Method for milling thin plate by four-high reversing cold mill

A technology for rolling thin plates and cold rolling mills, which is applied in rolling mill control devices, metal rolling, metal rolling, etc., and can solve the problems of inability to process wide and thin plates and high technical requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

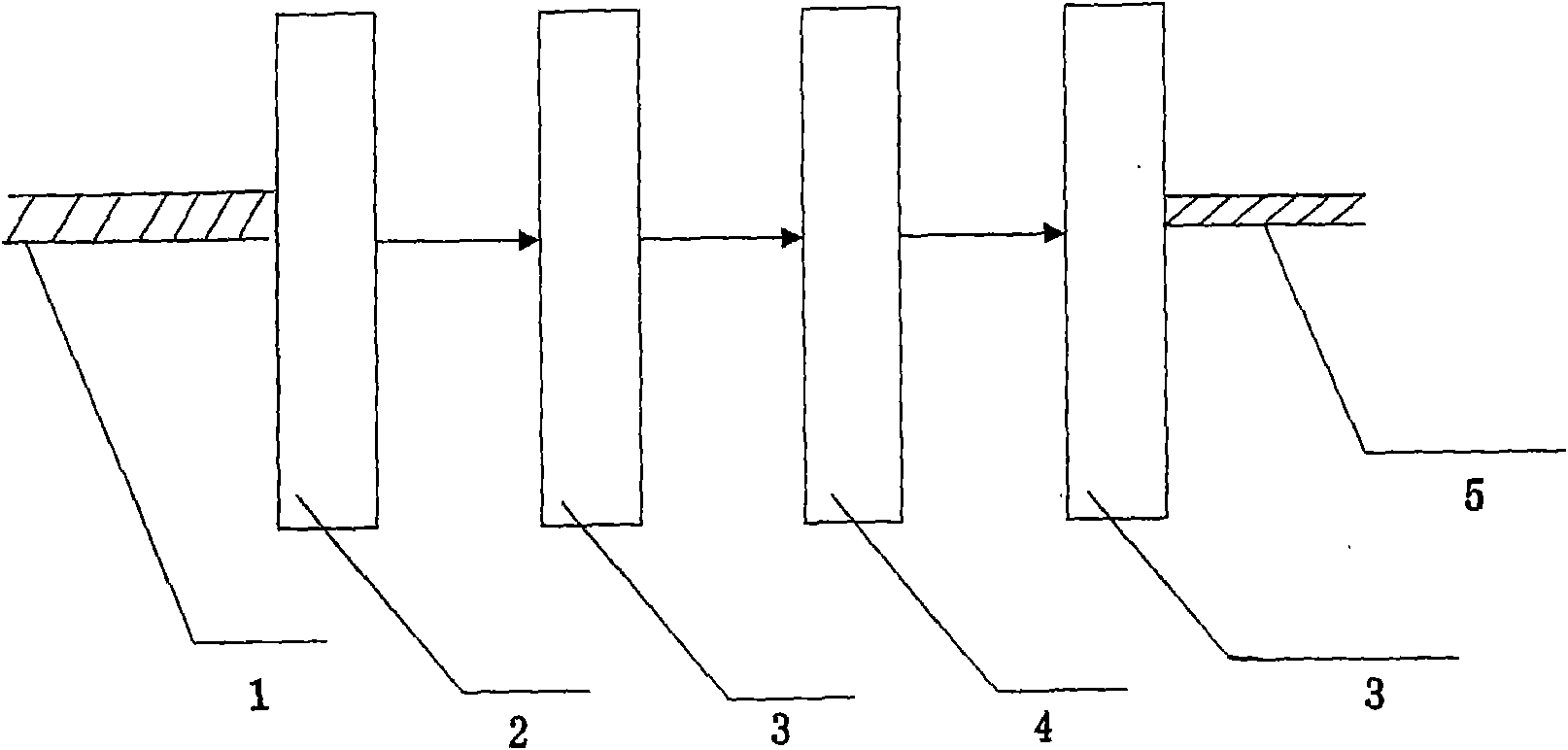

[0020] Please refer to the accompanying drawings. The hot-rolled coil raw material 1 is introduced into the pickling device 2 (also called pickling tank) for pickling to remove the surface oxide layer and ensure good edge trimming. After pickling, it is cold-rolled by the cold rolling mill 3, and the cold rolling mill It is a single-stand reversible four-high cold rolling mill with a stand width of 1450mm, and the material composition is 70Cr 3The diameter of the back-up roll of the medium carbon chromium steel of Mo is 1150mm, and the length is 1400mm, and the diameter of the work roll that material is Cr3 steel is 380mm, and cold rolling is divided into first-stage rolling and second-stage rolling, in the present embodiment Among them, the rolling in the first stage is divided into four passes. Specifically, the 3mm hot-rolled coil is cold-rolled successively to 2.28mm in the first pass, 1.767mm in the second pass, and 1.767mm in the third pass. 1.343mm and 1mm in the fourt...

Embodiment 2

[0022] Please refer to the accompanying drawings. The hot-rolled coil raw material 1 is introduced into the pickling device 2 (also called pickling tank) for pickling to remove the surface oxide layer and ensure good trimming. After pickling, it is cold-rolled by the cold rolling mill 3, and the cold rolling mill It is a single-stand reversible four-high cold rolling mill with a stand width of 1450mm, and the material composition is 50Cr 3 The diameter of the back-up roll of the medium carbon chromium steel of Mo is 1200mm, and the length is 1400mm, and the diameter of the work roll that material is Cr3 steel is 385mm, and cold rolling is divided into first-stage rolling and second-stage rolling, in the present embodiment Among them, the rolling in the first stage is divided into four passes. Specifically, the 3.5mm hot-rolled coil is cold-rolled successively to 2.670mm in the first pass, 1.990mm in the second pass, and 1.990mm in the third pass. 1.420mm of the 1.420mm and 1m...

Embodiment 3

[0024] Please refer to the accompanying drawings. The hot-rolled coil raw material 1 is introduced into the pickling device 2 (also called pickling tank) for pickling to remove the surface oxide layer and ensure good trimming. After pickling, it is cold-rolled by the cold rolling mill 3, and the cold rolling mill It is a single-stand reversible four-high cold rolling mill with a stand width of 1450mm, and the material composition is 70Cr 3 The diameter of the back-up roll of the medium carbon chromium steel of Mo is 1205mm, and the length is 1400mm, and the diameter of the work roll that material is Cr3 steel is 390mm, and cold rolling is divided into first-stage rolling and second-stage rolling, in the present embodiment Among them, the rolling in the first stage is divided into five passes. Specifically, the hot-rolled coils of 3.51mm are cold-rolled successively to 2.810mm in the first pass, 2.260mm in the second pass, and 2.260mm in the third pass. 1.740mm in the fourth p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com