEngineering

The invention relates to a connecting device having a female part and a complementary male part, wherein the female part is a sleeve able to receive at least partially the associated male part with a gap between the sleeve and the male part for receiving a brazing material. The sleeve at least partially has a conical shape. The conical shape has a first substantially conical part having a complementary shape to the male part, with a first inclination angle with respect to a longitudinal axis of the sleeve. The conical shape also has a second substantially conical part with a second inclination angle with respect to the axis, with the second inclination angle being larger than the first inclination angle.

Owner:VALEO VYMENIKY TEPLA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com